Evaporator For Loop Heat Pipe System

a technology of loop heat pipe and evaporator, which is applied in the direction of indirect heat exchangers, lighting and heating apparatus, etc., can solve the problems of large heat generation of electronic components such as cpus or semiconductor chips used in various electronic devices such as computers, severe deterioration of electronic devices, and damage to electronic devices. , to achieve the effect of increasing contact conductan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

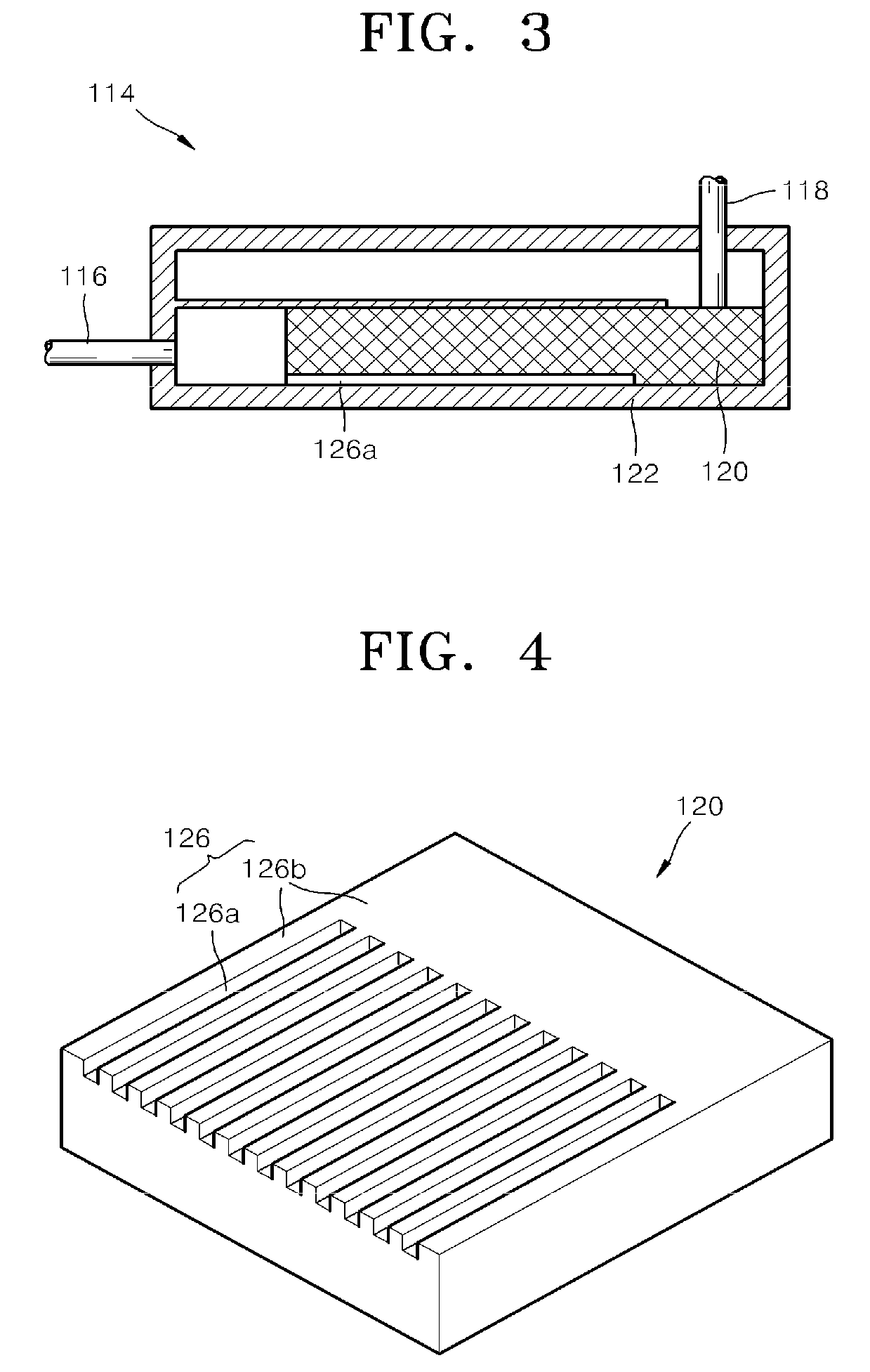

Embodiment Construction

[0032]The attached drawings for illustrating exemplary embodiments of the present invention are referred to in order to gain a sufficient understanding of the present invention, the merits thereof, and the objectives accomplished by the implementation of the present invention. Hereinafter, the present invention will be described in detail by explaining exemplary embodiments of the invention with reference to the attached drawings. Like reference numerals in the drawings denote like elements.

