Patents

Literature

31results about How to "Excessive oxidation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

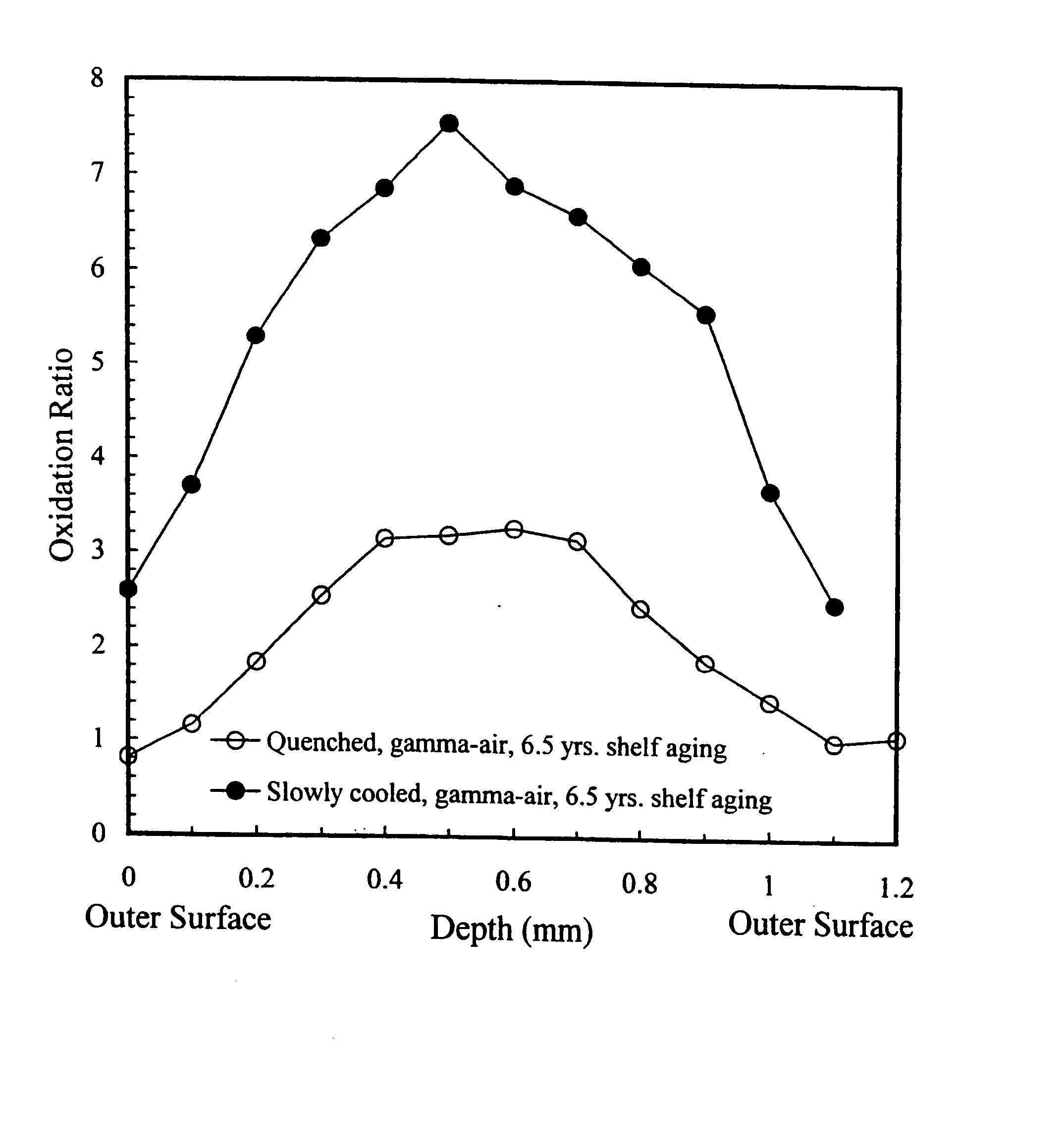

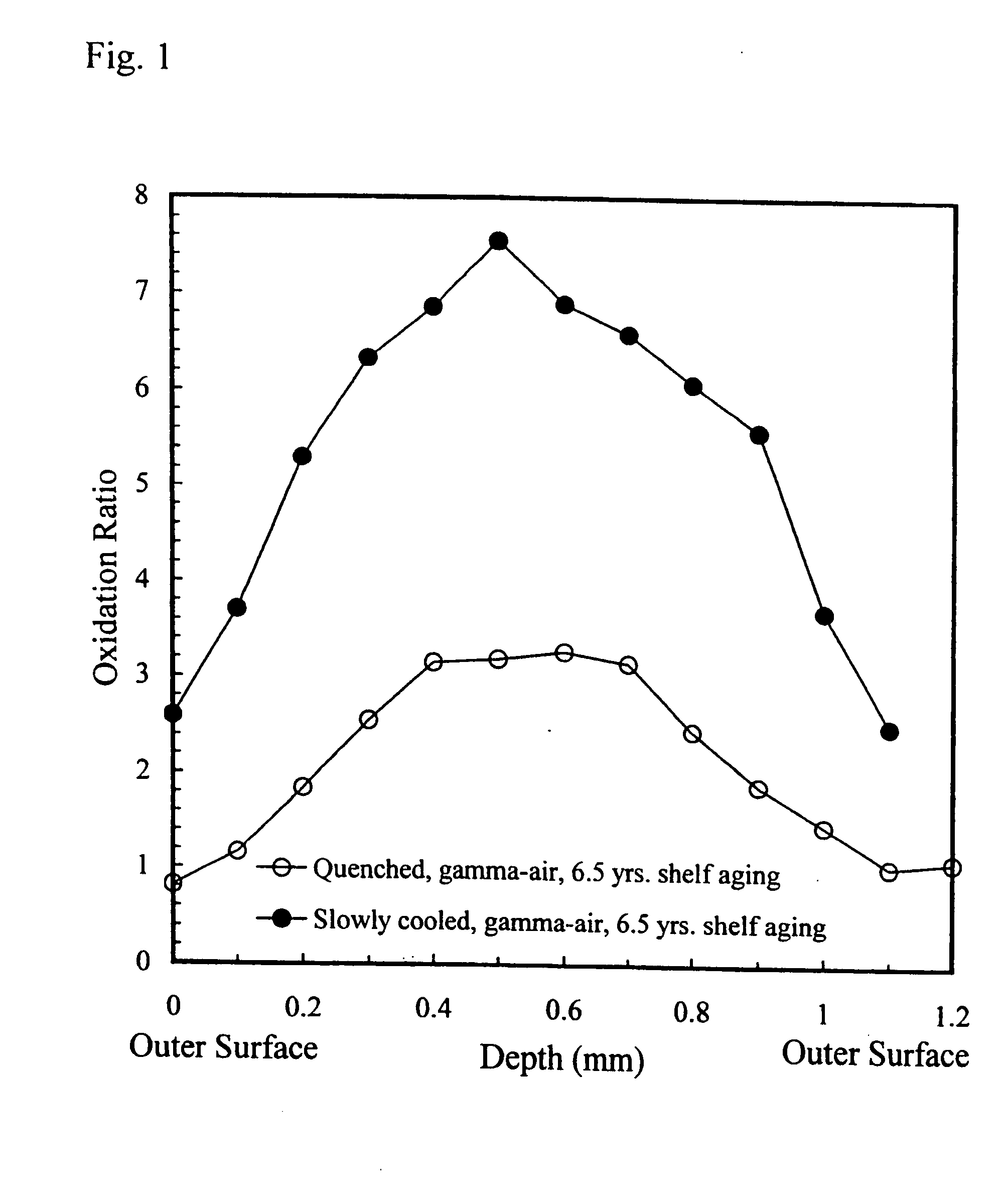

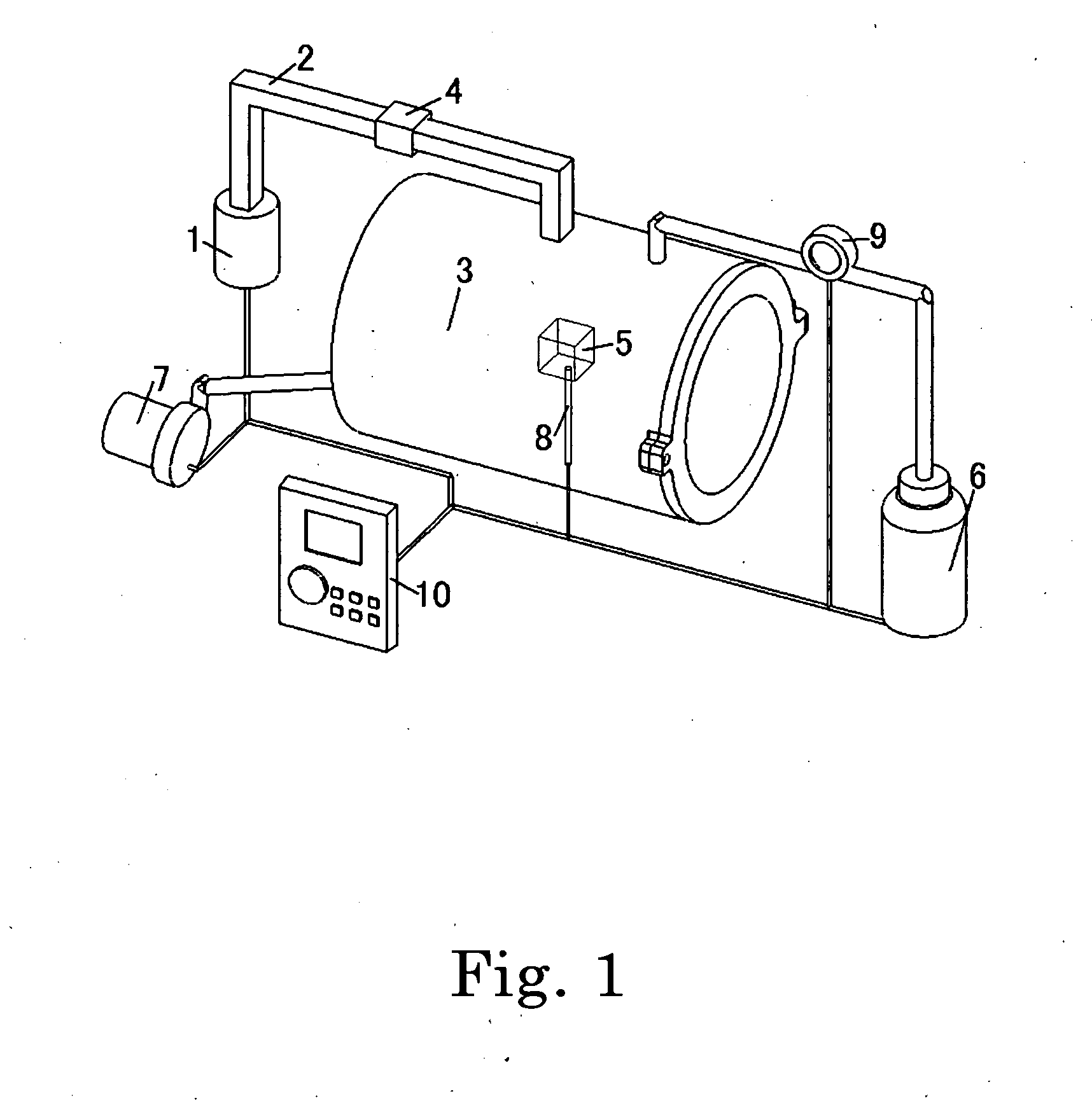

Oxidation-resistant and wear-resistant polyethylenes for human joint replacements and methods for making them

InactiveUS20070293647A1Improve wear resistanceImprove the immunitySurgeryPackage sterilisationPresent methodWear resistant

The present invention presents methods for making oxidation-resistant and wear-resistant polyethylenes and medical implants made therefrom. Preferably, the implants are components of prosthetic joints, e.g., a bearing component of an artificial hip or knee joint. The resulting oxidation-resistant and wear-resistant polyethylenes and implants are also disclosed.

Owner:THE ORTHOPAEDIC HOSPITAL

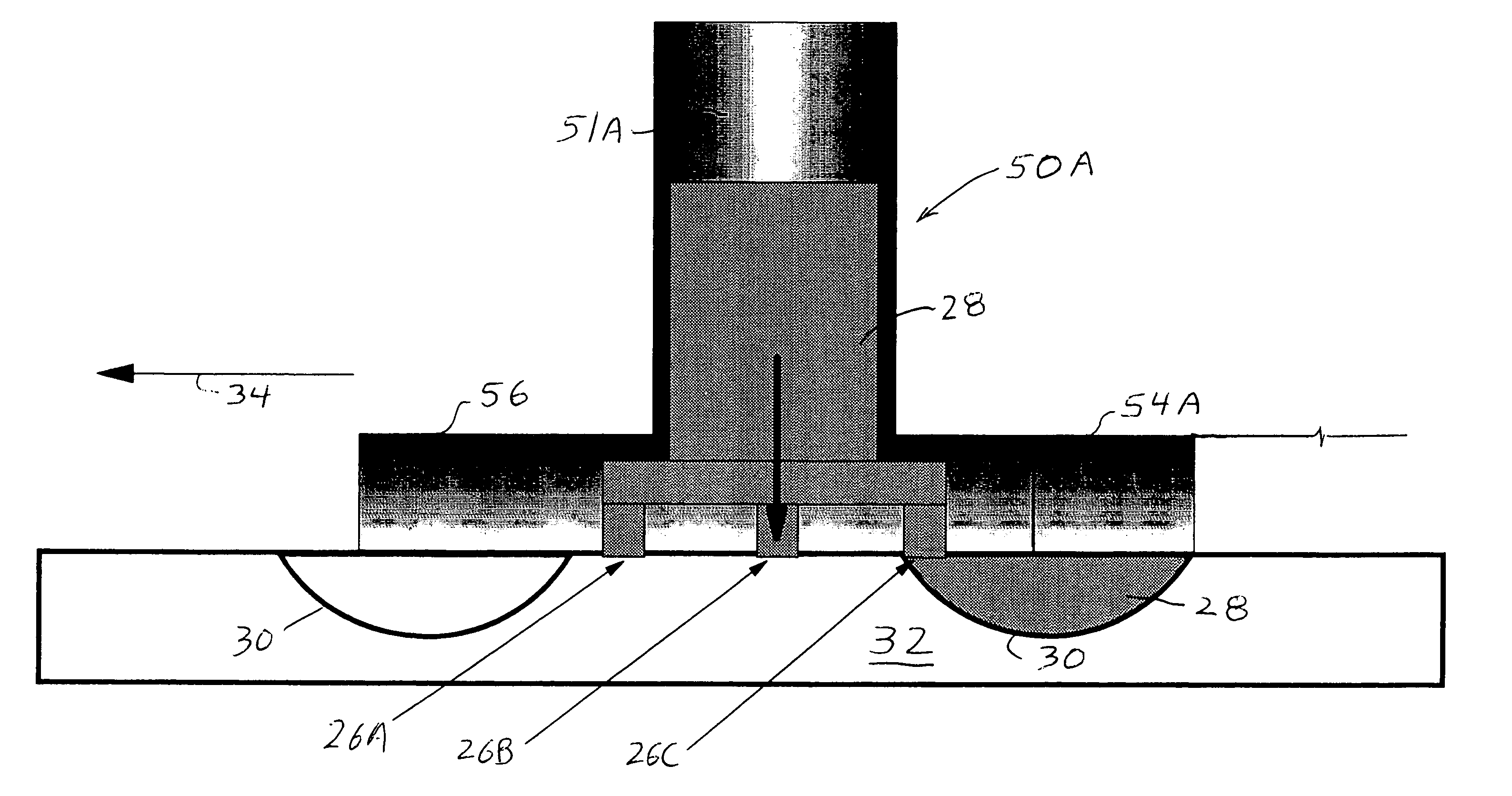

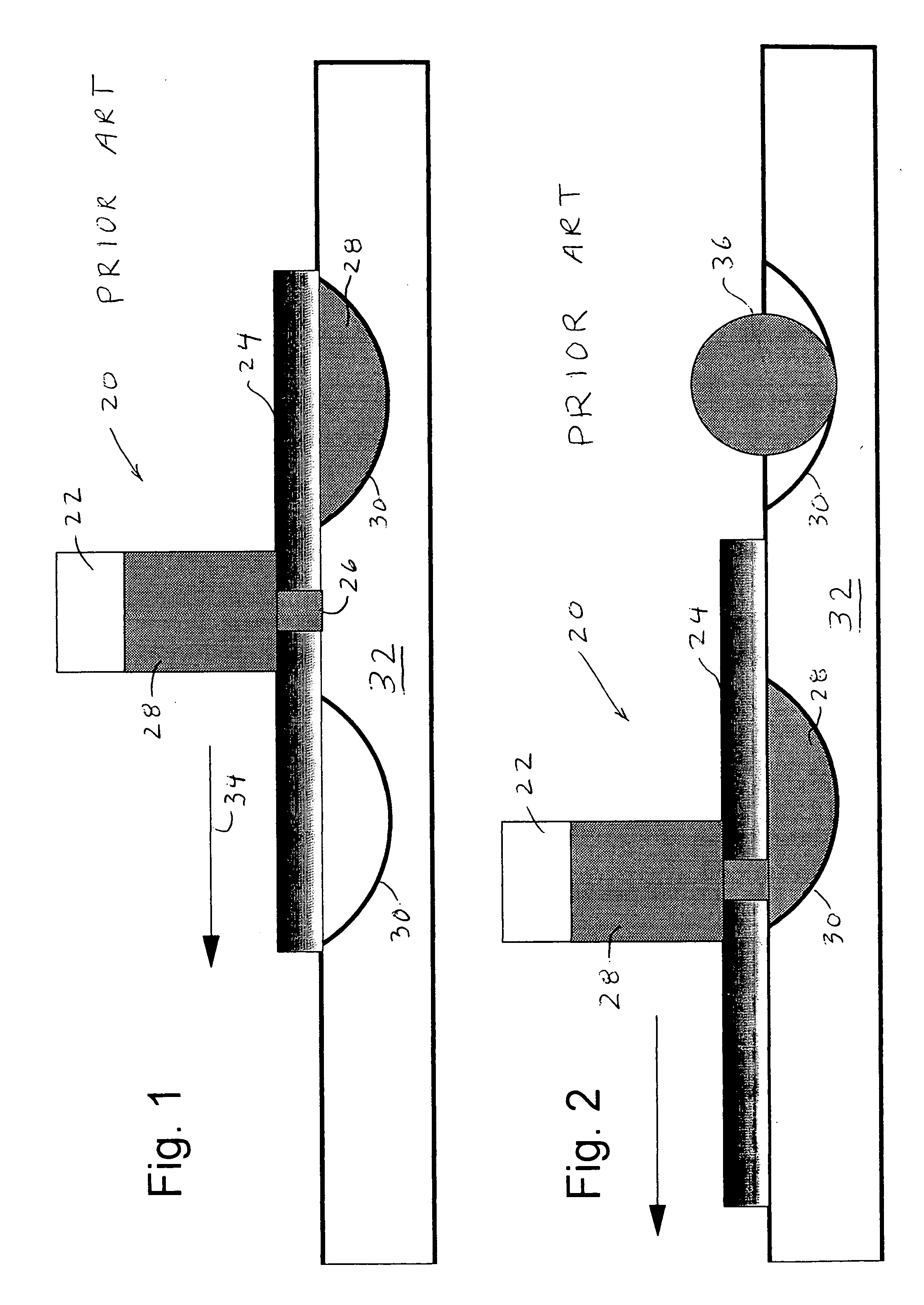

Injection molded continuously solidified solder method and apparatus

InactiveUS20050263571A1Accurate storageAccurately and completely fill the cavitiesPrinted circuit assemblingWelding/cutting media/materialsMetallurgyMaterials science

A method and apparatus for forming solder bumps by molten solder deposition into cavity arrays in a substrate immediately followed by solidification of molten solder such that precise replication of cavity volumes is consistently achieved in formed solder bump arrays. Various solder filling problems, such as those caused by surface tension and oxidation effects, are overcome by a combination of narrow molten Solder dispense slots and solidification of dispensed molten solder.

Owner:BELANGER LUC +12

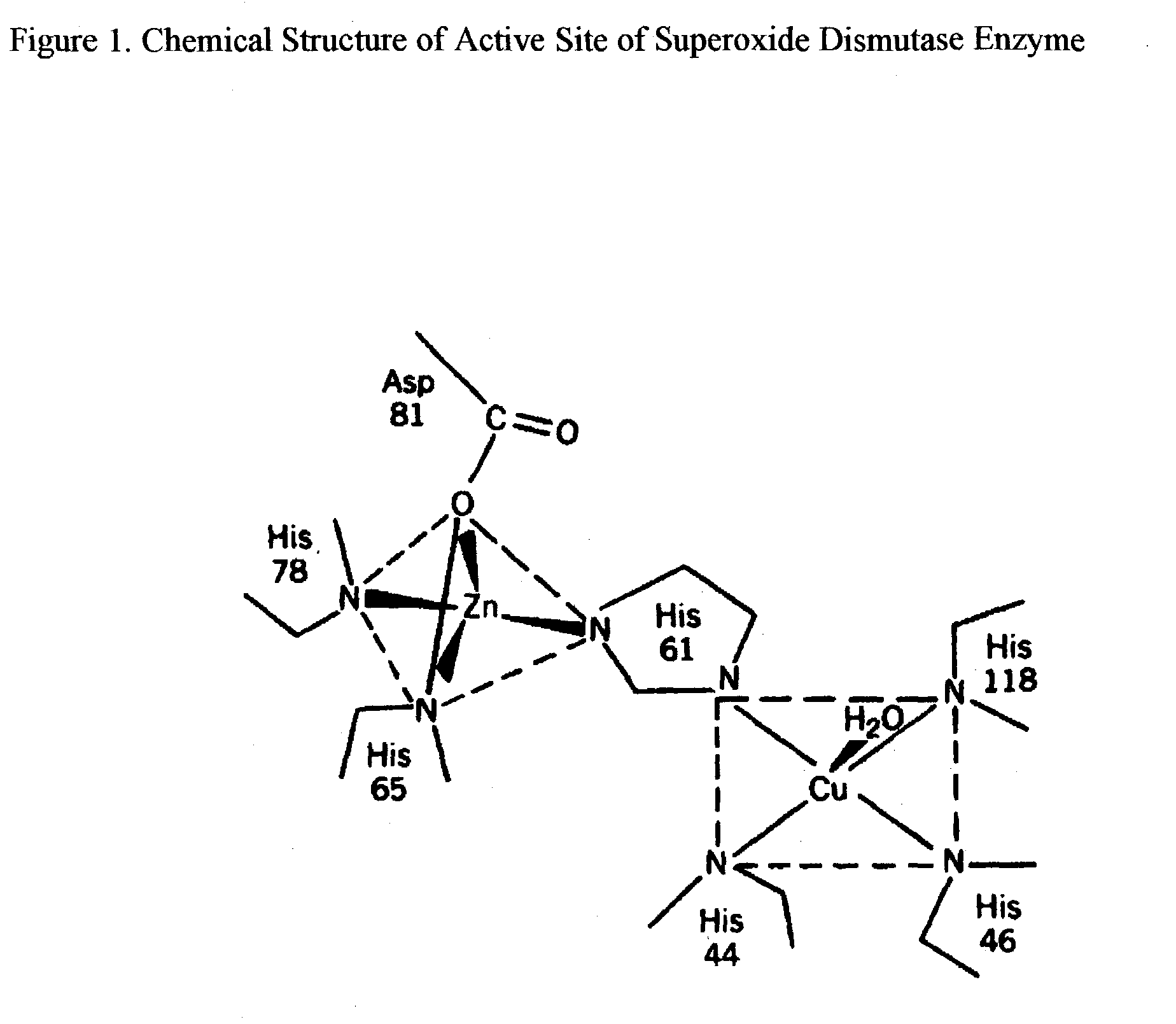

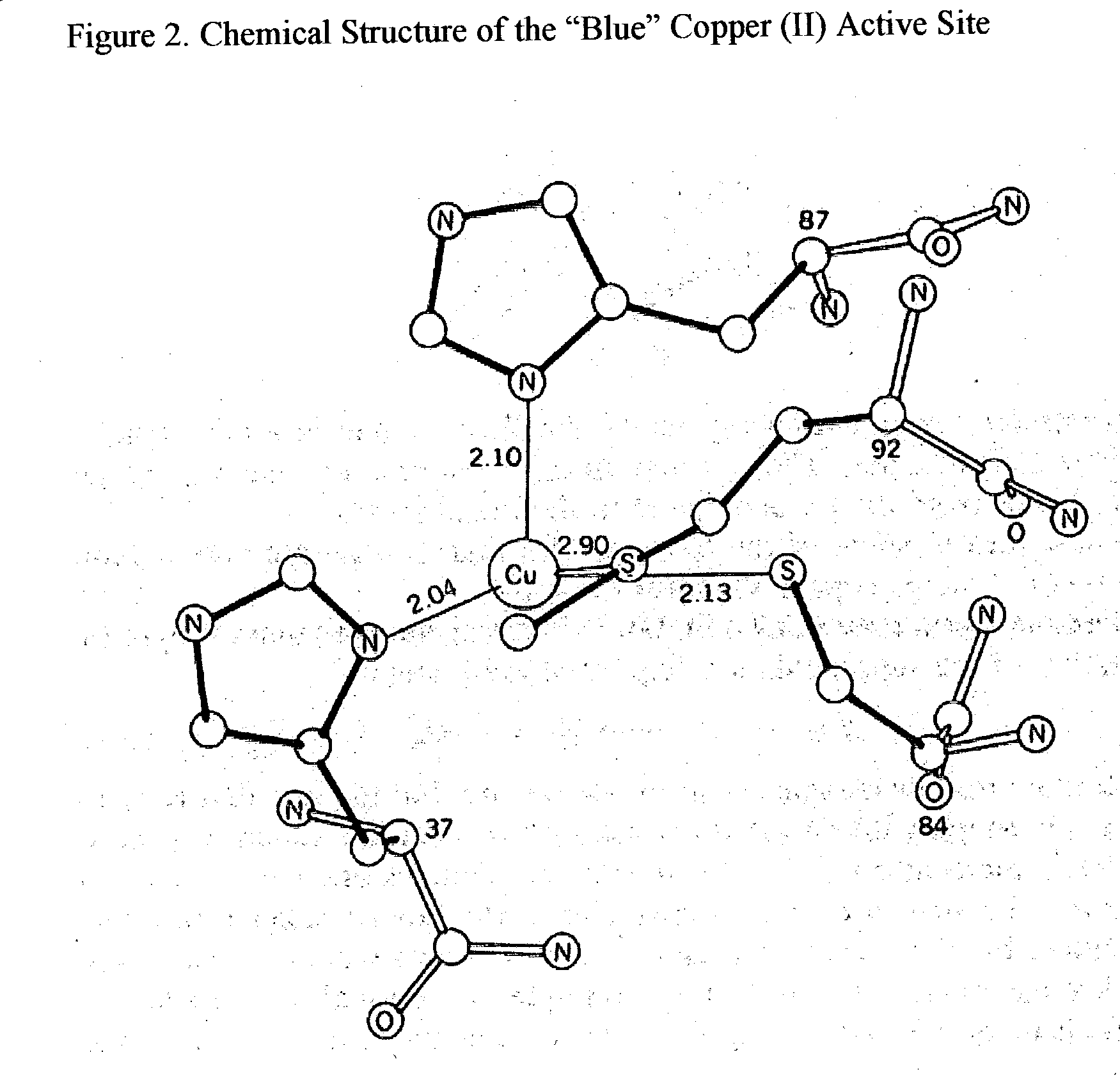

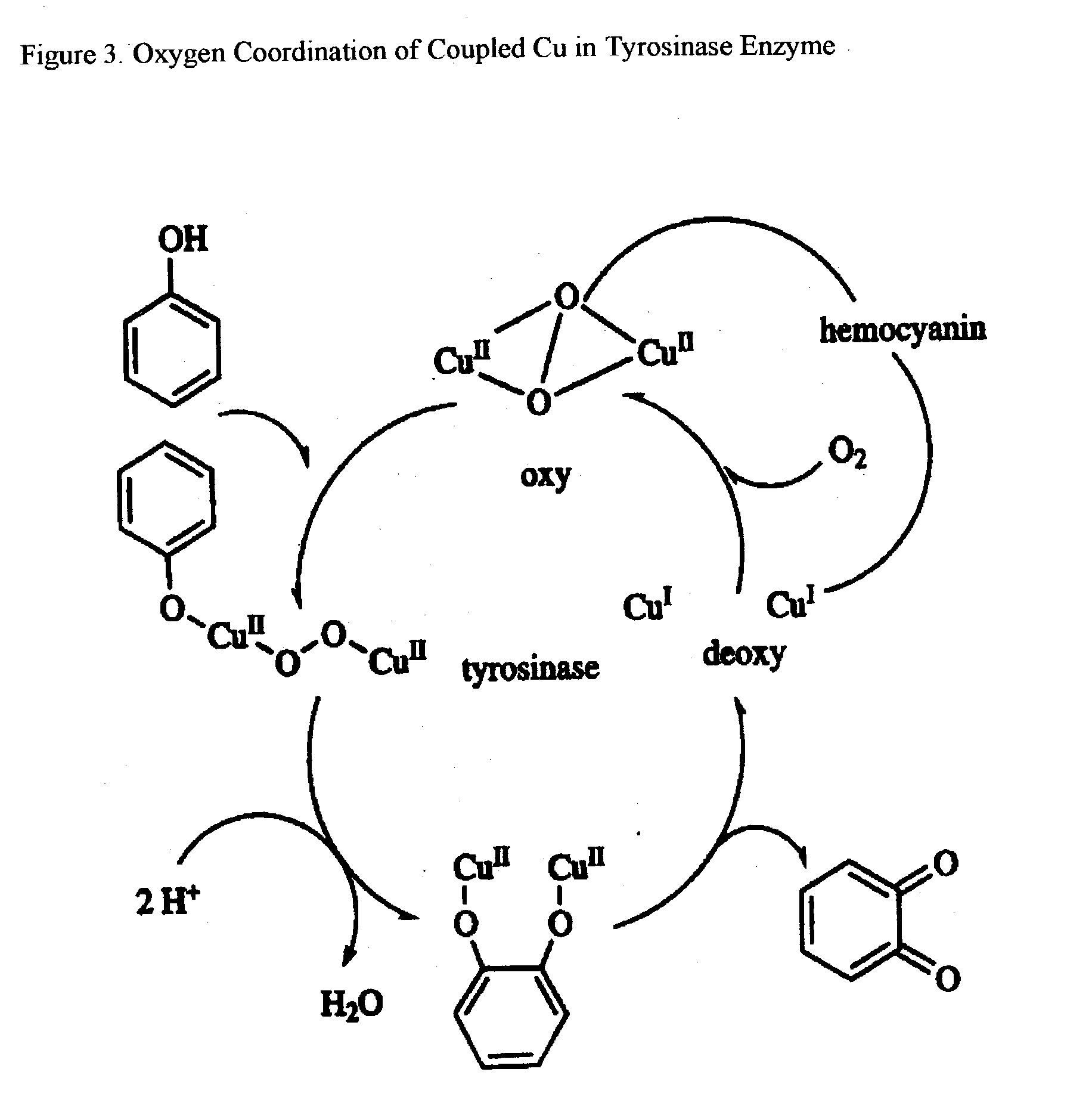

Trace Metals synergized copper nucleotides and copper glycosides for anti-aging and antiviral compositions

InactiveUS20040105894A1Simple preparation processImprove bioavailabilityCosmetic preparationsHeavy metal active ingredientsNucleotidePhosphorylation

I have discovered that trace metals such as copper, zinc, iron, and manganese that are necessary for the proper functioning of superoxide dismutase (SOD) and other deactivators of active-oxygen molecules (which cause aging of skin and other skin disorders), can be delivered from the topical compositions. This is achieved by the preparation of copper and other trace metal complexes with phosphorylated nucleosides, such as nucleotides, and phosphorylated monosaccharides, such as phosphorylated glycosides which act as small molecular weight (SMW) transporter molecules. These trace metal complexes of nucleotides and glycosides can be prepared by an in-situ method in water, water-miscible organic solvent, or a mixture of water and water-miscible organic solvent from commonly available ingredients in concentrations that are desirable and can be accurately controlled. I have additionally discovered compositions to achieve the transport of copper from the surface layers of skin into the deeper layers of skin utilizing SMW transporter molecules; and the intra-cellular storage of copper ions in the cell, for example in a bound form with glutathione; and the intra-cellular transport of copper from glutathione to SOD apoprotein by metallochaperones; and the supply of energetic molecules, such as ATP, ADP, or phosphorylated saccharides for SOD metallochaperones to perform their intra-cellular metal transfer function. These cosmetic or pharmaceutical compositions are useful for antiaging and antiviral benefits.

