Active clay and preparation thereof

A technology of activated clay and soil blocks, which is applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of long activation time, high production cost, and high energy consumption, and achieve environmental protection, reduce energy consumption, Realize the effect of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

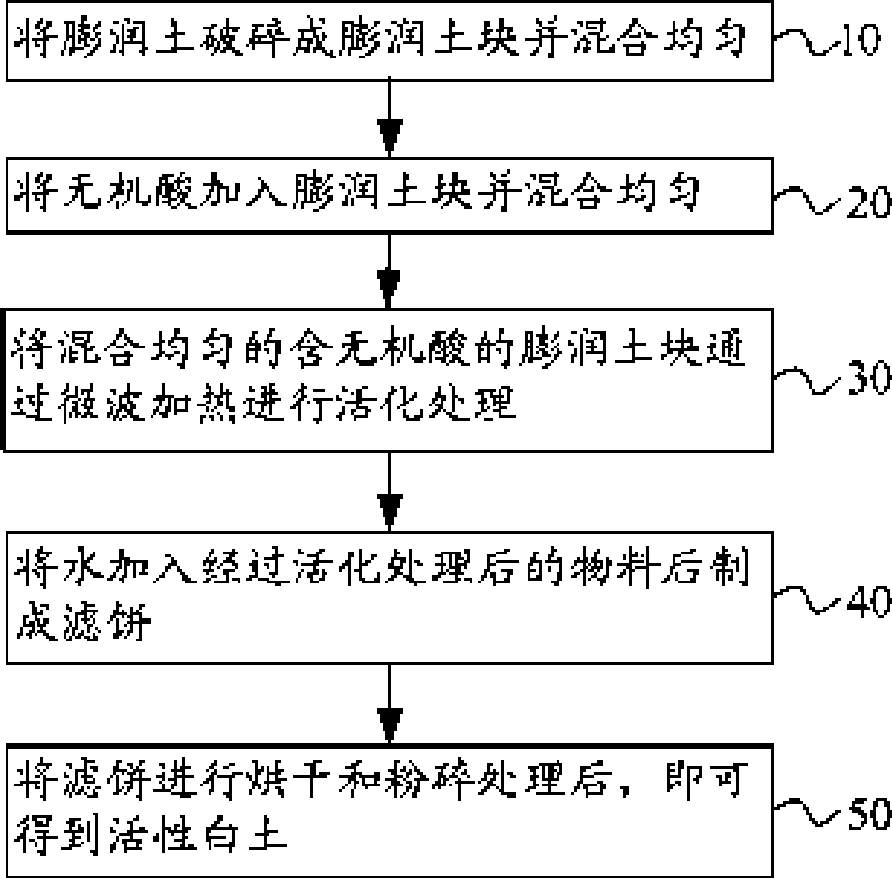

[0034] figure 1 It is a schematic flow diagram of the method for preparing activated clay of the present invention. Such as figure 1 As shown, the method includes the following steps:

[0035] Step 10. Crush the bentonite into bentonite blocks and mix them evenly.

[0036] The step 10 is to crush the bentonite into bentonite blocks with a particle size of less than or equal to 5 mm. The bentonite is composed of any one or more of sodium bentonite, calcium bentonite, palygorskite clay, sepiolite clay and attapulgite clay. In this implementation, the bentonite is preferably calcium-based bentonite.

[0037] Step 20: Add mineral acid to the bentonite block and mix it evenly.

[0038] The inorganic acid is composed of any one or more of phosphoric acid, sulfuric acid or hydrochloric acid. In this implementation, the inorganic acid is preferably sulfuric acid. In this embodiment, put the evenly mixed bentonite block into the silo of the mixing device, open the valve under the silo, th...

Embodiment 1

[0068] First, crush 200 kg of calcium-based bentonite into calcium-based bentonite blocks with a particle size of 5 mm; secondly, add 50 kg of sulfuric acid to the calcium-based bentonite blocks and mix them evenly; again, mix the evenly mixed calcium-based bentonite containing sulfuric acid The block is activated by microwave heating at 90°C for 25 minutes; then, 800 kg of water is added to the activated material for pulping and beating treatment, and the beating-treated mixture is filtered to separate the solid and liquid. Wash the separated solids with 800 kilograms of water and perform pressure filtration; then, repeat the washing with 800 kilograms of water and perform pressure filtration to form a filter cake; finally, the filter cake is placed in QGS -4 type multifunctional drying and crushing equipment is dried at 200°C for 4 seconds, crushed and classified so that about 90% of the materials pass through a 200-mesh sieve, then activated clay can be obtained. Technical indi...

Embodiment 2

[0070] First, crush 200 kg of calcium-based bentonite into calcium-based bentonite blocks with a particle size of 2 mm; secondly, add 50 kg of sulfuric acid to the calcium-based bentonite blocks and mix them evenly; again, mix the evenly mixed calcium-based bentonite containing sulfuric acid The block is activated by microwave heating at 80°C for 20 minutes; then, 800 kg of water is added to the activated material for pulping and beating treatment, and the beating-treated mixture is filtered to separate the solid and liquid. Wash the separated solids with 800 kilograms of water and press filter; then, repeat three times to wash the separated solids with 800 kilograms of water and press filter to make a filter cake; finally, the filter cake is placed in QGS -4 type multifunctional drying and crushing equipment is dried at 200°C for 6 seconds, crushed and classified so that about 90% of the materials pass through a 200-mesh sieve, then activated clay can be obtained. Technical indic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com