Office equipment for paper recycling

a technology for office equipment and paper recycling, which is applied in the direction of press section, machine wet end, and digester, etc., can solve the problems of increasing office paper consumption and not providing all required steps for paper manufacturing, and achieves the effect of surface strength and smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The preferred embodiment of the office paper recycling apparatus is described hereinafter in reference to the drawings. As the following detailed description should not be taken to limit the invention, some steps of the process described may be performed in a different order and the others may be excluded. The description of the well-know devices to those skilled in the art will not be given in details.

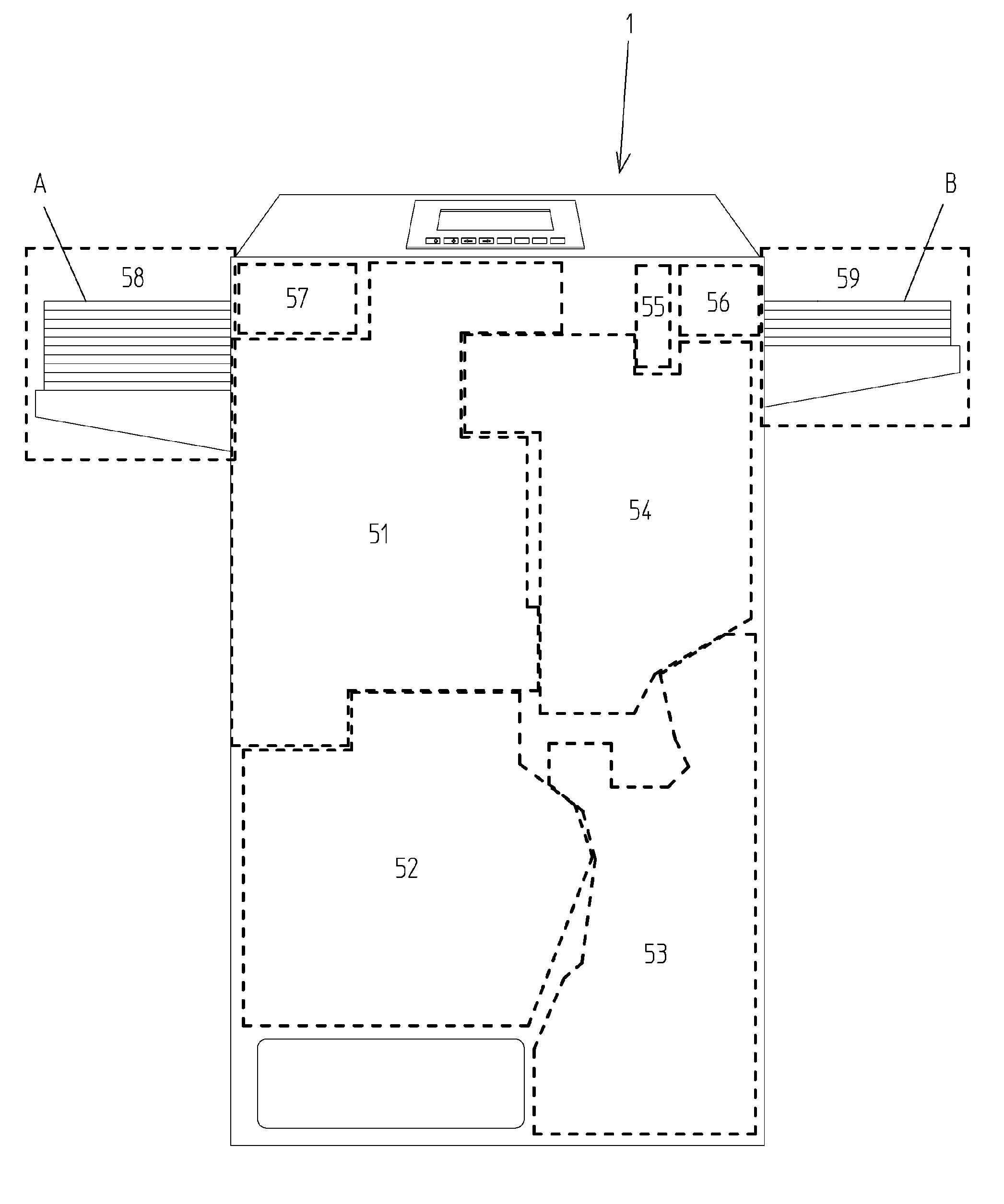

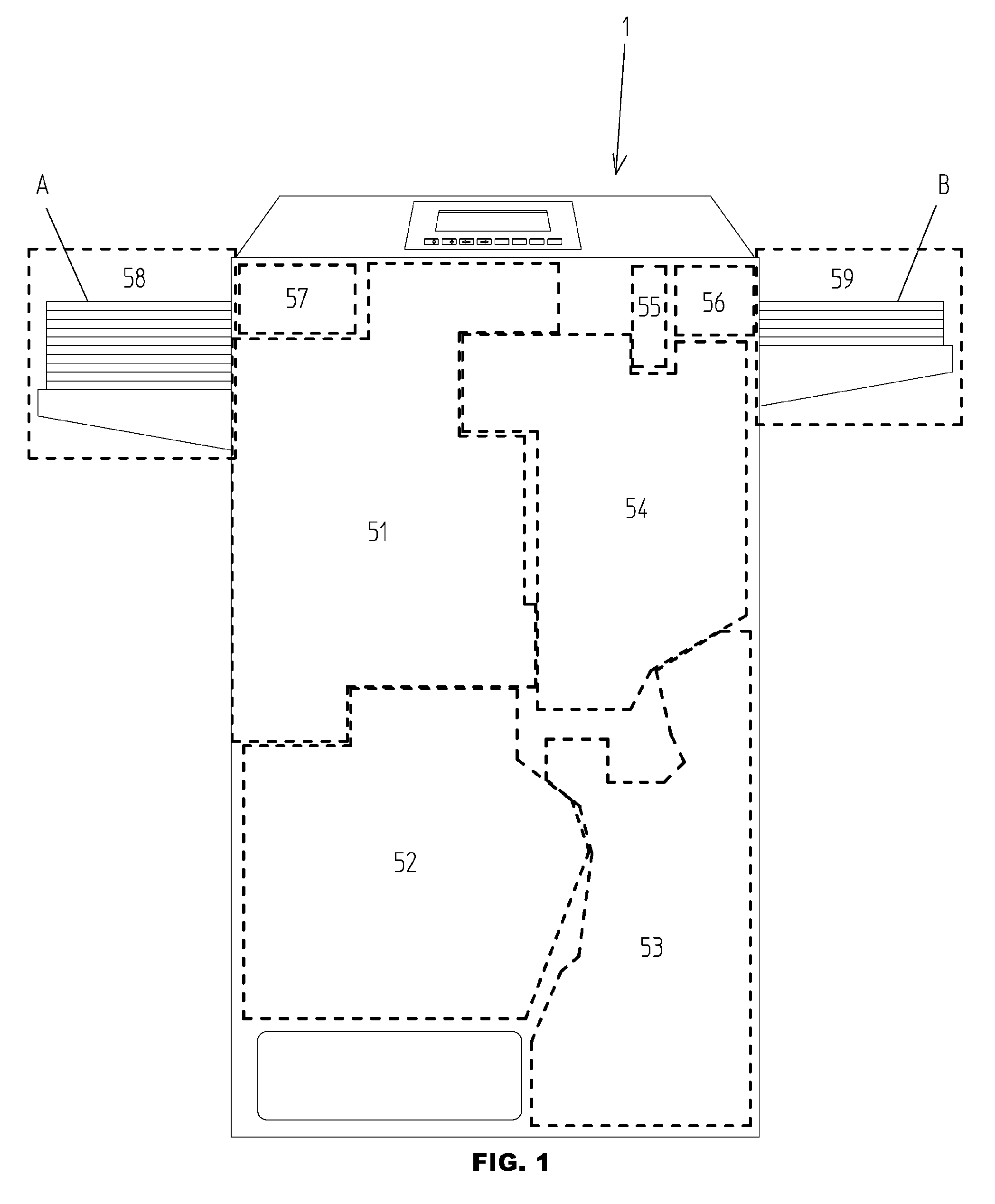

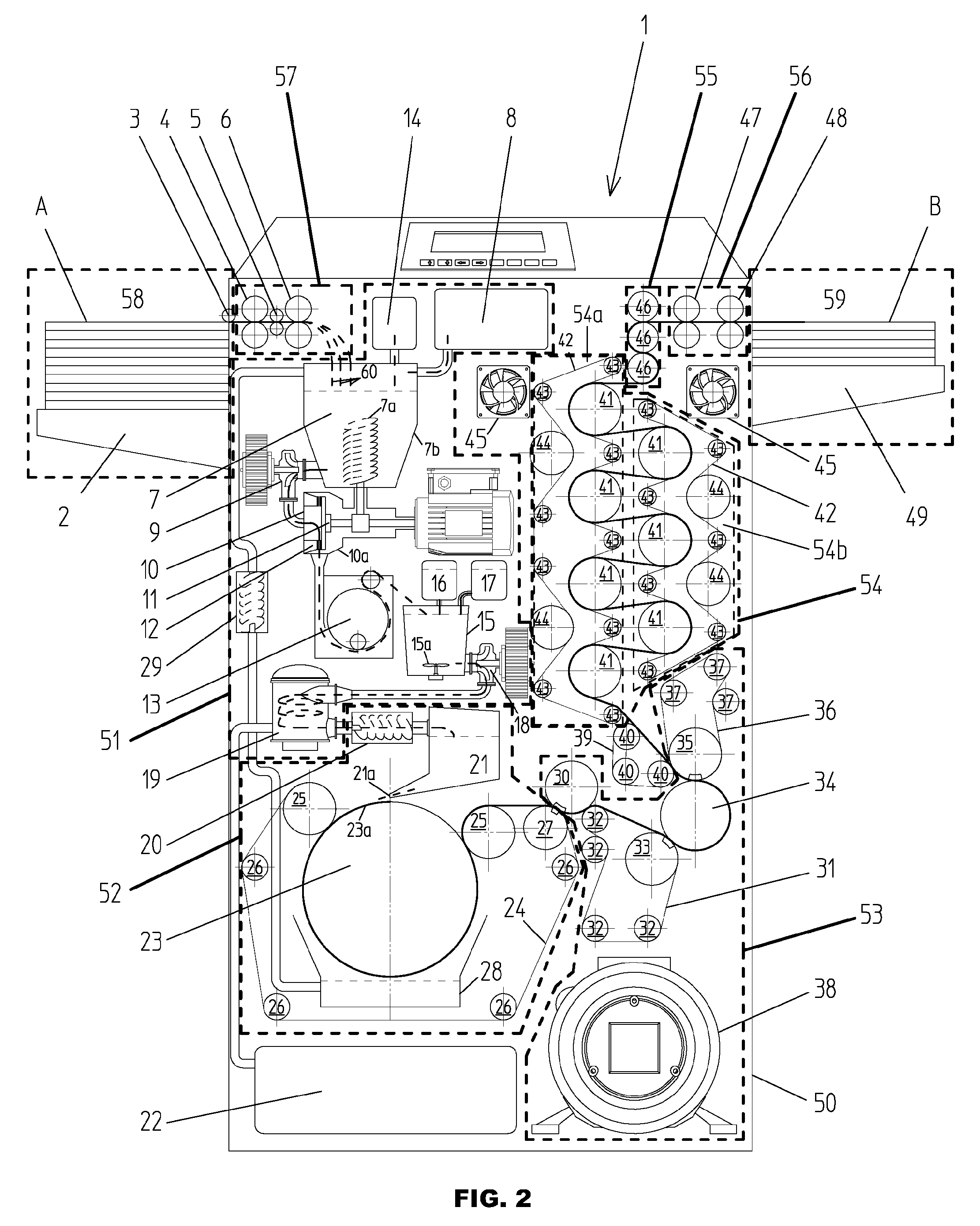

[0018] Referring to FIG. 1, the apparatus (1) comprises a used paper-feeding portion (58); a paper-shredding portion (57); a pulping portion (51); a paper-forming portion (52); a paper-press portion (53); a paper-drying portion (54); a paper-sizing portion (55); a paper-finishing portion (56) and a paper-collecting portion (59), where the new sheets are collected and stacked, ready to be used in office equipments. These portions are now described in more detail with reference to FIG. 2.

[0019] Used paper (A) in the form of sheets is manually loaded by operator onto the shelf (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| heat | aaaaa | aaaaa |

| dimensions | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com