Owner:GUPTA SHYAM K

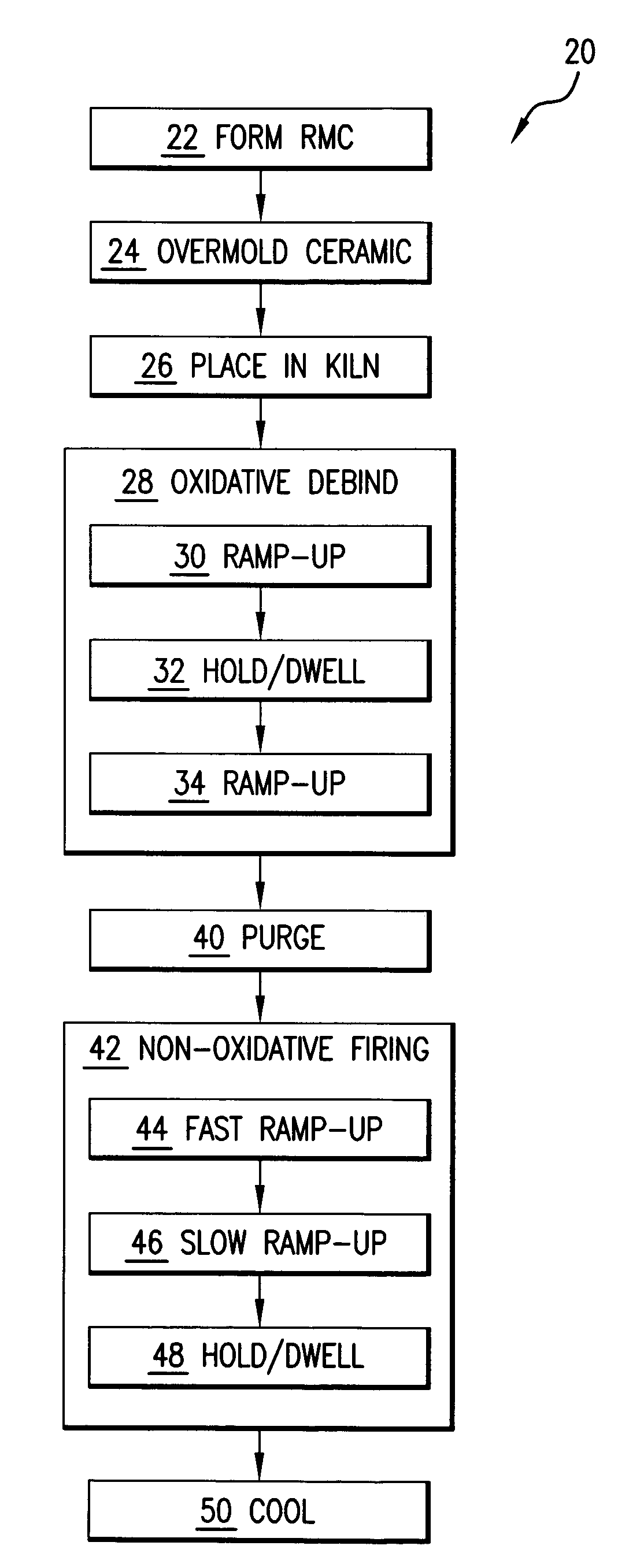

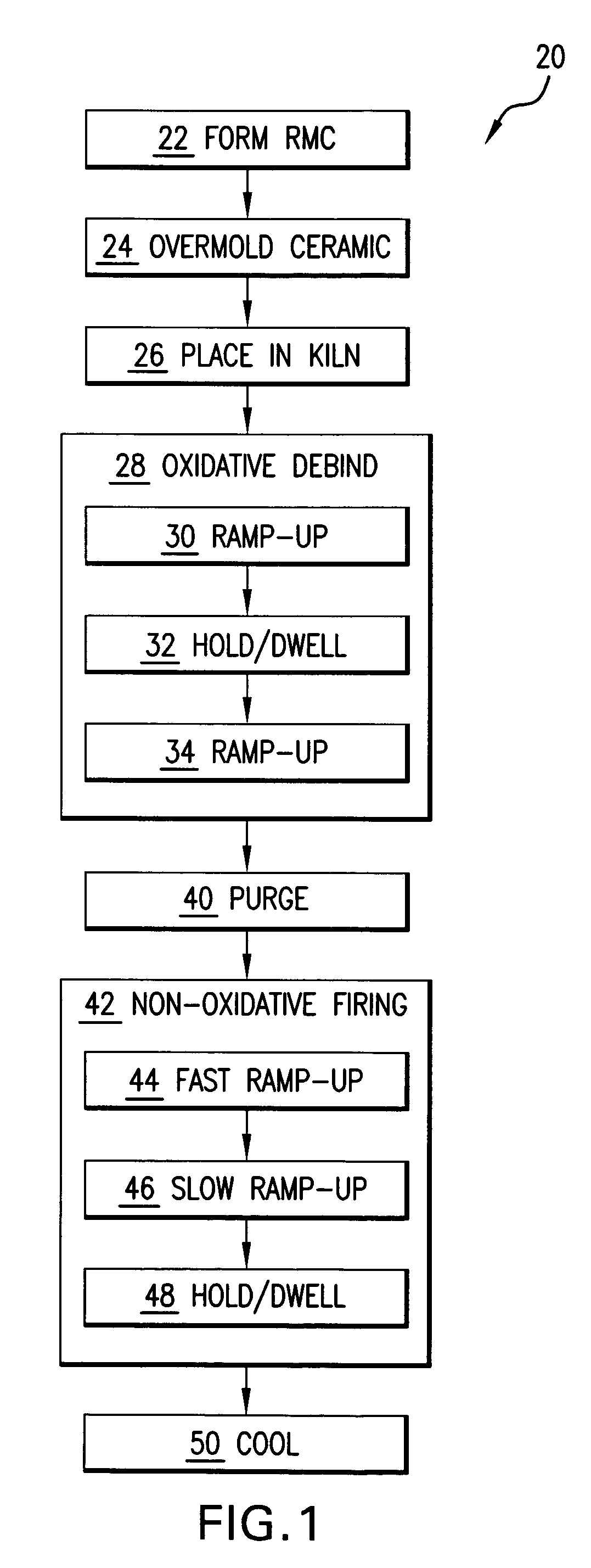

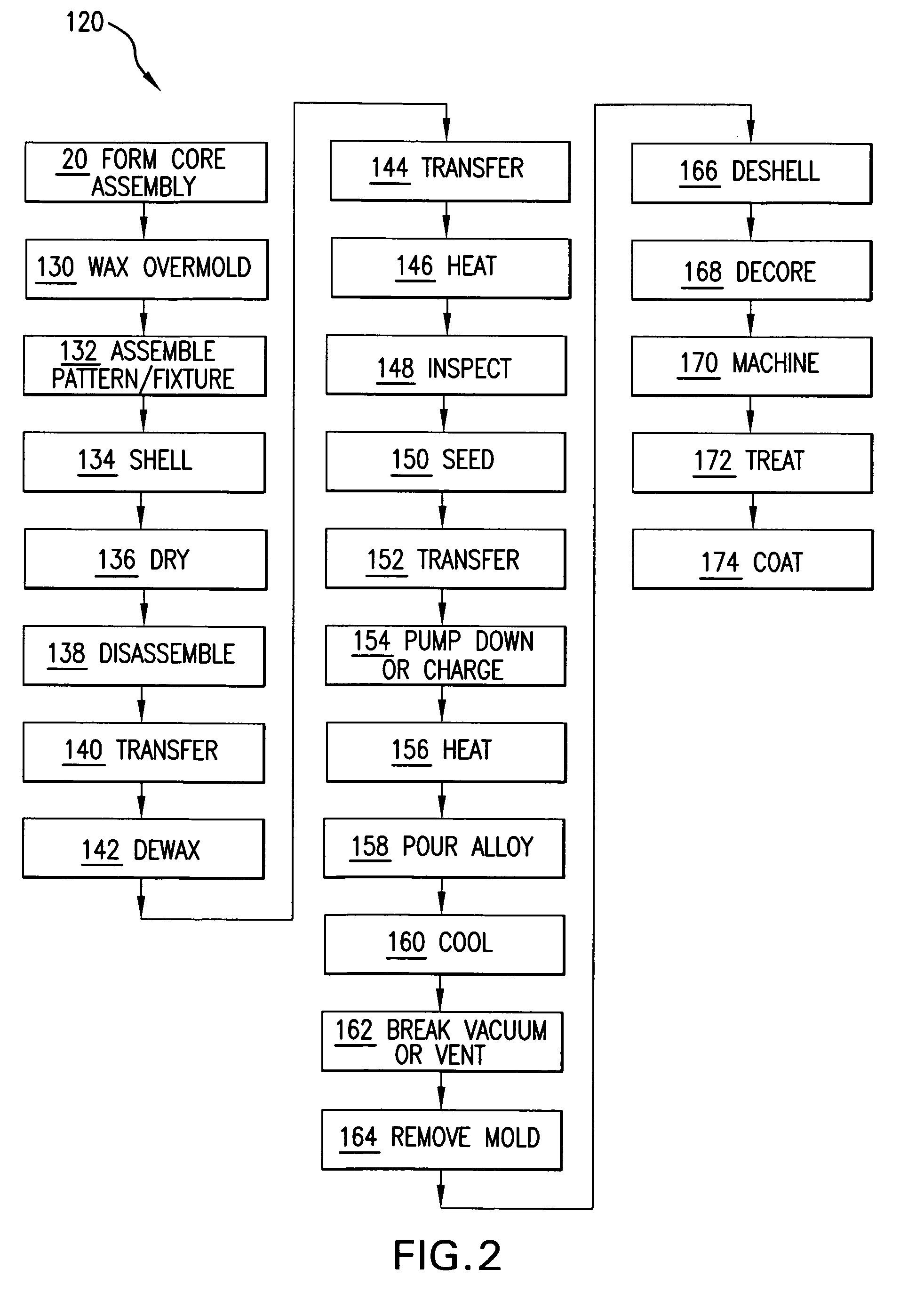

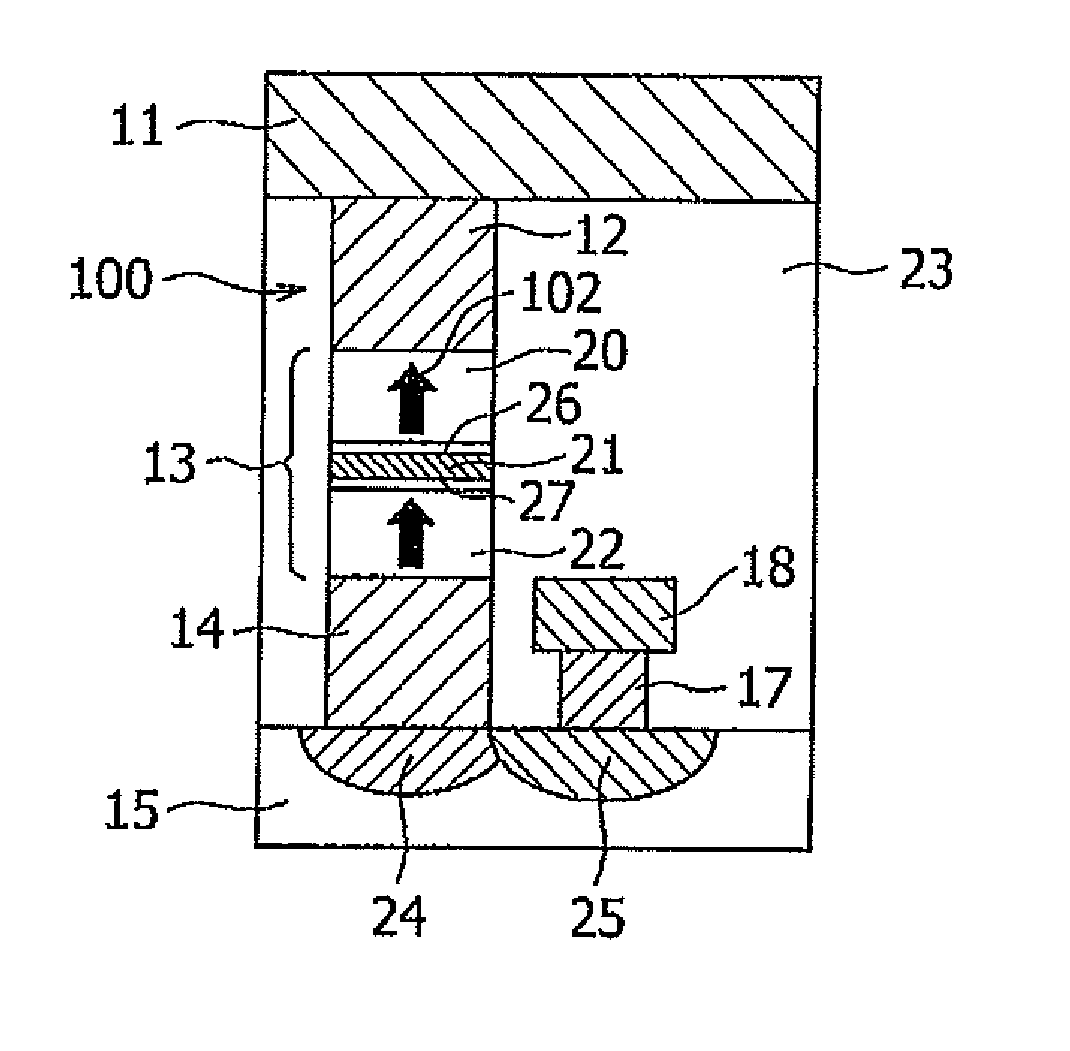

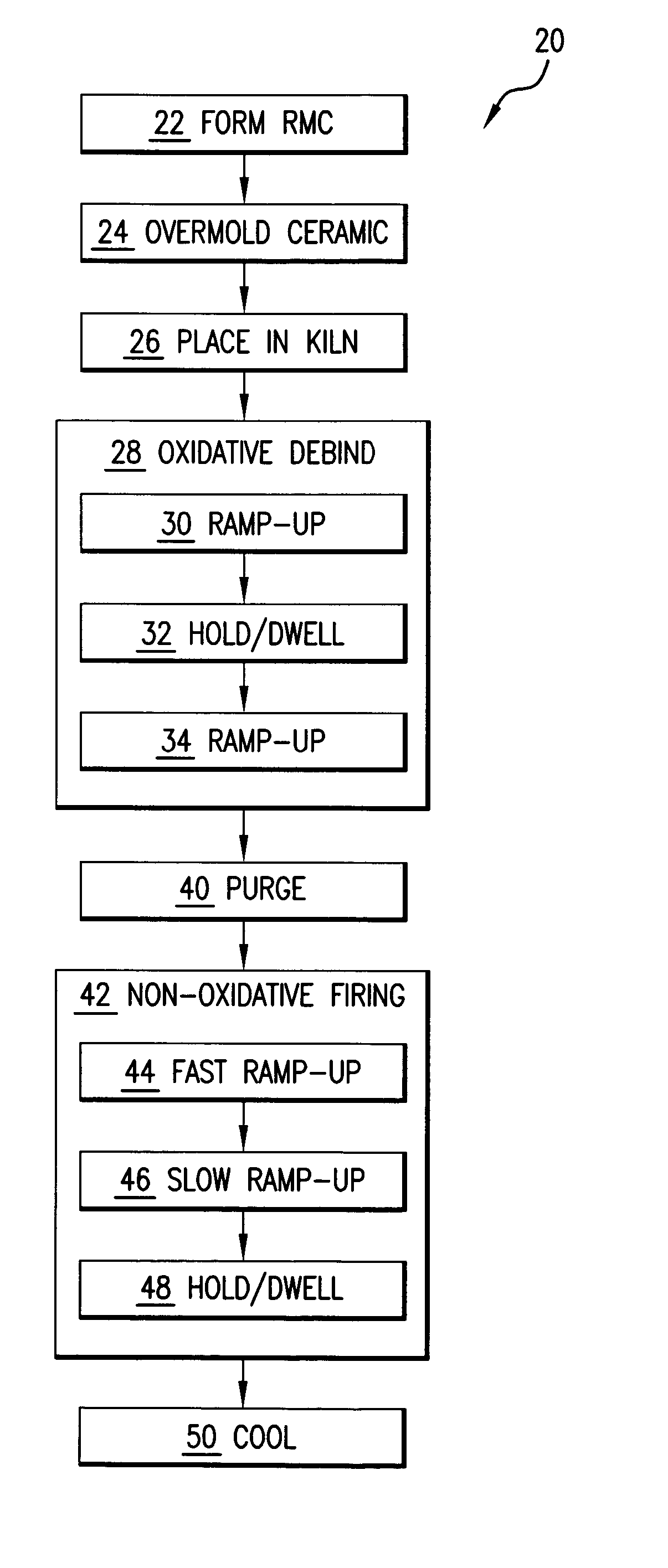

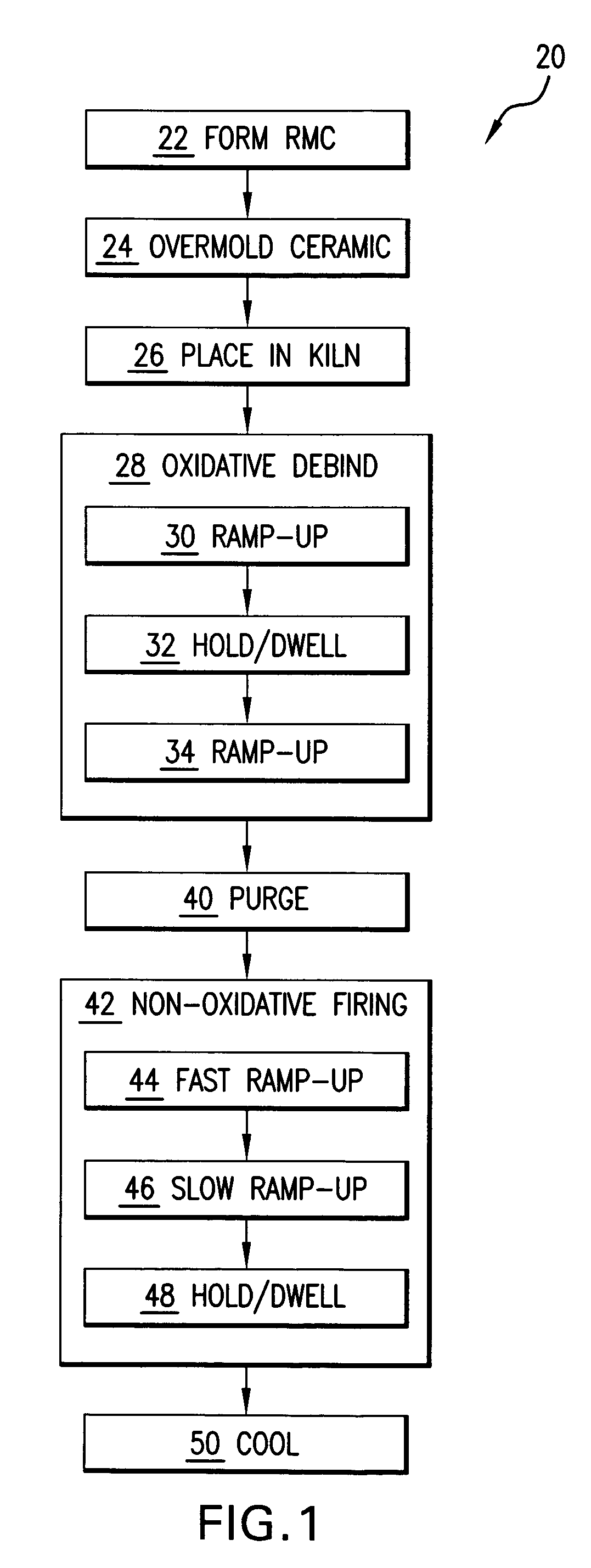

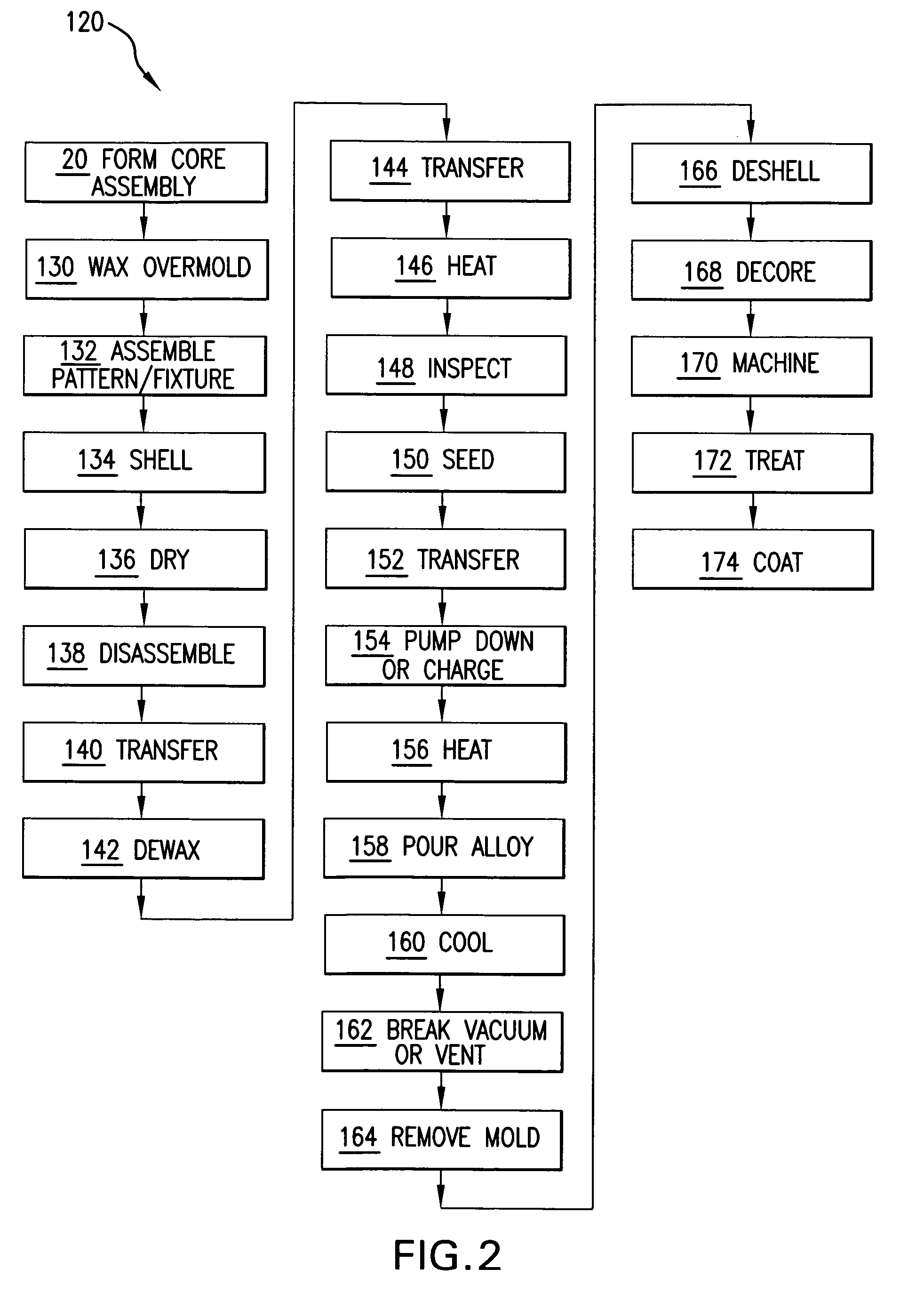

Method for firing a ceramic and refractory metal casting core

InactiveUS7861766B2Insufficient temperatureAvoid a lot of timeFoundry mouldsFoundry coresInvestment castingNon oxidative

In an investment casting process, a composite core is formed as a combination of ceramic casting core element and a non-ceramic casting core element. The core is heated in an oxidative atmosphere and then heated in a non-oxidative atmosphere.

Owner:RAYTHEON TECH CORP

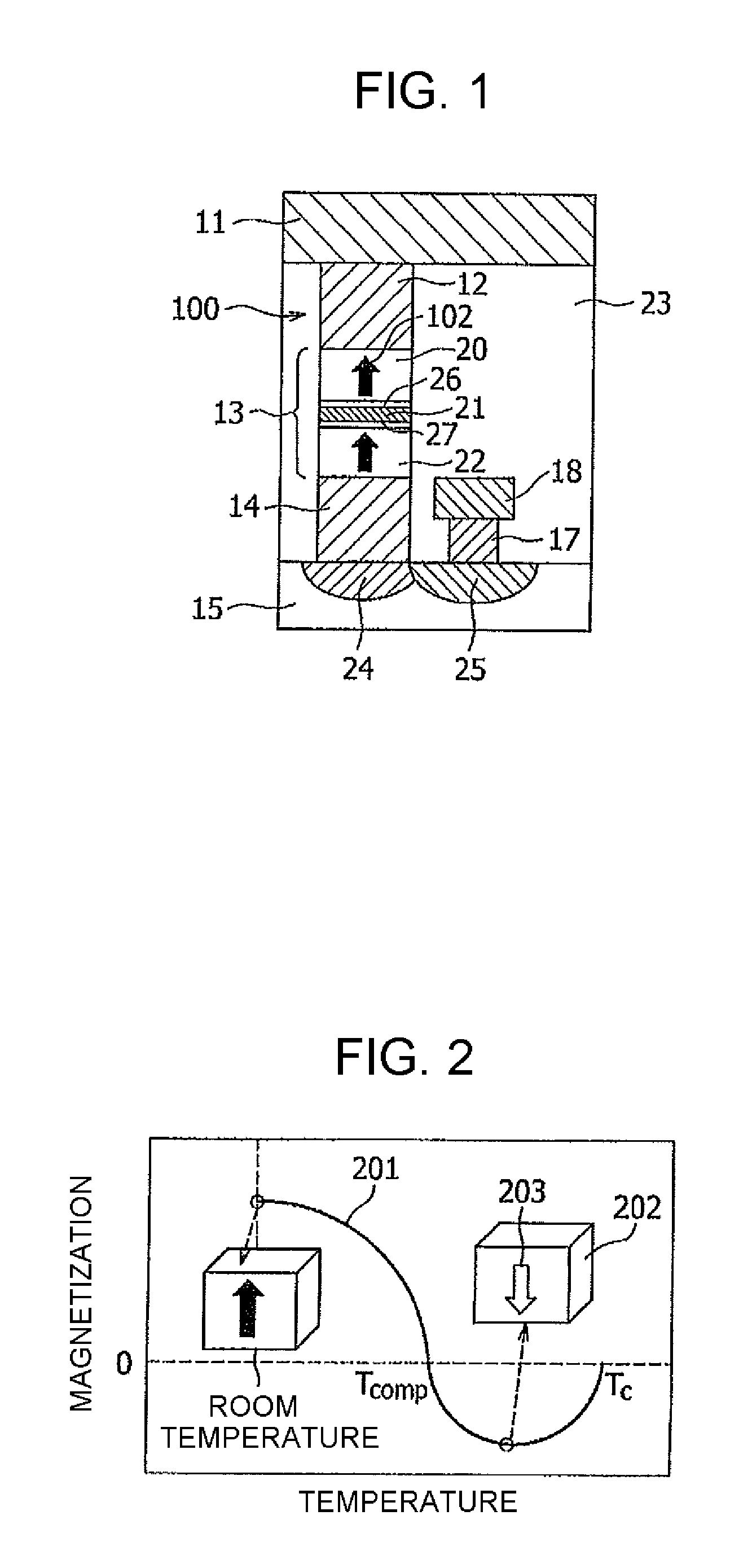

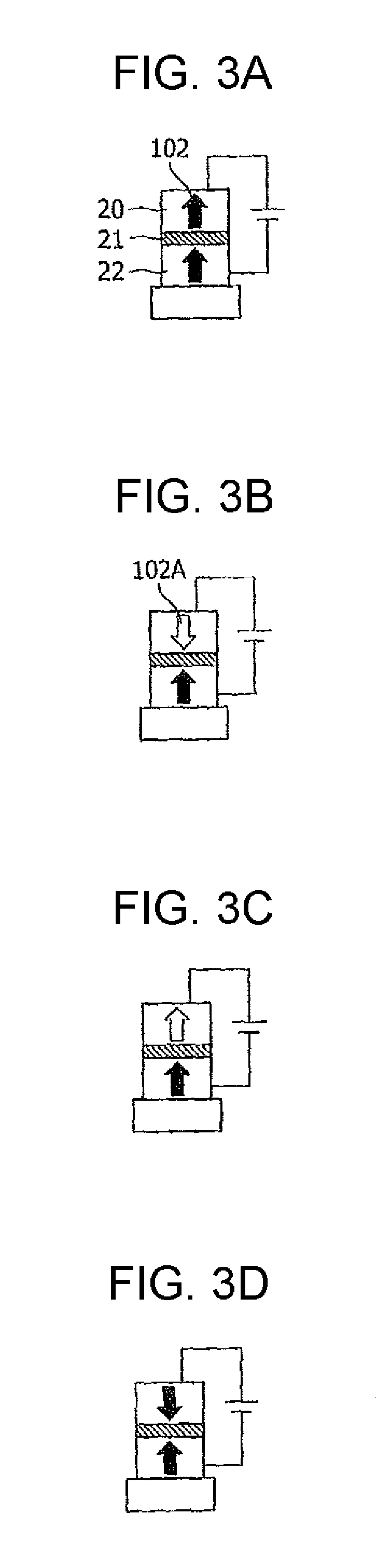

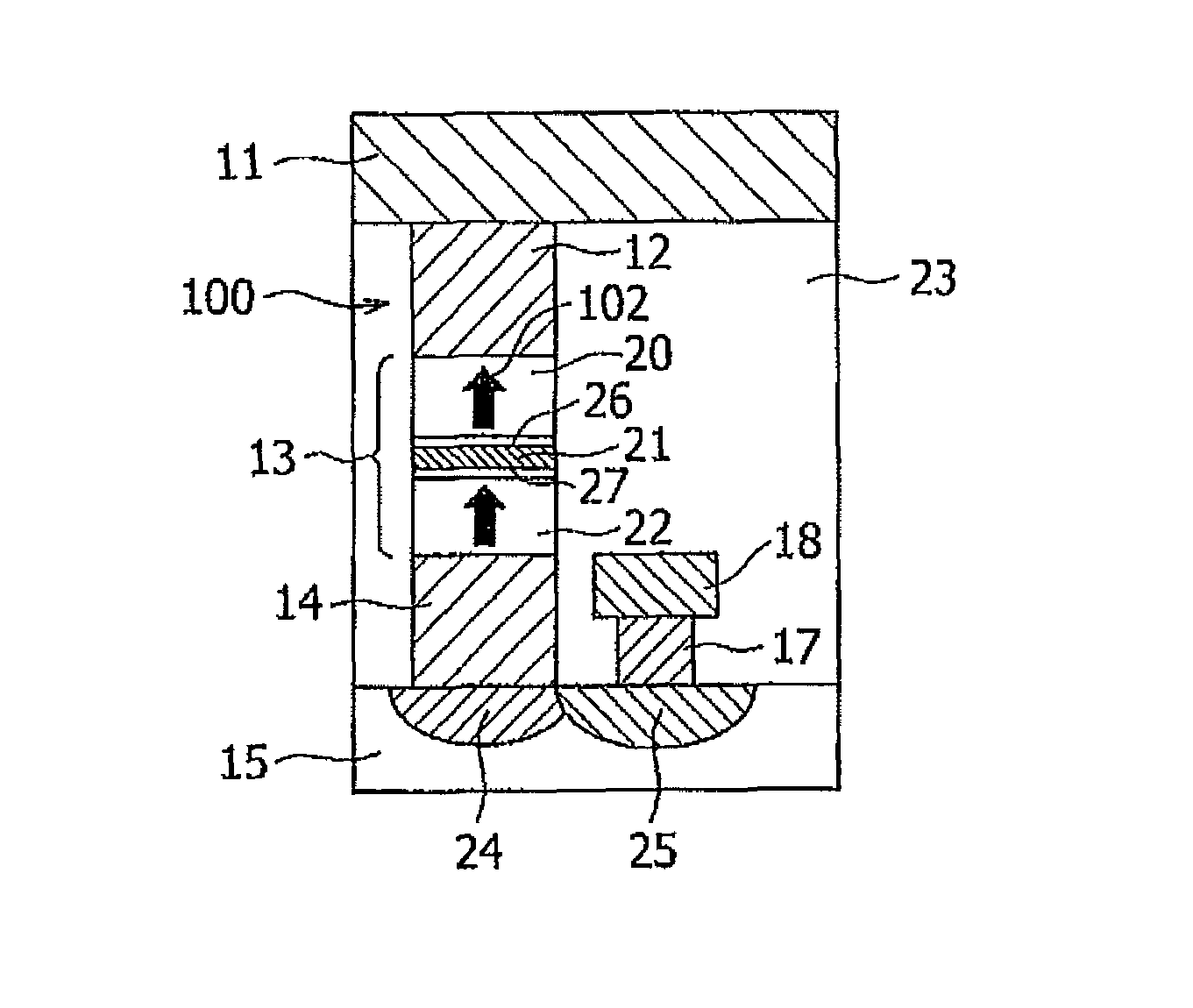

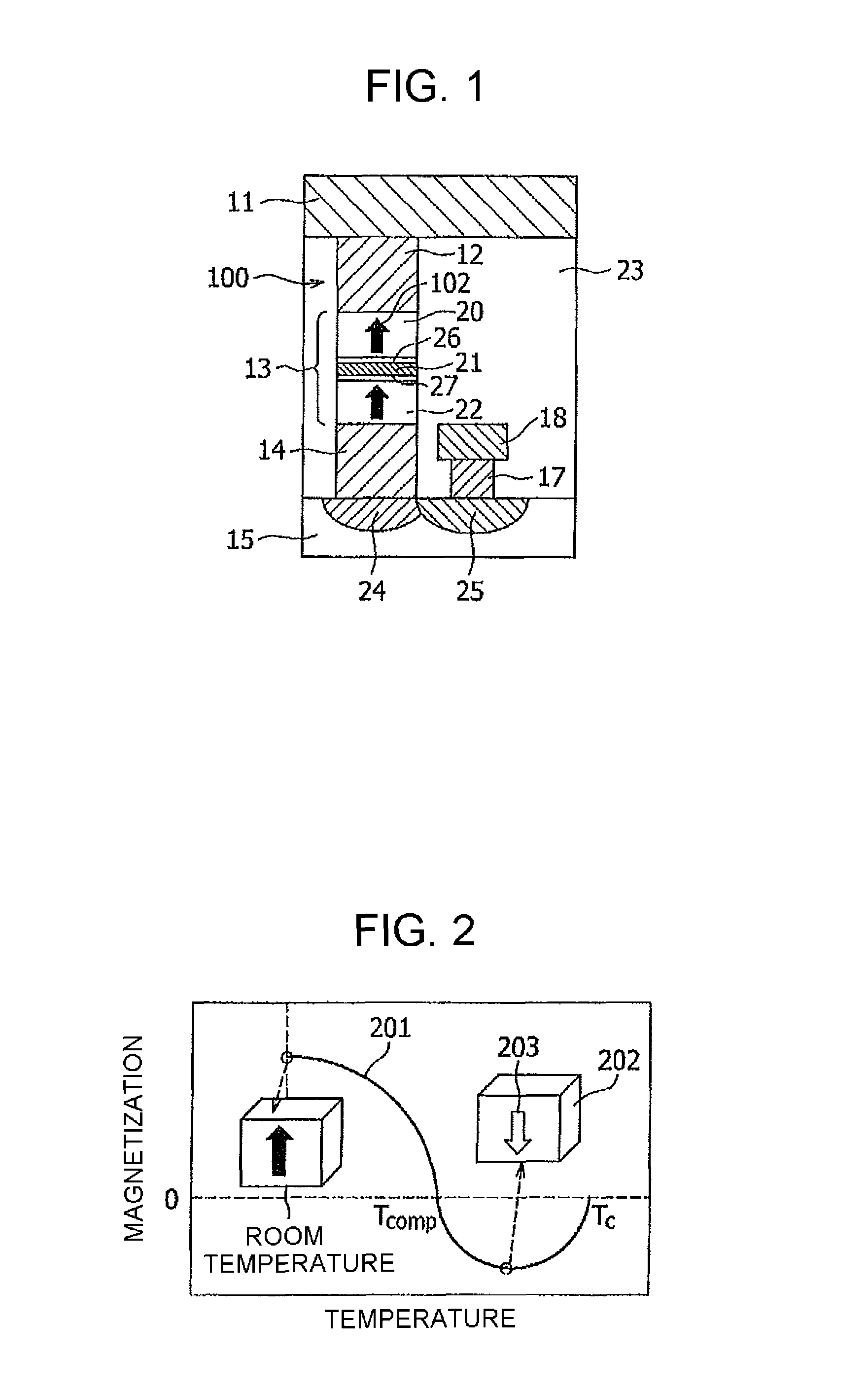

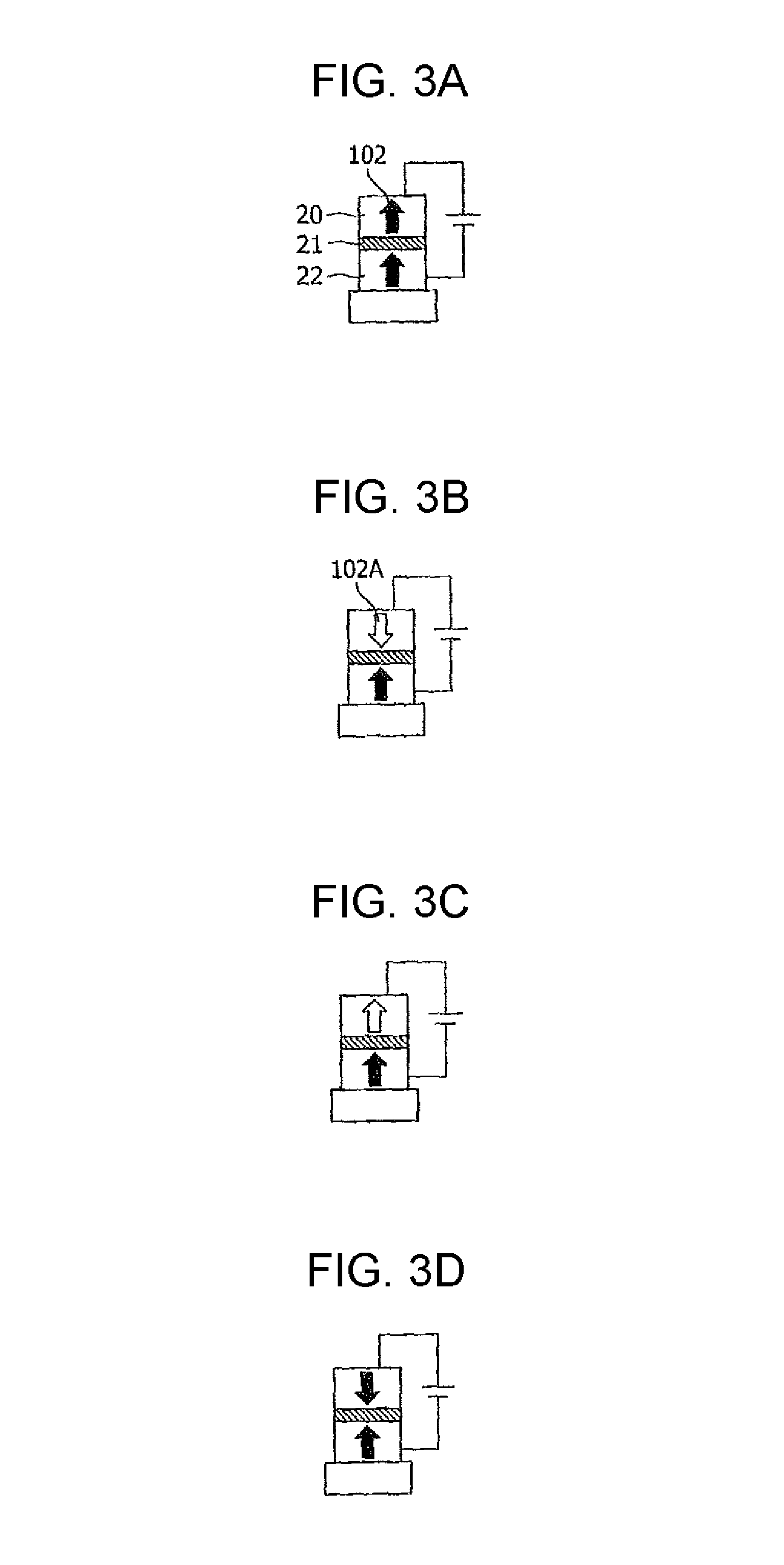

Magnetoresistance element and storage device using the same

ActiveUS20110310660A1Easy to operateIncrease the number ofNanomagnetismMagnetic-field-controlled resistorsMagnetic memoryNon magnetic

A magnetic memory element having a memory cell of size 4F2 is provided that realizes a crosspoint-type memory. In the magnetic memory element, a first magnetic layer, a third magnetic layer (spin polarization enhancement layer), an intermediate layer, a fourth magnetic layer (spin polarization enhancement layer), and a second magnetic layer are stacked in order. The intermediate layer is made of an insulating material or a nonmagnetic material. The second magnetic layer is composed of a ternary alloy of gadolinium, iron and cobalt, a binary alloy of gadolinium and cobalt, or a binary alloy of terbium and cobalt. Alternatively, the first magnetic layer is composed of a ternary alloy of terbium, iron and cobalt, or a binary alloy of terbium and cobalt.

