Flat-plate evaporators structure and loop type hot pipe possessing flat-plate evaporators structure

An evaporator and flat plate technology, applied in the field of loop heat pipes, can solve the problems of water molecules overflowing and unable to meet the heat dissipation requirements of microelectronic components, and achieve the effects of rapid response, avoiding short circuit of electronic components, and small thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The specific embodiments adopted by the present invention will be further described through the following embodiments and accompanying drawings.

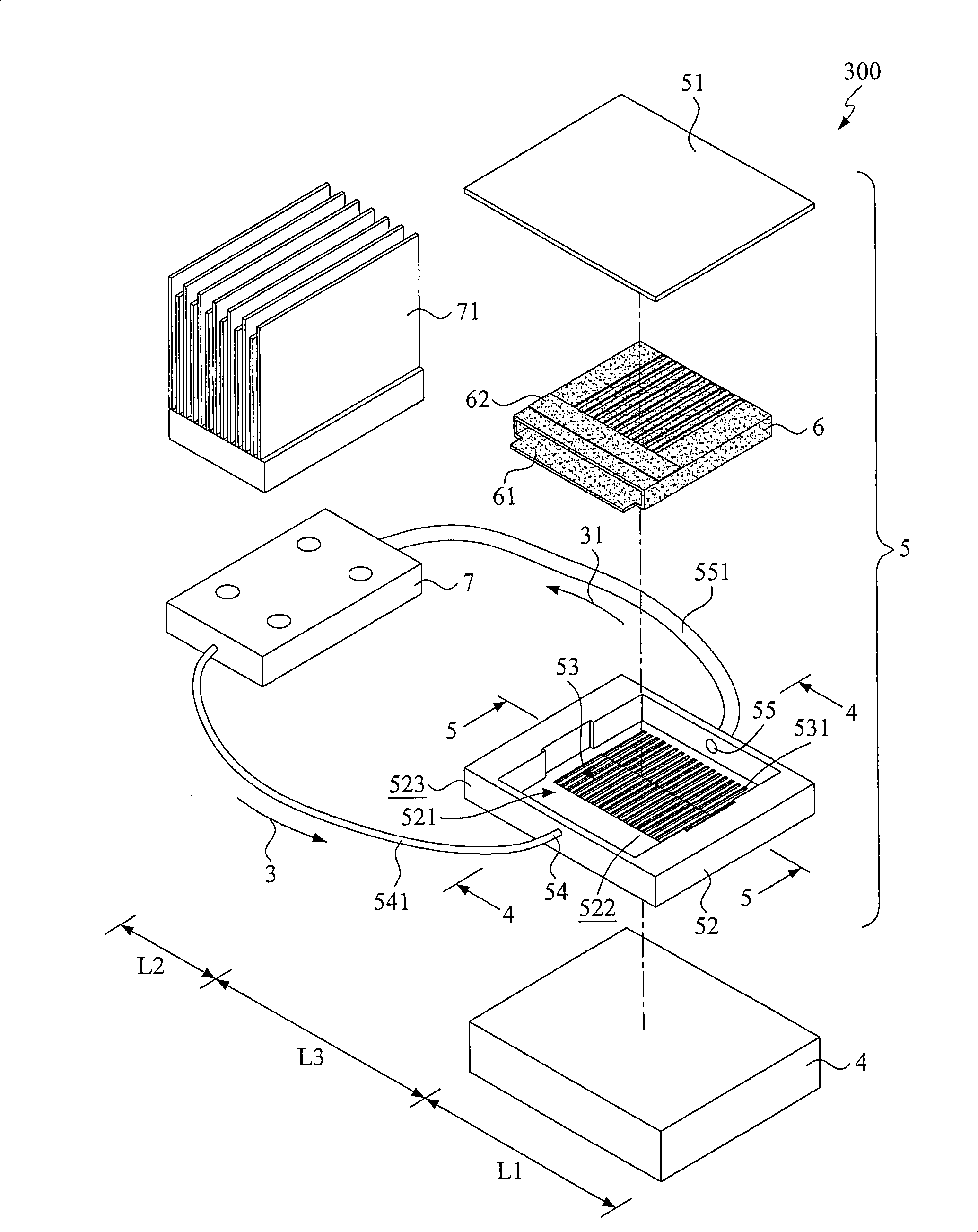

[0054] refer to image 3 As shown, it is a perspective view showing the loop heat pipe of the present invention with a flat plate evaporator structure, Figure 4 for display image 3 The 4-4 cross-sectional view, Figure 5 for display image 3 The 5-5 cross-sectional view. The evaporator 300 of the present invention is composed of an evaporating section L1 disposed on a heat source 4, and a conducting section L3 connected to a condensing section L2.

[0055] The evaporation section L1 includes an airtight accommodation structure 5 arranged on the heat source 4. The airtight accommodation structure 5 is composed of a cover body 51 and a box body 52 to form an airtight accommodation space 521, and includes There is a capillary structure 6 , a liquid inlet 54 and a corresponding gas outlet 55 .

[0056] The capillary struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com