Loop heat pipe and startup method for the same

a technology of loop heat pipe and startup method, which is applied in the direction of basic electric elements, semiconductor devices, lighting and heating apparatus, etc., can solve the problem of difficulty in securing an area for accommodating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

working examples

Working Example 1

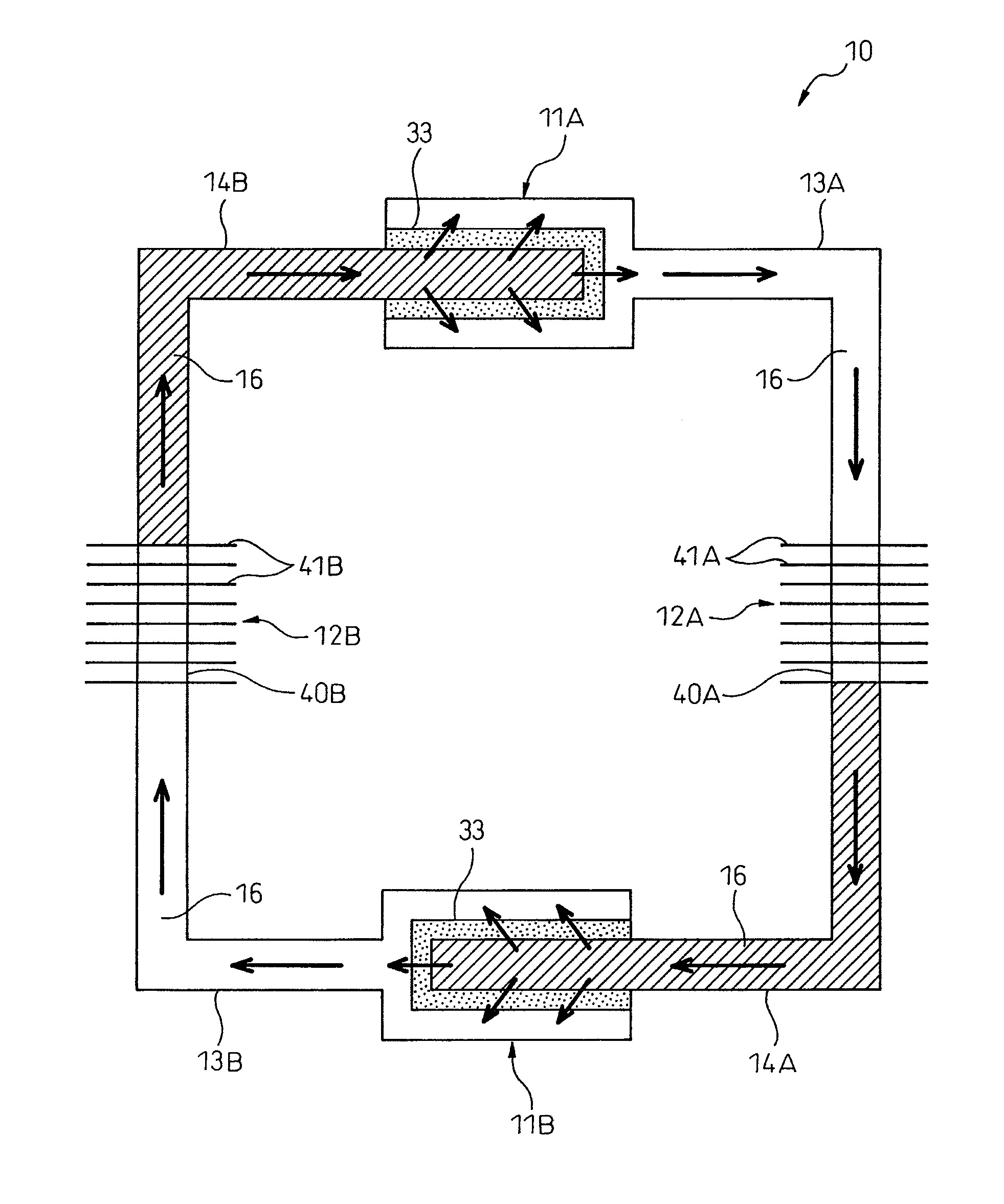

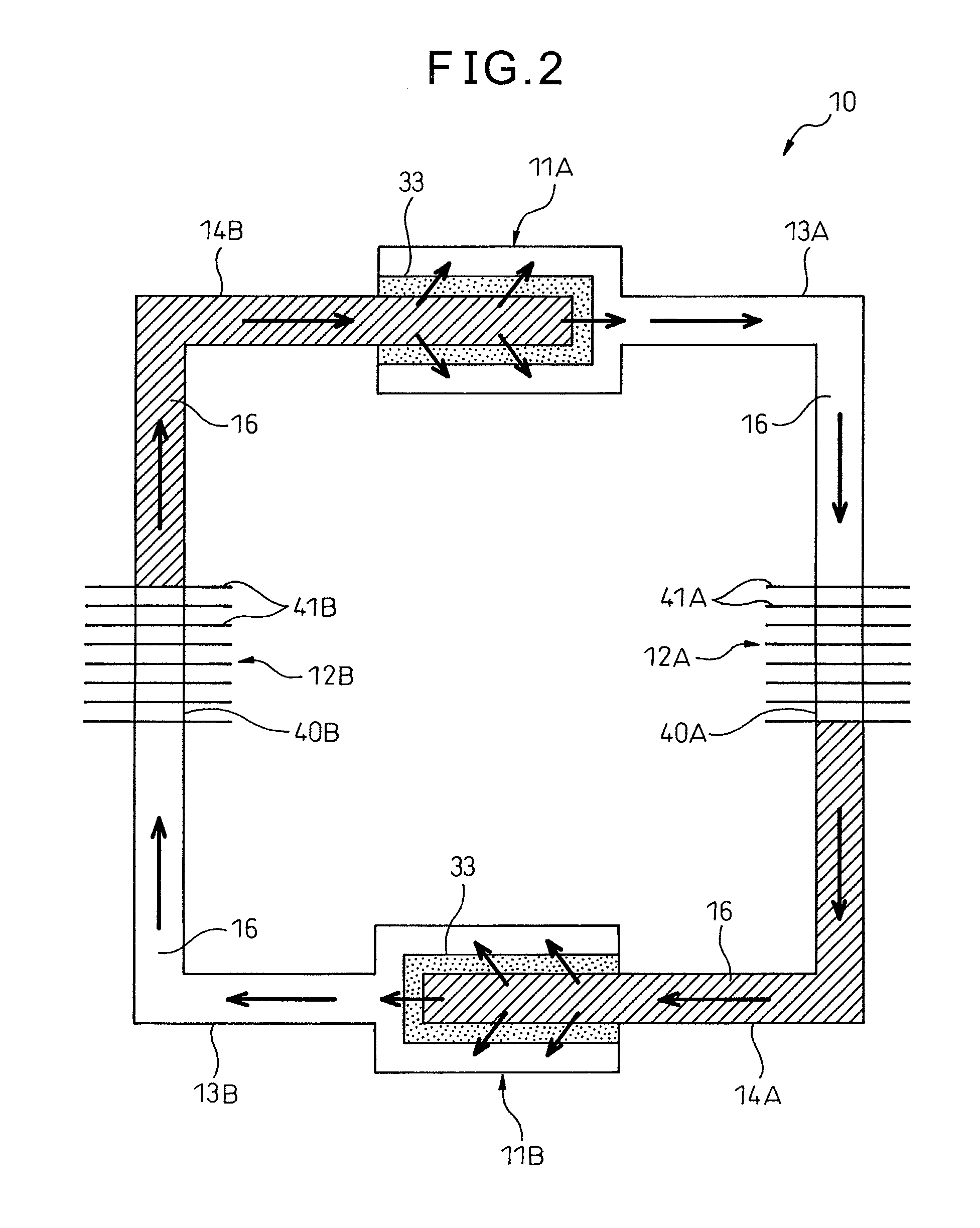

[0159]First, a loop heat pipe of the structure depicted in FIG. 8 was fabricated. Then, the loop heat pipe was assembled into a blade server such as depicted in FIG. 3. The blade server was set with its substrate surface oriented perpendicularly to the plumbline direction so that the two evaporators were arranged in a horizontal plane. The heat load of the CPU A whose heat was to be transferred to the first evaporator was 0 W, and the heat load of the CPU B whose heat was to be transferred to the second evaporator was 60 W; the loop heat pipe thus fabricated was taken as Working Example 1.

working example 2

[0160]Working Example 2 was fabricated in the same manner as Working Example 1, except that the heat load of the CPU A whose heat was to be transferred to the first evaporator was 20 W, and the heat load of the CPU B whose heat was to be transferred to the second evaporator was 60 W.

working example 3

[0161]Working Example 3 was fabricated in the same manner as Working Example 1, except that the heat load of the CPU A whose heat was to be transferred to the first evaporator was 40 W, and the heat load of the CPU B whose heat was to be transferred to the second evaporator was 60 W.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com