Pulp feeder for used paper recycling apparatus

A waste paper pulp and recycling technology, applied in papermaking, paper machine, wet end of paper machine, etc., can solve the problems of inability to develop and collect, and achieve the effect of low operating cost, environmental friendliness and high confidentiality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

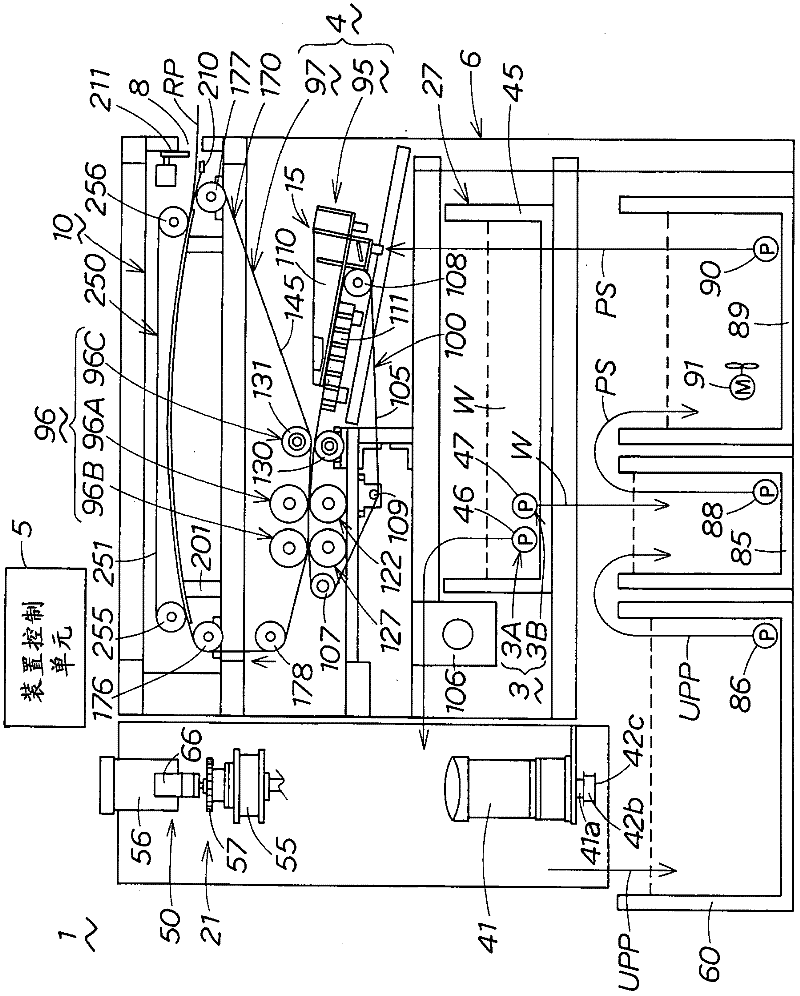

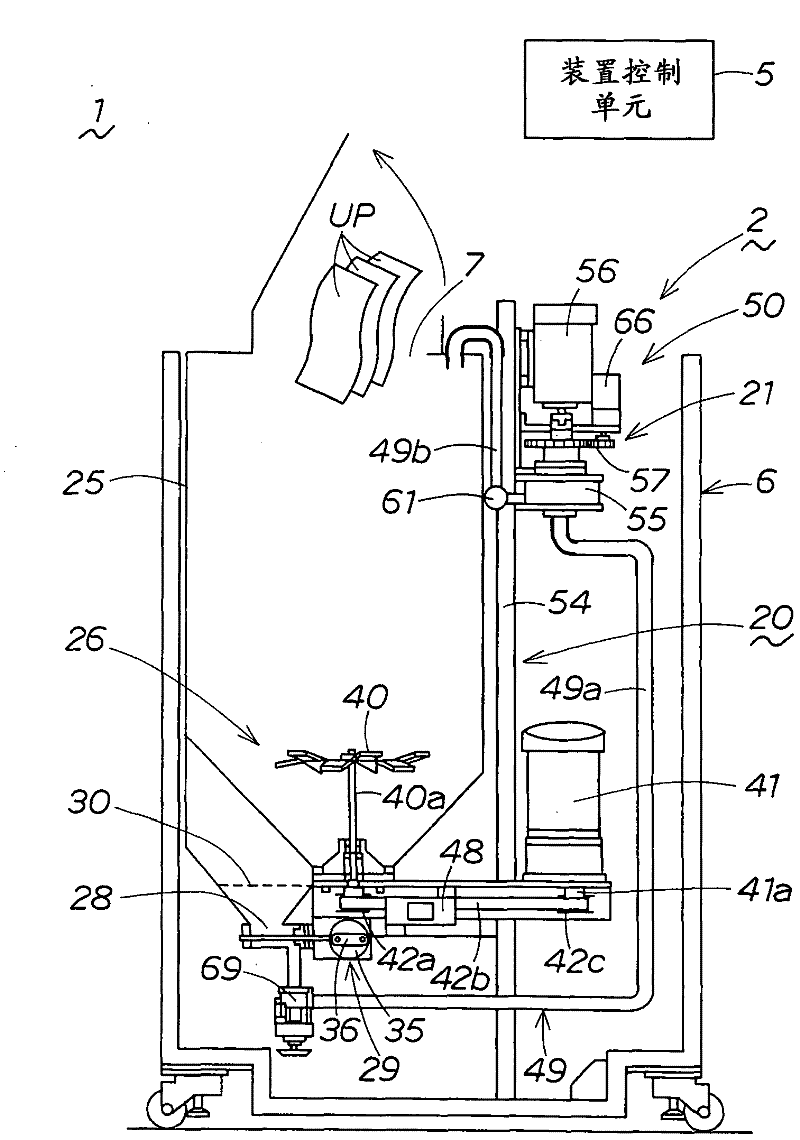

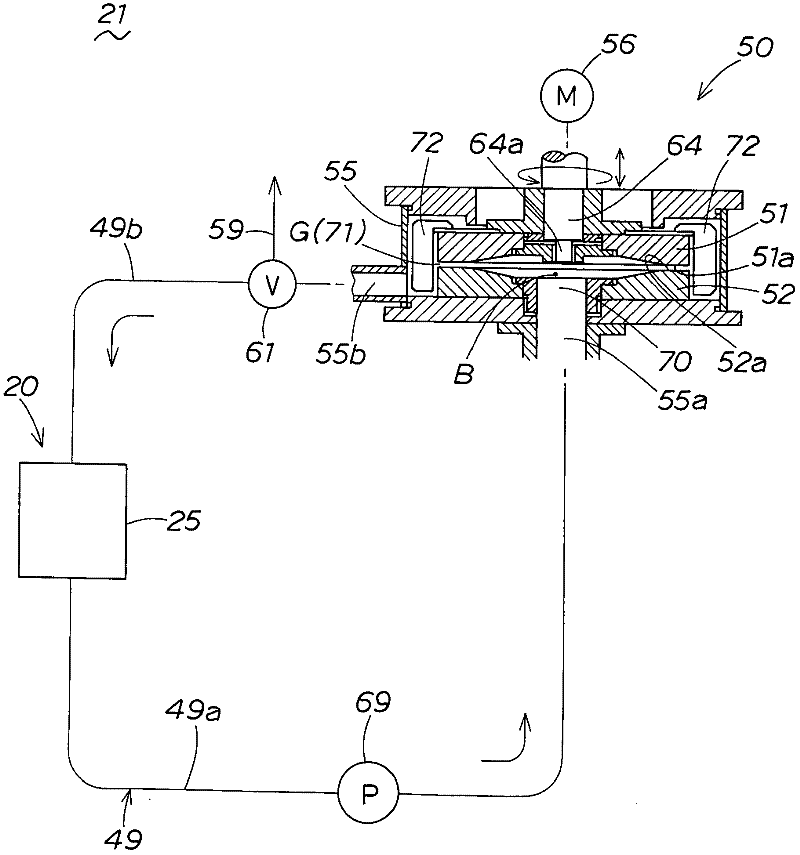

[0040] Preferred embodiments of the present invention will be specifically described below with reference to the accompanying drawings. Throughout the drawings, the same reference numerals denote the same or similar constituent parts or elements.

[0041] Figure 1 to Figure 11 shows the waste paper recycling equipment of the present invention, the waste paper recycling equipment 1 is installed especially at the source of waste paper, and is a device for regenerating reusable paper at the same position without processing Or discard waste paper UP including confidential documents of government offices and general company offices, private letters of general households, and other used and unnecessary documents.

[0042] Waste paper recycling equipment 1 is as small as the size of furniture, such as Figure 11 shown in , that is, small and compact, similar to file racks, cabinets, desks, copiers, personal computers, and other equipment installed in offices, and such as figure 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com