Fully-automatic bandage machine

A bandage machine, fully automatic technology, applied in the direction of bandage, medical science, external support, etc., can solve the problems of time-consuming, manual wrapping, manual shaft pulling, etc., to achieve significant economic benefits, improve production efficiency, and ensure winding The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

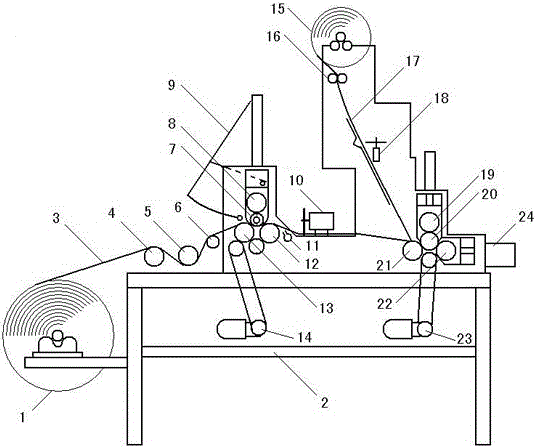

[0029] Example: such as figure 1 As shown in -8, the automatic bandage machine includes:

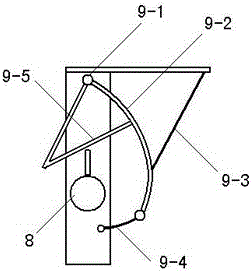

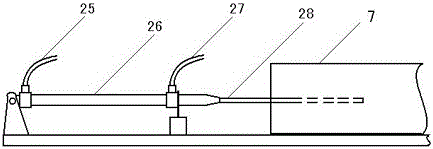

[0030] The original cloth roll 1 is placed in the front of the frame 2, and the original cloth roll 1 is provided with a shaft, which is placed on the front extension frame of the frame 2, and the original cloth roll 1 can rotate around the shaft, so as to gradually spread; the original cloth The front end of the gauze 3 on the volume 1 passes through the guide roller A4, the guide roller B5, and the spreading roller 6 (the two ends of the guide roller A4, the guide roller B5, and the spreading roller 6 are connected to the frame through bearings), and are wound on the mandrel 28 on; the mandrel 28 (see image 3 ) set on both sides ( figure 1 Both sides of the gauze 3 are wound on the mandrel 28, the mandrel 28 is placed in the push shaft cylinder 26, and the inner and outer ends of the push shaft cylinder 26 are respectively provided with air holes A and air holes B, and the two air h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com