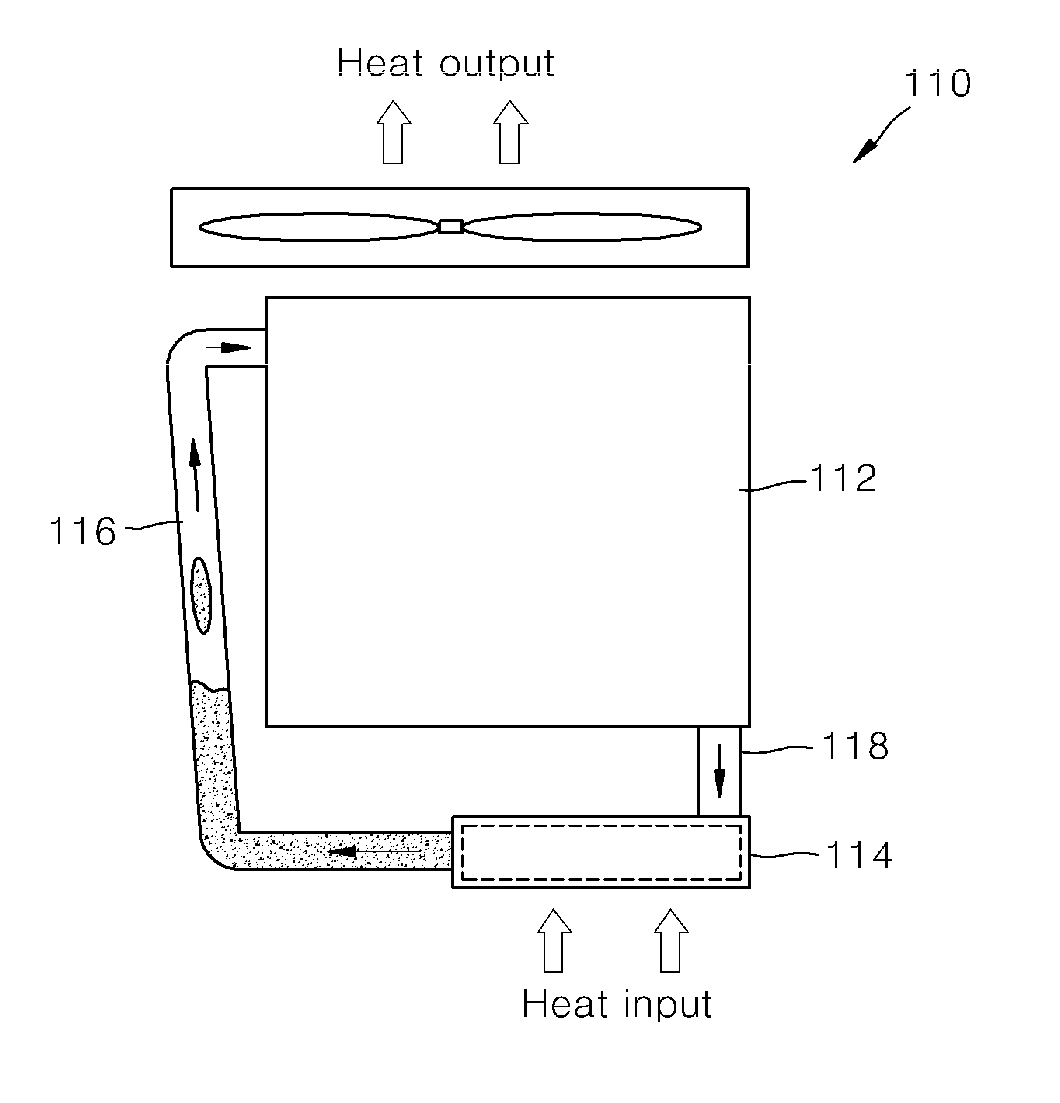

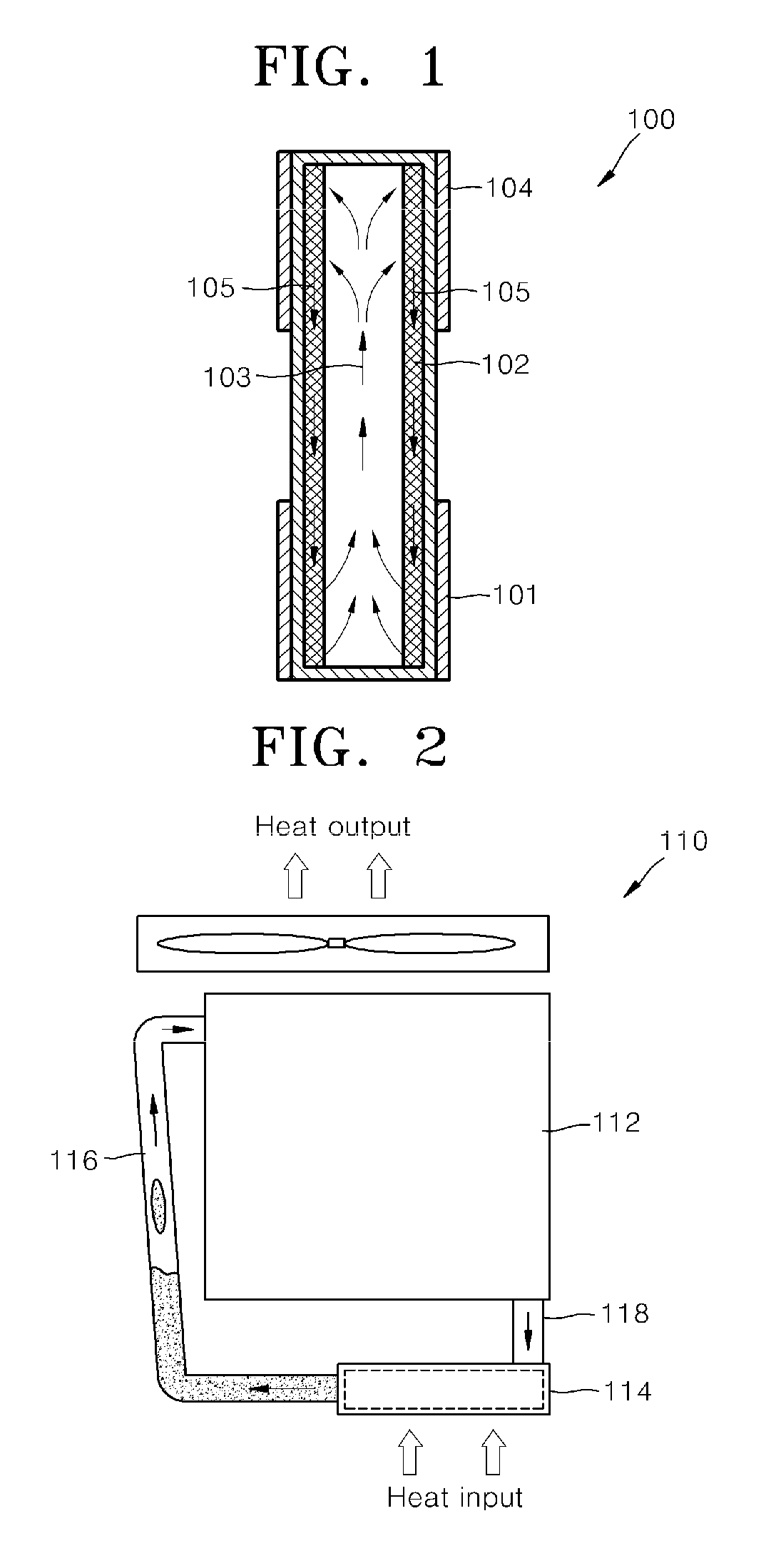

[0033]The present invention is related to an evaporator for a loop heat pipe system including a condenser, a vapor transportation line, and a liquid transportation line. FIG. 6 illustrates the structure of a loop heat pipe system according to an embodiment of the present invention. Referring to FIG. 6, the loop heat pipe system includes an evaporator 1, a condenser 210, a vapor transport line 220, and a liquid transport line 230.

[0034]The condenser 210 changes the phase of a working fluid in a va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com