Owner:III HLDG 3

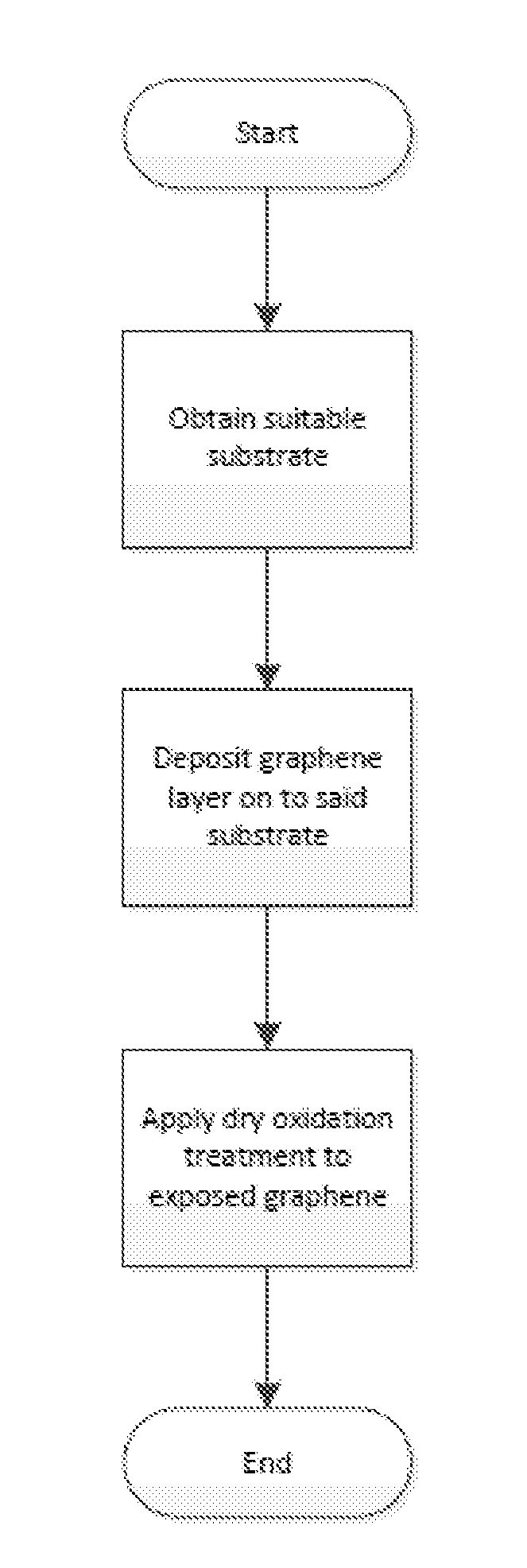

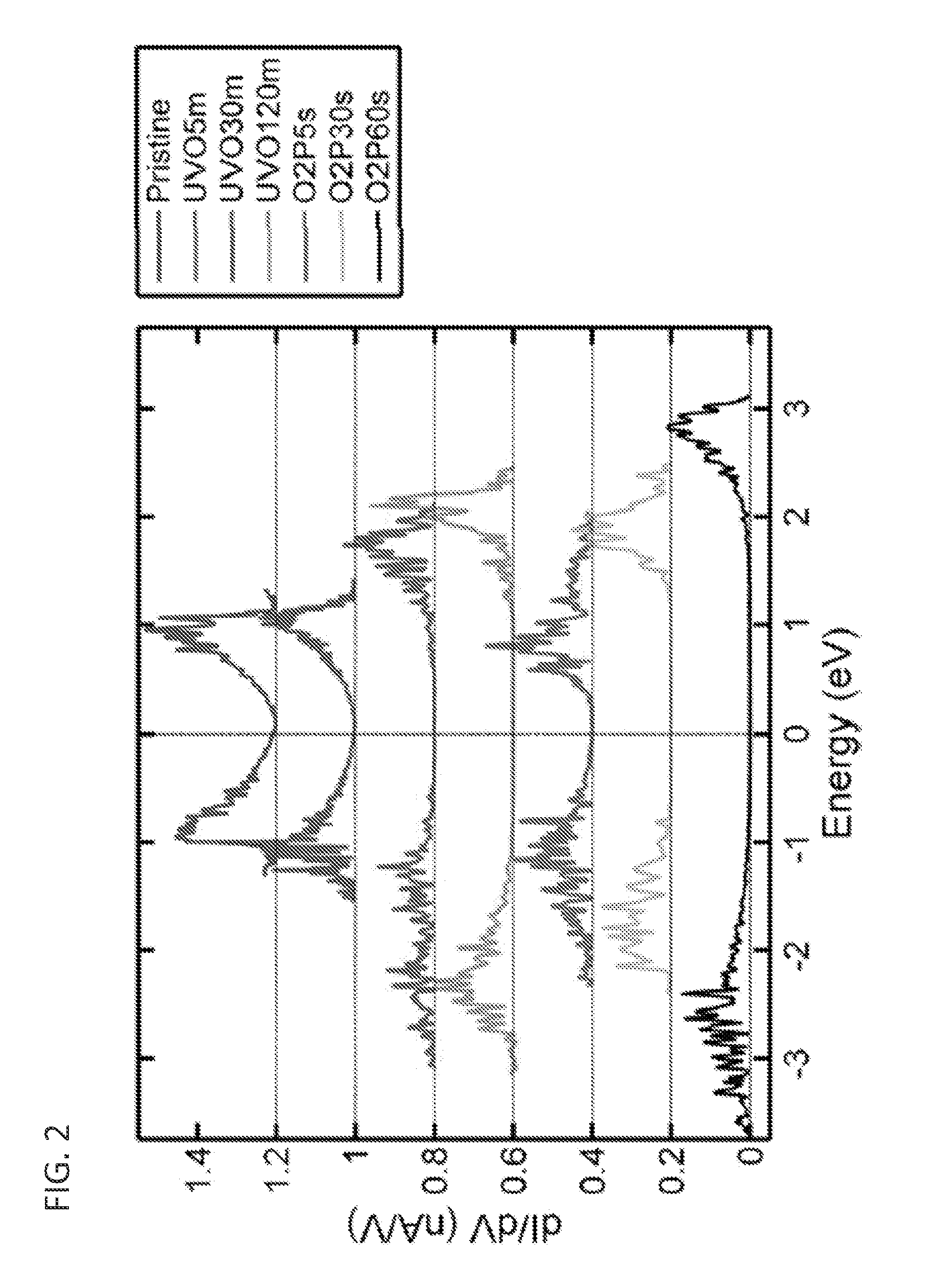

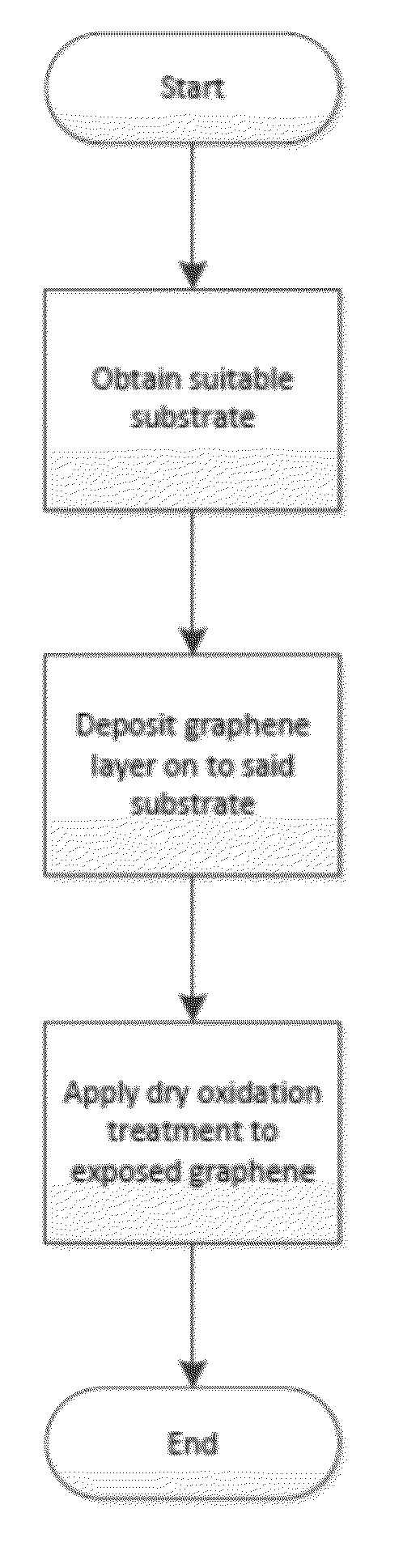

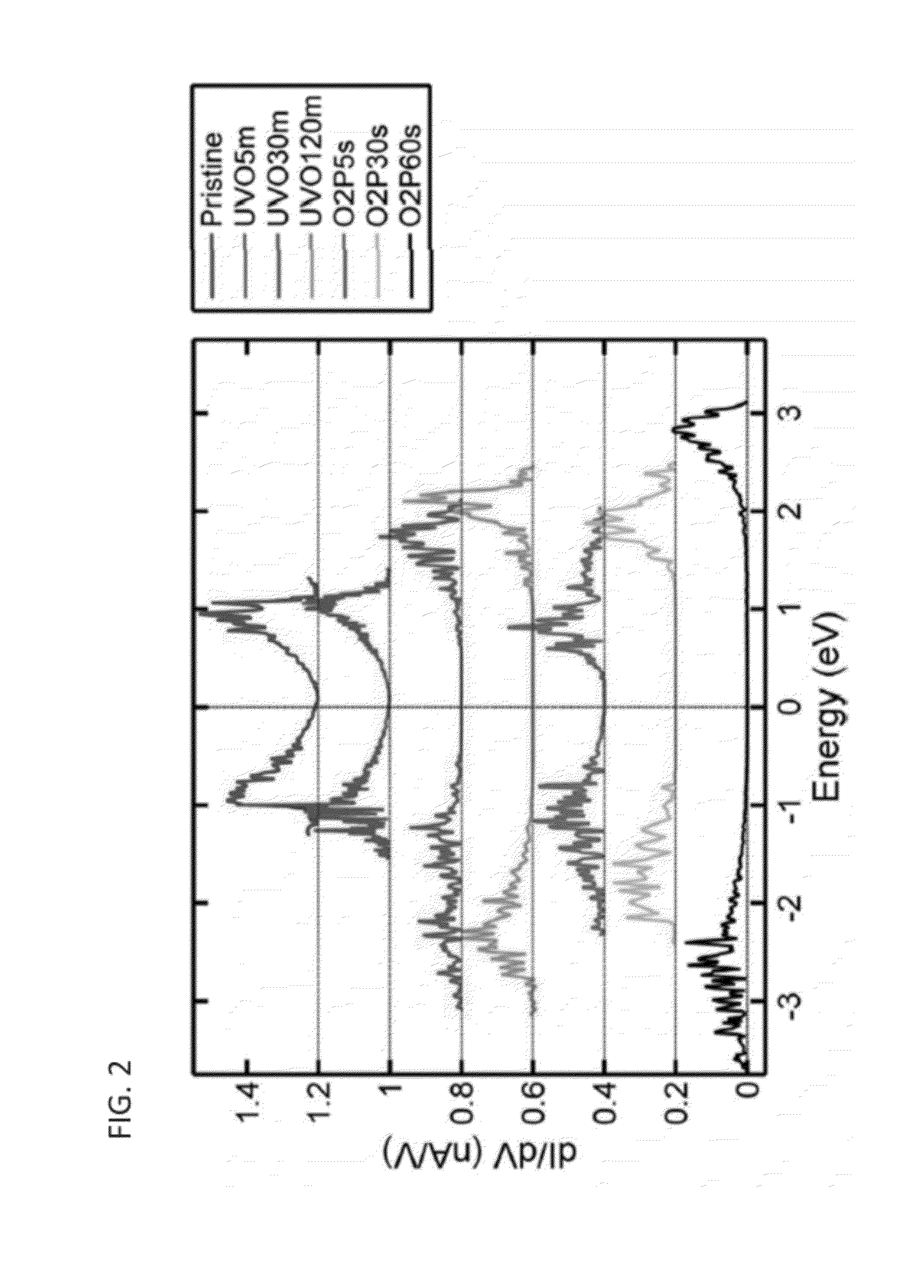

Method for producing graphene oxide with tunable gap

ActiveUS20120184065A1Practical to useExcessive oxidationMaterial nanotechnologyGraphiteMaterials scienceGraphite oxide

A method of fabricating a graphene oxide material in which oxidation is confined within the graphene layer and that possesses a desired band gap is provided. The method allows specific band gap values to be developed. Additionally, the use of masks is consistent with the method, so intricate configurations can be achieved. The resulting graphene oxide material is thus completely customizable and can be adapted to a plethora of useful engineering applications.

Owner:CALIFORNIA INST OF TECH

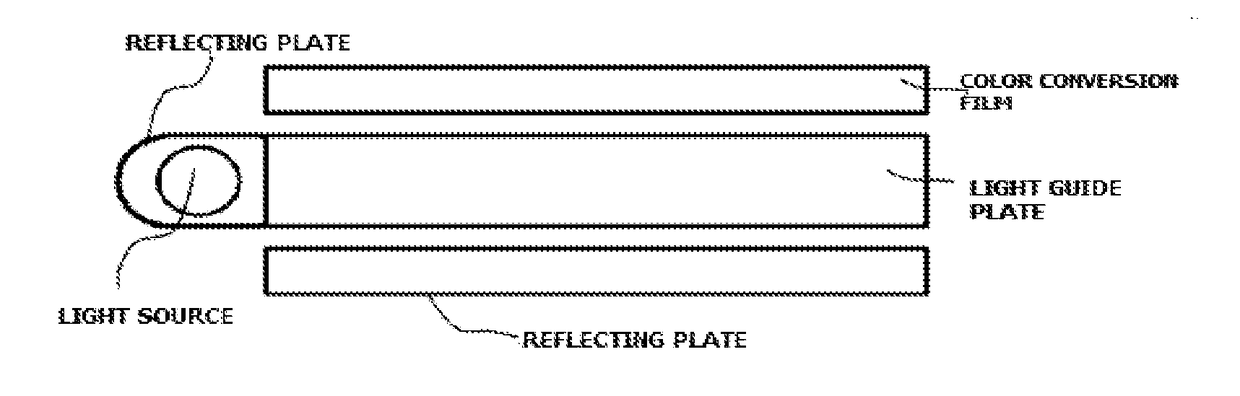

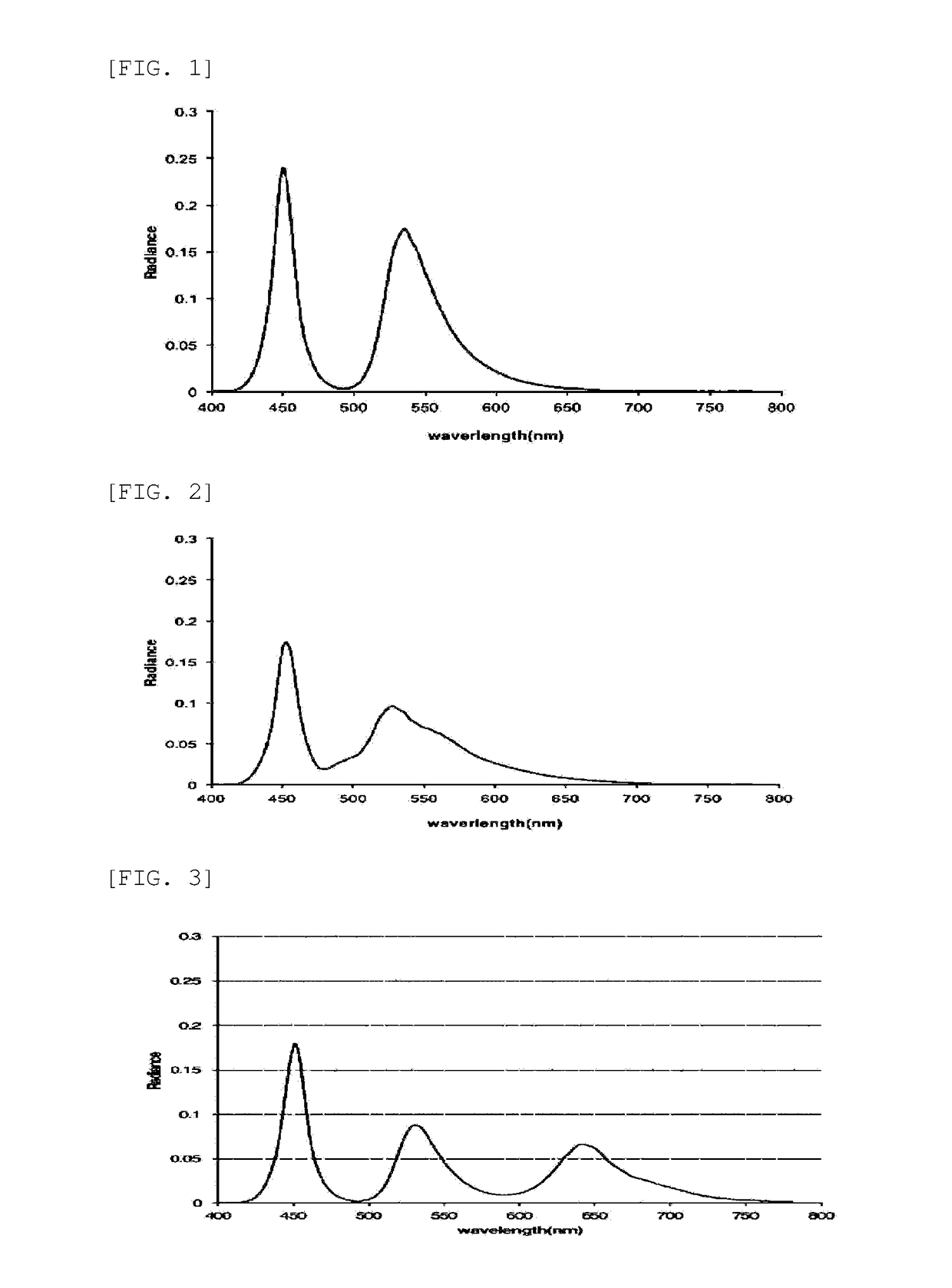

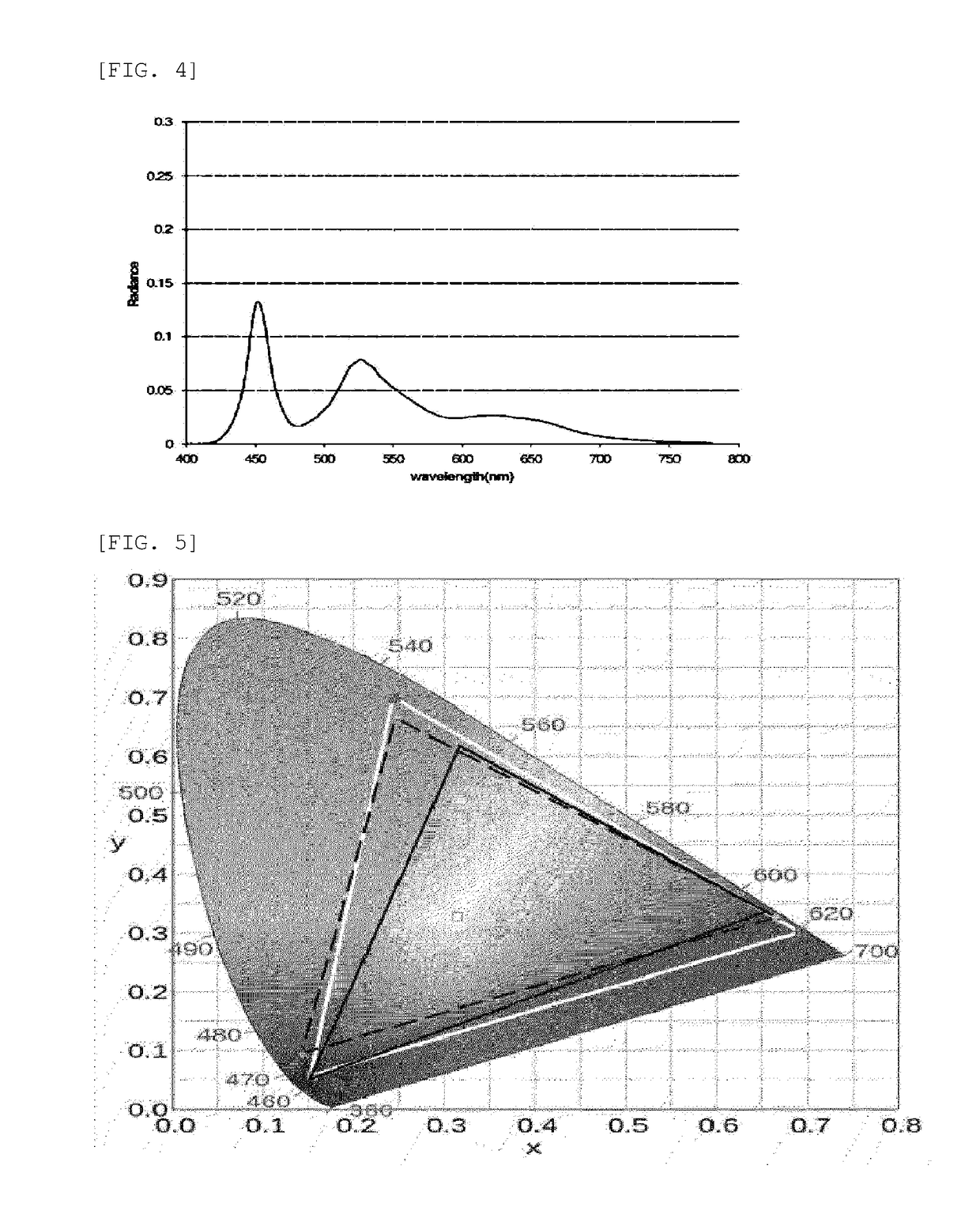

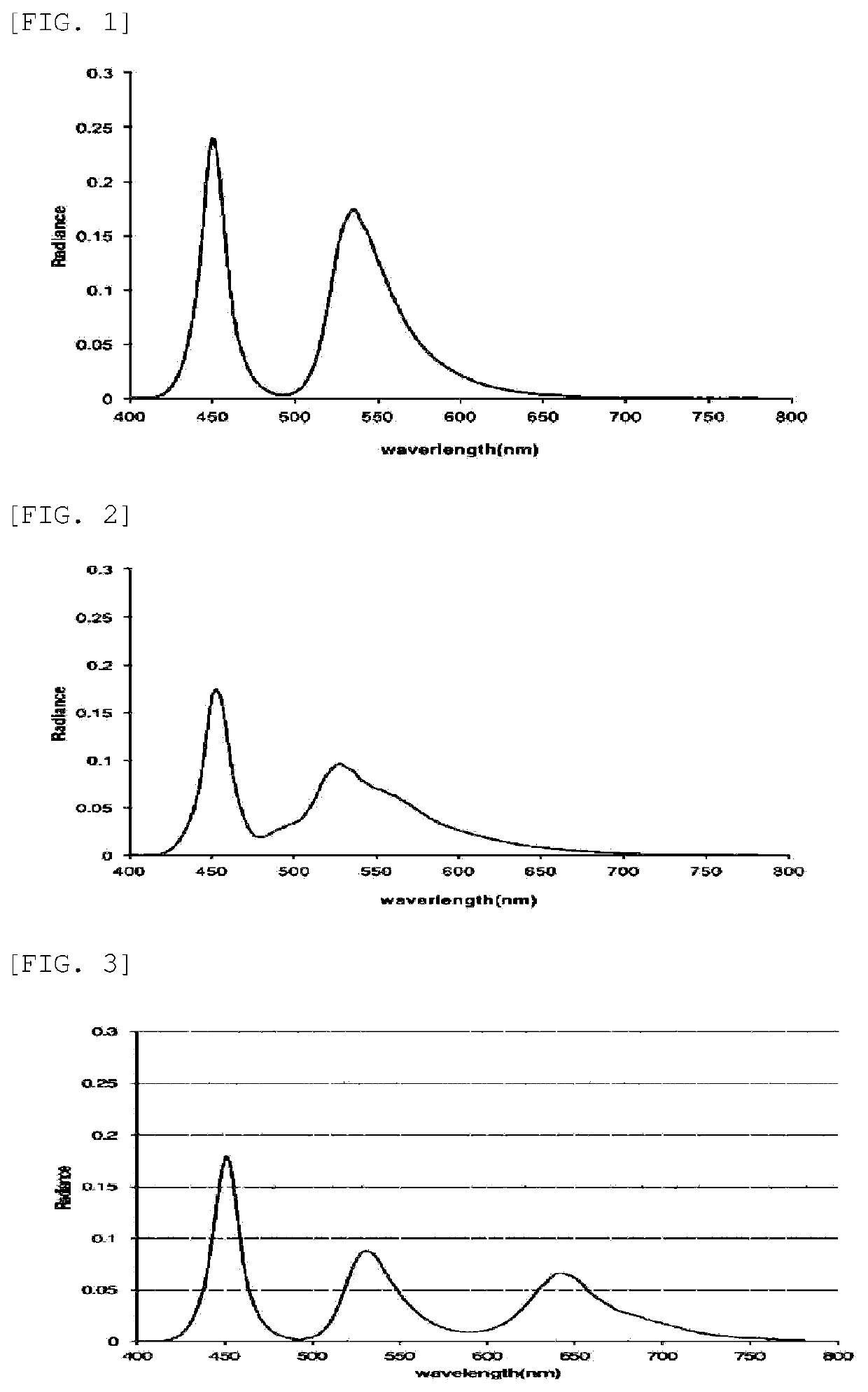

Color conversion film, method for producing same, back-light unit and display apparatus

ActiveUS20170267921A1Good environmental stabilitySimple molding processOptical filtersLuminescent compositionsQuantum efficiencyFluorescence

