Method of fabricating rare-earth sintered magnet and method of fabricating rare-earth bonded magnet

a rare earth sintered magnet and bonding technology, applied in the field of rare earth sintered magnet and method of fabricating rare earth bonding magnet, can solve the problems of insufficient magnetic characteristics, inability to use the compound in bulk form, and produced temperature difference between, so as to achieve excellent magnetic characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

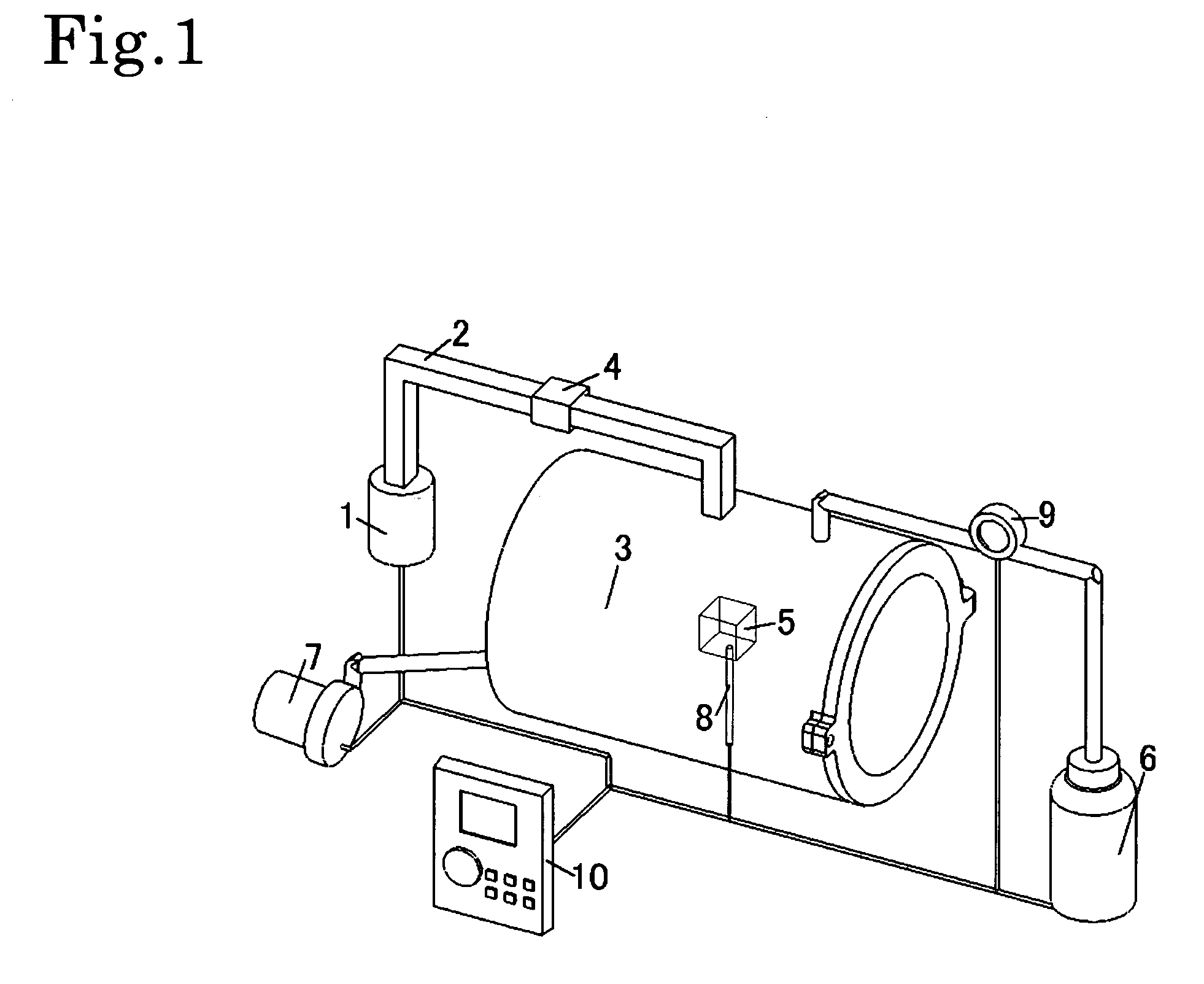

[0029]FIG. 1 is a schematic perspective view of equipment for implementing a method of fabricating a magnet in accordance with one embodiment of the present invention. The equipment includes a microwave-generating tube 1 producing microwaves. The tube 1 is connected with an applicator 3 via a waveguide 2. The microwaves generated by the microwave-generating tube 1 are transmitted to the applicator 3 through the waveguide 2. An isolator 4 is mounted in the waveguide 2. The isolator 4 transmits the microwaves in the waveguide 2 only toward the applicator 3, and absorbs microwaves transmitted in the reverse direction.

[0030]A sample 5 is placed within the applicator 3 and irradiated with the microwaves. The applicator 3 is a closed metal container and designed to prevent leakage of the microwaves to the outside. A gas supply source 6 for introducing an inert gas such as nitrogen is connected with the applicator 3. Furthermore, a pump 7 for venting the internal ambient is connected with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Frequency | aaaaa | aaaaa |

| Frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com