Hot-melt adhesive capable of losing adhesion after contacting of water, and product thereof

A technology of hot-melt adhesive and cohesive force, which is applied in the direction of adhesives, layered products, film/sheet adhesives, etc., and can solve the problem of irreplaceable paste mounting process, unable to unmount and repair calligraphy and painting, damage to calligraphy and painting, etc. problems, to achieve the effect of solving unmountable, convenient recycling and improving recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Embodiment 1: a kind of manufacture method of painting and calligraphy mounting adhesive film (the hot-pressed mounting adhesive film that can be demounted by water) comprises the following steps:

[0053] Step 1) Add conventional ethylene vinyl acetate (EVA) hot melt adhesive, accounting for 56% of the total amount; acrylic water-absorbing resin, accounting for 44% of the total amount, into a hot-melt mixing tank, and melt and mix. Then a non-porous hot-melt adhesive film is prepared by a coating machine and a casting machine.

[0054] Step 2) melt the above-mentioned hot melt adhesive and evenly apply it to the surface of the release paper (also called release paper) through a hot melt adhesive coating machine; then form a non-porous hot melt adhesive film through cooling and molding, and then roll it up Cut into rolls or sheets, which can be demounted with water and can be hot-pressed and mounted.

[0055] Step 3) Make the above-mentioned special hot melt adhesive i...

Embodiment 2

[0057] Embodiment 2: a kind of calligraphy and painting mounting adhesive film (the hot-pressed mounting adhesive film that can be demounted by water) and its manufacture method, comprise following steps:

[0058] Step 1) conventional ethylene vinyl acetate (EVA) hot melt adhesive, accounting for 70% of the total amount; acrylic acid water-absorbing resin, accounting for 25% of the total amount; silicon dioxide, accounting for 2% of the total amount; sodium bicarbonate, Add 3% of the total amount into the hot melt mixing tank, melt and mix. Then a porous hot-melt adhesive film is prepared by a coating machine and a casting machine.

[0059] Step (2) Manufacture of porous hot-melt adhesive film by coating method: install one roll of base paper that can be water-mounted and coated on the unwinding frame of the coating machine, and the paper is coated with hot-melt adhesive under the traction of the coating machine. Cloth head, the hot-melt adhesive is transferred to the anti-ad...

Embodiment 3

[0062] Embodiment 3: A kind of hot-melt adhesive product that meets water and loses cohesion, as figure 1 Shown, the structural representation of hot-melt adhesive film 1,

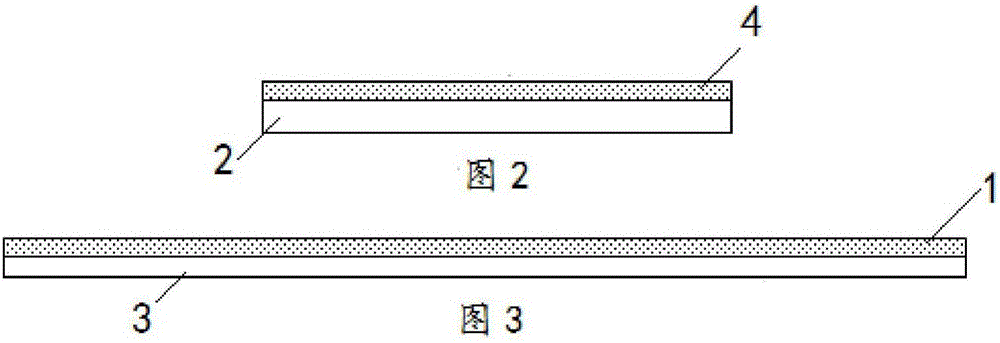

[0063] A hot-melt adhesive product that loses cohesive force when exposed to water, as shown in Figure 2, the hot-melt adhesive coating 4 on the surface of the hot-melt adhesive label paper is connected to the paper base 2 on the hot-melt adhesive label paper;

[0064] A hot-melt adhesive product that loses its cohesive force when exposed to water, as shown in Figure 3, a hot-melt adhesive film (including a porous film and a non-porous film) 1 is connected with a release paper, also known as an anti-sticking paper 3;

[0065] A hot-melt adhesive product that loses its cohesive force when it meets water. The hot-melt adhesive formula can be made into different hot-melt adhesive products. The components of the hot-melt adhesive formula are mixed, heated and melted, and then produced by a granulator Hot-melt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com