Portable printing machine for bottomless paper label

A technology of linerless paper and printers, applied in typewriters, printing, etc., can solve the problems of cumbersome water application, stickiness of the hydrophilic adhesive layer, and restrictions on the wide application of linerless paper labels, and achieve the effect that is conducive to widespread use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

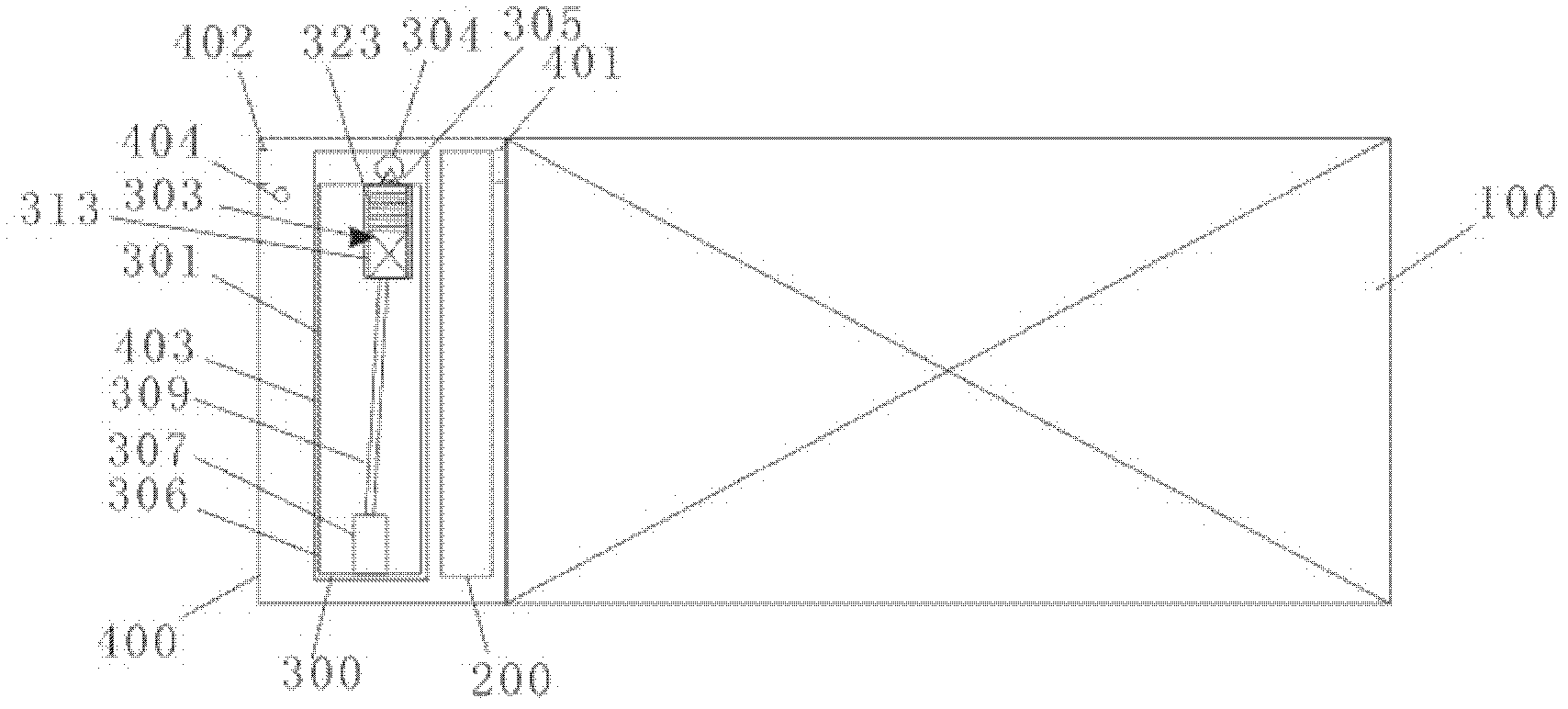

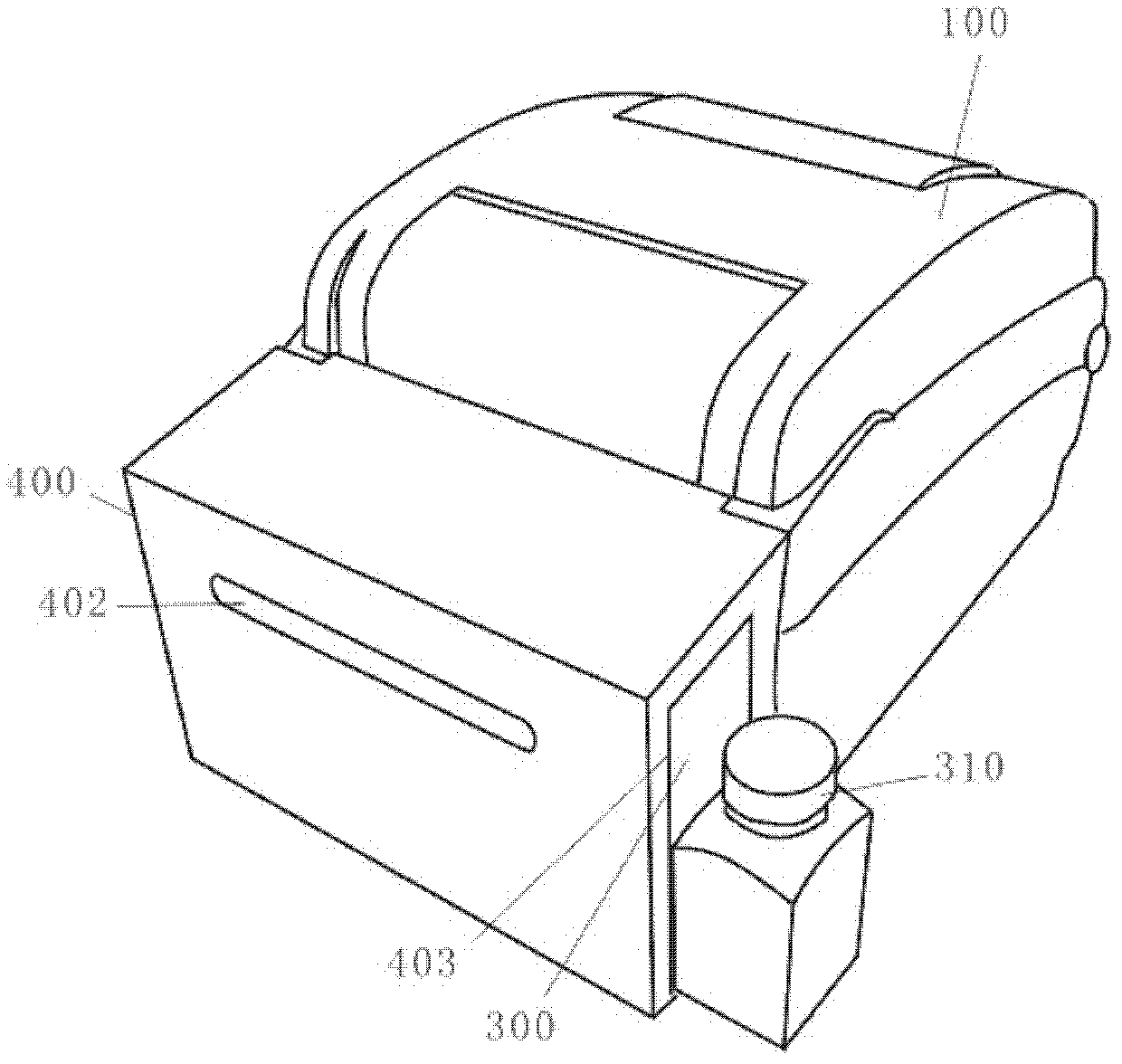

[0023] such as 1 and figure 2 As shown, the portable linerless label printer of the present invention includes a printing module 100 , a paper cutting module 200 and a watering module 300 .

[0024] Wherein, the paper cutting module 200 and the water coating module 300 are integrated in the casing 400 . Both sides of the upper part of the casing 400 respectively have a paper inlet 401 and a paper outlet 402 . The paper cutting module 200 is fixed on the side of the paper inlet 401 in the casing. The casing 400 has a cavity 403 with a side opening in the middle, and the water coating module 300 can be inserted into the cavity 403 of the casing 400 from the side.

