Flat loop Heat pipe

a heat pipe and loop technology, applied in indirect heat exchangers, reinforcing means, lighting and heating equipment, etc., can solve the problems of difficult activation of thermal dissipation circulation and over-great pressure, and achieve the effect of enhancing the heat-dissipation performance of flat lhp

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

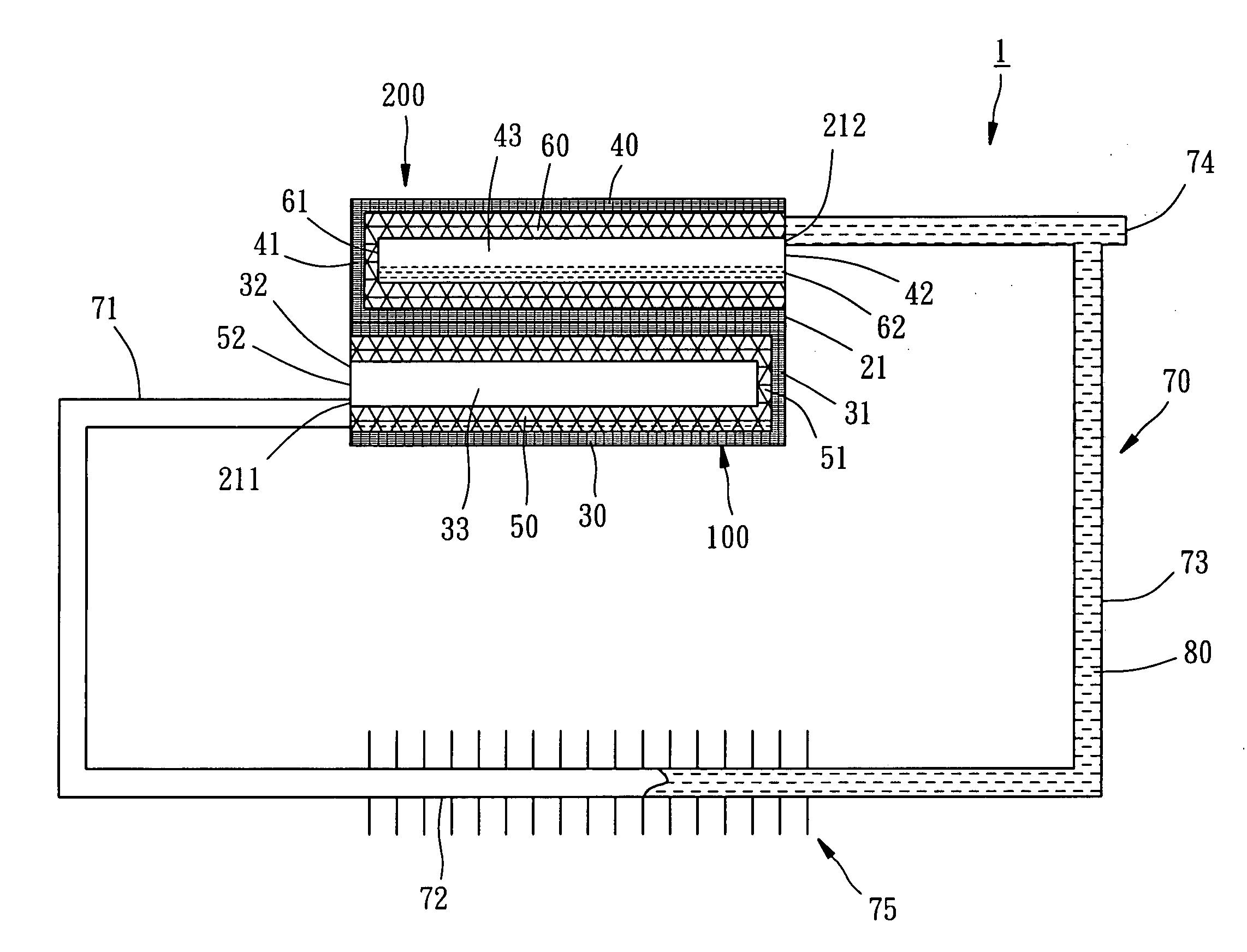

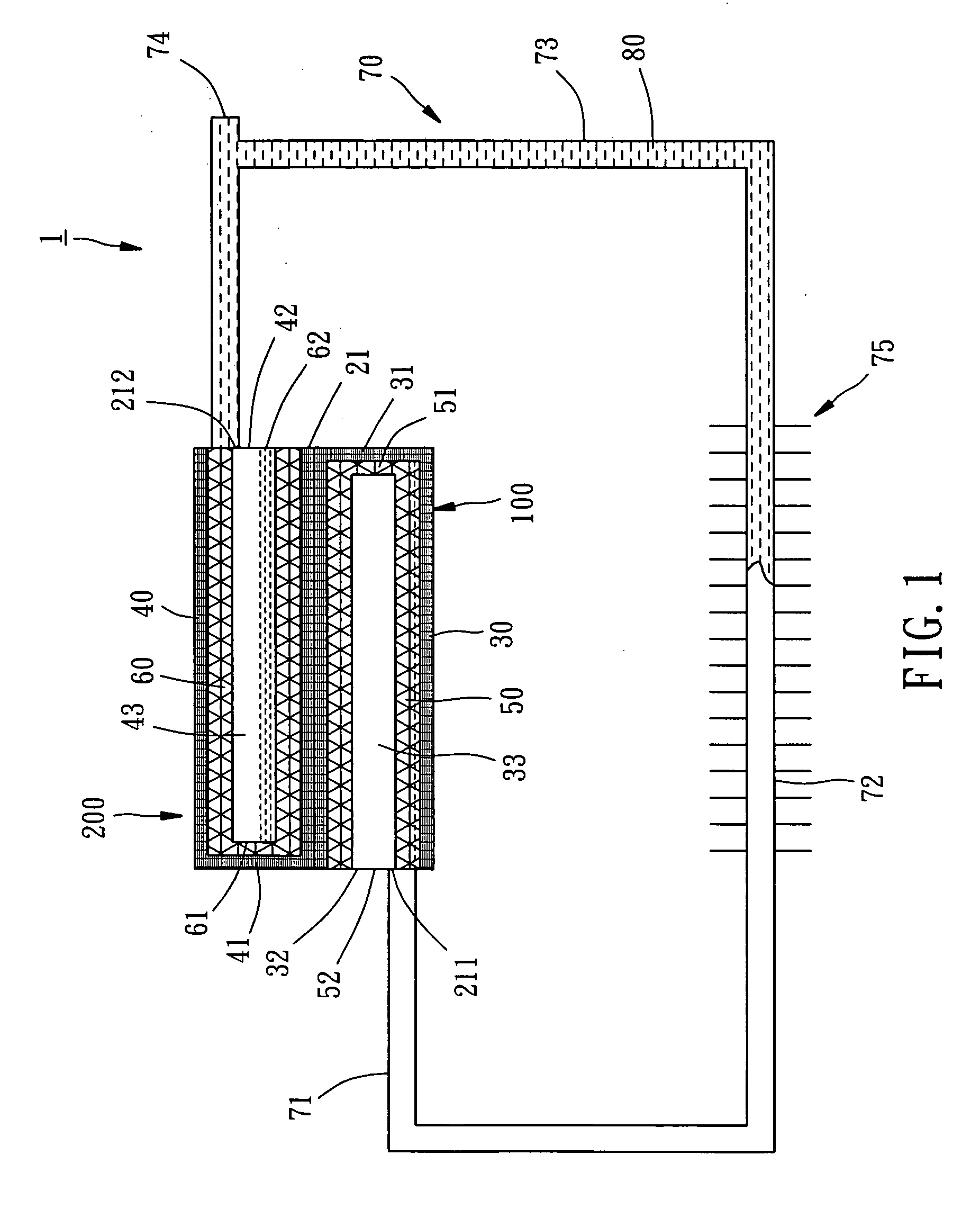

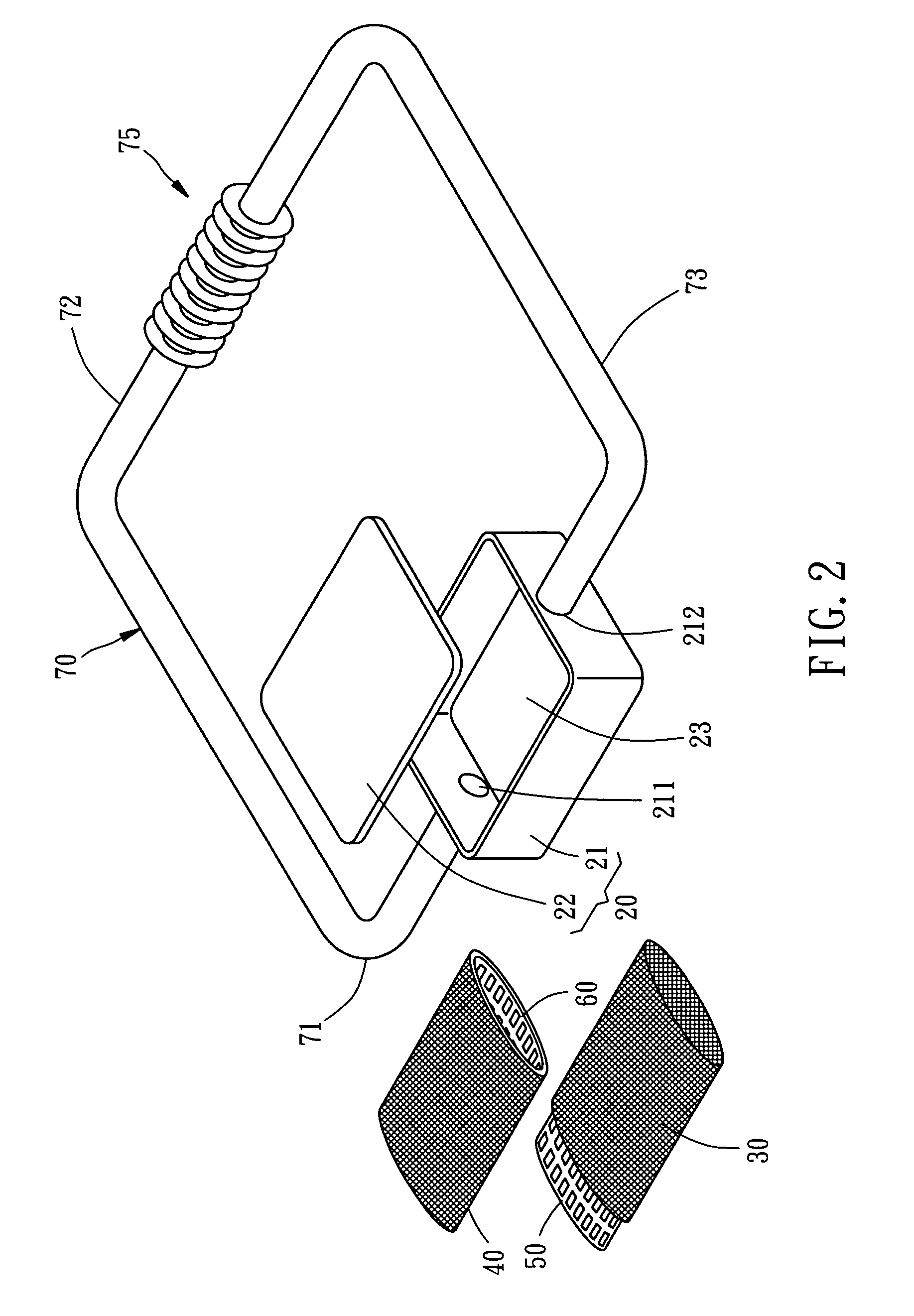

[0014]Referring to FIGS. 1-4, a flat LHP 1 constructed according to a preferred embodiment of the present invention is composed of a container 20, a first capillary core 30, a second capillary core 40, a first support member 50, a second support member 60, a circulatory pipeline 70, and a working fluid 80.

[0015]The container 20 includes a case 21 and a cover 22. A chamber 23 is formed inside the container 20 and between the case 21 and the cover 22. The case 21 has two openings, which are a vapor outlet 211 and a liquid inlet 212 respectively. The distance between a center of the vapor outlet 211 and a bottom side of the base 21 is smaller than the distance between a center of the liquid inlet 212 and the bottom side of the case 21. The vapor outlet 211 and the liquid inlet 212 are mounted to a left side and a right side of the base 21.

[0016]Each of the first and second capillary cores 30 and 40 is structurally capillary and thin sleeve-shaped, having a close end 31(41) at one end t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com