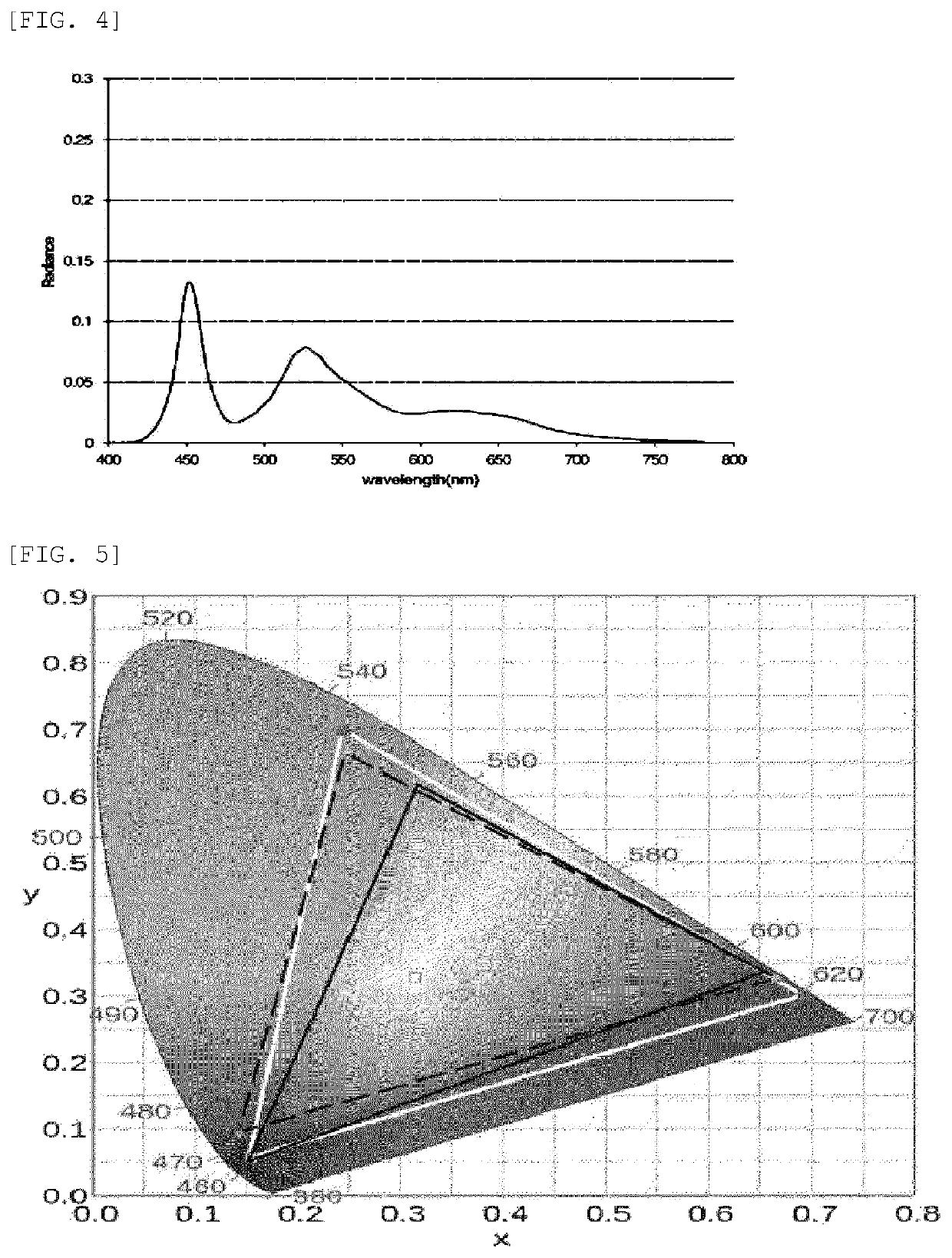

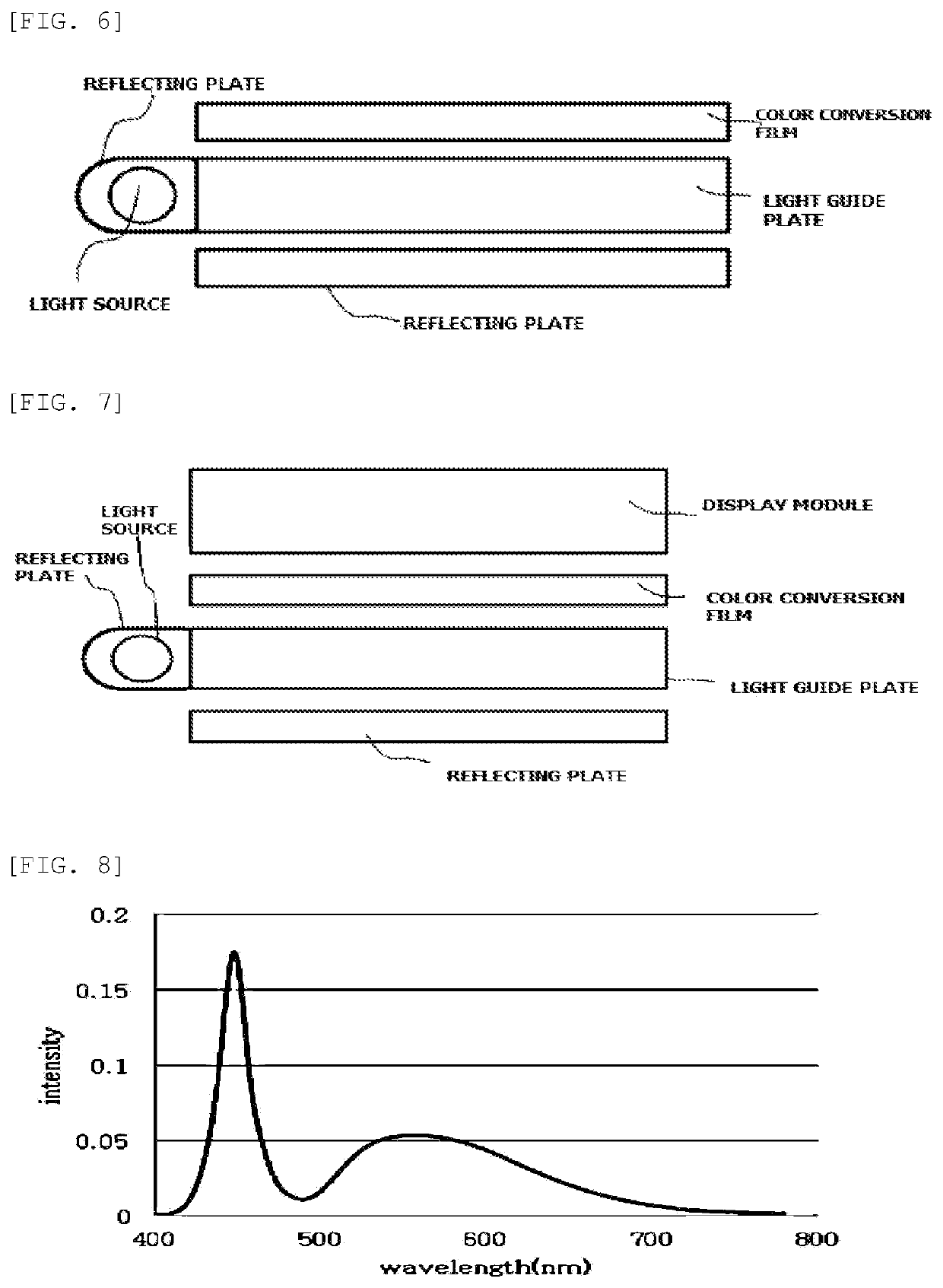

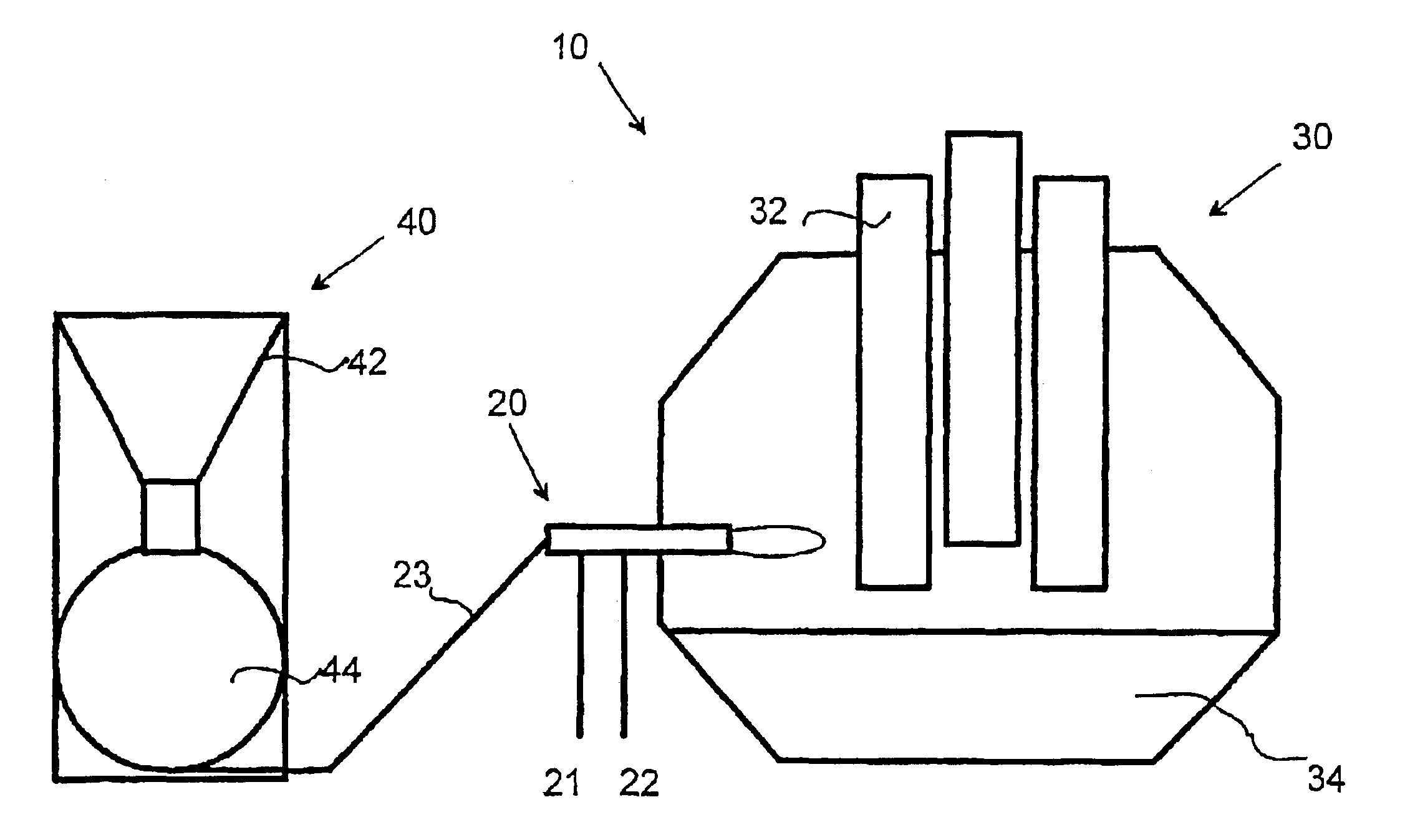

The invention described in the present specification relates to a color conversion film including a resin matrix; and an organic fluorescent substance dispersed in the resin matrix, and absorbing blue or green light and emitting light having a wavelength different from the absorbing light, wherein the resin matrix includes a thermoplastic resin, and the color conversion film has a light emission peak with a FWHM of 60 nm or less, quantum efficiency of 80% or greater and an absorption coefficient of 30,000 M−1cm−1 or greater at a maximum absorption wavelength when irradiating light having a light emission peak at 450 nm, a FWHM of 40 nm or less and monomodal light emission intensity distribution, a method for preparing the same, and a backlight unit including the color conversion film.

Owner:LG CHEM LTD

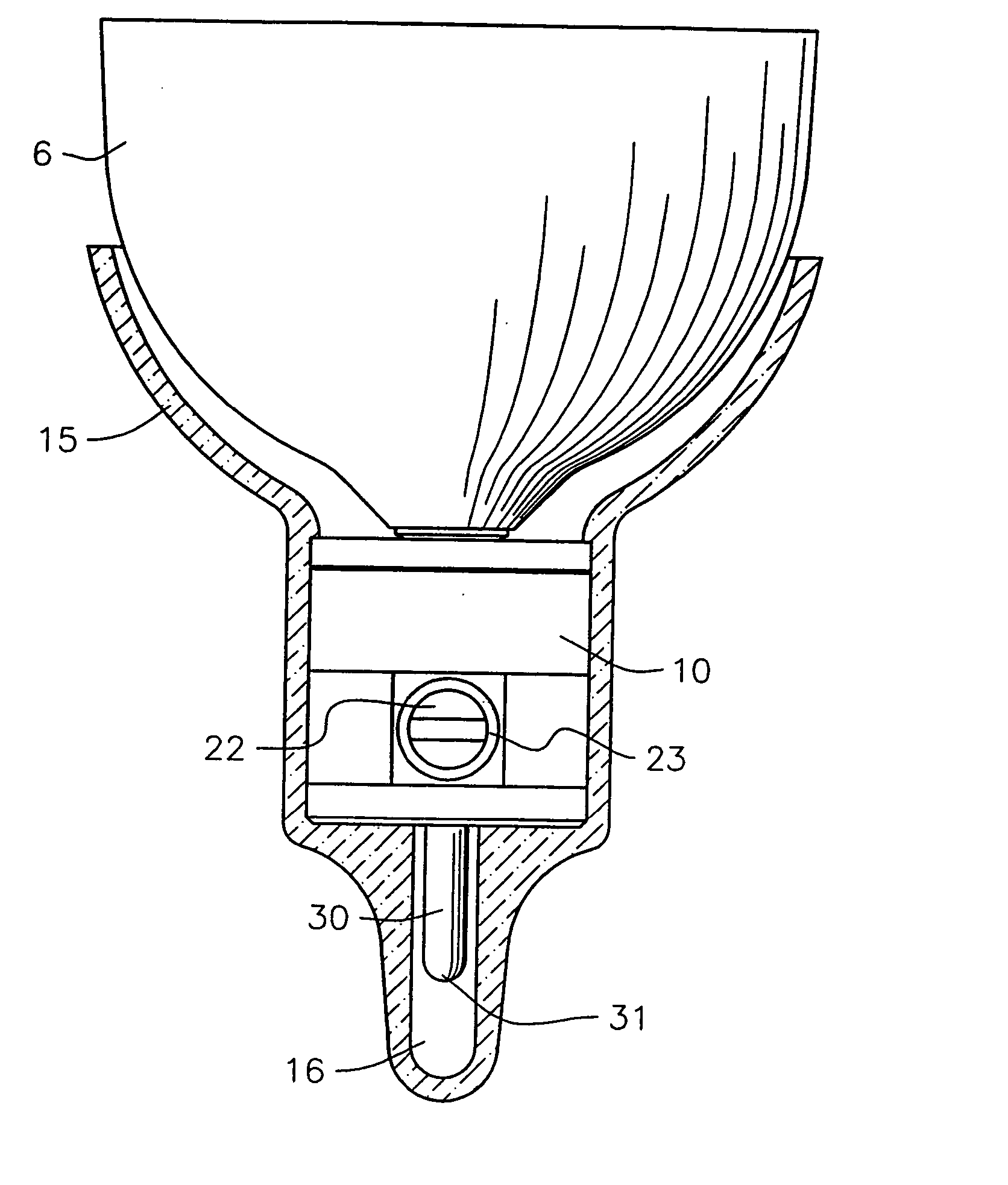

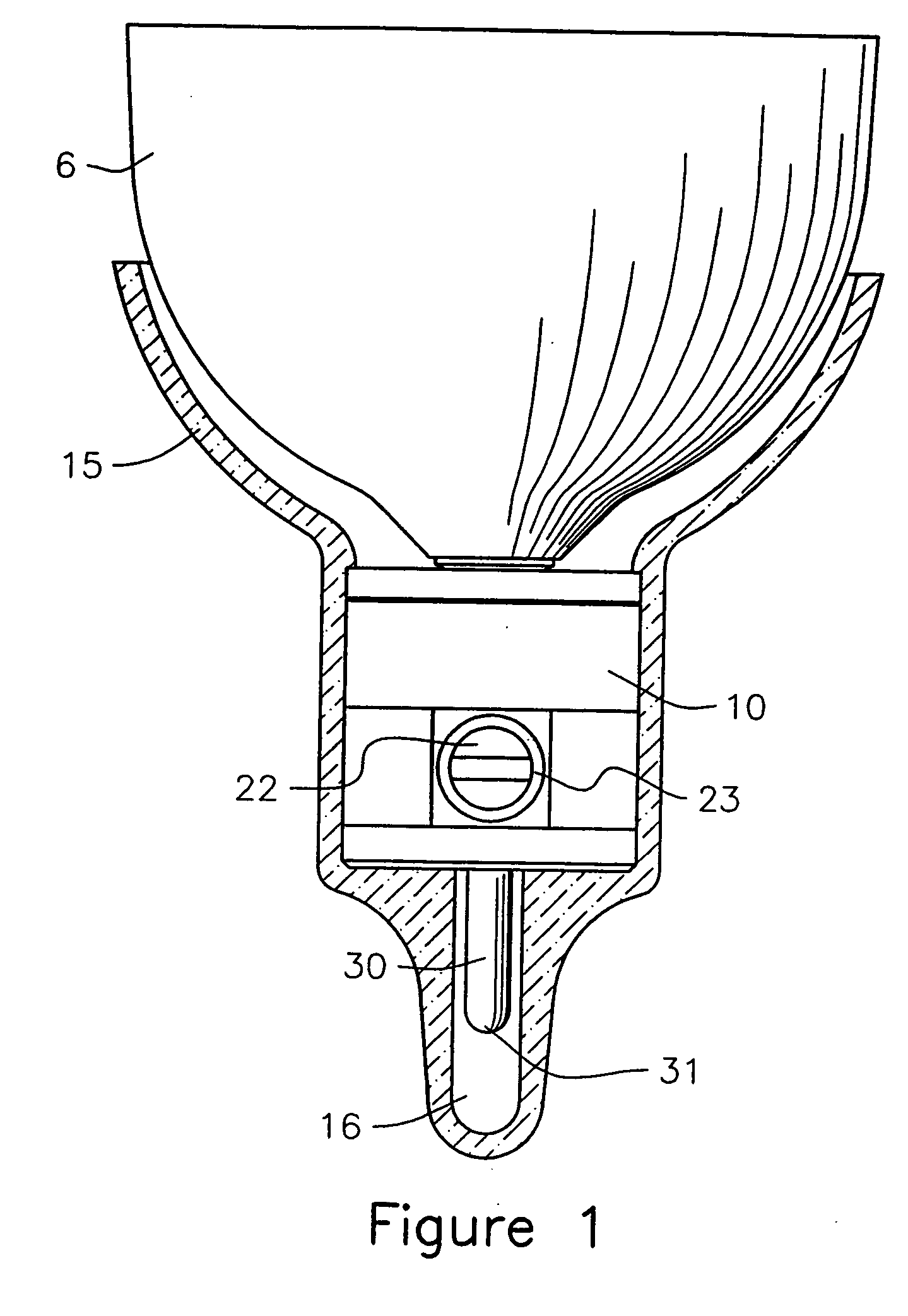

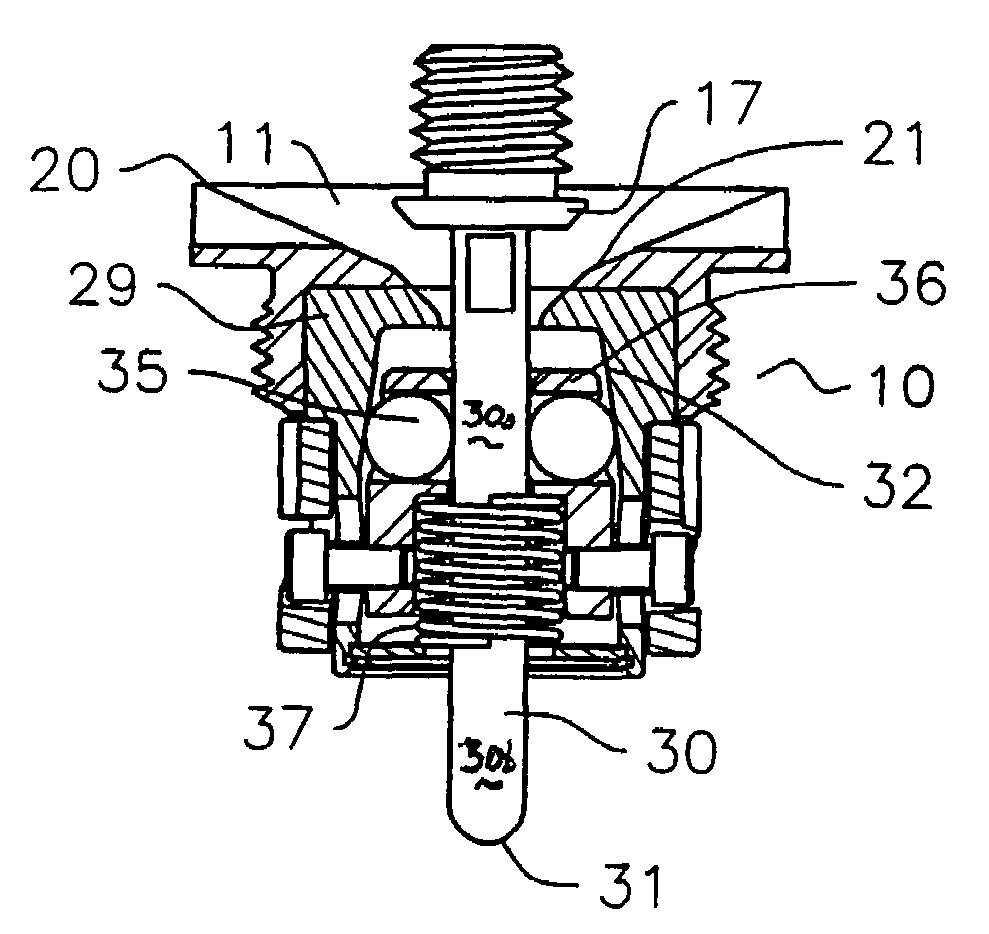

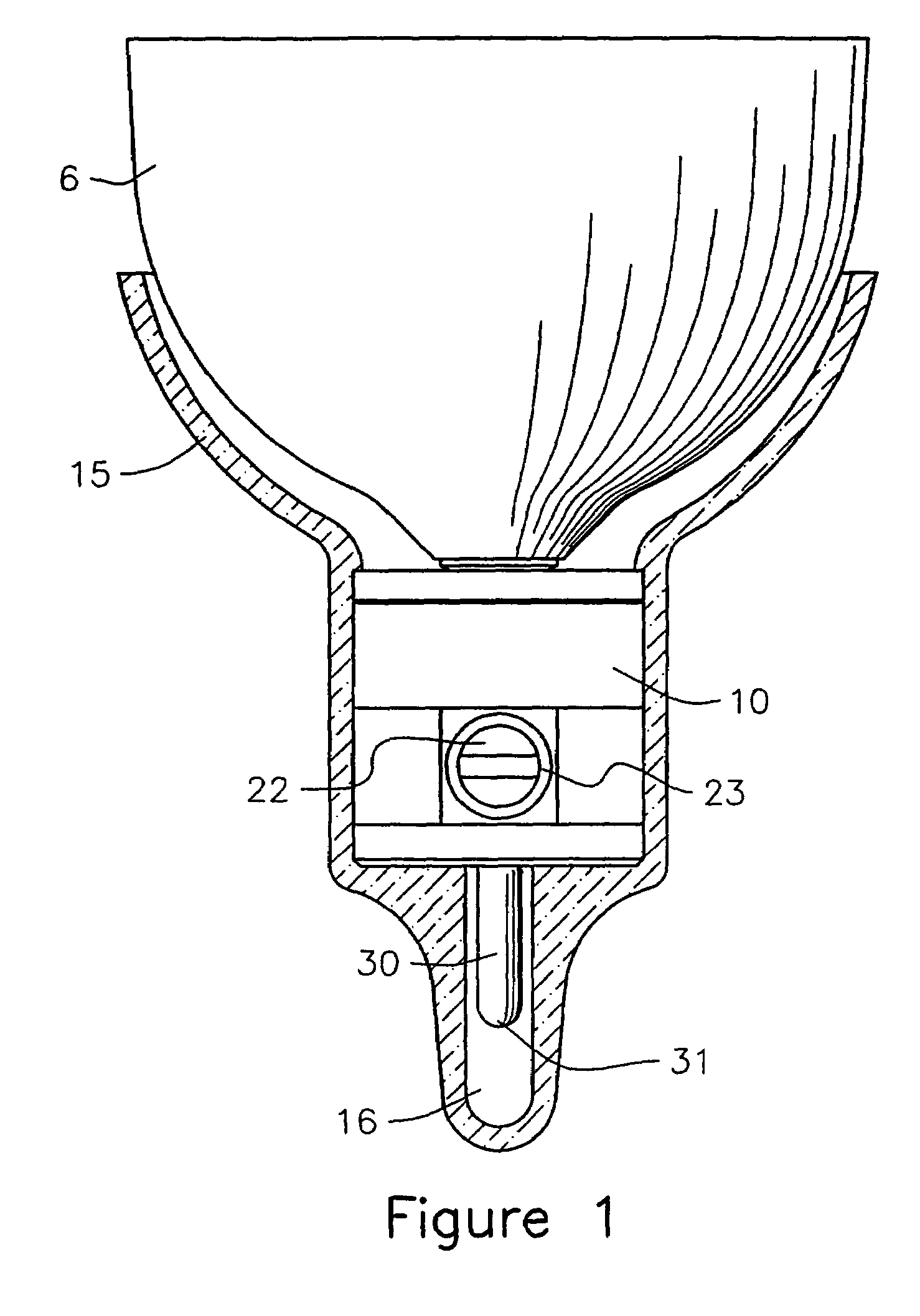

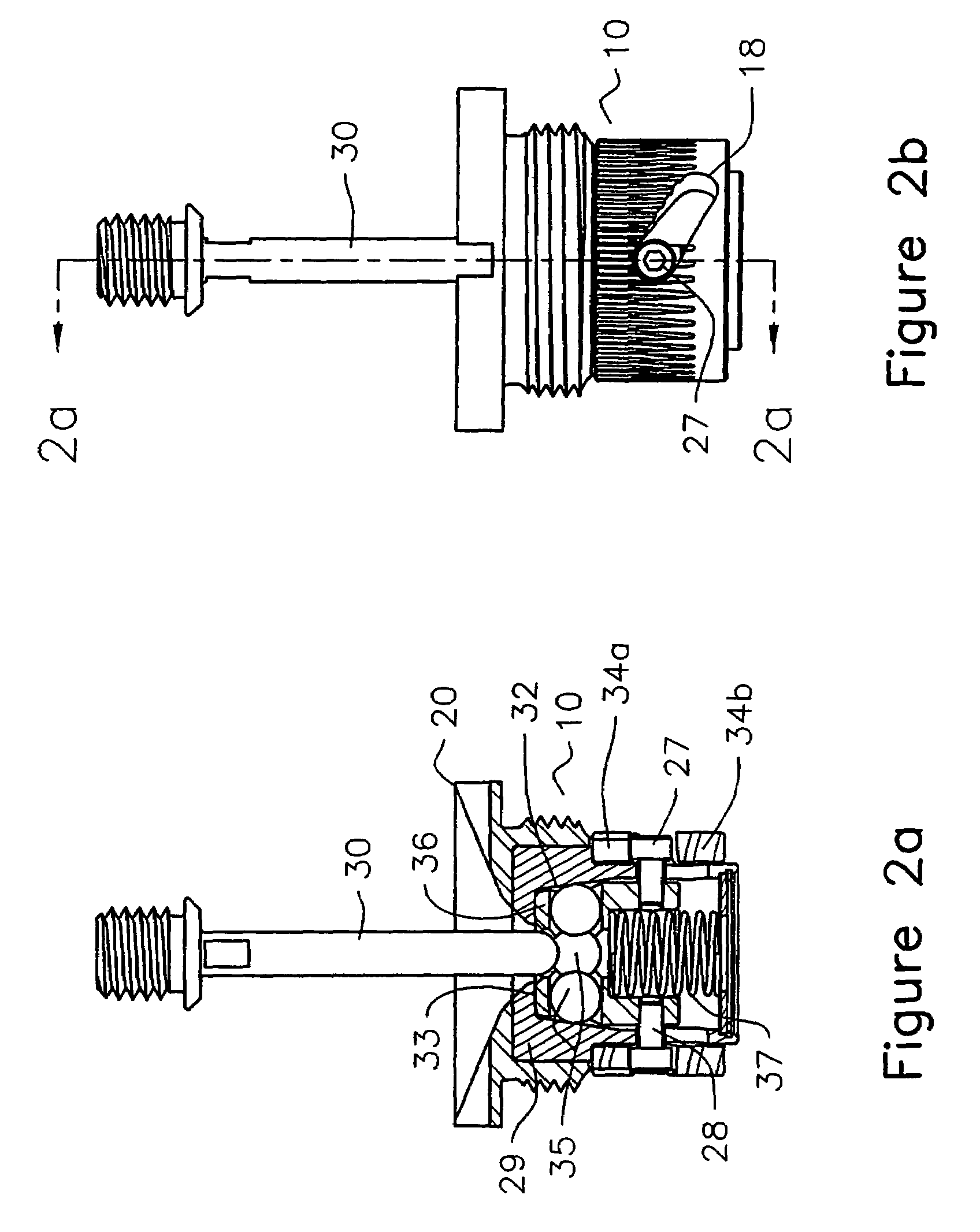

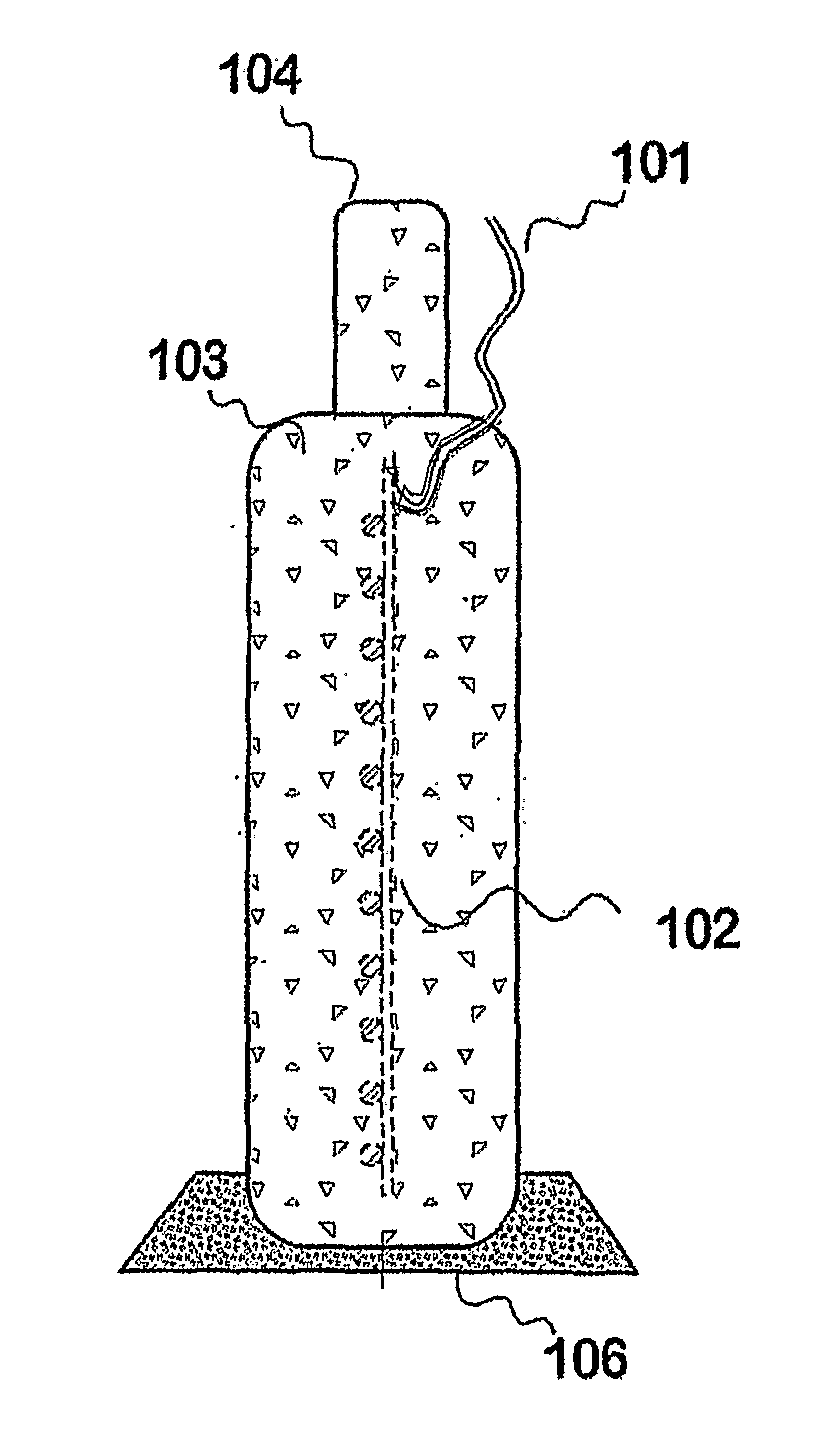

Prosthetic locking device

InactiveUS20050131550A1Resistant to oxidationLess concern of rustingArtificial legsResidual limbDevice prosthetic

A device is provided to lock the residual limb of an amputee into a prosthesis. The device is comprised of rolling elements within a tapered housing which accepts a smooth plunger, such as a wire, cable, or rod connected to a suspension sleeve, with minimal resistance while opposing removal of the plunger from the locking device until the rolling elements have been retracted with a release mechanism. The nature of this device allows it to compensate for irregularities or wear in the plunger while continuing to securely lock the prosthesis to the sleeve. This locking device will function properly with a certain amount of misalignment between the lock and the plunger.

Owner:FILLAUER

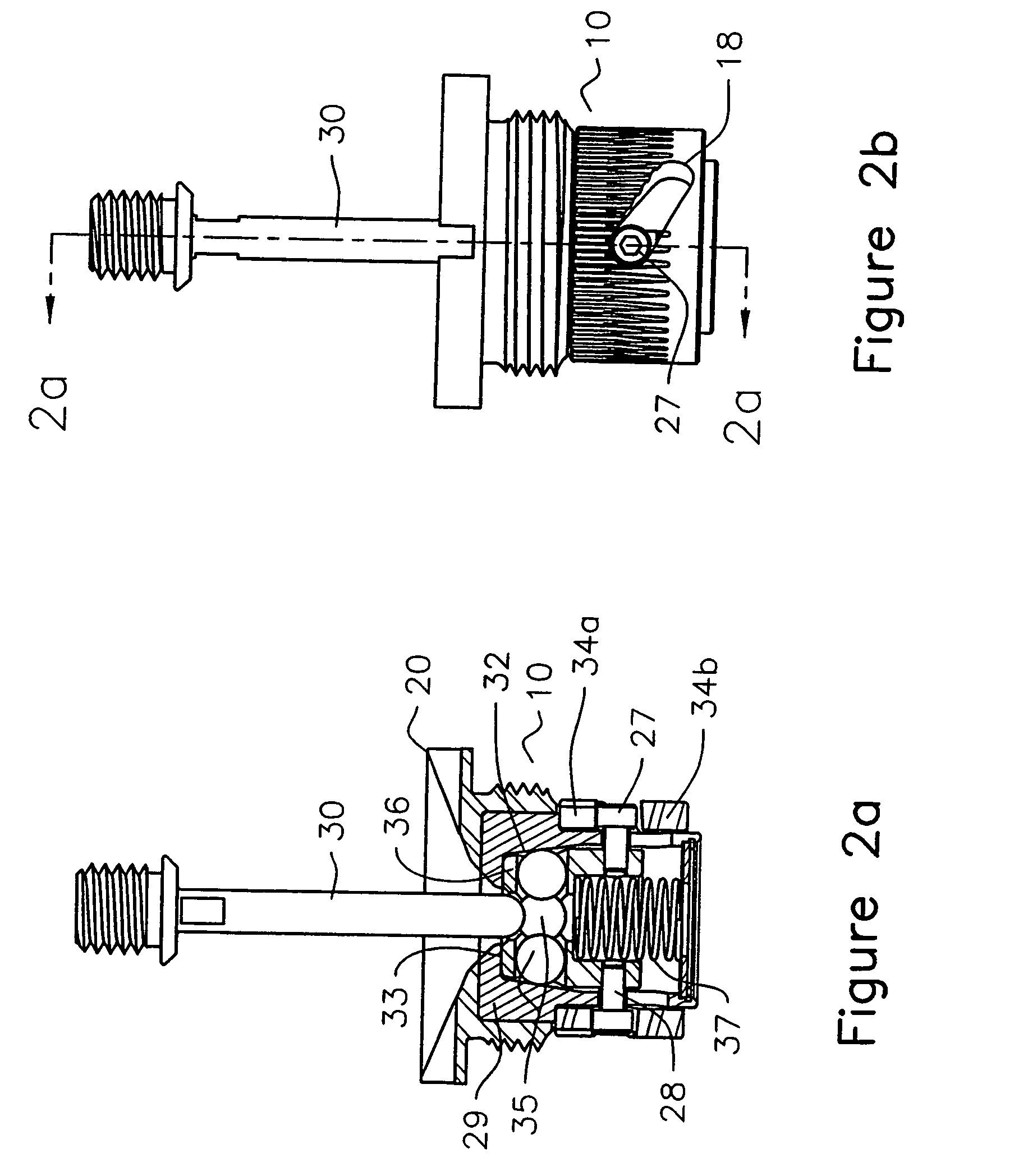

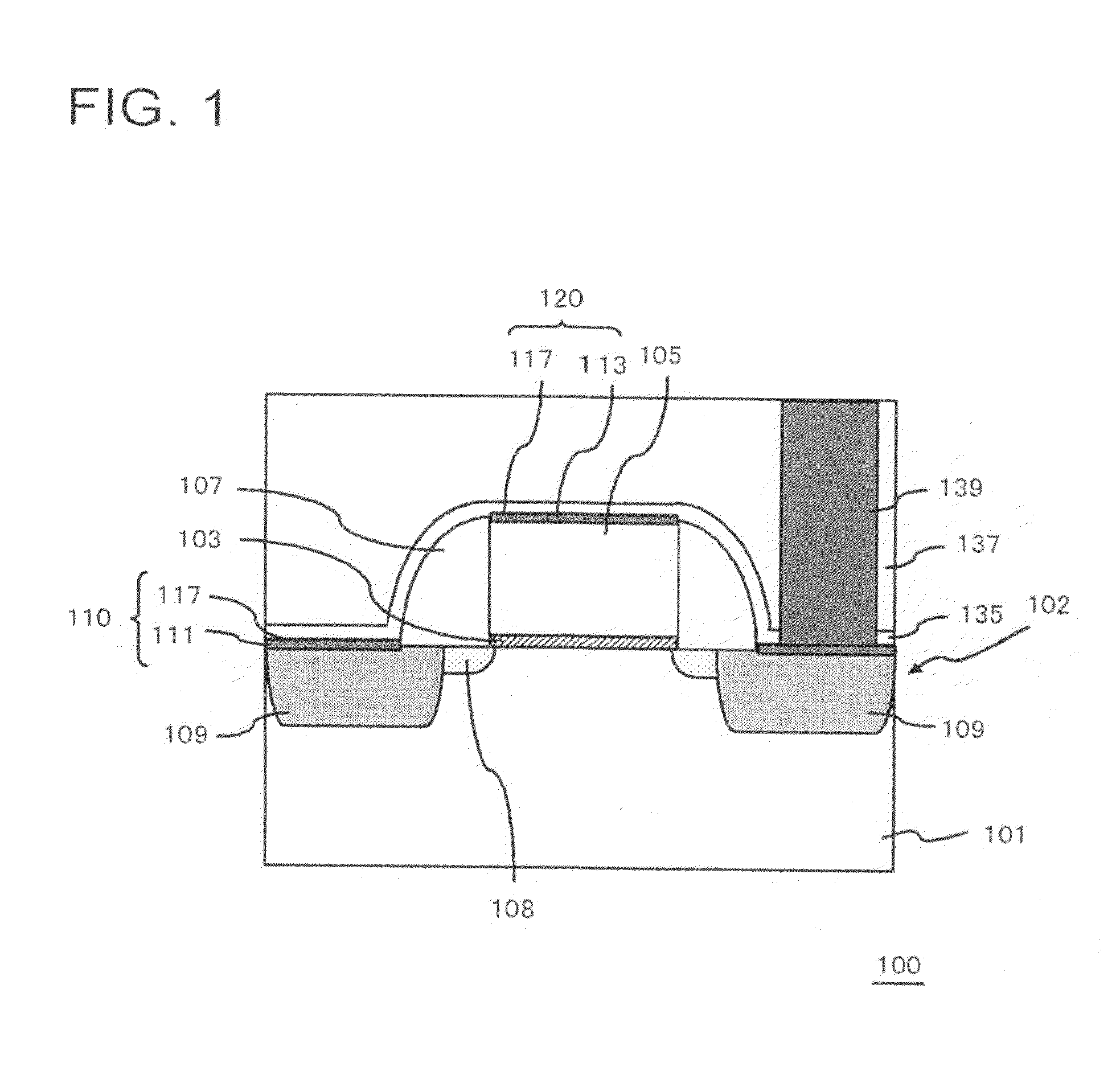

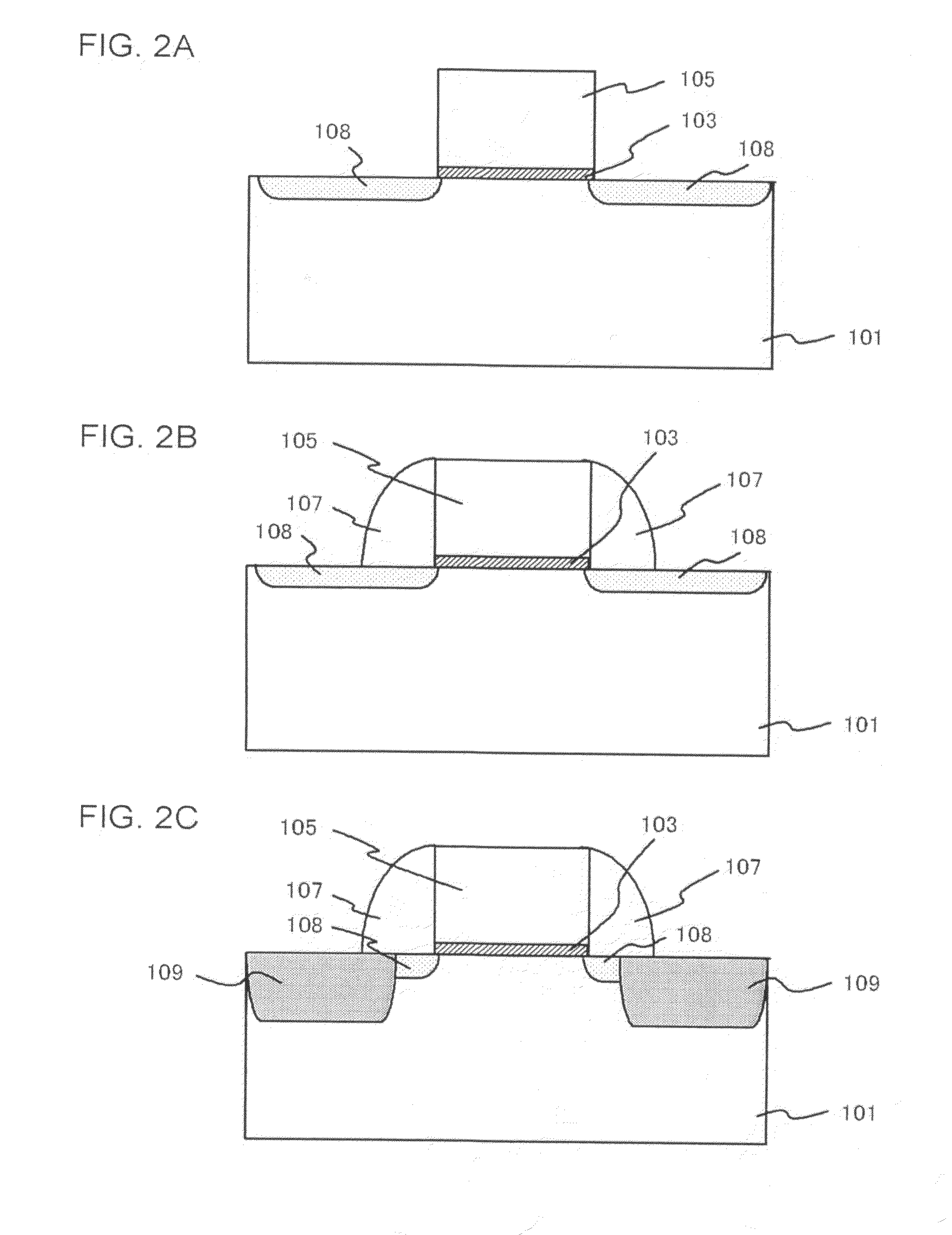

Semiconductor device and method of manufacturing the same

ActiveUS20070254480A1Increase influenceLow process temperatureTransistorSemiconductor/solid-state device detailsNitrogenTotal thickness

A semiconductor device includes a silicon substrate, and a NiSi layer provided on the silicon substrate aiming to suppress oxidation of the surface of a NiSi layer and the resistivity increase. The NiSi layer includes a bottom NiSi region and a top NiSi region. The bottom NiSi region provided in contact with silicon surface, and containing substantially no nitrogen. The top NiSi region is a nitrided NiSi region provided in contact with the bottom NiSi region, and containing nitrogen. The NiSi layer has a total thickness of 50 nm or below.

