Landfill gas extraction flare

a technology of gas extraction and landfill, which is applied in the direction of incinerator equipment, combustion types, lighting and heating equipment, etc., can solve the problem of not achieving better turndown ratios

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

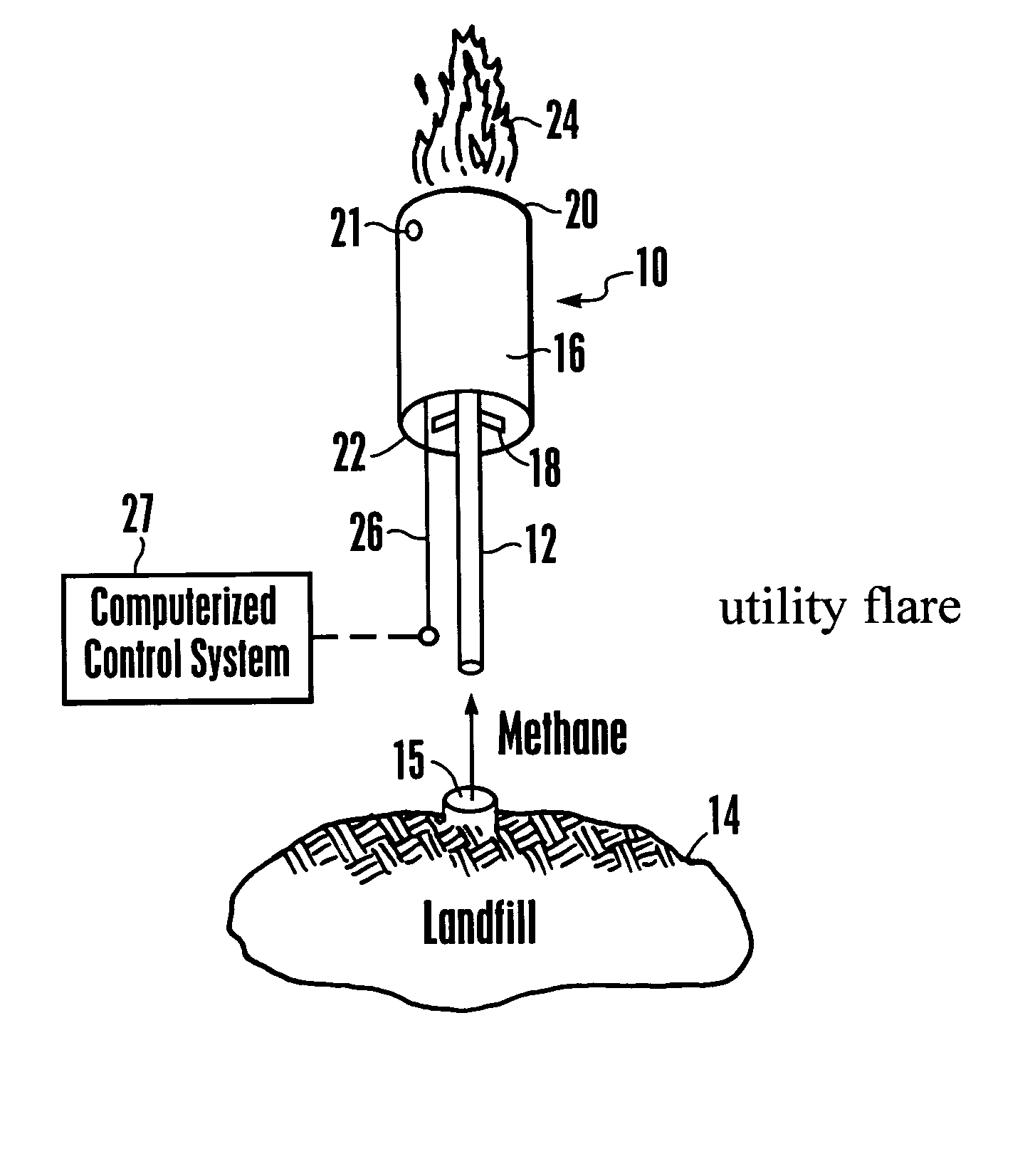

[0020] Referring initially to FIG. 1, a flare is shown, generally designated 10, that includes a methane riser 12 in fluid communication with a landfill 14 for removing methane gas from the landfill 14. A methane pump or blower 15 can be provided to direct methane gas to the methane riser 12.

[0021] The flare 10 includes a shroud 16 surrounding the methane riser 12, if desired in a coaxial relationship and radially spaced therefrom, with the shroud 16 being located above the ground. Brackets 18 can connect the shroud 16 and the methane riser 12. The shroud 16 has an open top end 20. An ignition device 21 can be provided near the open top end 20 to provide an ignition spark within the flare 10. If desired, the shroud 16 can have an open bottom end 22. When burning methane, a flame 24 appears inside and above the open top end 20. Also, a louver actuator 26 is disposed in the shroud 16 and has an end that extends outside the shroud 16 for purposes to be shortly disclosed. It is to be u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com