Treatment of Green Pellets Using Microwave Energy

a green pellet and microwave energy technology, applied in the field of green pellets containing iron, can solve the problems of micro-cracking or other physical changes in the ore particles, and achieve the effect of facilitating a more complete oxidation of the magnetite ores and reducing processing time and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Batch Testing

[0073]A laboratory sized 1 metre diameter pelletizing disc was used for the production of green pellets. The pelletizing disc was operated at approximately 30 rpm at a disc angle of 45 degrees to the horizontal. Green pellets were produced with varying binder types, namely bentonite and an organic binder produced by Lamberti under the proprietary name Carbocel. The organic binder was preferred as the silica content of the bentonite (29-52%) was considered to be too high as it marginally increases the overall pellet SiO2 content and subsequently reduces iron grade. An additional advantage of using an organic binder is its ability to reduce during the heating a curing process, thereby producing a more porous pellet suitable for DRI or blast furnace applications as well as assisting in oxidation within the microwave process.

[0074]The green pellets were screened for fines removal and sized by hand (>15 mm pellets returned as feed material). Selected pellets were subjected t...

example 2

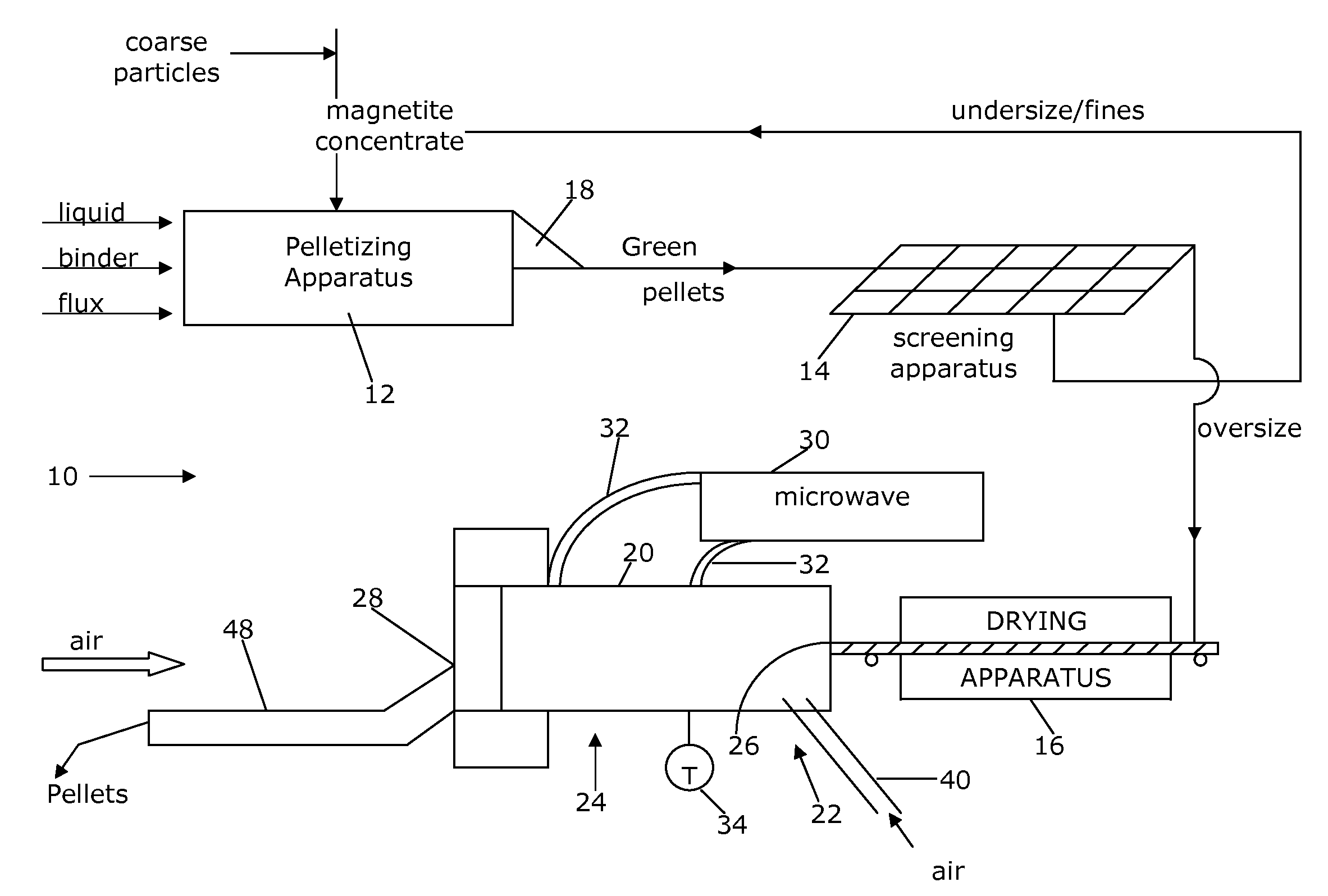

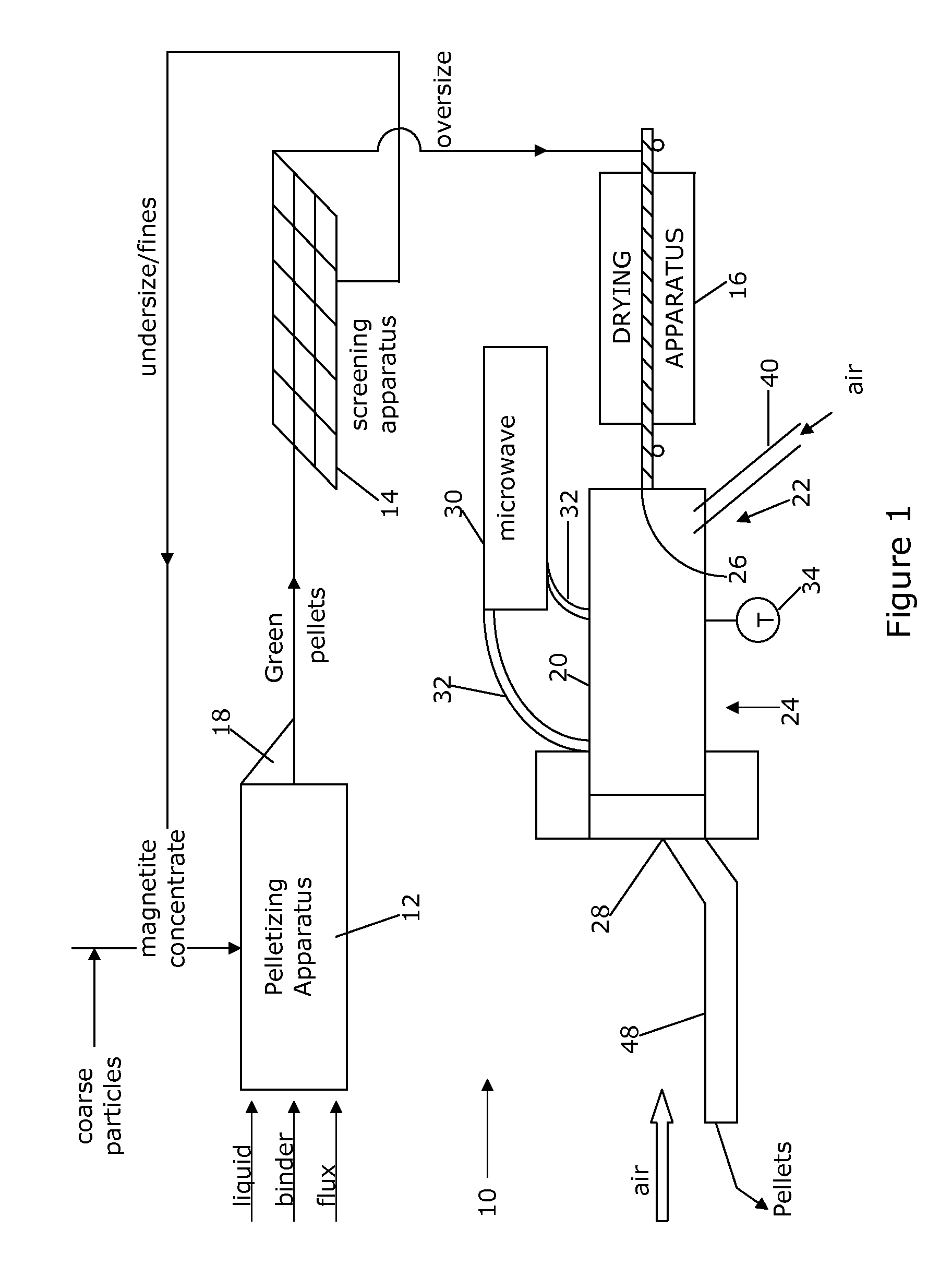

[0091]A rotary kiln was used for continuous testing using a 100 mm internal rotating kiln tube approximately 1.5 metre long with variable speed drive and 6 internal 8 mm×8 mm lifters. The kiln tube was constructed of stainless steel / nickel alloy to withstand the high temperatures (˜1150° C.) with external cladding for heat recovery. The rotary kiln had an adjustable kiln angle with microwave chokes incorporated on both feed and discharge ends to limit microwave radiation. The feed and discharge ends of the kiln were supported and guided using an external bearing arrangement. Microwave power was supplied to the furnace using a 5 kW 2.45 GHz microwave generator with the microwaves being introduced into the kiln via aluminium waveguides (62 mm wide×30 mm high). The waveguides were arranged to allow the option of introducing microwaves into the kiln from either feed or discharge ends or both. The kiln was further fitted with a variable speed vibratory feeder for pellet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com