Owner:RENESAS ELECTRONICS CORP

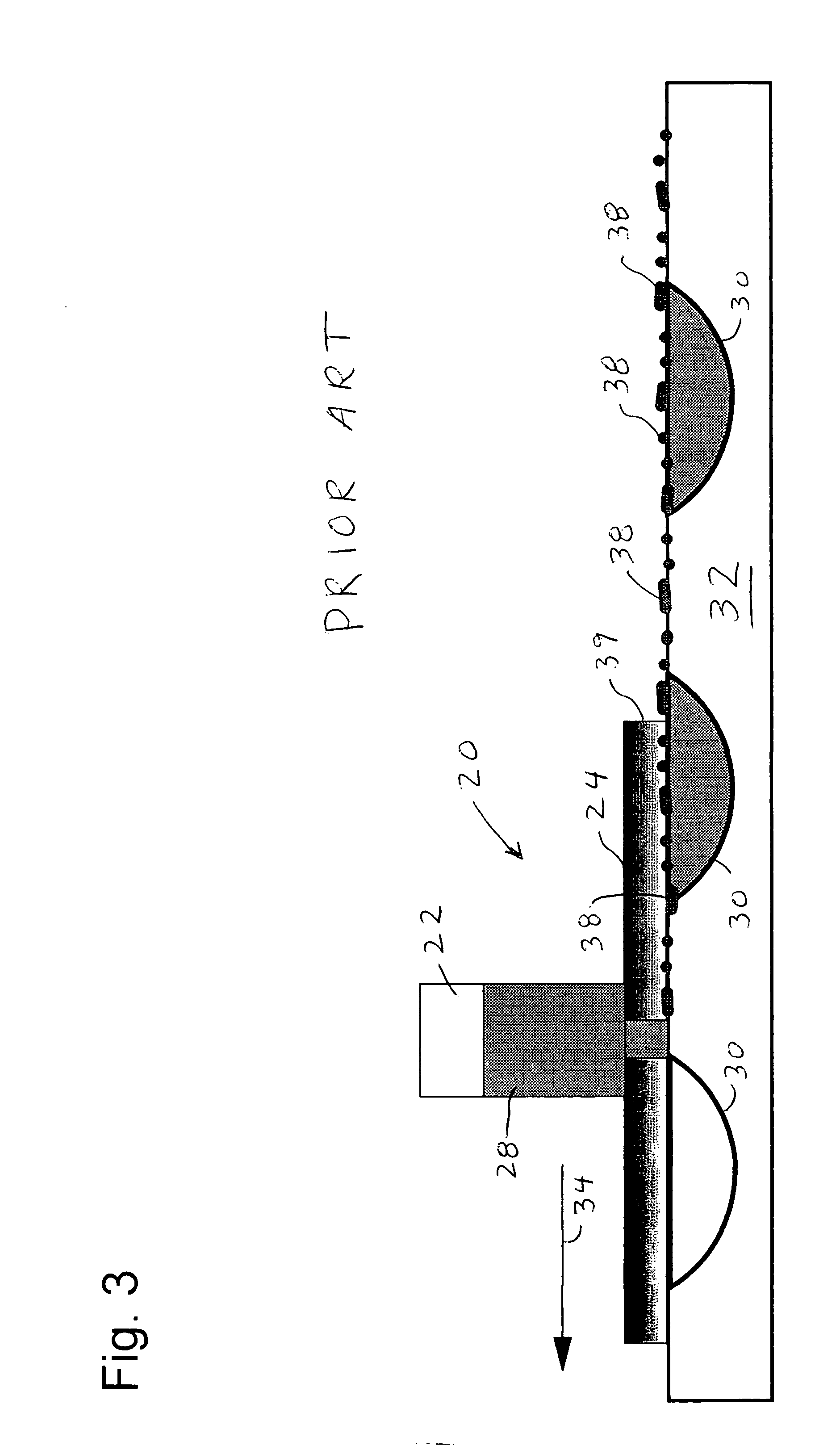

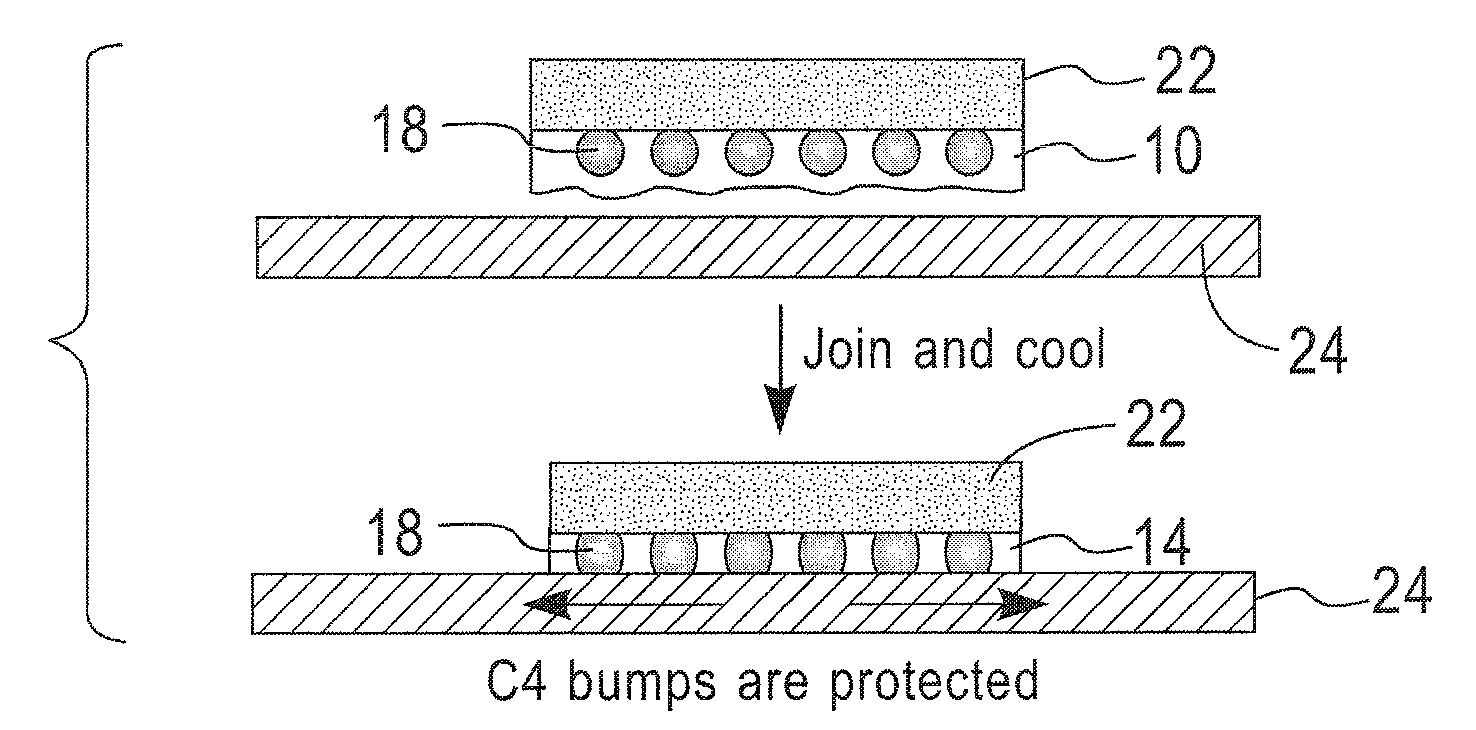

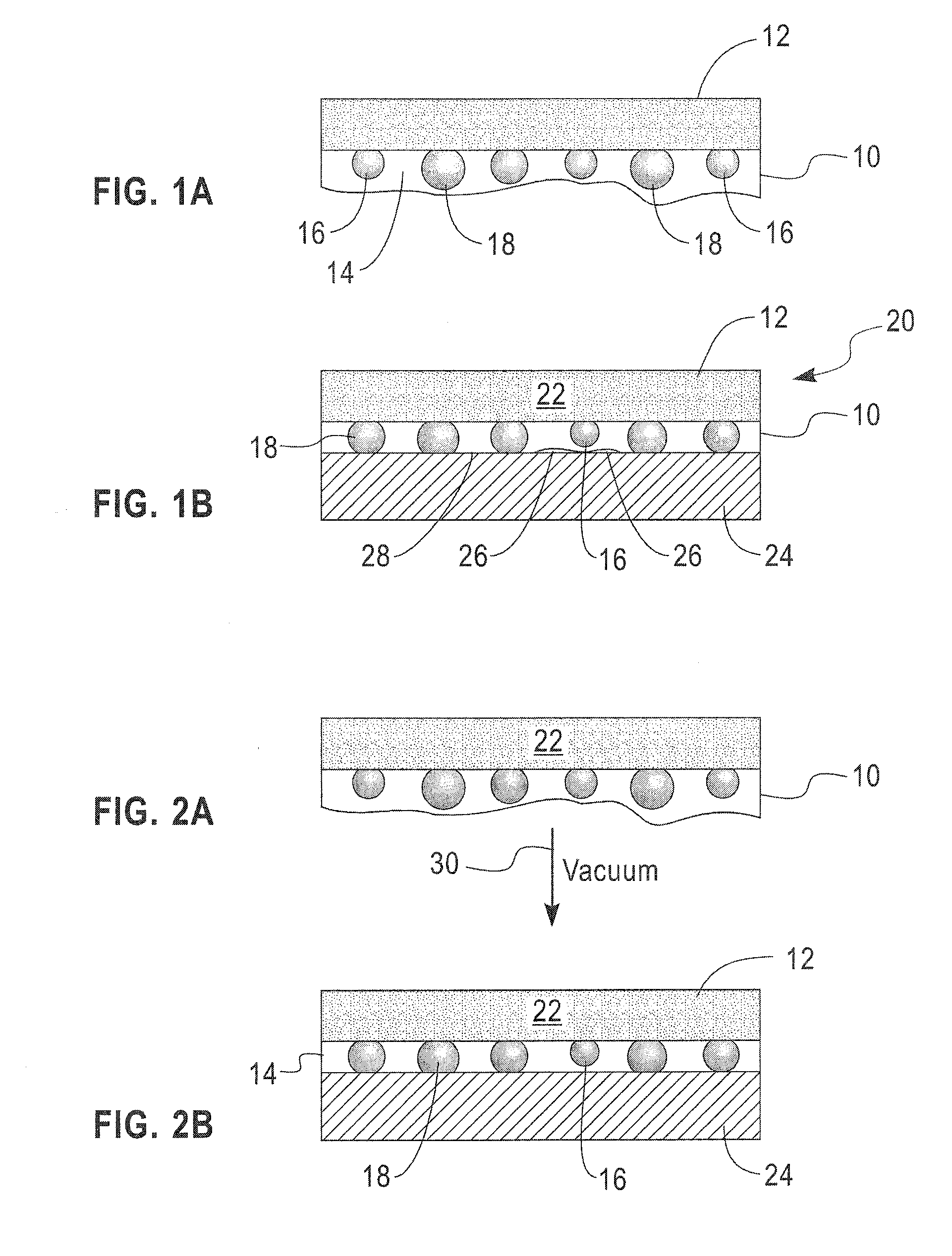

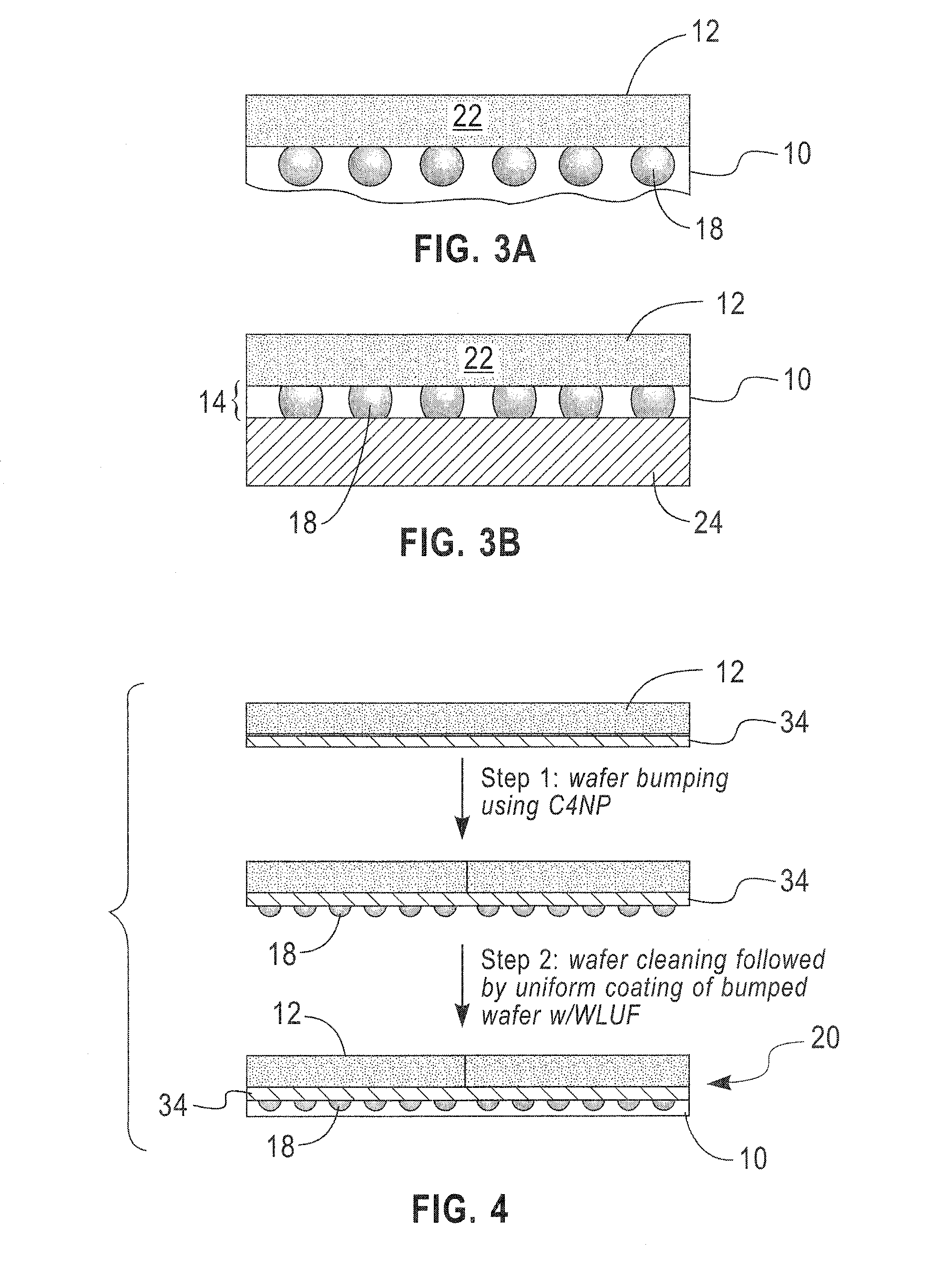

Wafer-level underfill process using over-bump-applied resin

InactiveUS20090108472A1Increasing the thicknessExcessive oxidationSemiconductor/solid-state device detailsSolid-state devicesWaferingEngineering

A process of fabricating wafer-level underfilled microelectronic packages using over-bump application of a self-fluxing resin to a wafer, b-staging of the resin, dicing of the coated wafer, and joining the diced chips to substrates producing wafer-level underfilled microelectronic flip-chip packages. Moreover, provided are microelectronic packages, which are produced in accordance with the inventive process.

Owner:IBM CORP

Method for firing a ceramic and refractory metal casting core

InactiveUS20070235158A1Insufficient temperatureAvoid a lot of timeFoundry mouldsFoundry coresInvestment castingNon oxidative

In an investment casting process, a composite core is formed as a combination of ceramic casting core element and a non-ceramic casting core element. The core is heated in an oxidative atmosphere and then heated in a non-oxidative atmosphere.

Owner:RAYTHEON TECH CORP

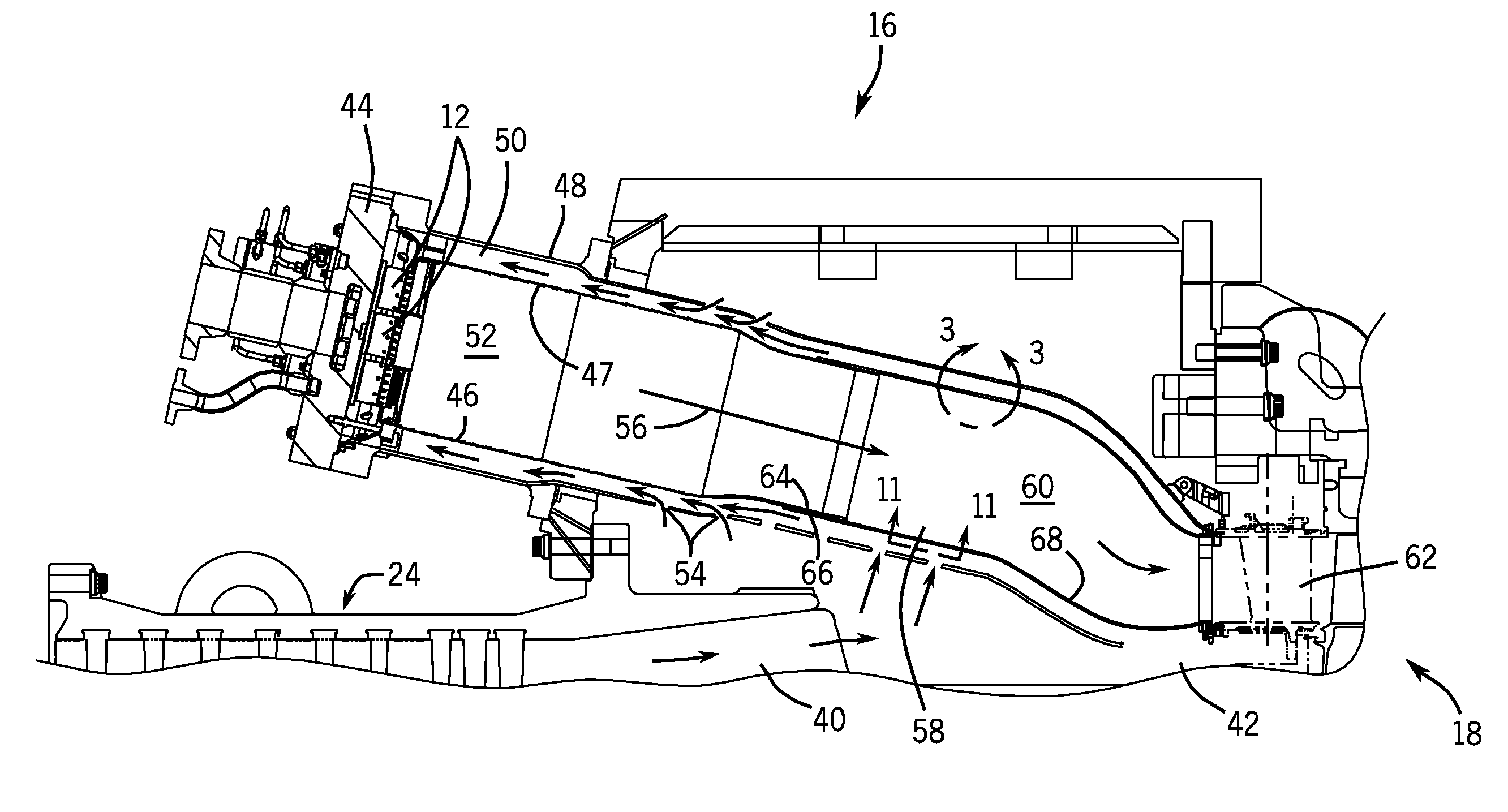

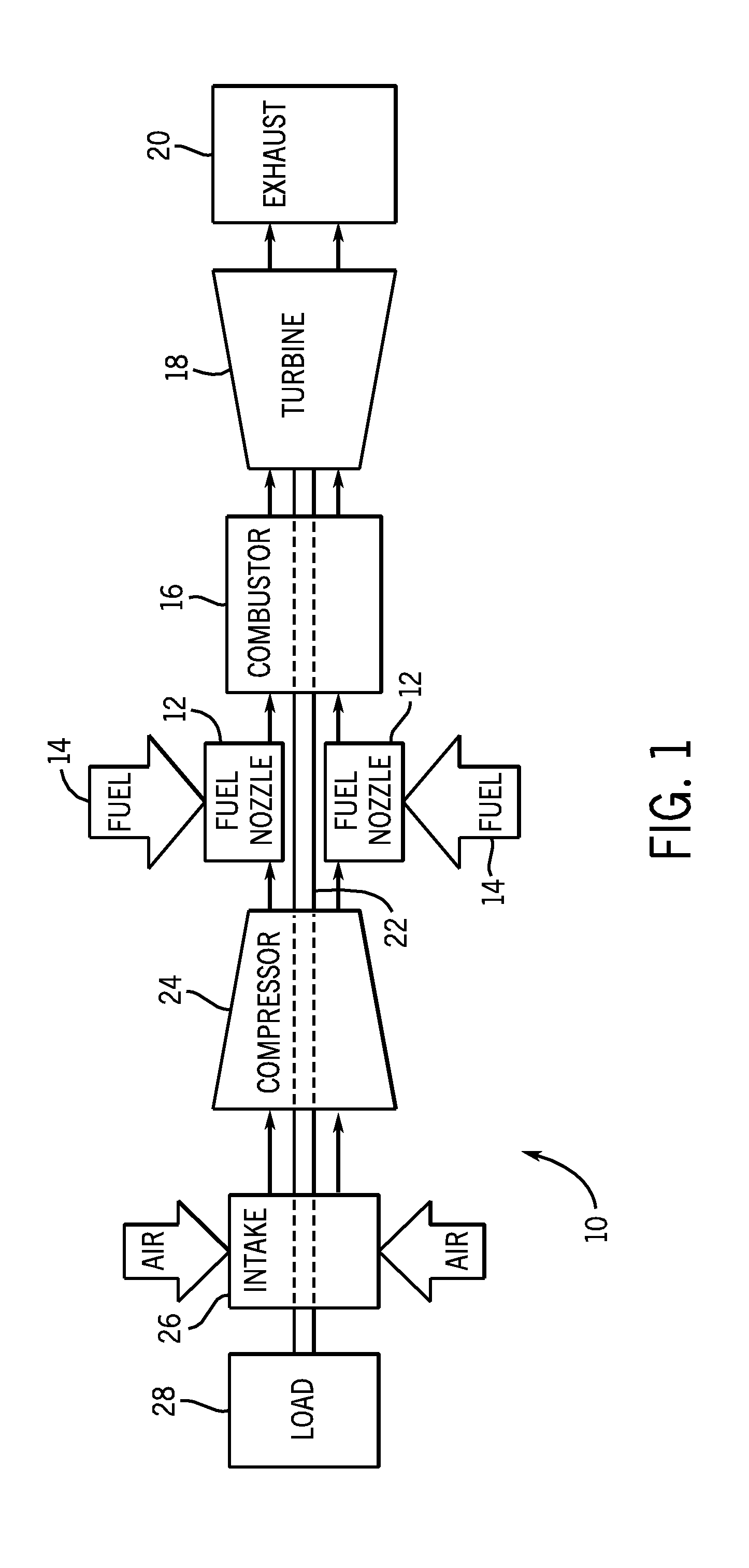

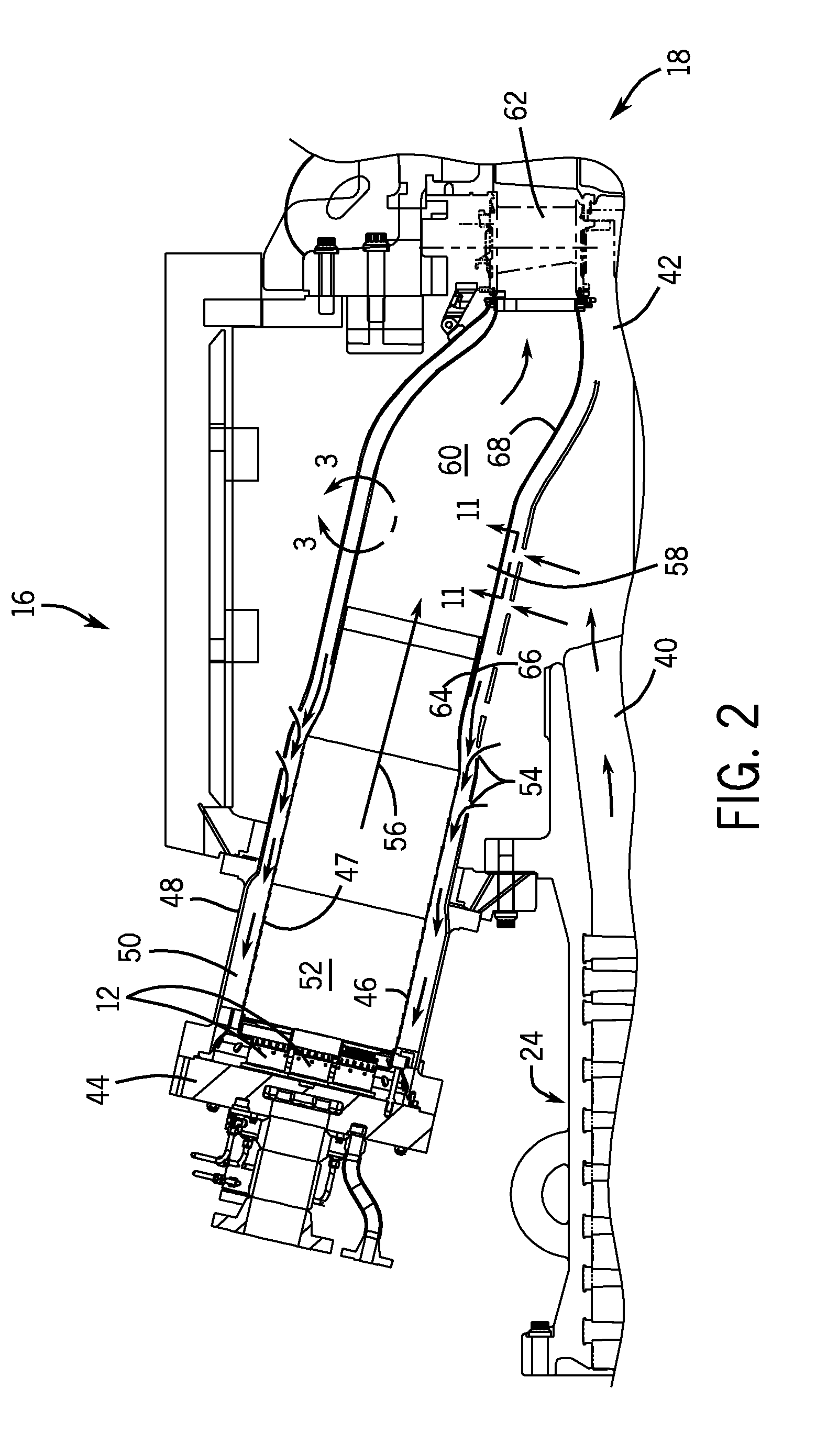

System for Protecting an Inner Wall of a Combustor

InactiveUS20140157783A1Excessive oxidationContinuous combustion chamberEfficient propulsion technologiesCombustion chamberCombustor

In a first embodiment a system, including a gas turbine combustor, including an inner wall disposed about a combustion chamber, and an outer wall disposed about the inner wall, wherein a coolant flow path extends between the inner and outer walls, wherein the inner wall comprises a material blocking a plurality of openings, and the plurality of openings are configured to open after the material is consumed or depleted to define a plurality of coolant passages through the inner wall.

Owner:GENERAL ELECTRIC CO

Method of fabricating rare-earth sintered magnet and method of fabricating rare-earth bonded magnet

InactiveUS20090081067A1Improve featuresExcellent magnetic propertiesTransportation and packagingMetal-working apparatusRare-earth elementMicrowave

A method of fabricating a rare-earth based sintered magnet having improved magnetic and mechanical characteristics is offered. Also, a method of fabricating a rare-earth bonded magnet having improved magnetic and mechanical characteristics is offered. The method of fabricating the rare-earth based sintered magnet is started with preparing powder of an alloy including a rare-earth element and a transition metal. The powder of the alloy is mixed with an additive. The mixture is compression molded and irradiated with microwaves to cause the powder to self-heat. As a result, the mixture is sintered.

