Energy recovery-based landfill leachate autotrophic nitrogen removal method

A technology for landfill leachate and autotrophic denitrification, applied in the field of biological sewage treatment, can solve the problems of high energy consumption and poor effluent stability, and achieve the effects of less excess sludge, less greenhouse gas emissions and slow growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

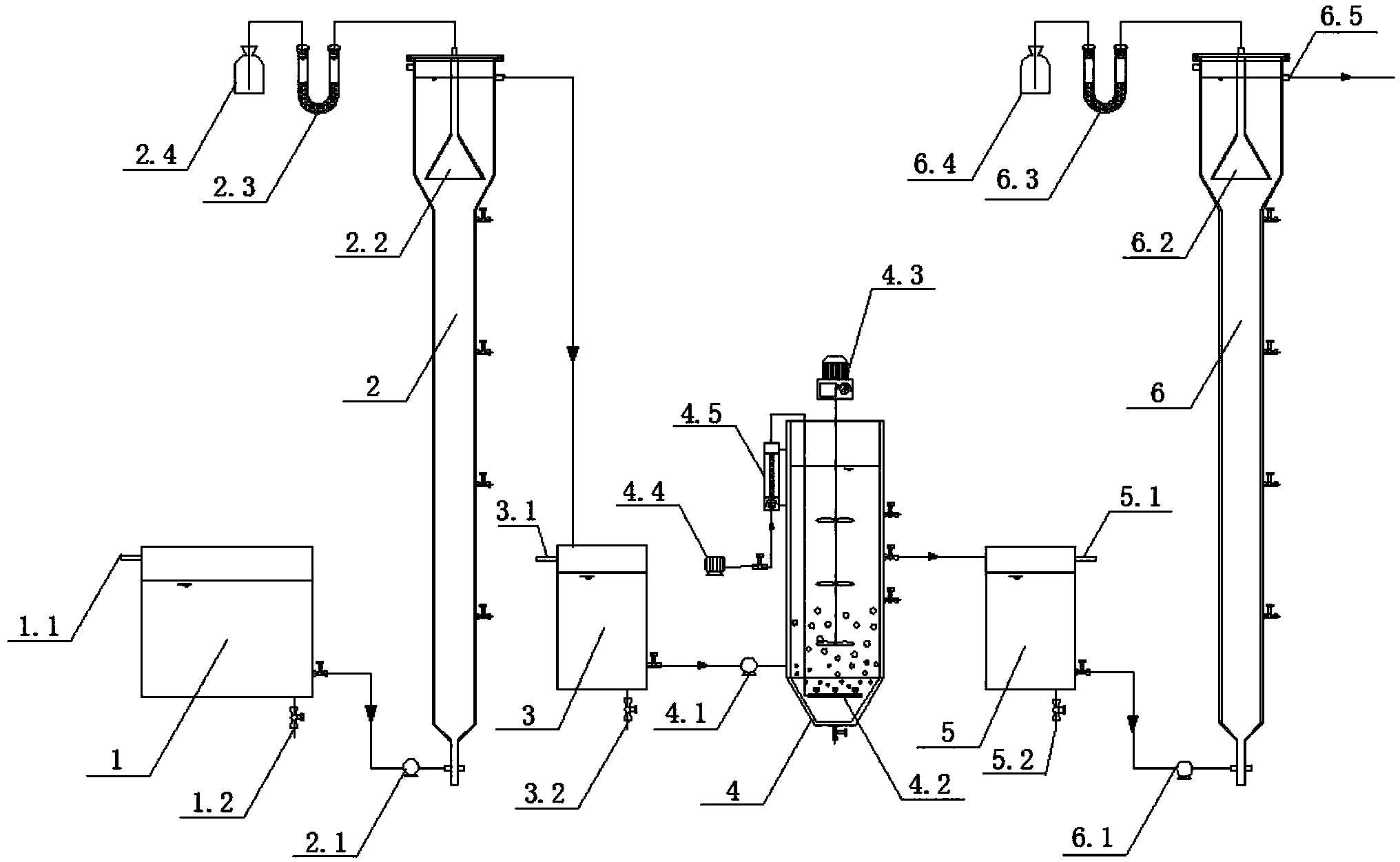

[0023] Below in conjunction with accompanying drawing and embodiment the present invention will be further described: as figure 1 The shown autotrophic denitrification device for landfill leachate based on energy recovery is equipped with landfill leachate raw water tank 1, anaerobic methanogenesis reactor 2, intermediate water tank A3, SBR reactor 4, intermediate water tank B5, and anaerobic ammonium oxidation reactor 6. Landfill leachate raw water tank 1 is provided with overflow pipe 1.1 and vent pipe 1.2; Landfill leachate raw water tank 1 is connected to the water inlet pipe of anaerobic methanogenic reactor 2 through inlet pump 2.1; anaerobic methanogenic reactor 2 It is a UASB reactor, the direction of water flow is from bottom to top, and a built-in three-phase separator 2.2 is used for the separation of solid-liquid-gas three-phase. After methane gas is dried by U-shaped tube dryer 2.3, it is collected by gas collecting bottle 2.4; anaerobic methane production The rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com