Treatment method for infiltration liquid in domestic refuse burying field

A technology of domestic waste and treatment method, applied in the field of leachate treatment of urban domestic waste landfill, can solve the problems of high investment and operation cost of leachate treatment, and achieve the effect of improving treatment effect, water quality and uniform flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

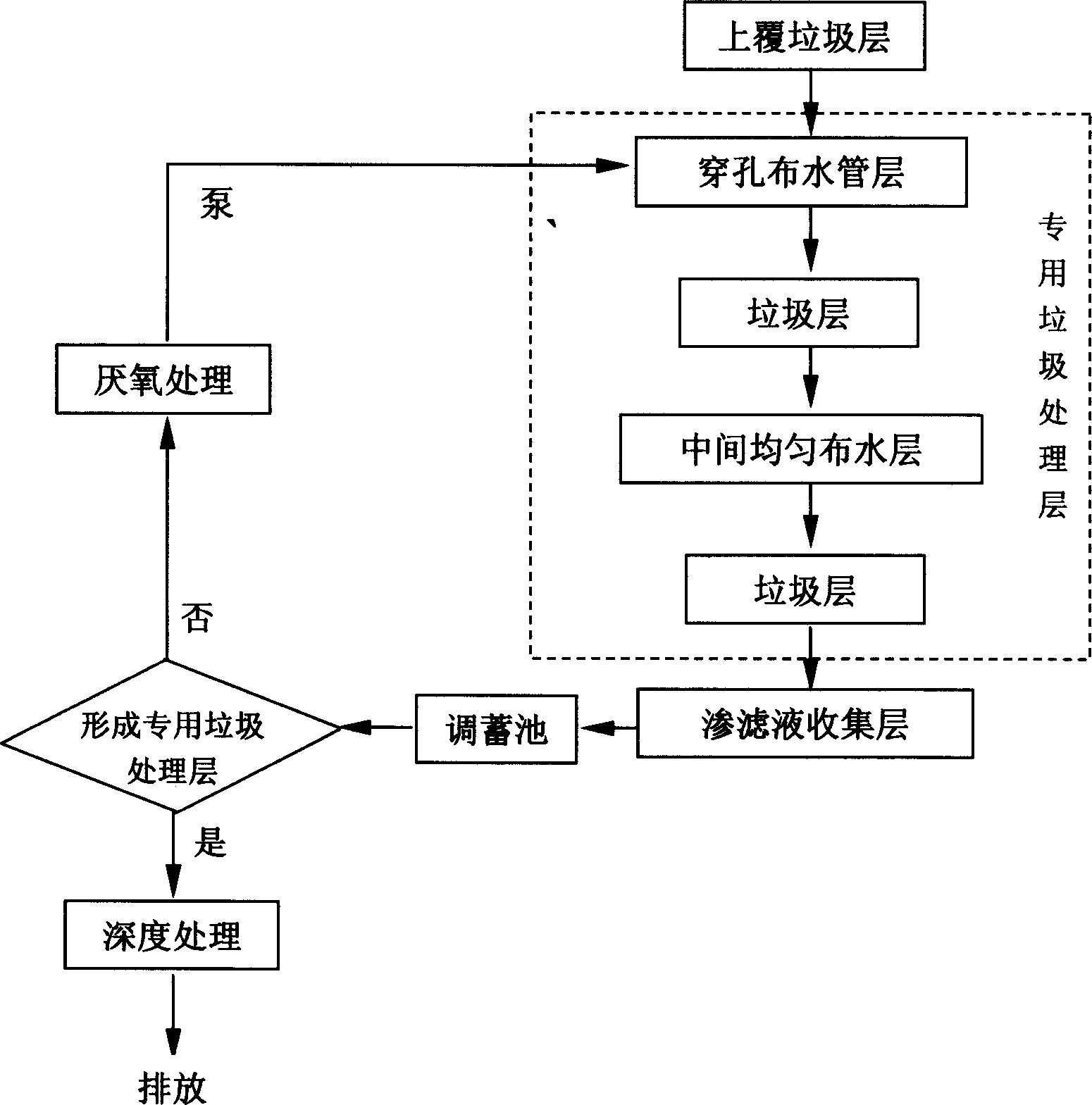

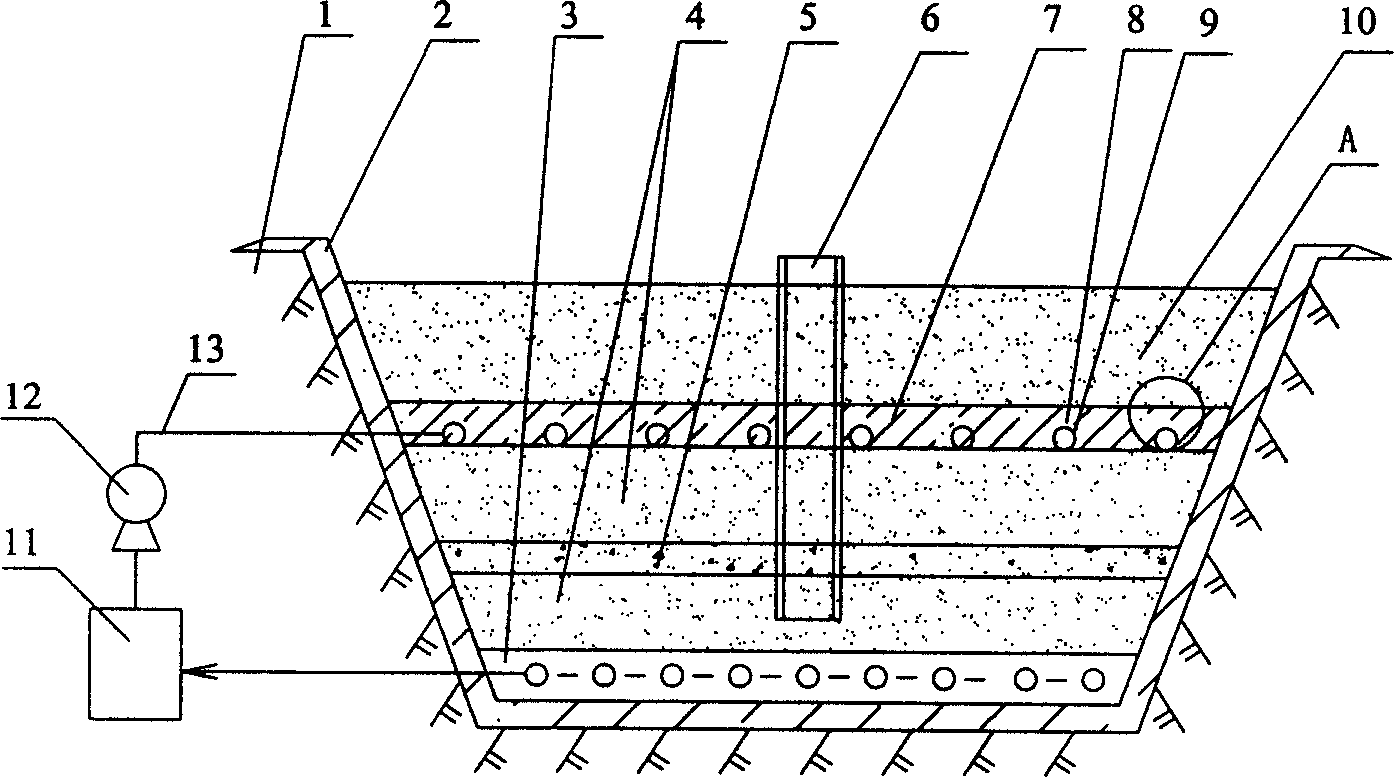

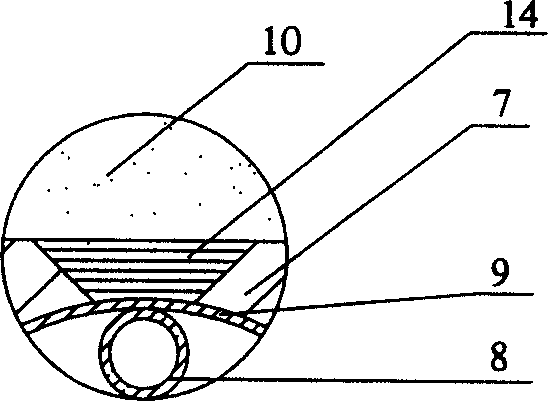

[0016] see figure 1 , 2 , 3. Before landfilling, the anti-seepage layer 2 should be laid on the base soil layer 1 according to the requirements of the sanitary landfill, and then the leachate collection layer 3 should be laid, and the special garbage should be buried on the leachate collection layer 3 Layer 4. Before landfilling garbage, landfill partitions should be formed by separating them with soil barriers (about 1m in height), each with an area of about 1000m 2 . When the landfill thickness of the garbage layer reaches 1.5-2.0m, the middle uniform water distribution layer 5 formed by mixing graded crushed stone and construction sand is evenly laid on this layer, the particle size of graded crushed stone is 5-30mm, and the graded crushed stone The ratio of stone to construction sand is 1:1 by volume. Continue to fill the special garbage 4 on the uniform water distribution layer 5 in the middle until the thickness reaches 1.5-2.0m, then lay the porous water distribu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com