Owner:SEIKO INSTR INC

Prosthetic locking device

InactiveUS7637958B2Excessive oxidationLess concern of rustingArtificial legsEngineeringResidual limb

Owner:FILLAUER LLC

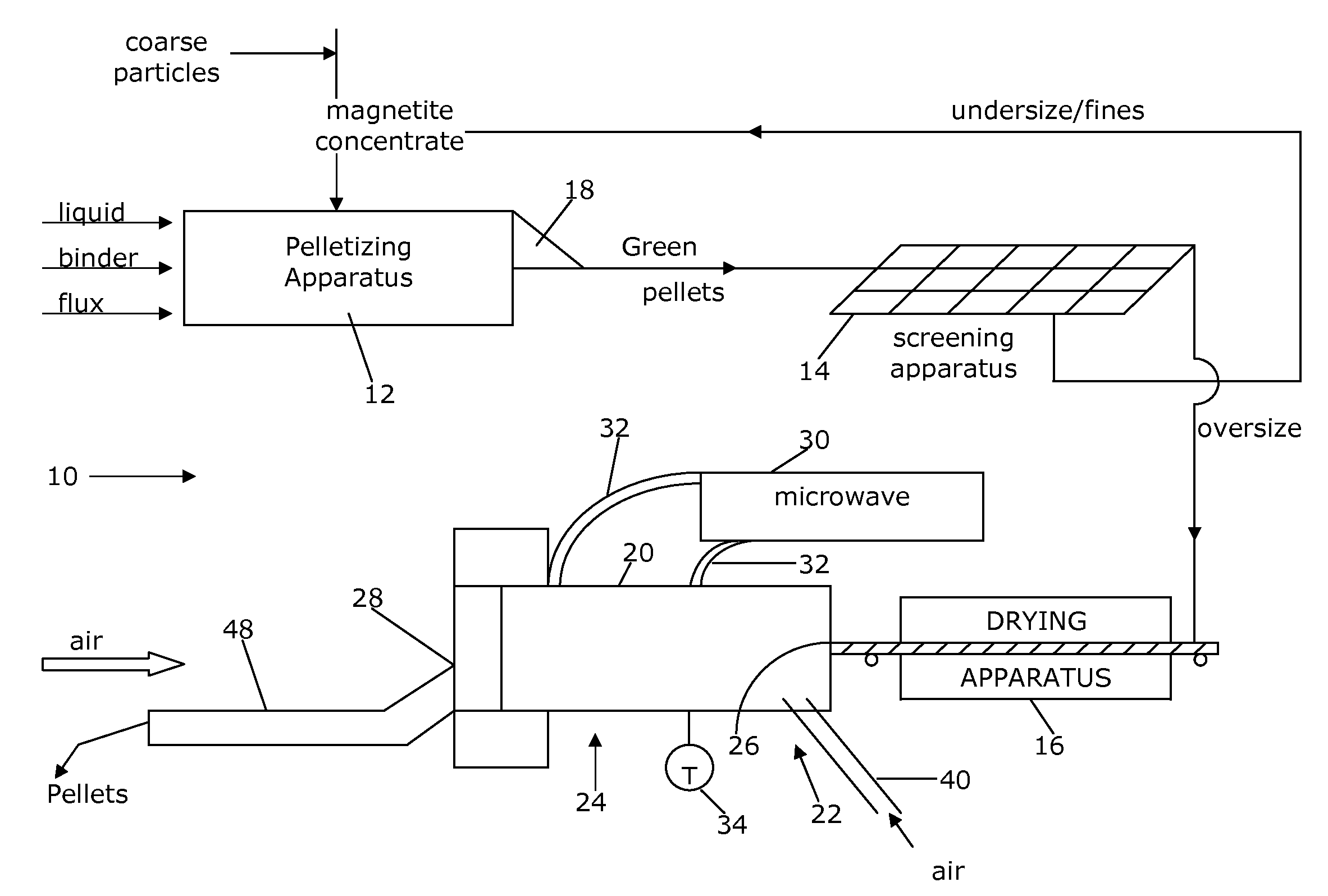

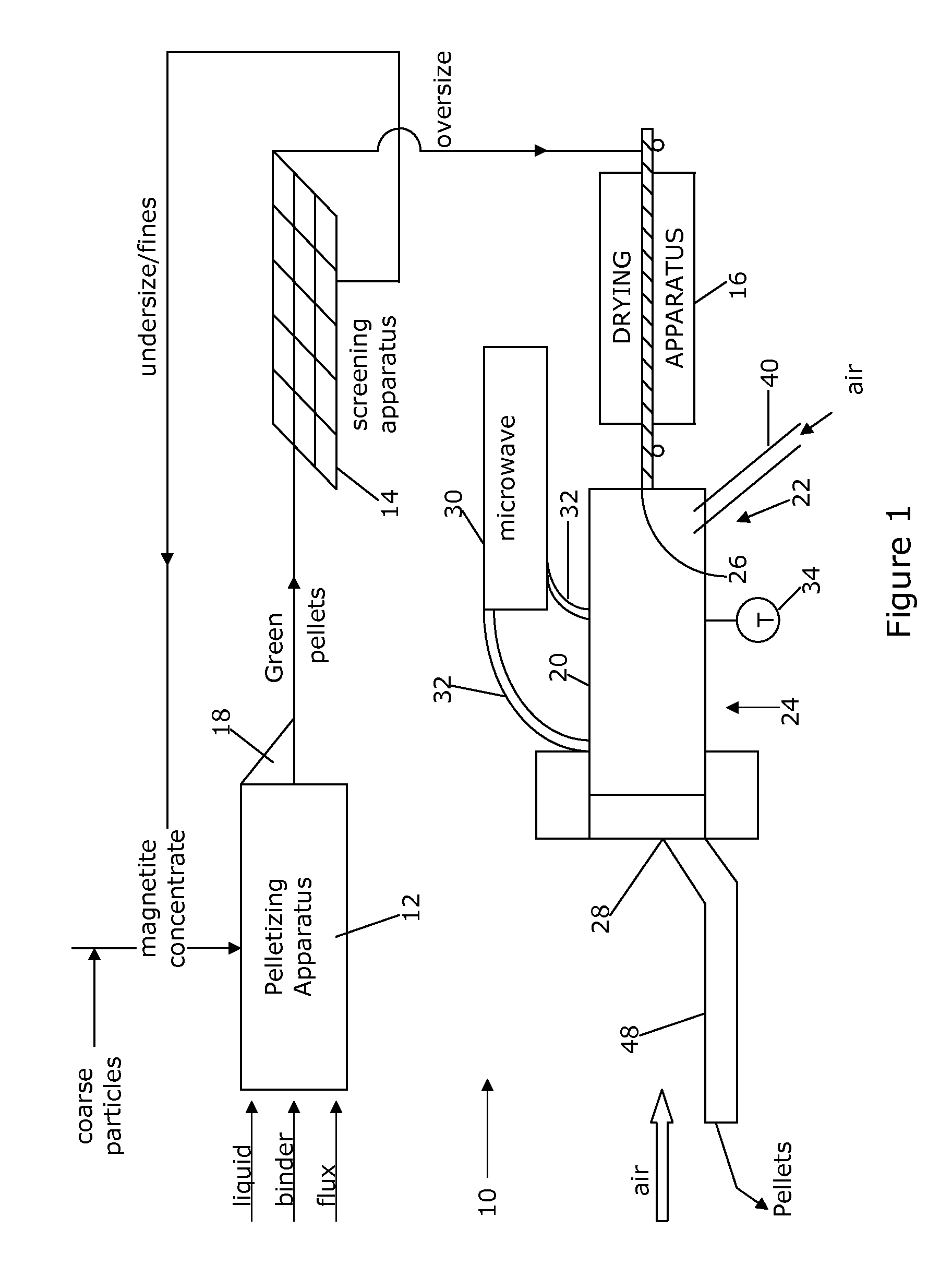

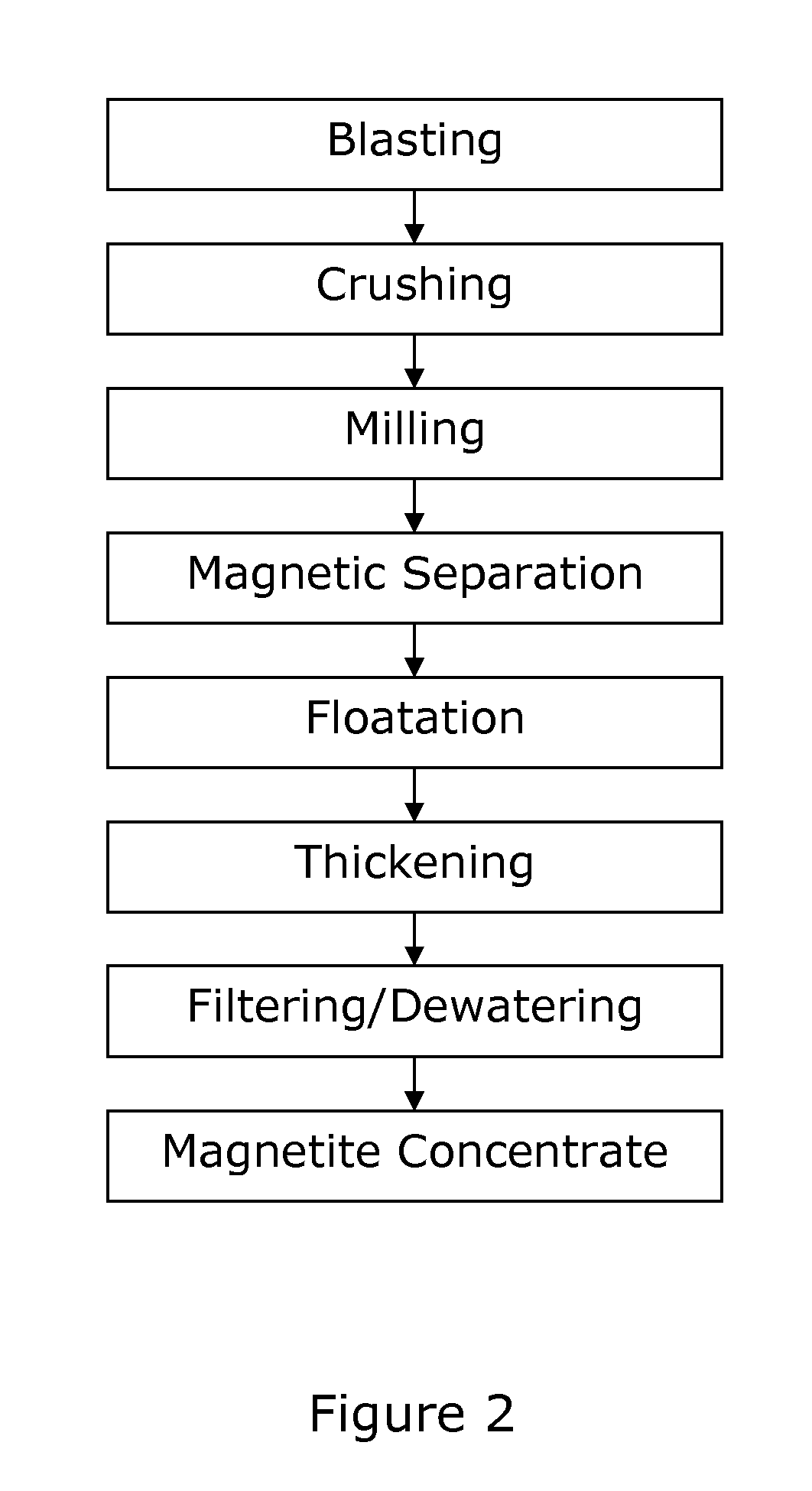

Treatment of Green Pellets Using Microwave Energy

InactiveUS20110068521A1Excessive oxidationLow costBlast furnace componentsRotary drum furnacesMicrowaveMagnetite

Owner:ORE PRO PTY LTD

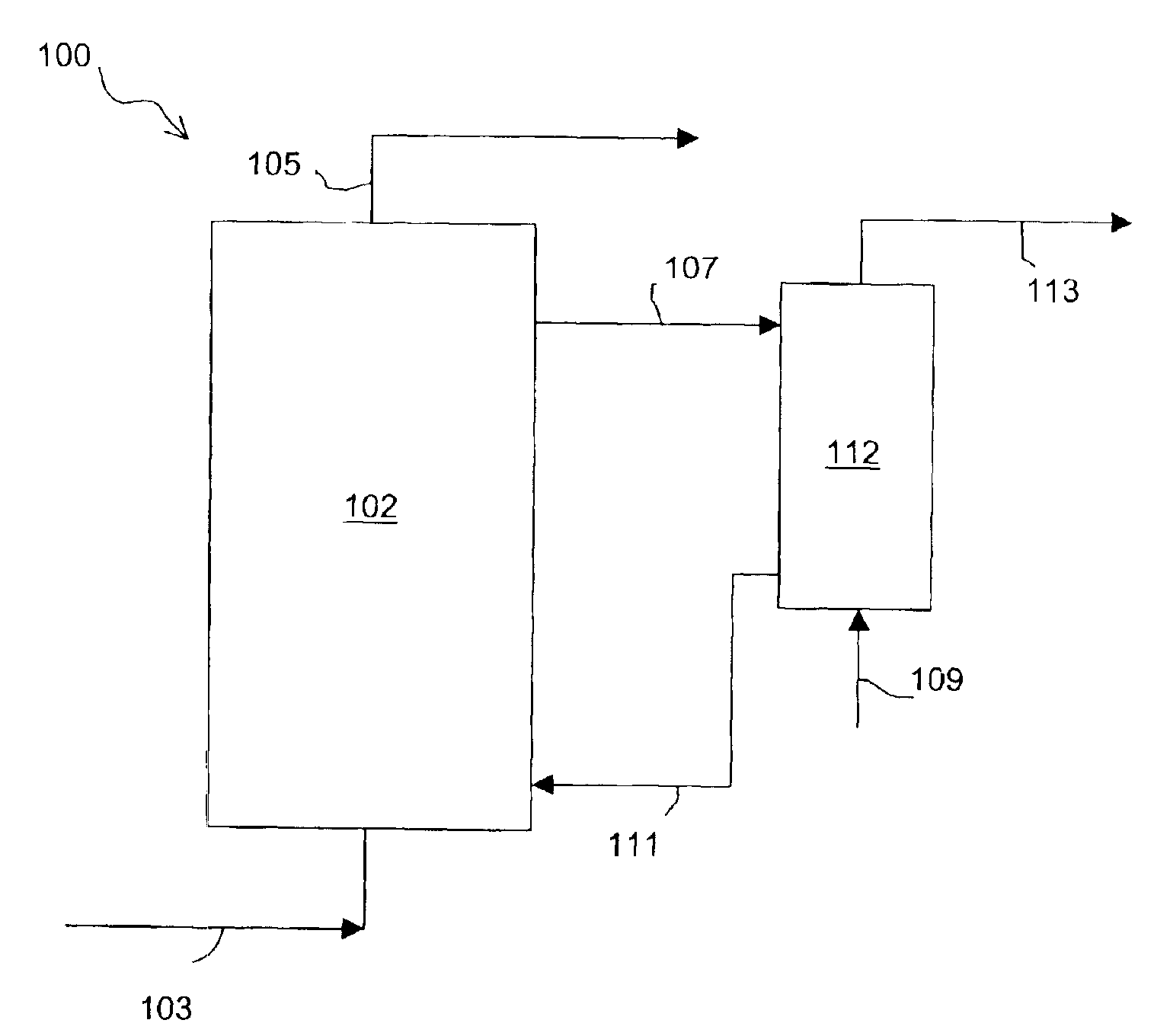

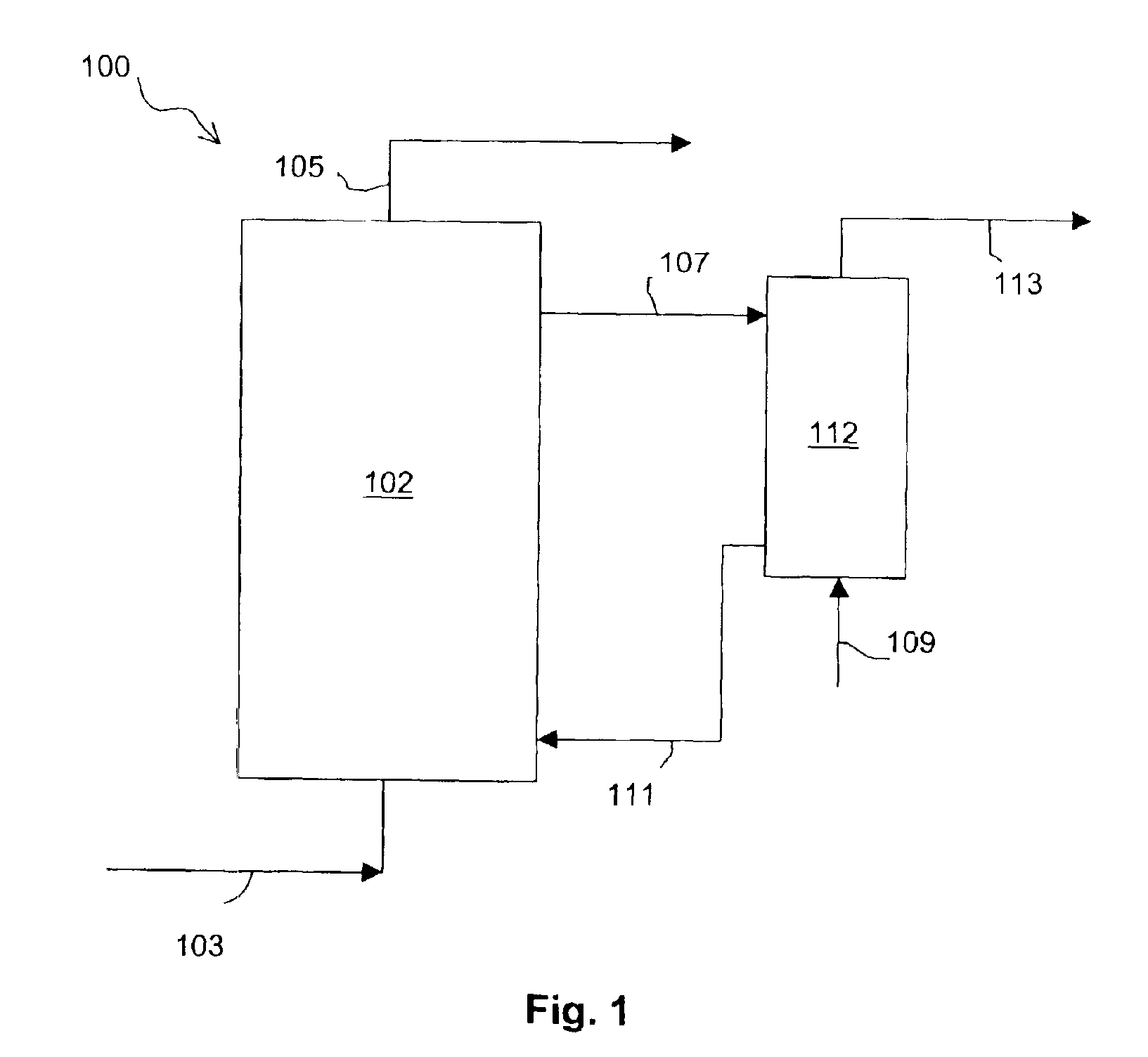

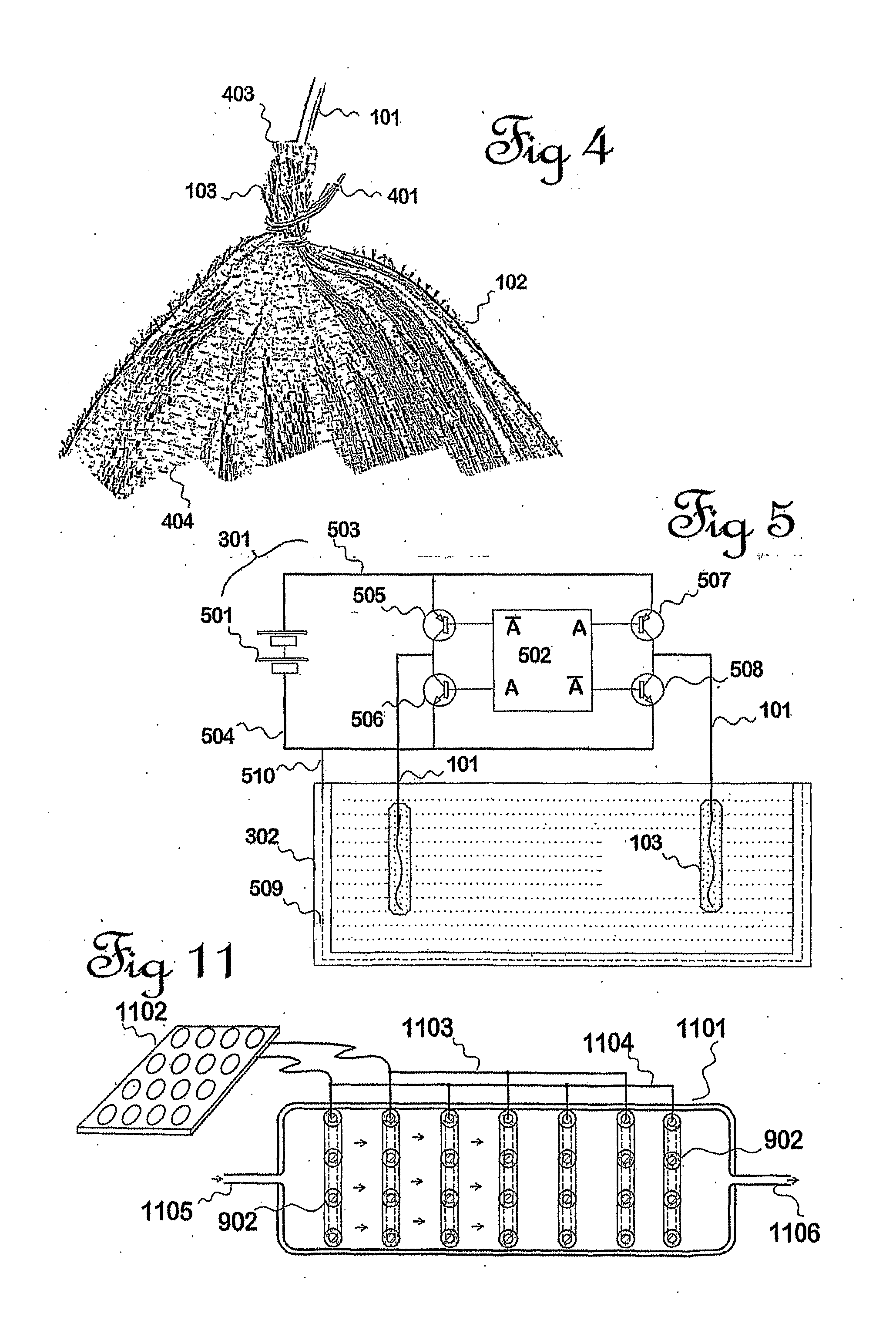

Method for reducing water concentration in a multi-phase column reactor

InactiveUS6956063B2Speed up the conversion processExcessive oxidationSolvent extractionDistillation regulation/controlWater concentrationSlurry

The present invention relates to a method and apparatus for water removal in multi-phase reactors operating at Fischer-Tropsch conditions. In a preferred embodiment of the present invention, a method of reducing the concentration of water in a multi-phase reactor for Fisher-Tropsch synthesis containing an expanded slurry bed and a water-rich slurry region includes removing a portion of water from the water-rich slurry from a predetermined region in the reactor, removing the water from the water-rich slurry to form a water-reduced slurry, and returning the water-reduced slurry back to the reactor. Preferably the water-rich slurry region is located between ½ H to H and ½ R to R, where H is the height of the expanded slurry bed and R is the radius of the expanded slurry bed.

Owner:PHILLIPS 66 CO

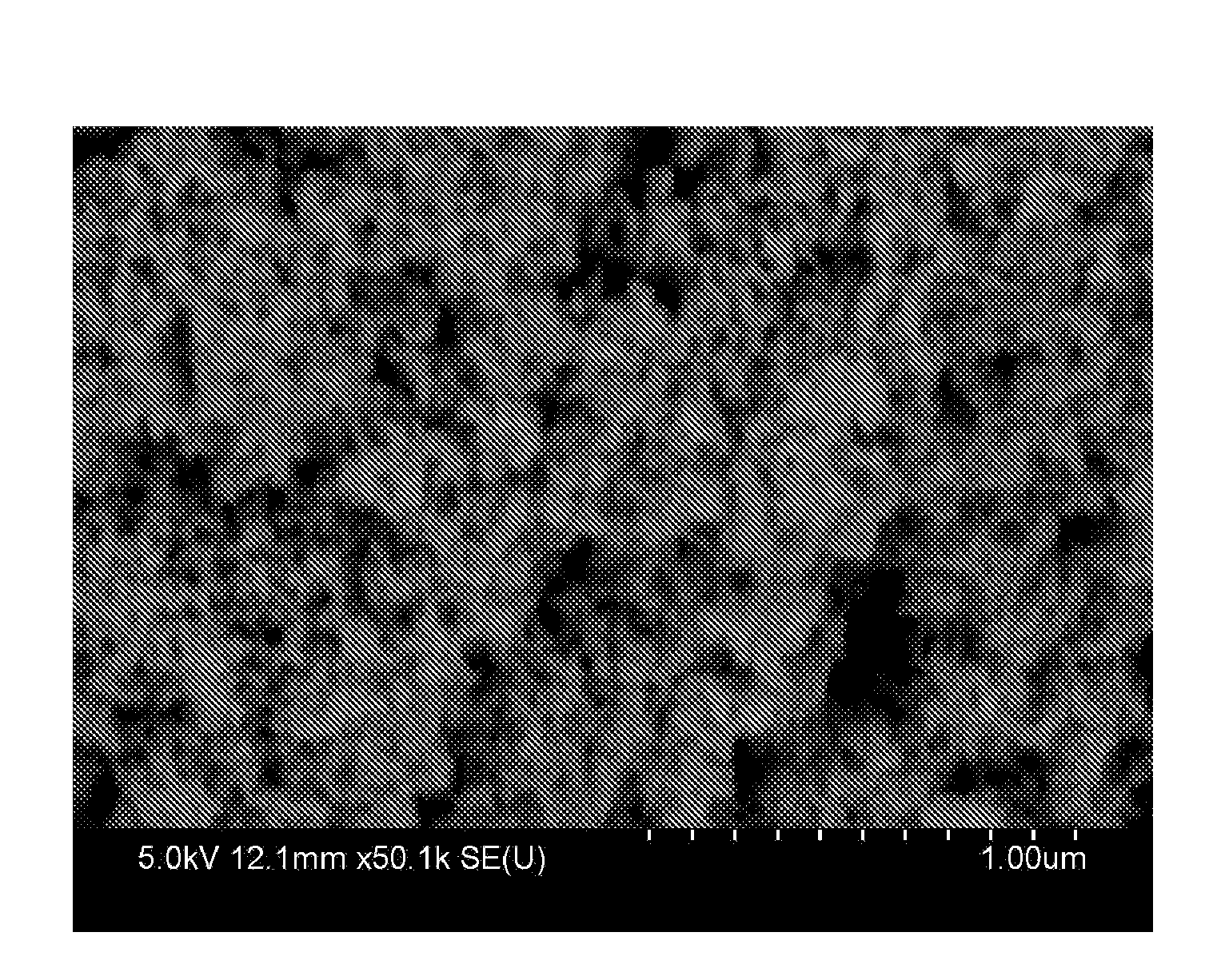

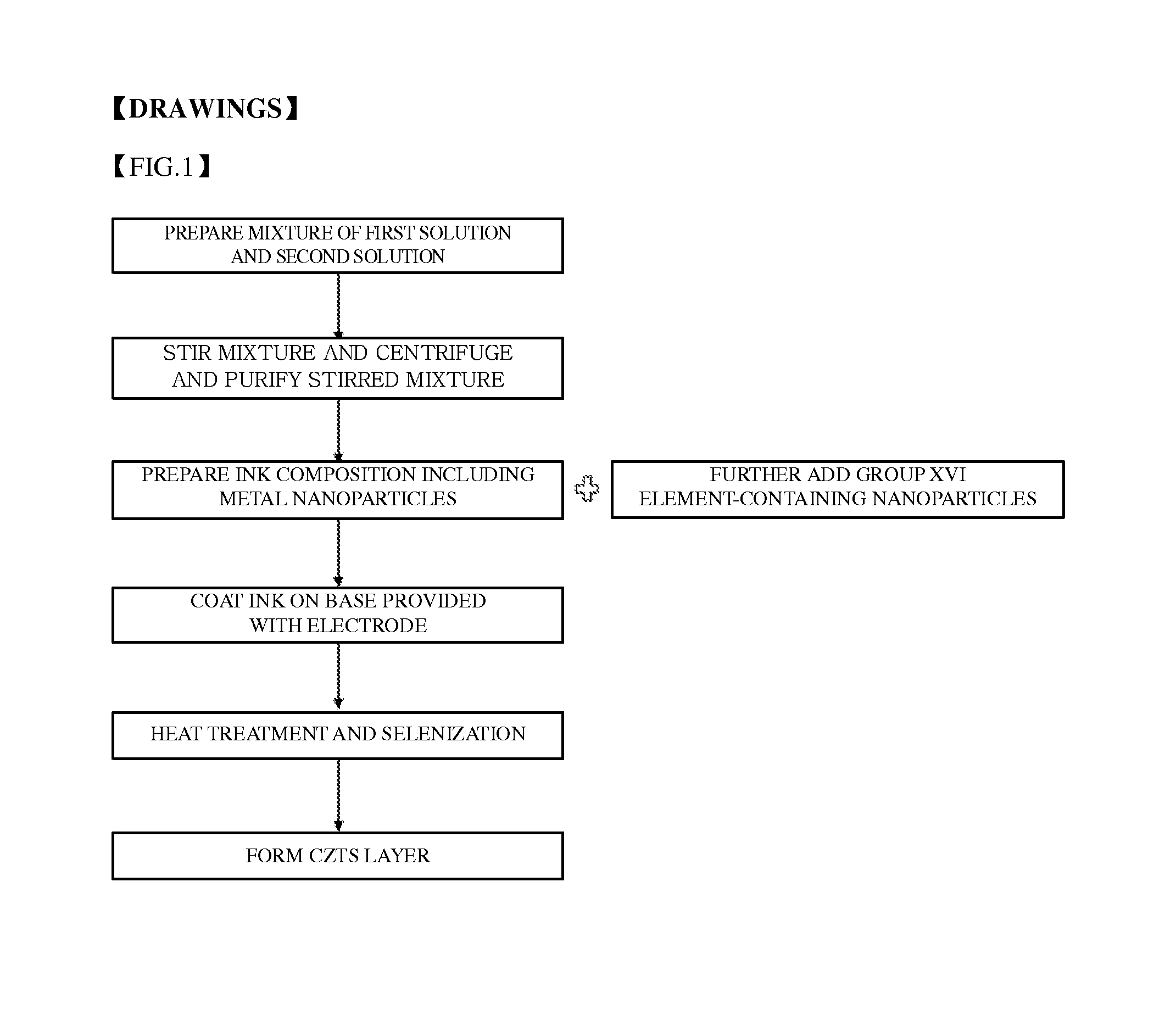

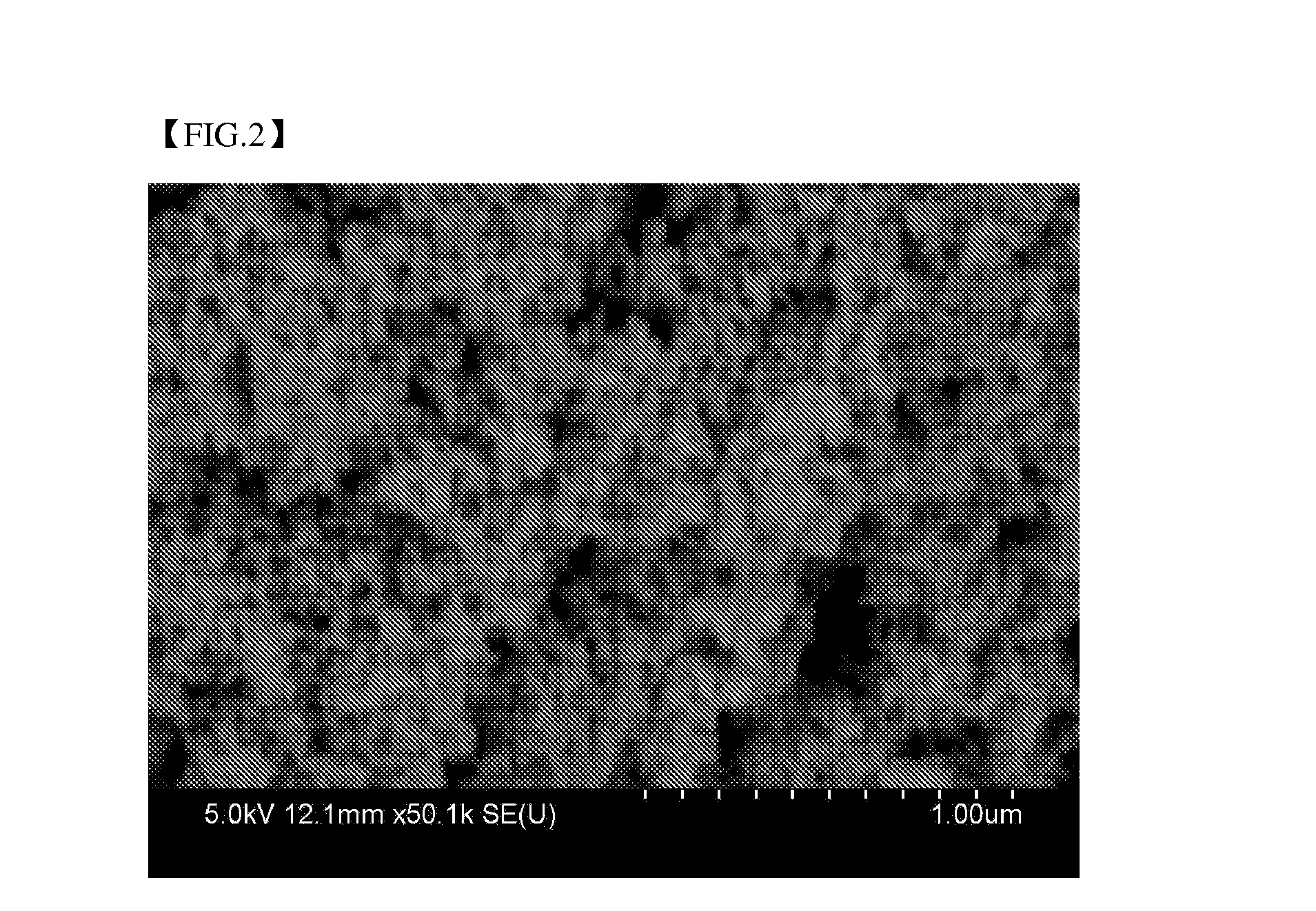

Method of preparing metal nanoparticles for solar cell, ink composition including the metal nanoparticles, and method of preparing thin film using the same

ActiveUS20150325724A1Reduce manufacturing costExcessive oxidationPigmenting treatmentTransportation and packagingCopperSolar cell

Disclosed are a method of preparing metal nanoparticles for solar cells, an ink composition including the metal nanoparticles, and a method of preparing a thin film using the same. More particularly, there are provided a method of preparing metal nanoparticles for forming a light absorption layer of a solar cell, including preparing a first solution including a reducing agent, preparing a second solution including at least two salts selected from the group consisting of a copper (Cu) salt, a zinc (Zn) salt, and a tin (Sn) salt, preparing a mixture by mixing the first solution and the second solution, and synthesizing at least one kind of metal nanoparticles by reaction of the mixture and purifying the synthesized metal nanoparticles, an ink composition including the metal nanoparticles, and a method of preparing a thin film using the same.

Owner:LG CHEM LTD

Electrodes for electrolysis of water

InactiveUS20120037512A1Excessive oxidationPromotes rapid oxidationCellsMachining electrodesCarbon fibersDc current

Electrodes for electrolysis of water, for encouraging growth of algae and aerobic bacteria, for removing suspended solids from wastewater during treatment, or for rendering water sterile and potable have a concrete coating over a metallic or carbon fibre core. The coating is from 2 to 50 mm thick; preferably 5 to 25 mm thick. Preferably, a DC current passed between the immersed electrodes periodically reversed but there is no visible “rusting” at the anode if the DC current is steady. The resistive nature of the concrete tends to suppress concentrations of current upon the electrode surface.

Owner:ROBERTSON MAURICE JAMES

Method of manufacturing rare-earth magnet powder, and method of manufacturing rare-earth bond magnet

InactiveUS20120164019A1Improve magnetic propertiesHeating fastSolid state diffusion coatingInductances/transformers/magnets manufactureRare-earth elementMicrowave

A method of manufacturing rare-earth magnet powder having excellent magnetic properties, and a method of manufacturing a rare-earth bond magnet are provided. A nitriding step is performed, in which when nitrided rare-earth magnet powder is produced, rare-earth-element / transition metal-based alloy powder is irradiated with a microwave at an atmosphere containing nitrogen atoms, so that the nitrogen atoms are allowed to enter into a crystal lattice.

