Landfill leachate treatment method based on high-frequency vibration membrane

A landfill leachate, high-frequency vibration technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. The effect of improving filtration flux, strong anti-clogging ability, and strengthening denitrification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

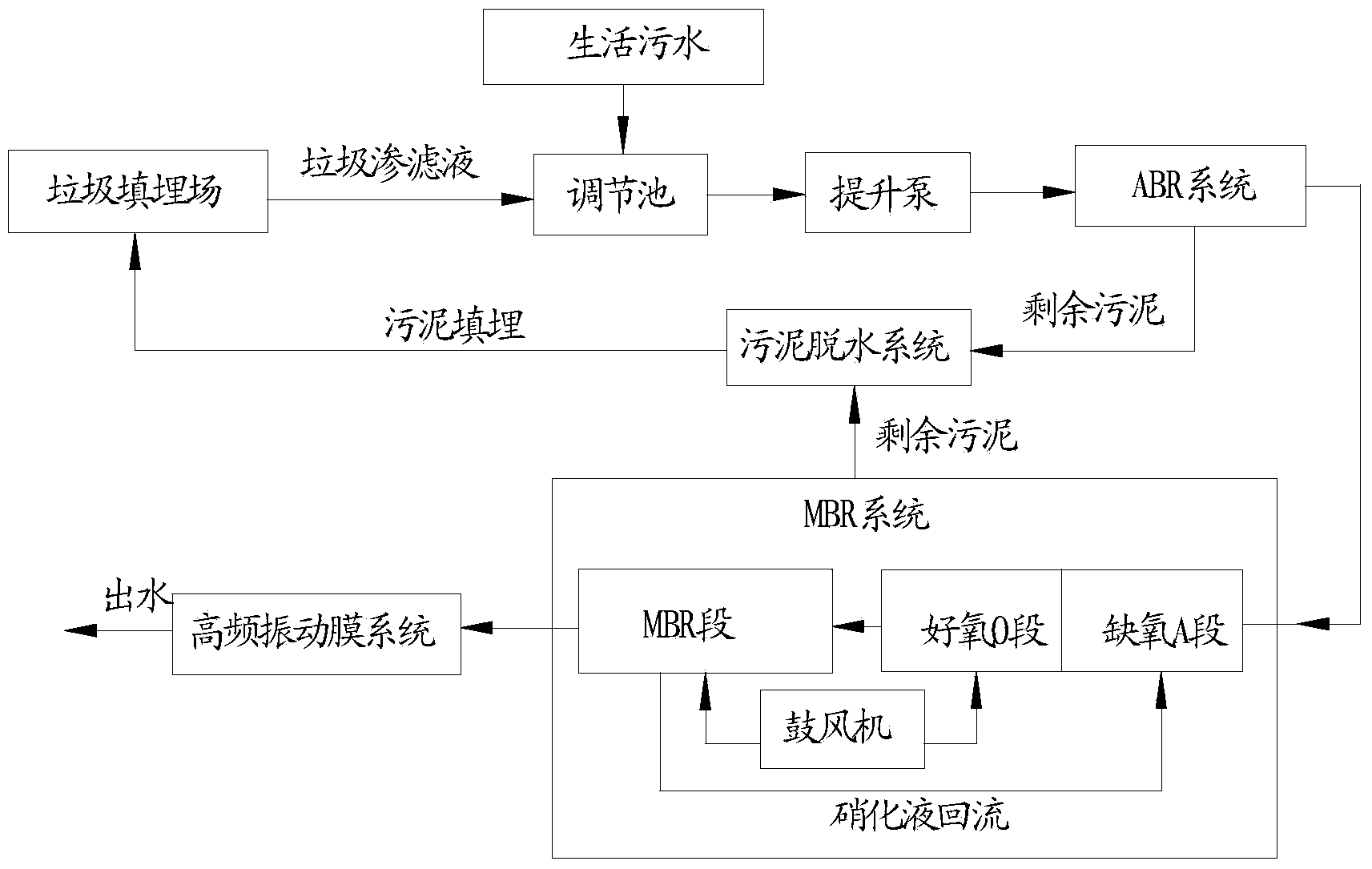

[0038] Such as figure 1 As shown, the landfill leachate treatment method based on high-frequency vibrating membrane described in this embodiment mainly includes: regulating tank→ABR reactor system→MBR reactor→high-frequency vibrating membrane system→standard discharge.

