Metal lithium secondary battery and negative electrode and porous copper current collector thereof

A technology of secondary batteries and current collectors, applied in battery electrodes, lithium batteries, electrode carriers/current collectors, etc., can solve the problems of increasing the internal resistance and polarization of batteries, difficult practical application, and complex conductive frameworks, and achieves slowing down. Effect of volume change, inhibition of lithium dendrite generation, and improvement of coulombic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

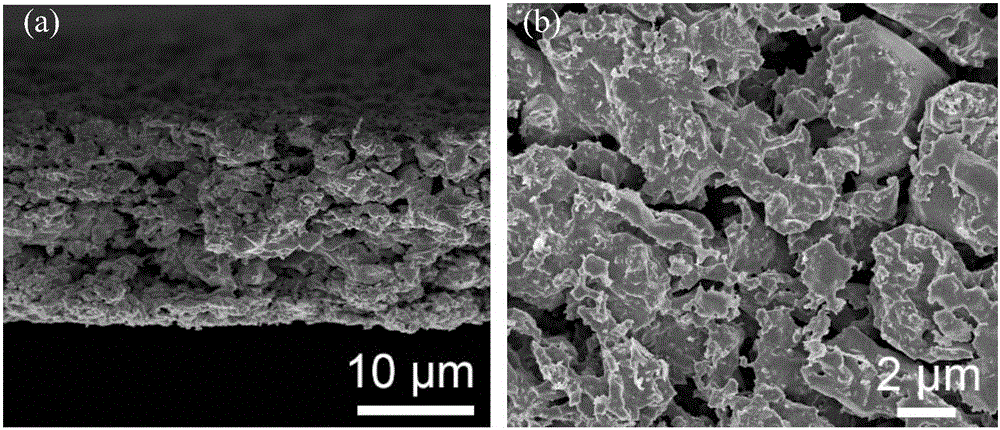

[0038] The present embodiment provides a porous copper current collector for a negative electrode of a metal lithium secondary battery. The current collector has a three-dimensional connected porous structure and has a pore diameter in the range of 0.1-20 μm.

[0039] (1) In this embodiment, the method for preparing the porous copper current collector is a chemical dealloying method, which is obtained by chemically dealloying the binary Cu-Zn alloy strip. The Cu-Zn alloy used is H62 brass with a copper content of 60.5 to 63.5%. The thickness of the alloy strip is 20 μm.

[0040] First, clean the contaminants on the surface of the Cu-Zn alloy strip with absolute ethanol. Then, the alloy strip was immersed in a mixed solution of 1 mol / L dilute hydrochloric acid and 5 mol / L ammonium chloride solution by the dipping method in a water bath at 70° C. for chemical dealloying reaction for 12 hours. After that, the sample was taken out, and the dealloyed sample was cleaned four times with...

Embodiment 2

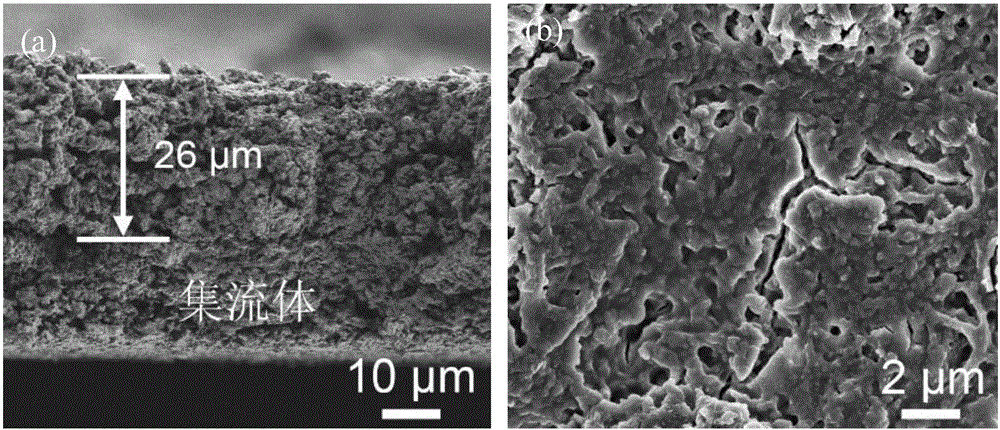

[0051] The difference from Example 1 is: (1) The process of preparing the porous copper current collector is as follows: Binary Cu-Zn alloy strip (H62 brass, copper content 60.5-63.5%) is used, and its thickness is 30 μm. The alloy strip was immersed in a mixed solution of 2mol / L dilute hydrochloric acid and 4mol / L ammonium chloride solution in a water bath at 80°C for chemical dealloying reaction for 9h. The rest is the same as in Embodiment 1, and will not be repeated here.

Embodiment 3

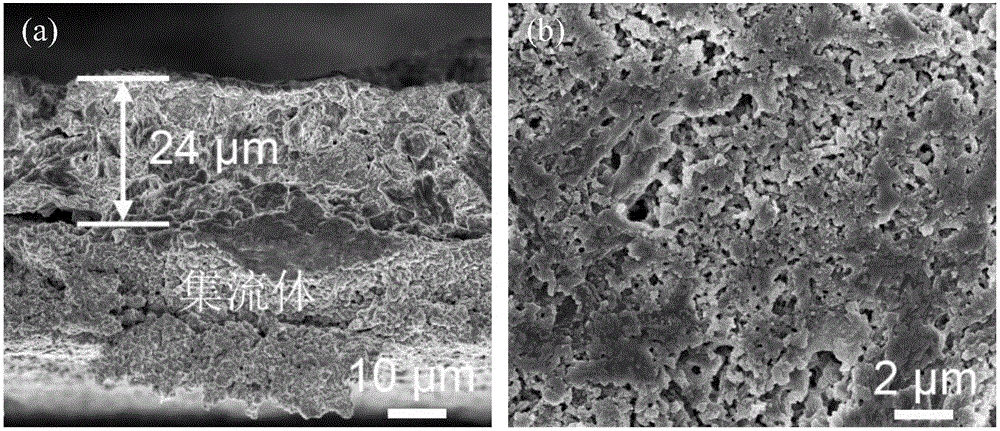

[0053] The difference from Example 1 is that the process of preparing the porous copper current collector in (1) is as follows: a binary Cu-Mg alloy strip is used, in which the copper content is 40%, and the thickness is 40 μm. The alloy strip was immersed in a mixed solution of 2 mol / L dilute hydrochloric acid and 1 mol / L phosphoric acid in a water bath at 60°C for chemical dealloying reaction for 15 hours. The rest is the same as in Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com