Owner:SEIKO INSTR INC

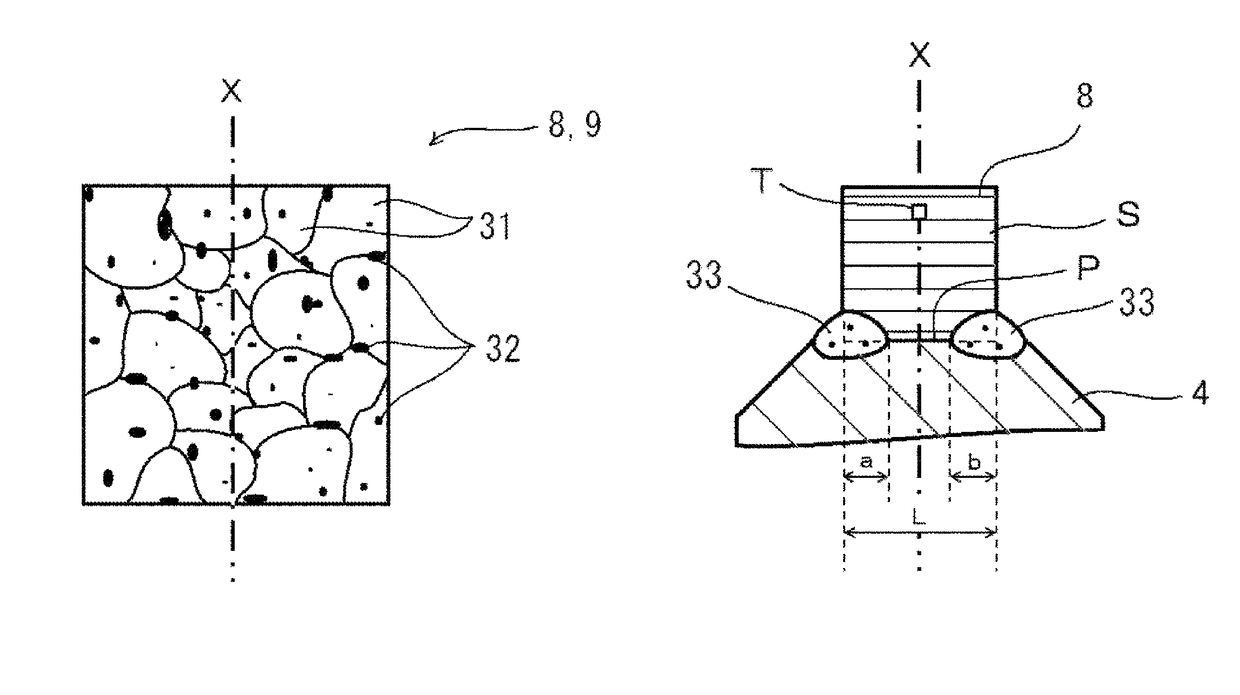

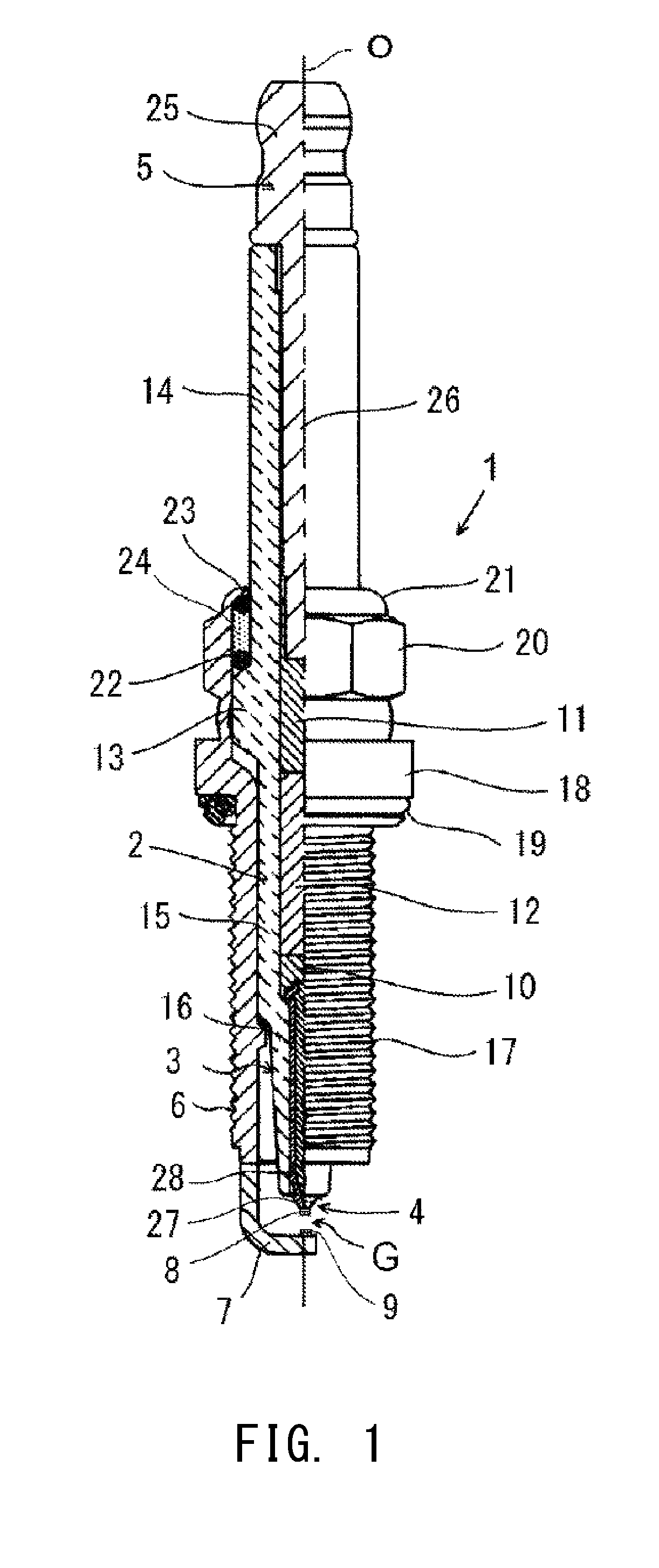

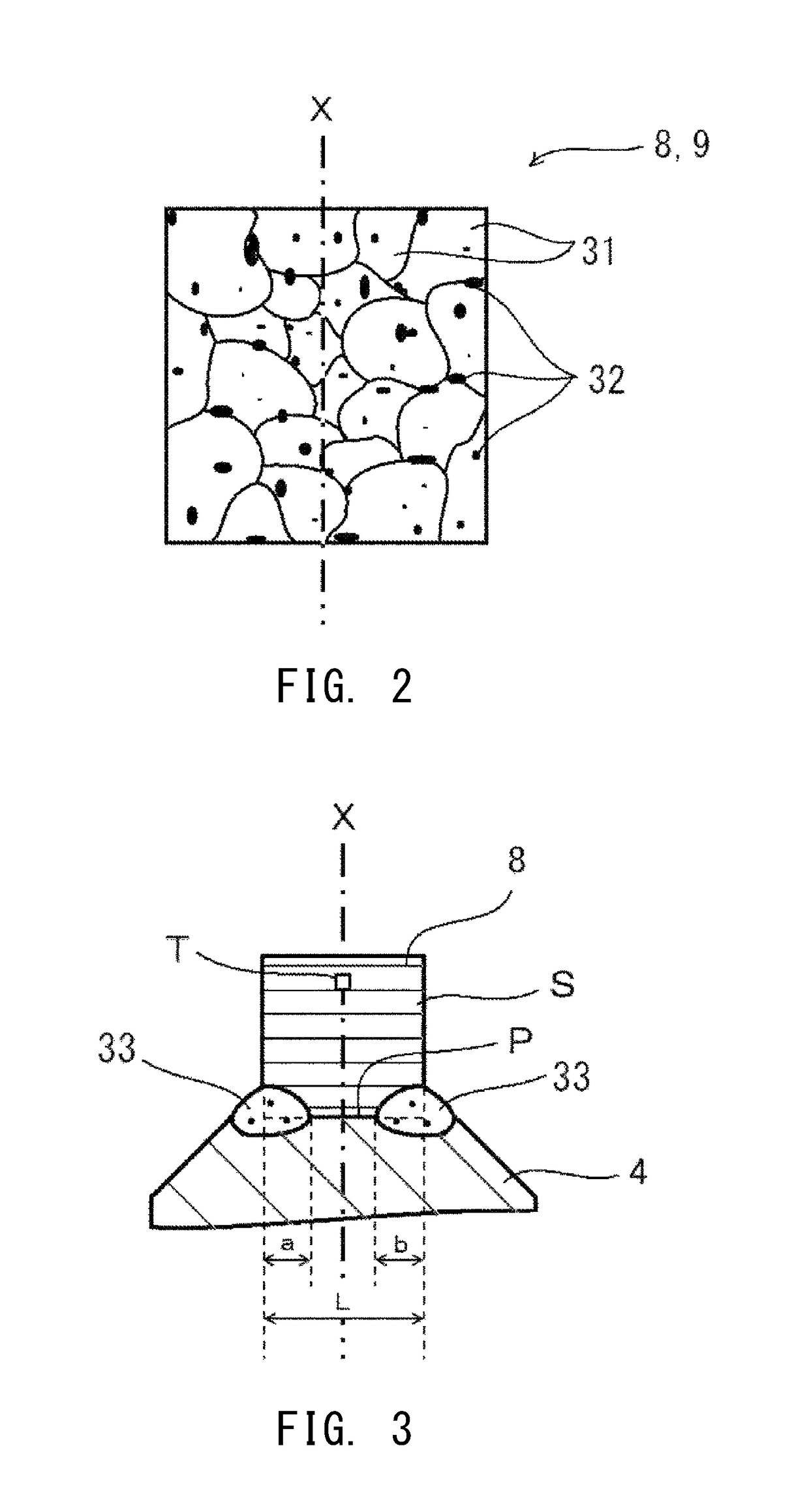

Spark plug

ActiveUS9627857B2Increase resistanceIncreased durabilitySparking plugs manufactureEngineeringWear resistance

An object of the present invention is to provide a spark plug which includes, at at least one of a center electrode and a ground electrode, a tip having excellent spark wear resistance in a high temperature environment, thereby having excellent durability. A spark plug includes a center electrode and a ground electrode disposed with a gap provided between the center electrode and the ground electrode. At least one of the center electrode and the ground electrode includes a tip which defines the gap. The tip includes a metal base material containing Ir as a main component, and oxide particles containing at least one of oxides having a perovskite structure represented by general formula ABO3 (A is at least one element selected from elements in group 2 in a periodic table, and B is at least one element selected from metal elements). When a cross section of the tip is observed, an area proportion of the oxide particles is not lower than 1% and not higher than 13%.

Owner:NGK SPARK PLUG CO LTD

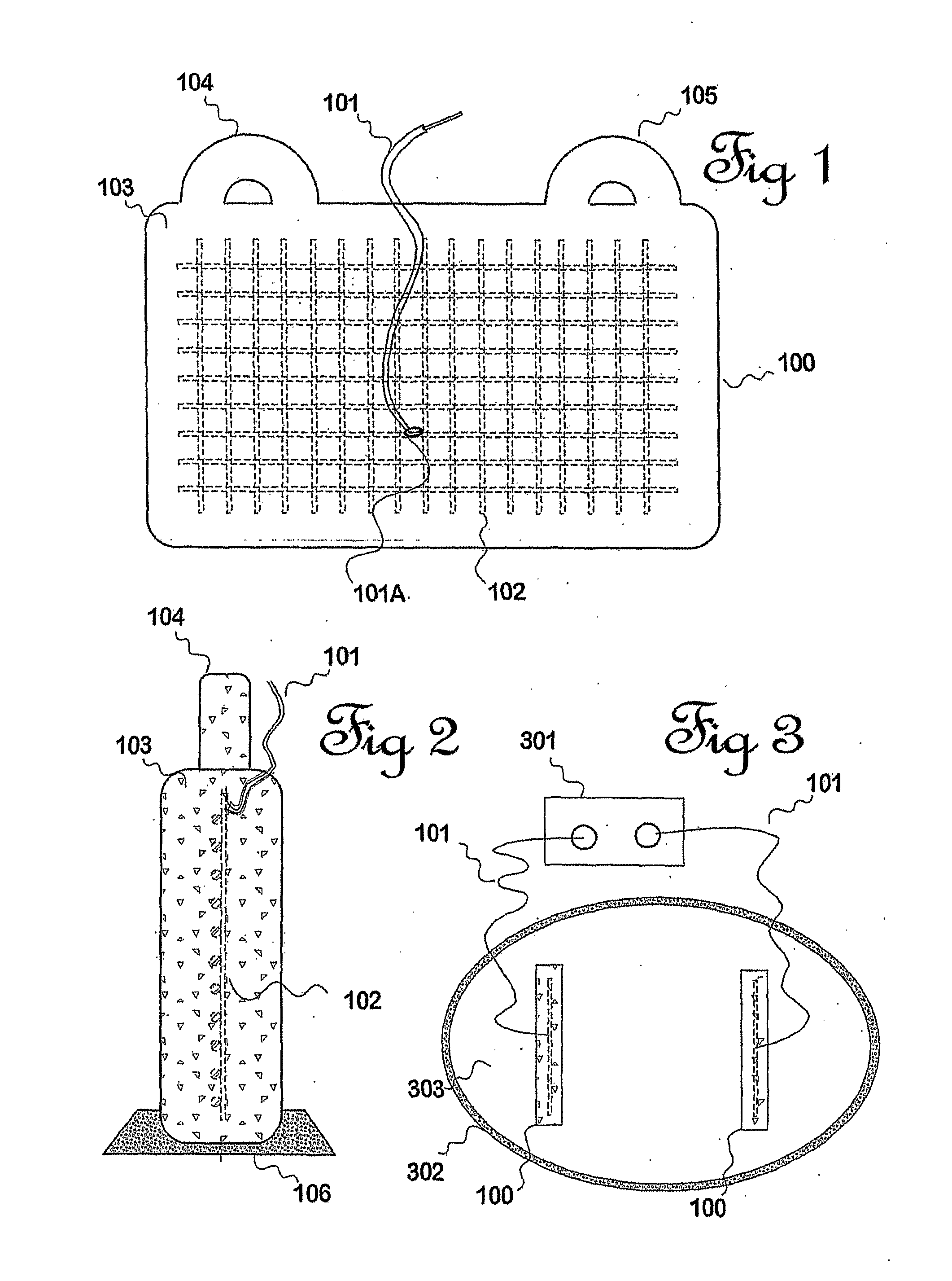

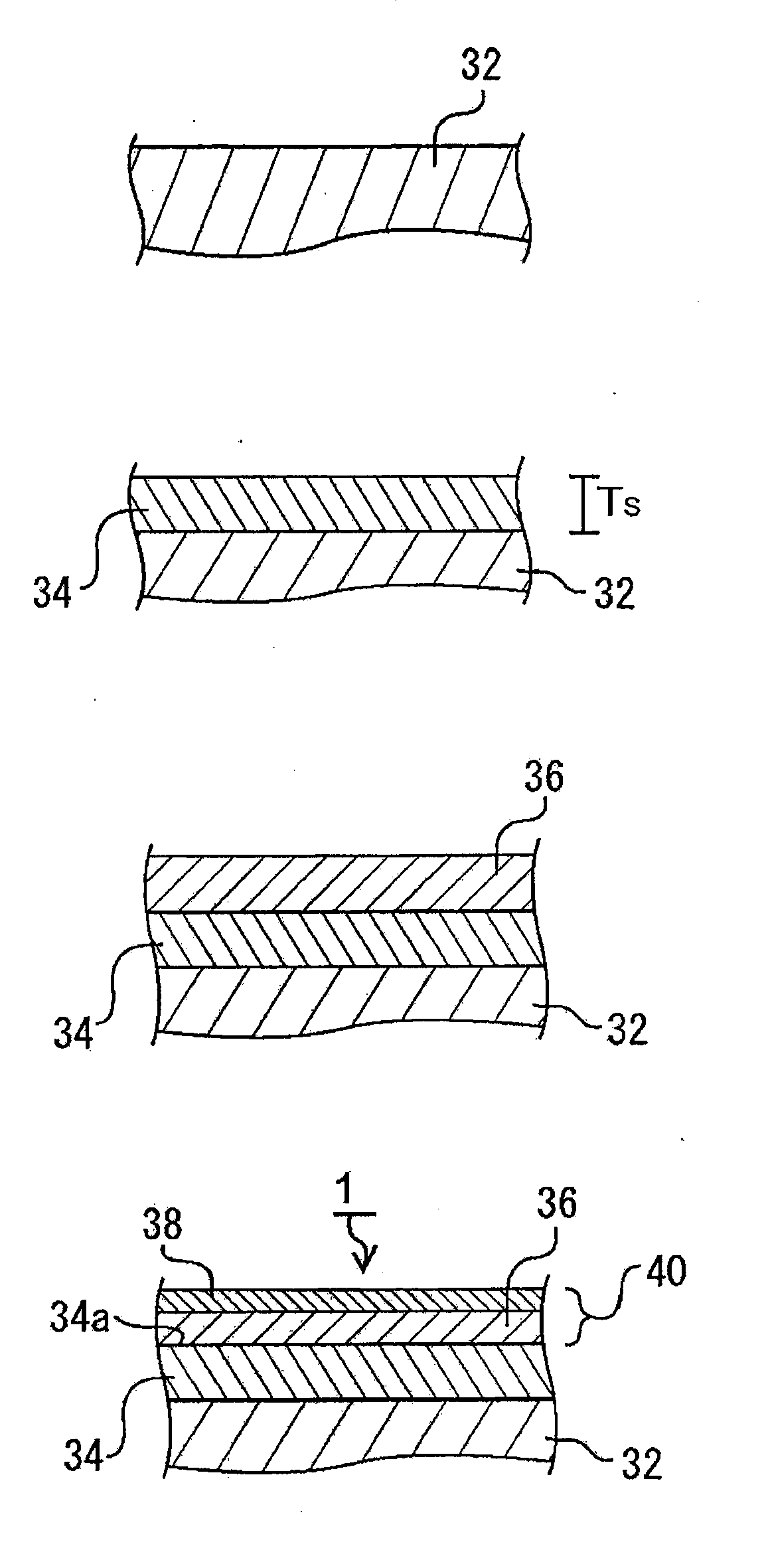

Catalyst Body for Production of Brush-shaped Carbon Nanostructure

ActiveUS20110319260A1Efficient growth processSuitable catalyst performanceMaterial nanotechnologyCarbon nanotubesNanometreHigh density

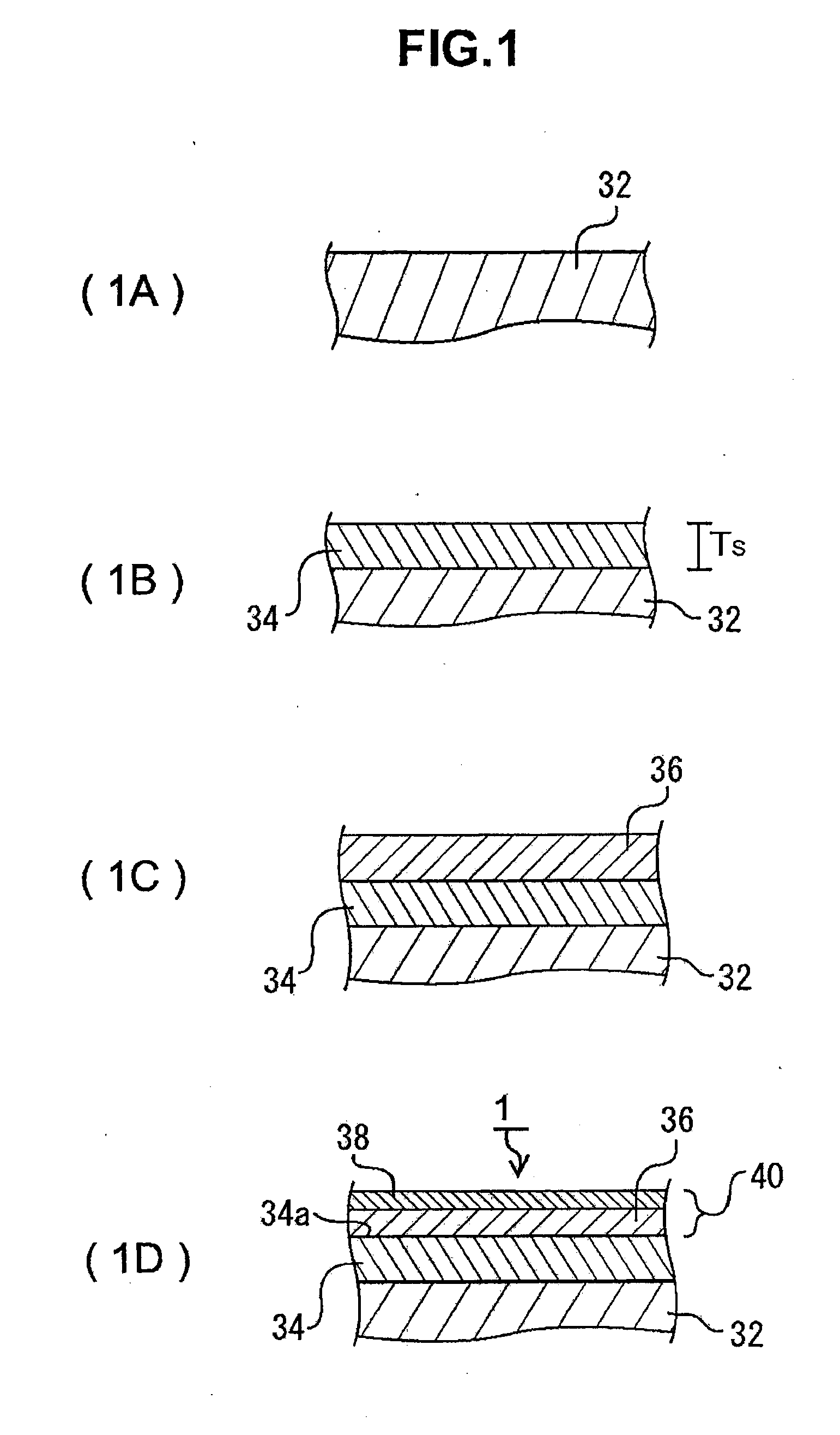

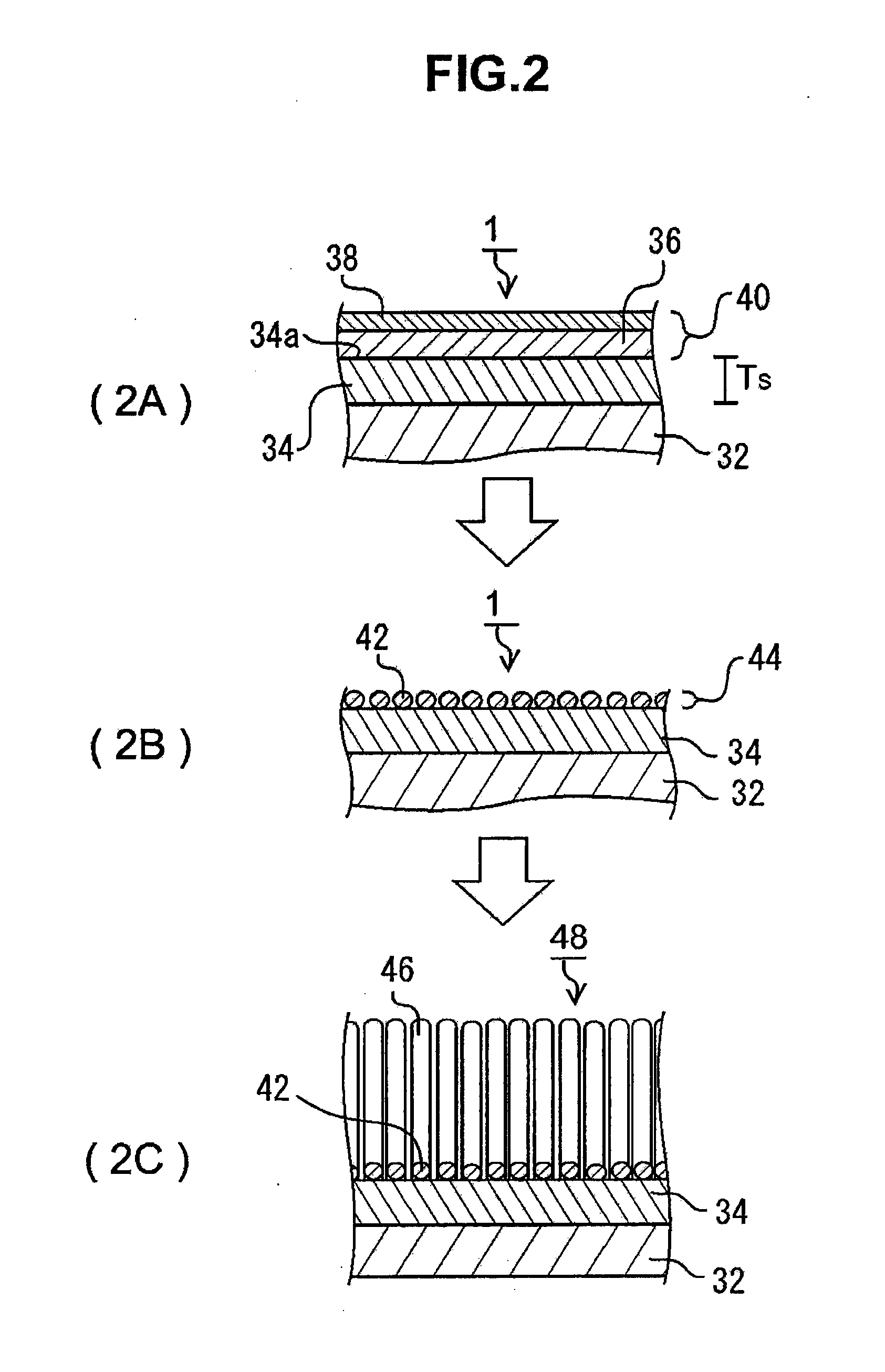

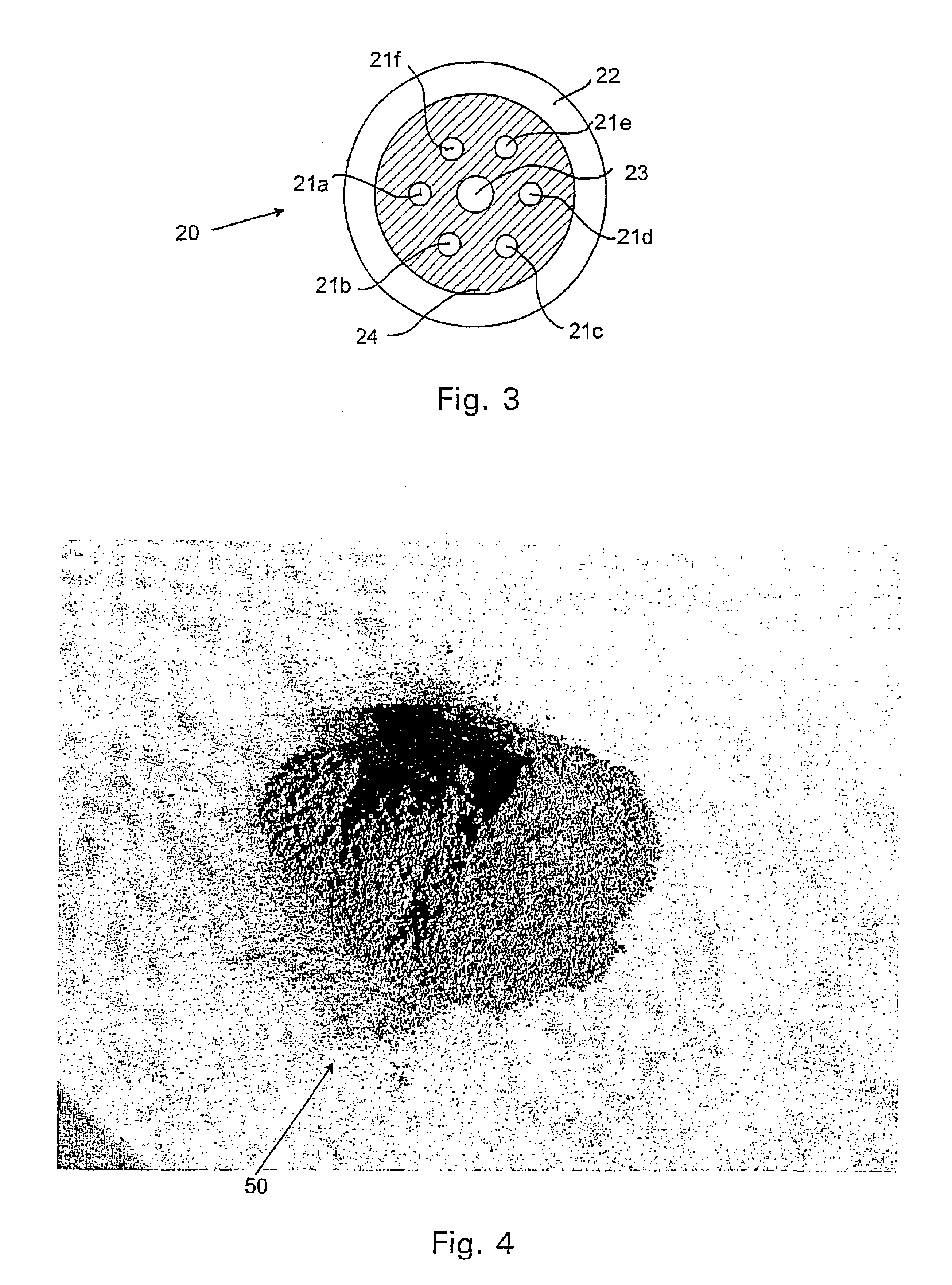

It is intended to highly efficiently produce a high-density brush shaped carbon nanostructure useful in the production of CNT assembly, such as rope-shaped CNTs, and provide a catalyst body for production of brush-shaped carbon nanostructure that enables the production. The catalyst body for production of brush-shaped carbon nanostructure is one comprising a substrate (32), an aggregation suppressive layer (34) superimposed on a surface thereof and a catalyst layer superimposed on the aggregation suppressive layer (34). The catalyst layer is a catalyst particle layer (44) consisting of metallic catalyst particles (42) composed mainly of a catalytic metal. The metallic catalyst particles (42) have an average particle diameter, D, satisfying the relationship 0.5 nm≦D≦80 nm, and individual particles of the metallic catalyst particles (42) have a diameter, d, falling within the range of the above average particle diameter (D). Further, there are disclosed a process for producing the catalyst body, a brush-shaped carbon nanostructure and a process for producing the same.

