Ac-powered LED light engines, integrated circuits and illuminating apparatuses having the same

a led light engine and led light technology, applied in the direction of electroluminescent light sources, electric lighting sources, semiconductor lamp usage, etc., can solve the problems of emi filter, flicker phenomenon, and need for a more complicated and expensive driving circui

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021]The detailed explanation of the present invention is described as follows. The preferred embodiments are presented for purposes of illustrations and description, and not intended to limit the spirit and scope of the present invention.

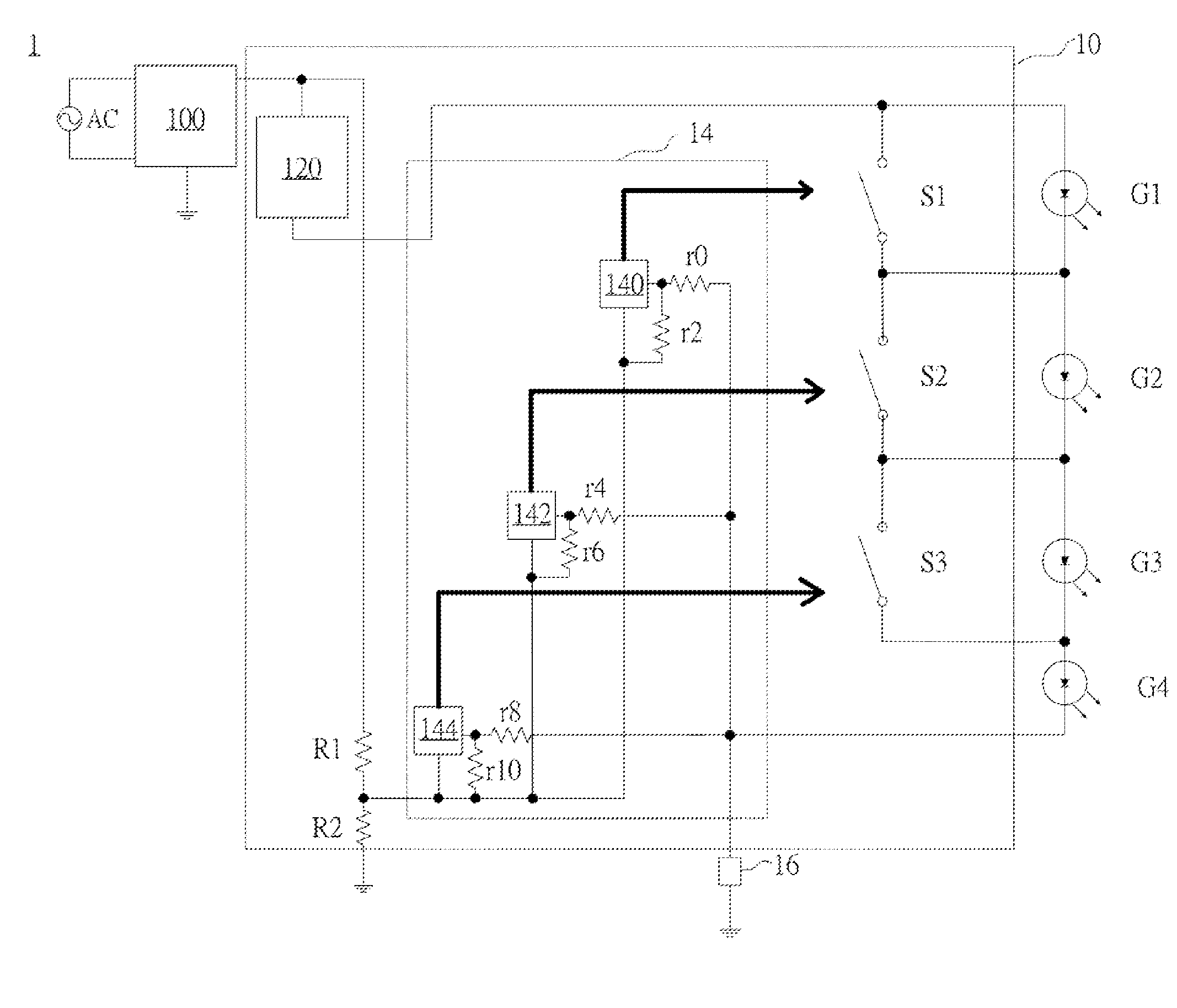

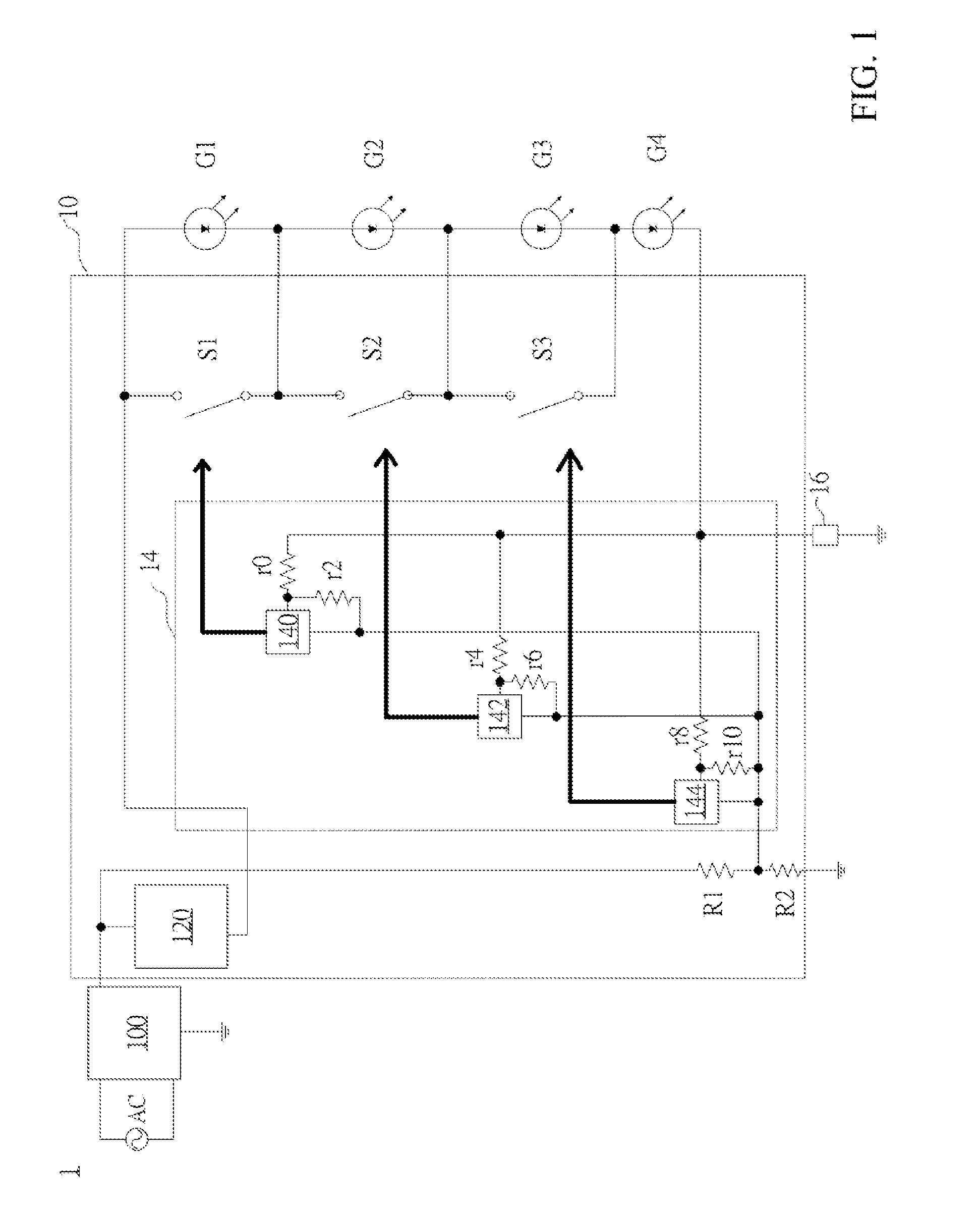

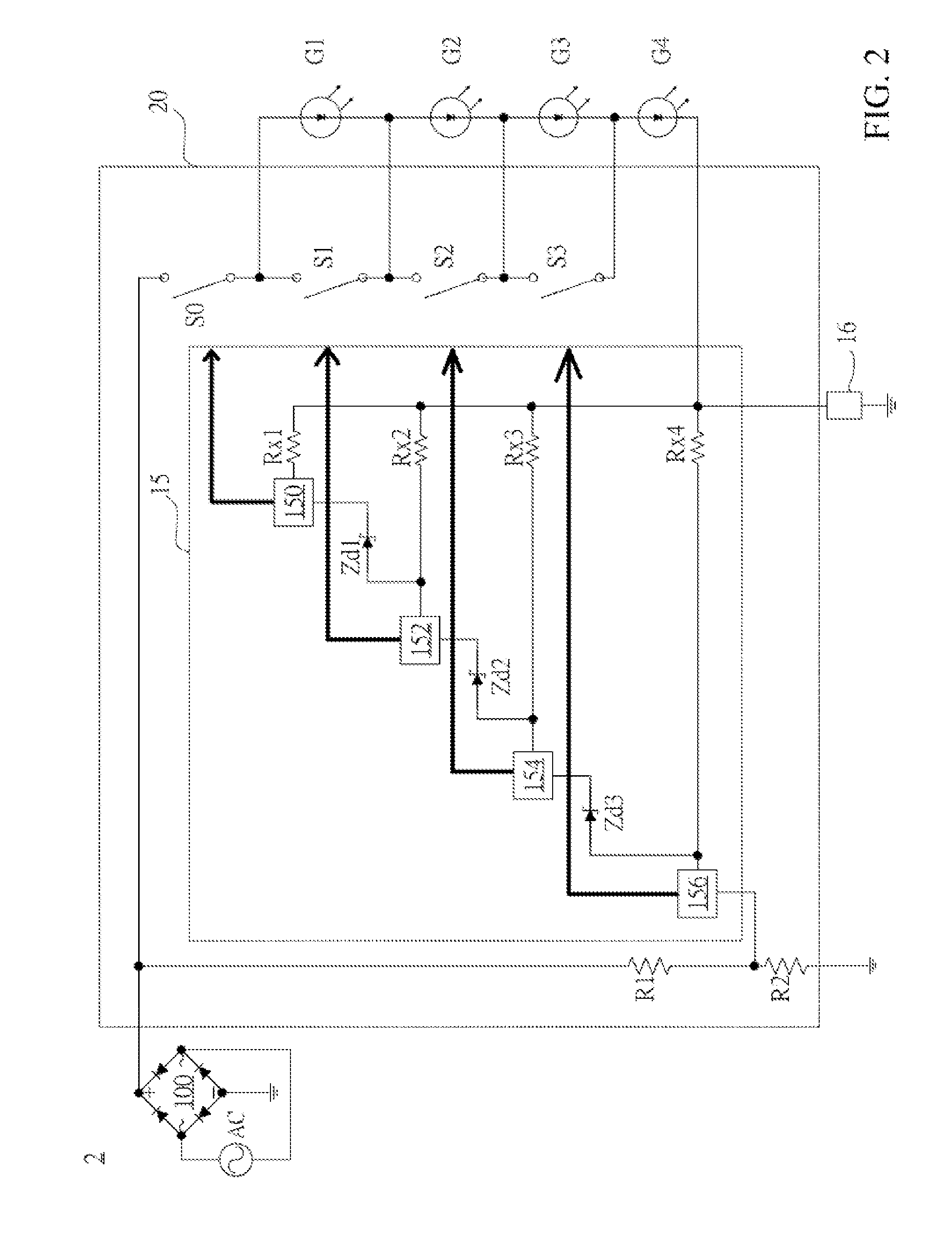

[0022]FIG. 1 illustrates a block diagram of an illuminating apparatus 1 equipped with an AC-powered LED light engine 10 designed to gear up from the bottom up and gear down from the top down the extrinsic LED sub-arrays (G1, G2, G3, and G4) in accordance with an embodiment of the present invention. The illuminating apparatus 1 comprises a rectifier 100 coupled to an AC mains, an AC-powered LED light engine 10, and a shared current sense and modulation unit 16, and is loaded up with a plurality of extrinsic LED sub-arrays (G1, G2, G3, and G4).

[0023]The AC-powered LED light engine 10 is coupled between the rectifier 100 and the extrinsic LED sub-arrays (G1, G2, G3, and G4), and has a normally closed current regulator 120 coupled to the rectifier 100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com