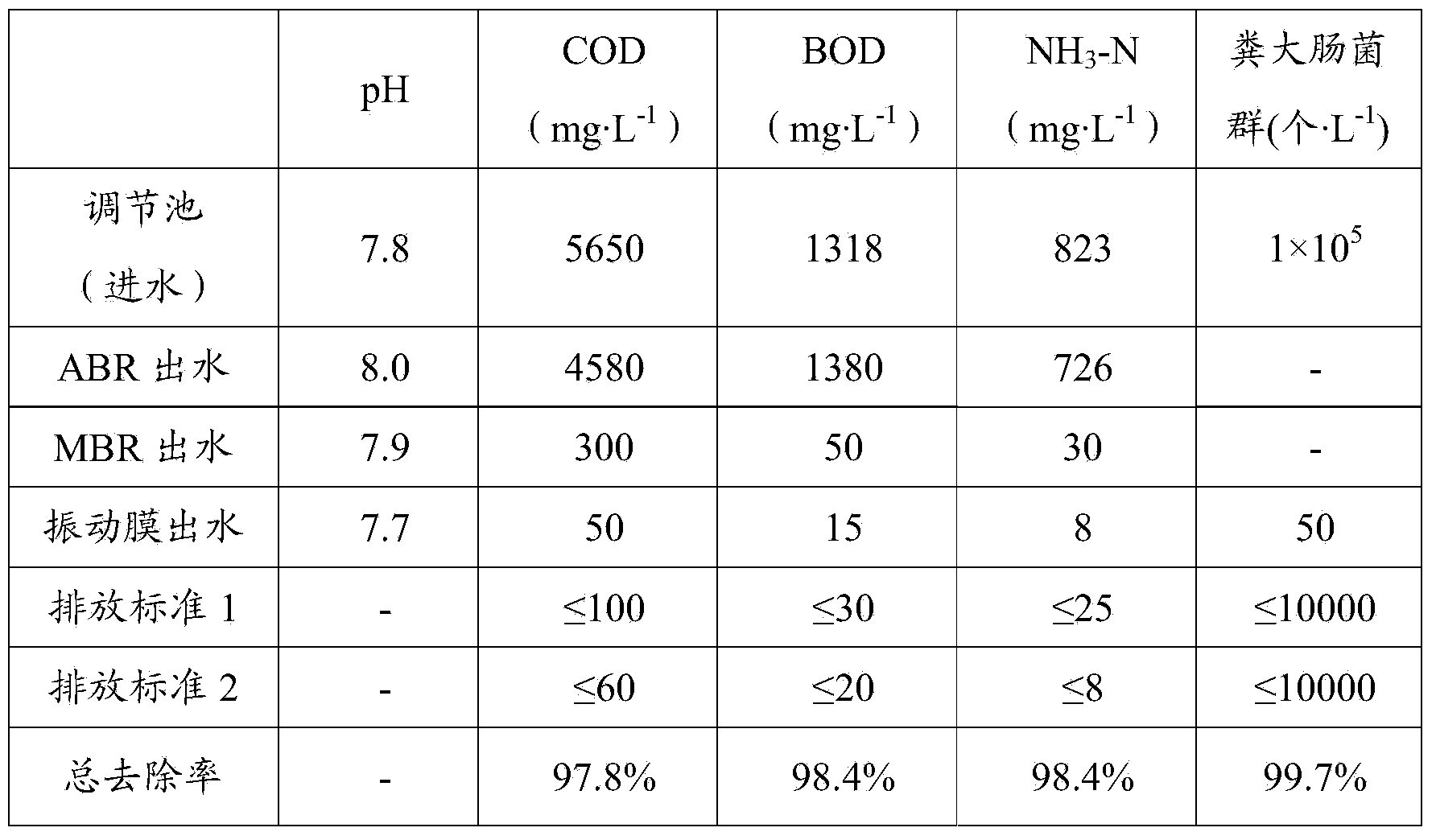

[0039] The waste treatment capacity of a sanitary landfill in a southern city is about 500t / d. According to investigation and analysis, the main components of the landfill waste are 45.63% organic matter, 25.17% inorganic matter, and 29.20% waste products (paper, plastic, fabric, glass, metal, etc.). The leachate produced by it is 300m 3 / d, the water quality is shown in Table 1:

[0040] Table 1 Landfill leachate water quality

[0041] project

Influent water quality

pH

7.8

Chroma / fold

800

SS / (mg·L- 1 )

650

BOD 5 / (mg·L- 1 )

1218

COD / (mg·L- 1 )

5650

TP / (mg·L- 1 )

20

TN (mg·L- 1 )

1632

NH 4+ -N / (mg...

Embodiment 2

[0058]The feature of this embodiment is that it also includes a sludge treatment step: collecting the remaining sludge of the ABR, MBR system, and overfrequency vibrating membrane system, concentrating and dehydrating it, and transporting it to a landfill to be buried together with the garbage. The amount of residual sludge in the anaerobic part is about 1.3m 3 / d, the remaining sludge volume of the MBR system is about 10.9m 3 / d, about 45.0m concentrated solution of super frequency vibrating membrane system 3 / d, about 57.2m in total 3 / d. Others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com