Owner:TAIYO NIPPON SANSO CORP

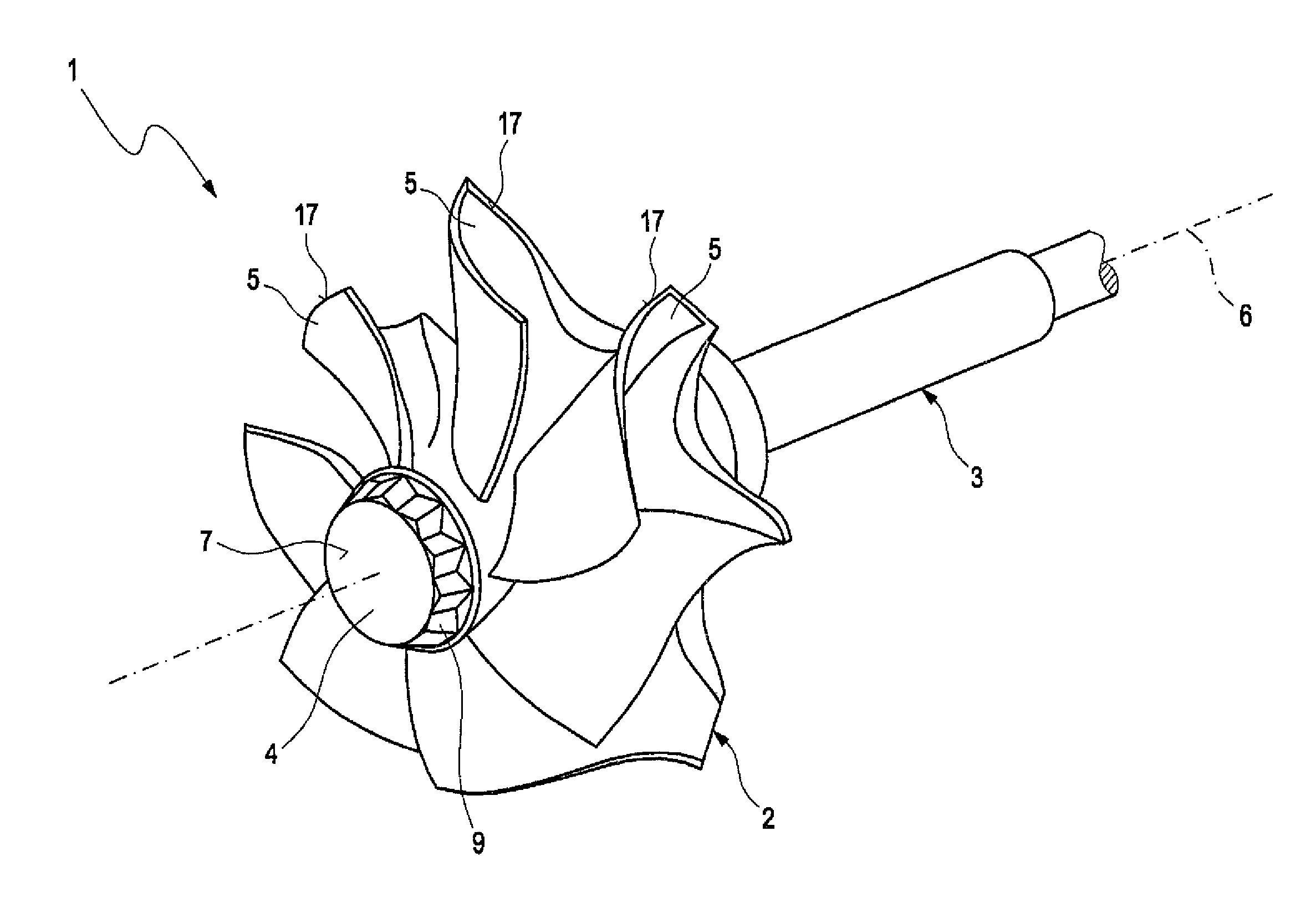

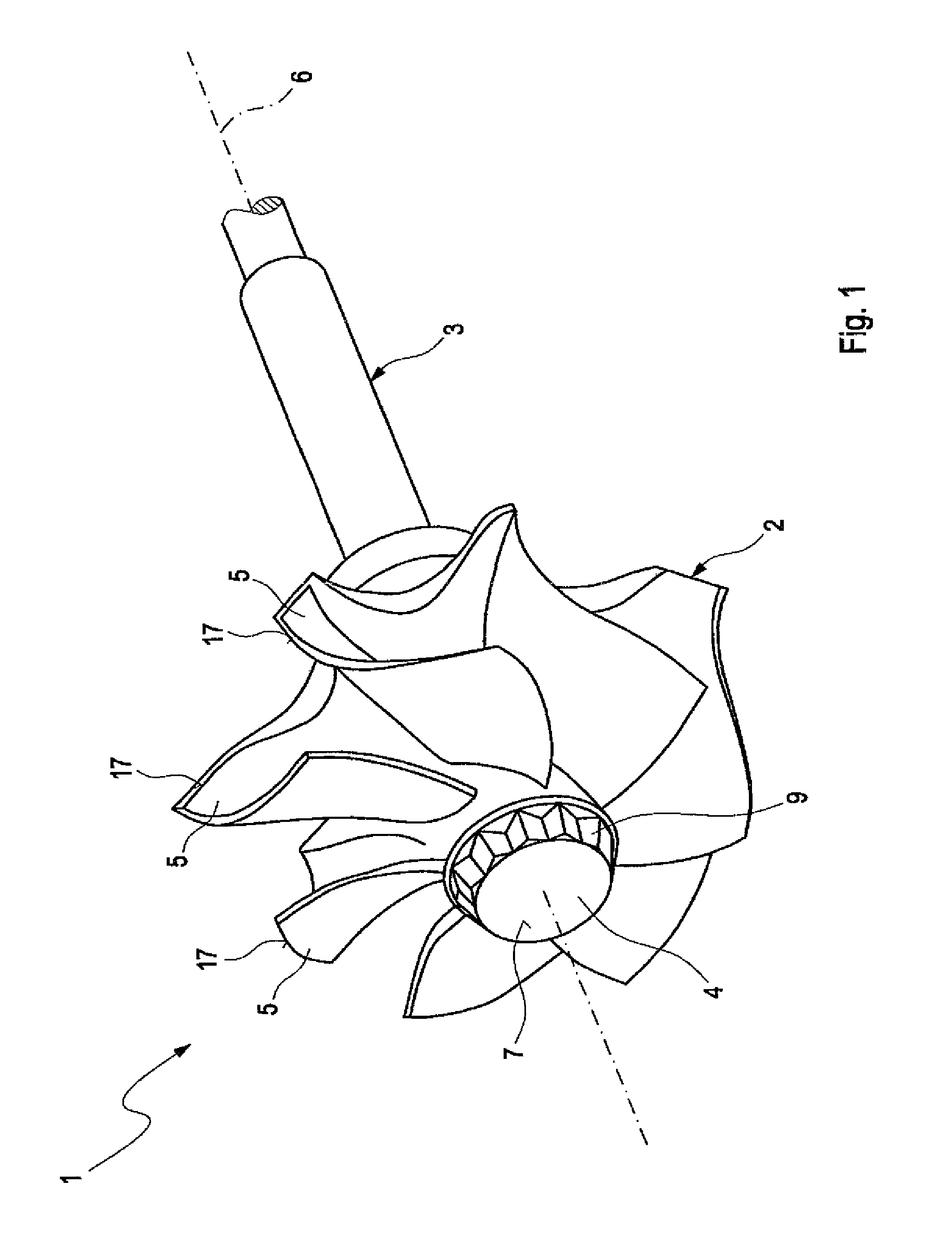

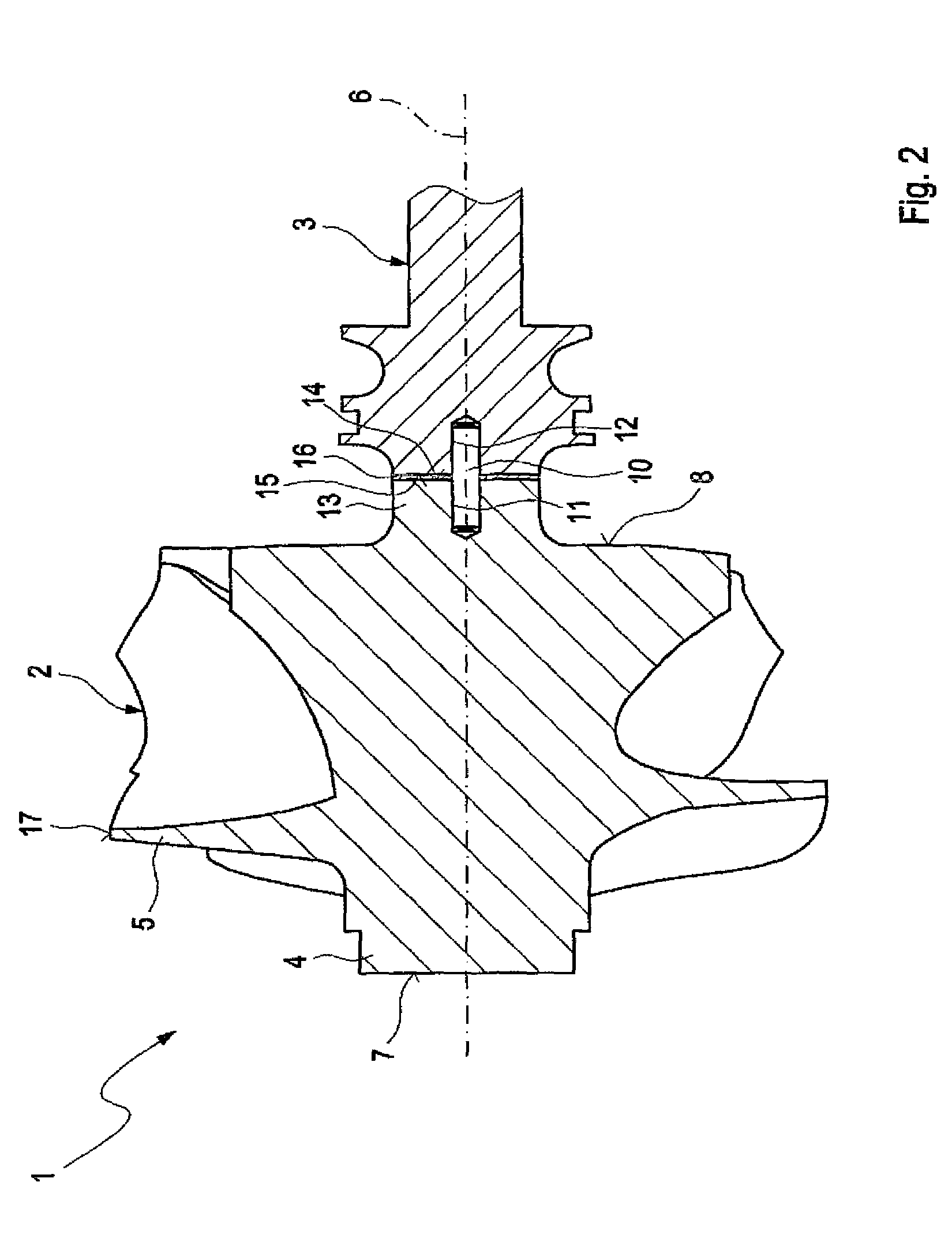

Method for producing a turbine rotor of an exhaust gas turbocharger, and use of a turbine rotor

ActiveUS9186758B2Low densityLow implementation costBlade accessoriesVacuum evaporation coatingImpellerTurbine wheel

A method for producing a turbine rotor of an exhaust gas turbocharger, wherein the turbine rotor includes a turbine wheel with a hub and turbine blades that extend from the hub, and a shaft, includes the steps of: providing the turbine wheel and the shaft; forming a protective layer by applying or introducing a halogen on or in the surface of the turbine wheel and subsequently heat-treating the turbine wheel; and connecting the shaft to the hub of the turbine wheel after the protective coating is formed.

Owner:AUDI AG

Method for producing graphene oxide with tunable gap

ActiveUS8609458B2Practical to useExcessive oxidationMaterial nanotechnologyGraphiteCvd grapheneMaterials science

Owner:CALIFORNIA INST OF TECH

Magnetoresistance element and storage device using the same

ActiveUS8456896B2Reduce magnetizationExcessive oxidationNanomagnetismMagnetic-field-controlled resistorsMagnetic memoryNon magnetic

A magnetic memory element having a memory cell of size 4F2 is provided that realizes a crosspoint-type memory. In the magnetic memory element, a first magnetic layer, a third magnetic layer (spin polarization enhancement layer), an intermediate layer, a fourth magnetic layer (spin polarization enhancement layer), and a second magnetic layer are stacked in order. The intermediate layer is made of an insulating material or a nonmagnetic material. The second magnetic layer is composed of a ternary alloy of gadolinium, iron and cobalt, a binary alloy of gadolinium and cobalt, or a binary alloy of terbium and cobalt. Alternatively, the first magnetic layer is composed of a ternary alloy of terbium, iron and cobalt, or a binary alloy of terbium and cobalt.

Owner:III HLDG 3

Color conversion film, method for producing same, back-light unit and display apparatus

ActiveUS11299669B2Improve luminous efficiencyPrevent degradationOptical filtersLuminescent compositionsQuantum efficiencyLuminous intensity

The invention described in the present specification relates to a color conversion film including a resin matrix; and an organic fluorescent substance dispersed in the resin matrix, and absorbing blue or green light and emitting light having a wavelength different from the absorbing light, wherein the resin matrix includes a thermoplastic resin, and the color conversion film has a light emission peak with a FWHM of 60 nm or less, quantum efficiency of 80% or greater and an absorption coefficient of 30,000 M−1cm−1 or greater at a maximum absorption wavelength when irradiating light having a light emission peak at 450 nm, a FWHM of 40 nm or less and monomodal light emission intensity distribution, a method for preparing the same, and a backlight unit including the color conversion film.

Owner:LG CHEM LTD

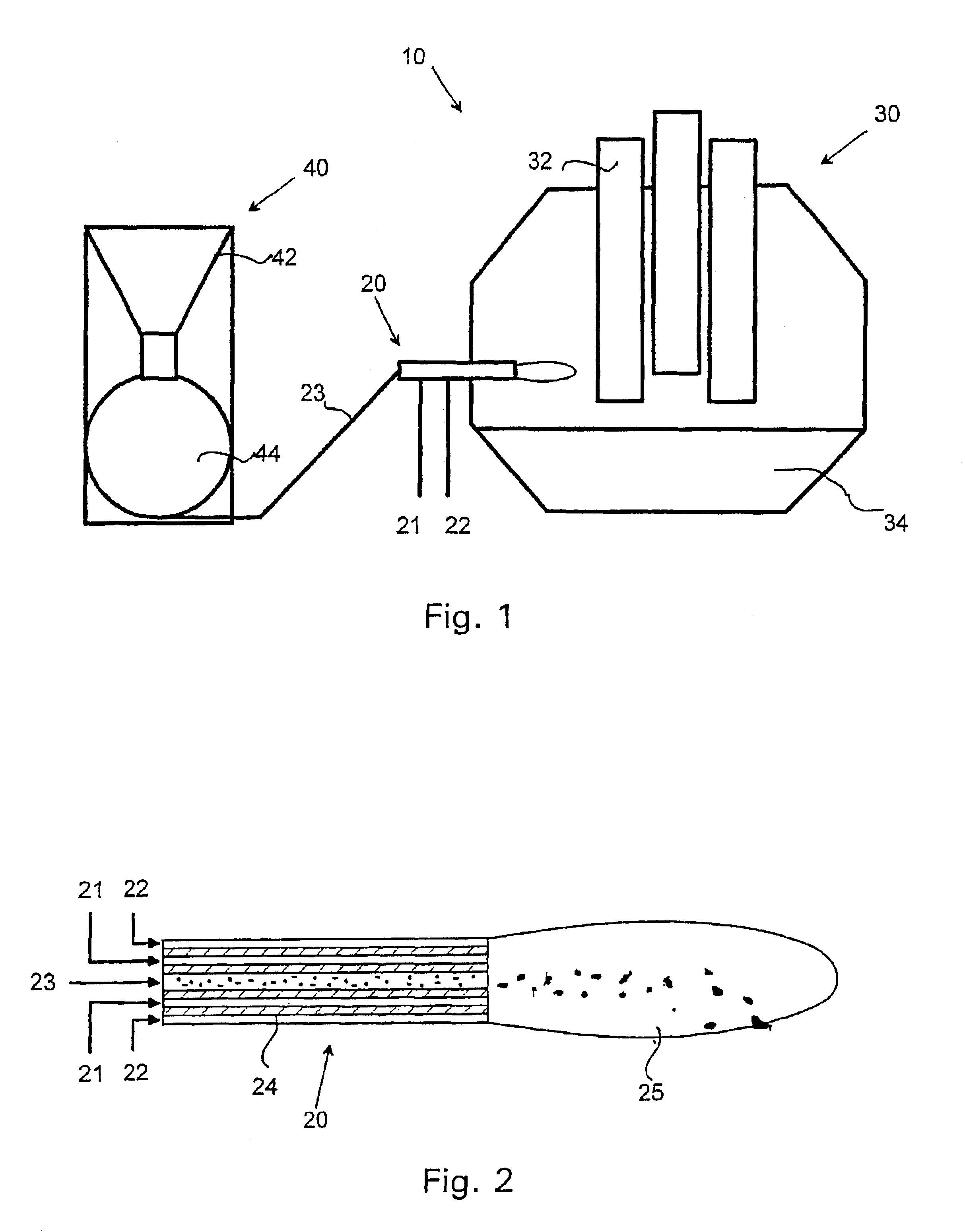

Method and an apparatus for recovery of metals

InactiveUS6989043B2Avoid burnPrevent oxidationProcess efficiency improvementChemical compositionMetal

A method for recovery of metals from essentially metallic fines comprises the following steps: supplying said essentially metallic fines to a flame of a burner (20), bringing said fines to agglomerate by means of heat from the flame without essentially changing the chemical composition thereof, thereby providing an essentially metallic agglomerated product. The agglomerated product is subsequently recovered, preferably in a furnace (30). By means of the method, the recovery of metals is facilitated. An apparatus for performing the method is also provided.

Owner:AGA AB

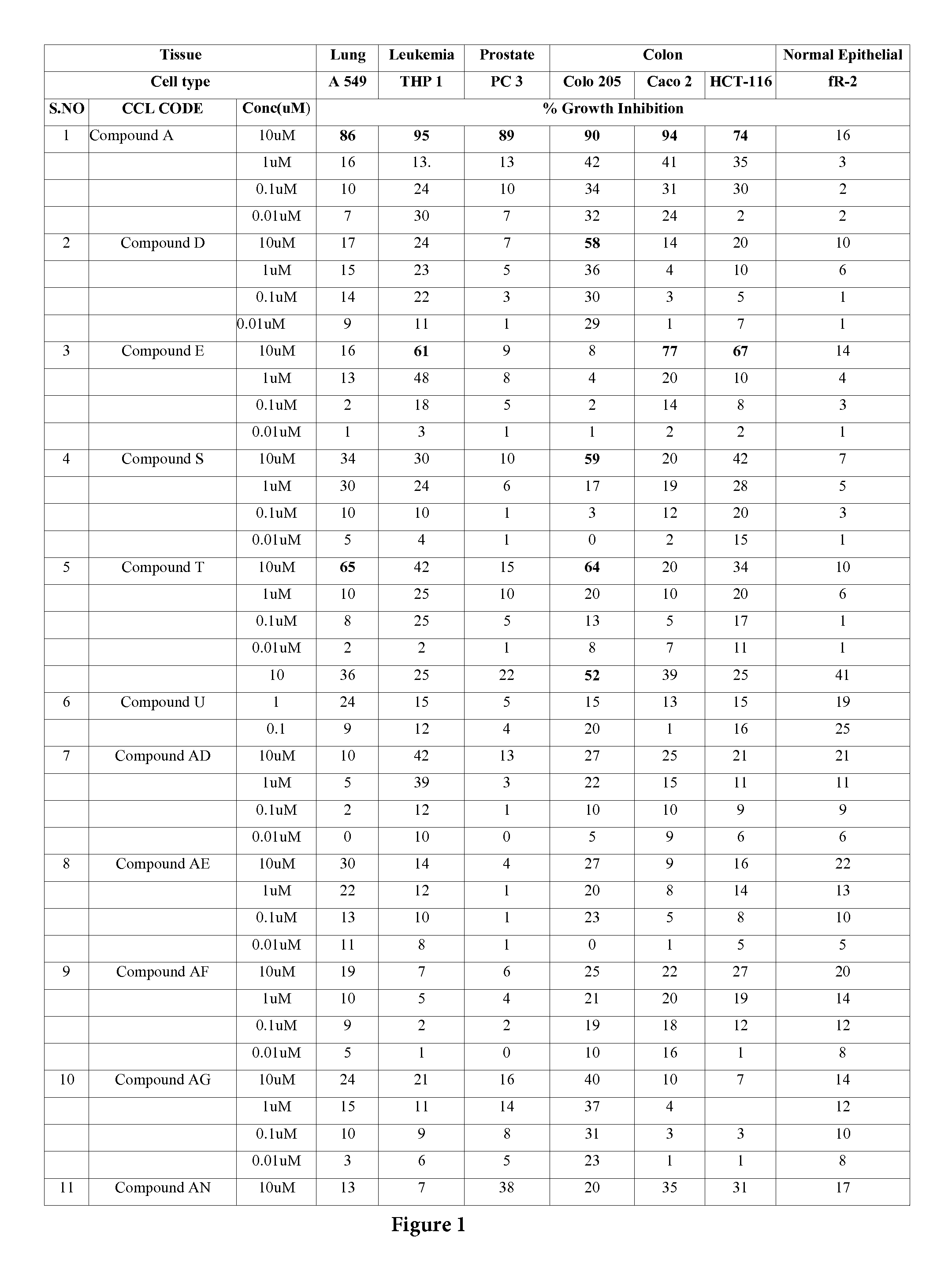

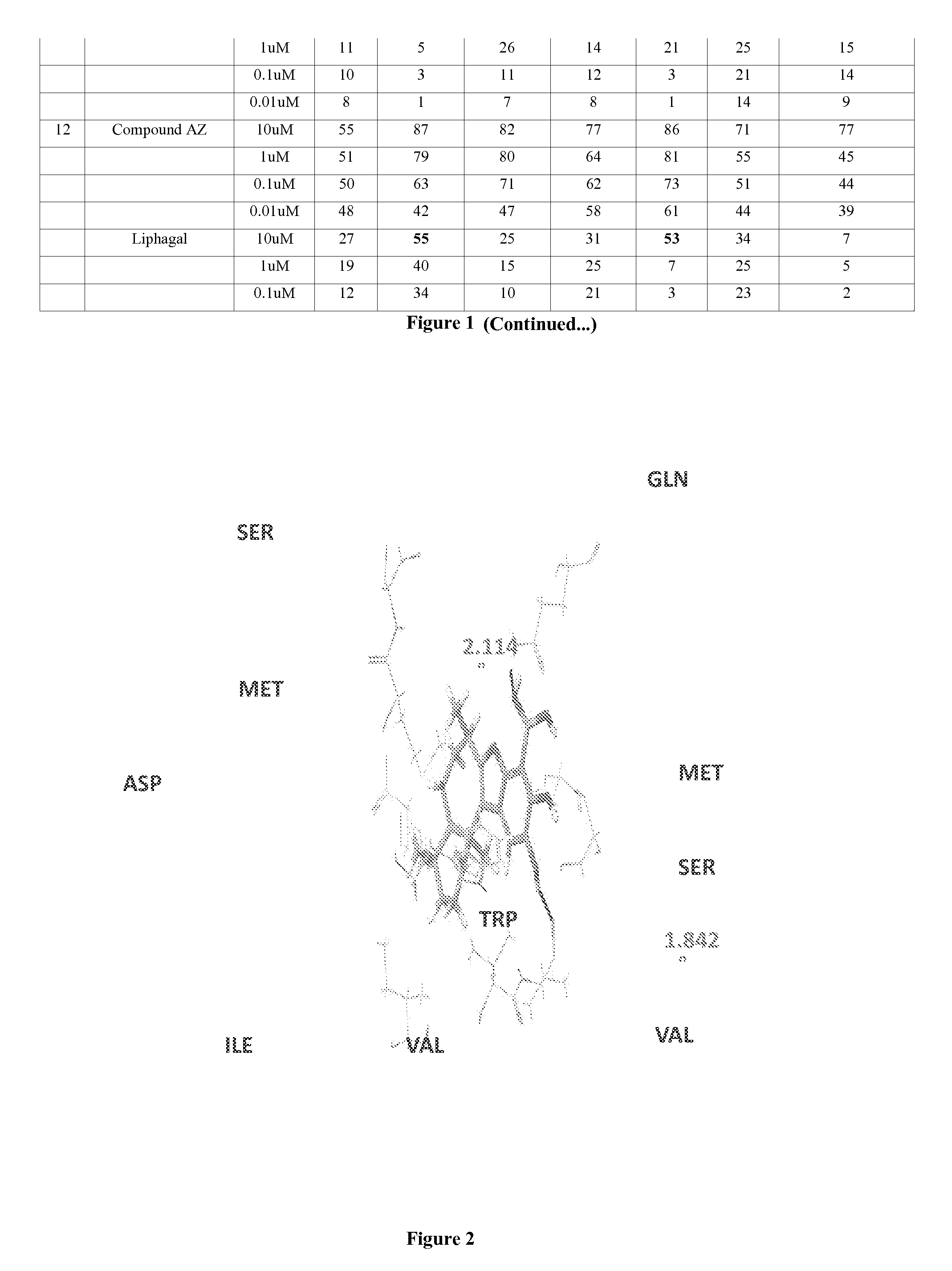

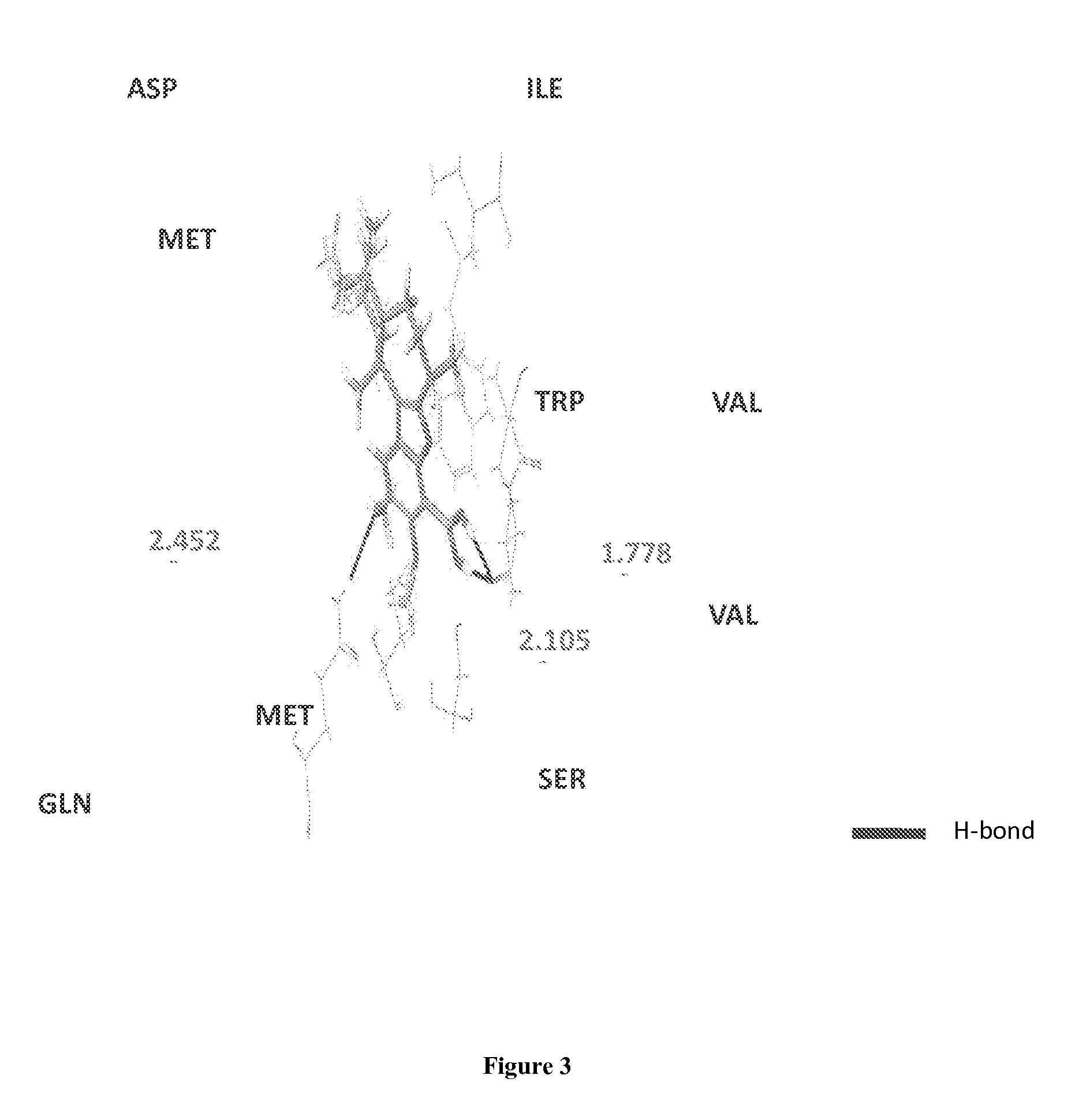

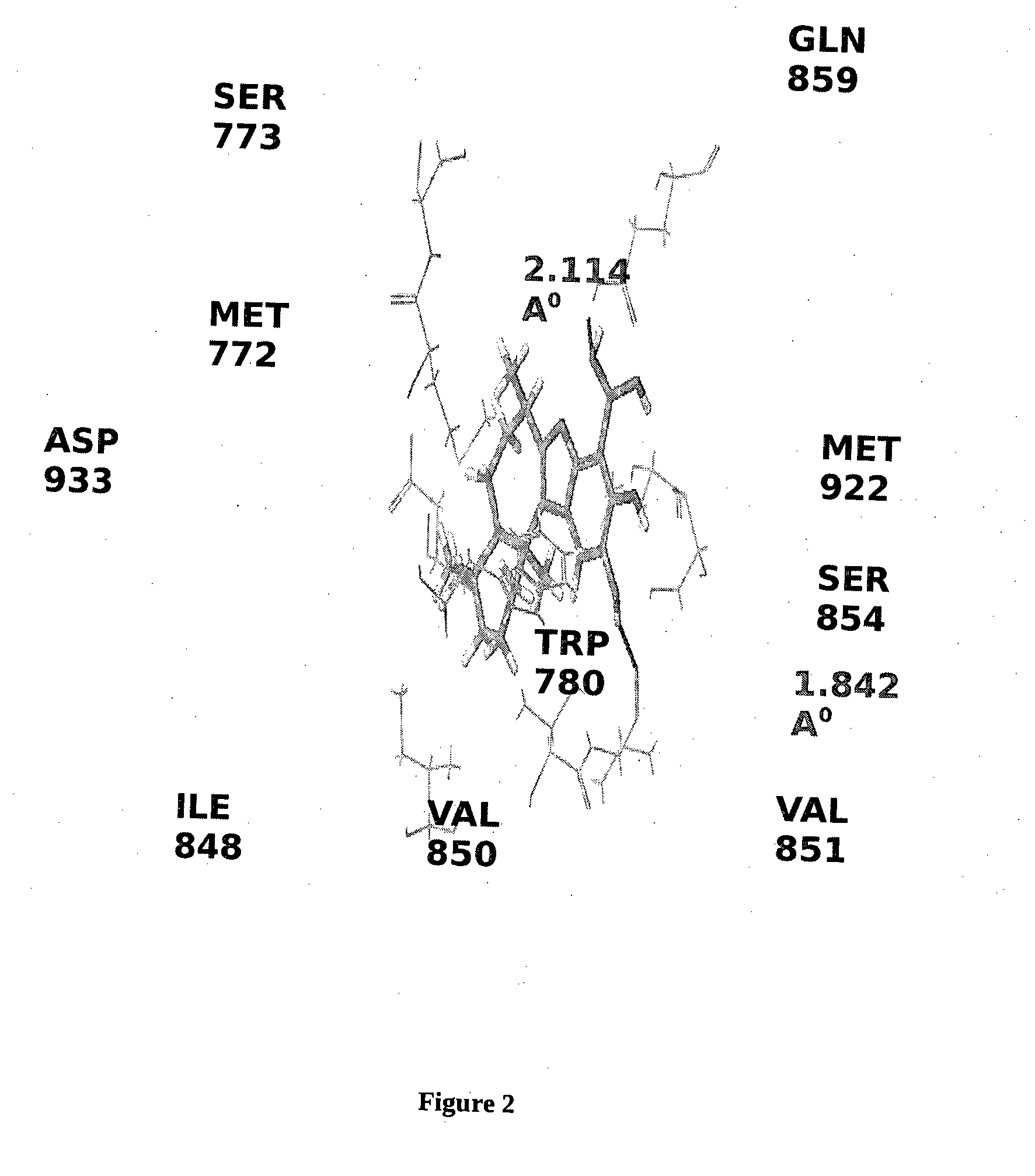

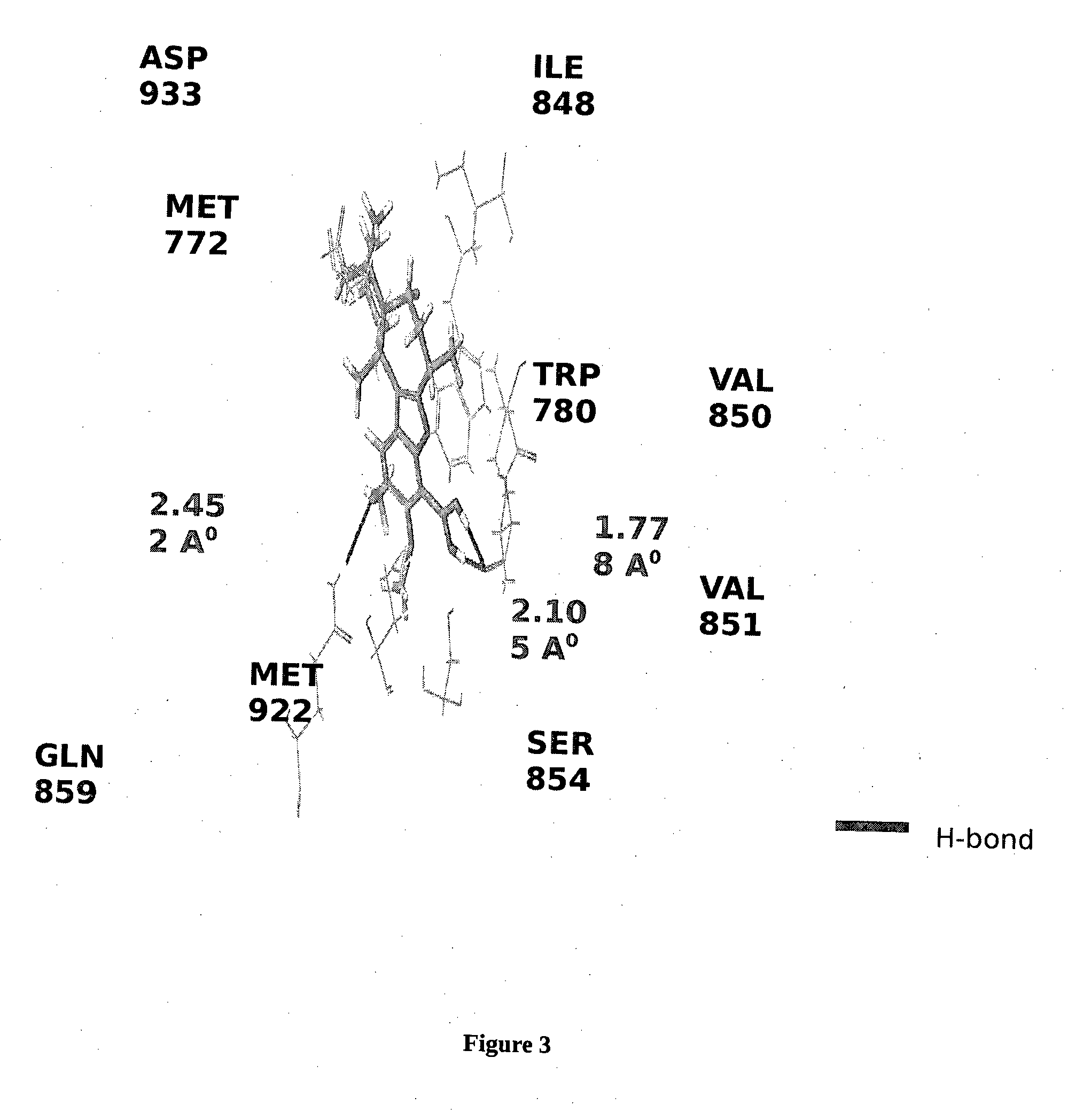

Boronic acid bearing liphagane compounds as inhibitors of P13K-α and/or β

ActiveUS9206201B2Great chemical structure stabilityExcess rigidityBoron compound active ingredientsGroup 3/13 element organic compoundsAnticarcinogenBoronic acid

Owner:COUNCIL OF SCI & IND RES

BORONIC ACID BEARING LIPHAGANE COMPOUNDS AS INHIBITORS OF P13K- a AND/OR B

ActiveUS20150051173A1Great chemical structure stabilityExcess rigidityBiocideBoron compound active ingredientsPhosphoric acidBoronic acid

Compounds with unique liphagane meroterpenoid scaffold having boronic acid functionality in the skeleton are described (formula 1) together with pharmacological potential of these compounds as anticancer agents. A method of preparation and inhibiting the activity of phosphoinositide-3-kinase (PI3K-alpha and beta) has been presented. In particular, the invention describes a method of inhibiting PI3K isoforms, wherein the compounds are novel structures based on liphagane scaffold with unique boronic acid functionality. The methods and uses thereof are described herein this invention.

Owner:COUNCIL OF SCI & IND RES

Liquid composition

ActiveUS10549344B2Improve conductivityReducing atmosphereOrganic chemistryTransportation and packagingMicron scaleOrganic acid

A liquid composition includes copper particles, an organic acid, and a solvent. The copper particle has a particle size of 0.5 μm˜30 μm which falls in a micron scale. The liquid composition performs reaction sintering by redox reactions taken place between the copper particles and an organic acid solution at a low temperature of 150° C. in order to produce a dense copper layer and improve the conventional micron-scale copper particles that requires a protective atmosphere for the high-temperature sintering before achieving the required densification. This liquid composition also prevents an excessive oxidation of the nano copper particles during the low-temperature sintering process and a failure of the dense sintering. Due to the agglomeration of nano copper particles, some areas have to be sintered first, so that the sintered products have a good uniformity of tissue and a low resistance below 0.04 ohm per square (Ω / □).

Owner:SHENMAO TECH

Liquid composition

ActiveUS20190054525A1Improve sintering efficiencyImprove structural compactnessOrganic chemistryTransportation and packagingMicron scaleOrganic acid

A liquid composition includes copper particles, an organic acid, and a solvent. The copper particle has a particle size of 0.5 μm˜30 μm which falls in a micron scale. The liquid composition performs reaction sintering by redox reactions taken place between the copper particles and an organic acid solution at a low temperature of 150° C. in order to produce a dense copper layer and improve the conventional micron-scale copper particles that requires a protective atmosphere for the high-temperature sintering before achieving the required densification. This liquid composition also prevents an excessive oxidation of the nano copper particles during the low-temperature sintering process and a failure of the dense sintering. Due to the agglomeration of nano copper particles, some areas have to be sintered first, so that the sintered products have a good uniformity of tissue and a low resistance below 0.04 ohm per square (Ω / □).

Owner:SHENMAO TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com