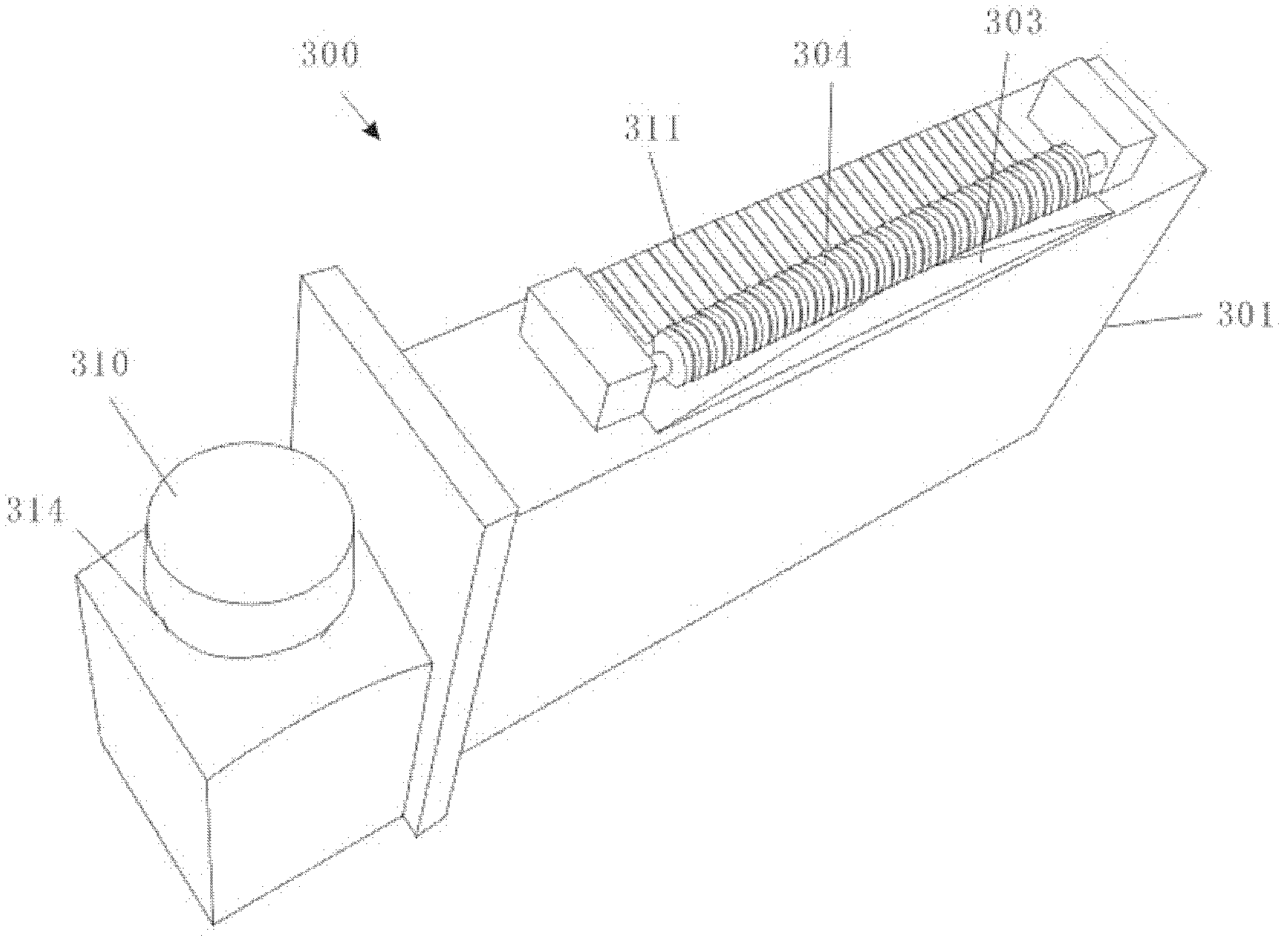

[0025] to combine image 3 As shown, the water coating module 300 includes a water tank 301, which is located at the top of the water tank 301 near the paper inlet side and has a storage tank 302 leading to the upper surface. The storage tank 302 is placed with a water coating block 303 with water absorption perfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com