System for Protecting an Inner Wall of a Combustor

a technology of combustor and inner wall, which is applied in the direction of efficient propulsion technology, machines/engines, light and heating apparatus, etc., can solve the problems of unsatisfactory consumption/depletion, costly repairs and replacements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019]Certain embodiments commensurate in scope with the originally claimed invention are summarized below. These embodiments are not intended to limit the scope of the claimed invention, but rather these embodiments are intended only to provide a brief summary of possible forms of the invention. Indeed, the invention may encompass a variety of forms that may be similar to or different from the embodiments set forth below.

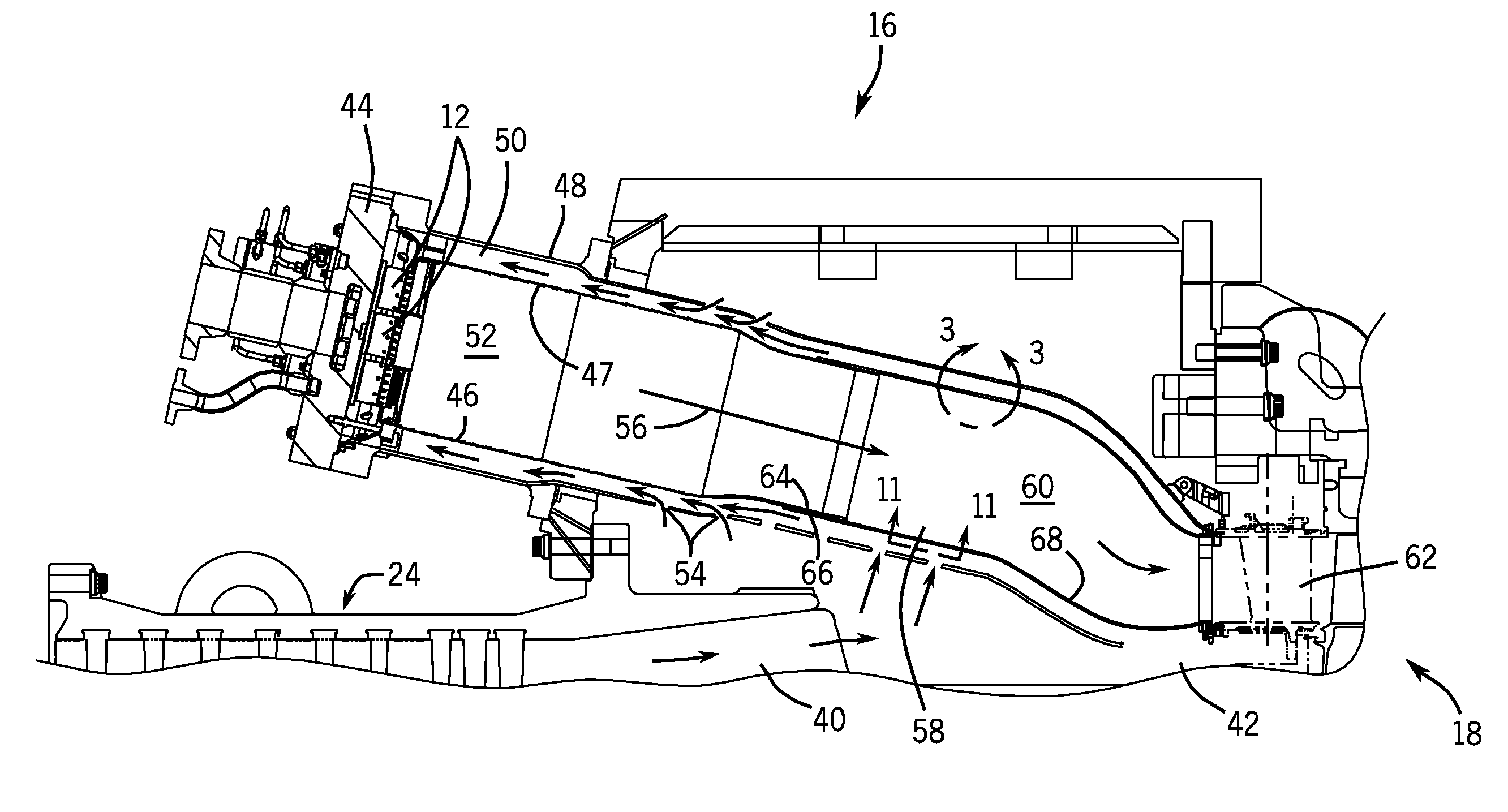

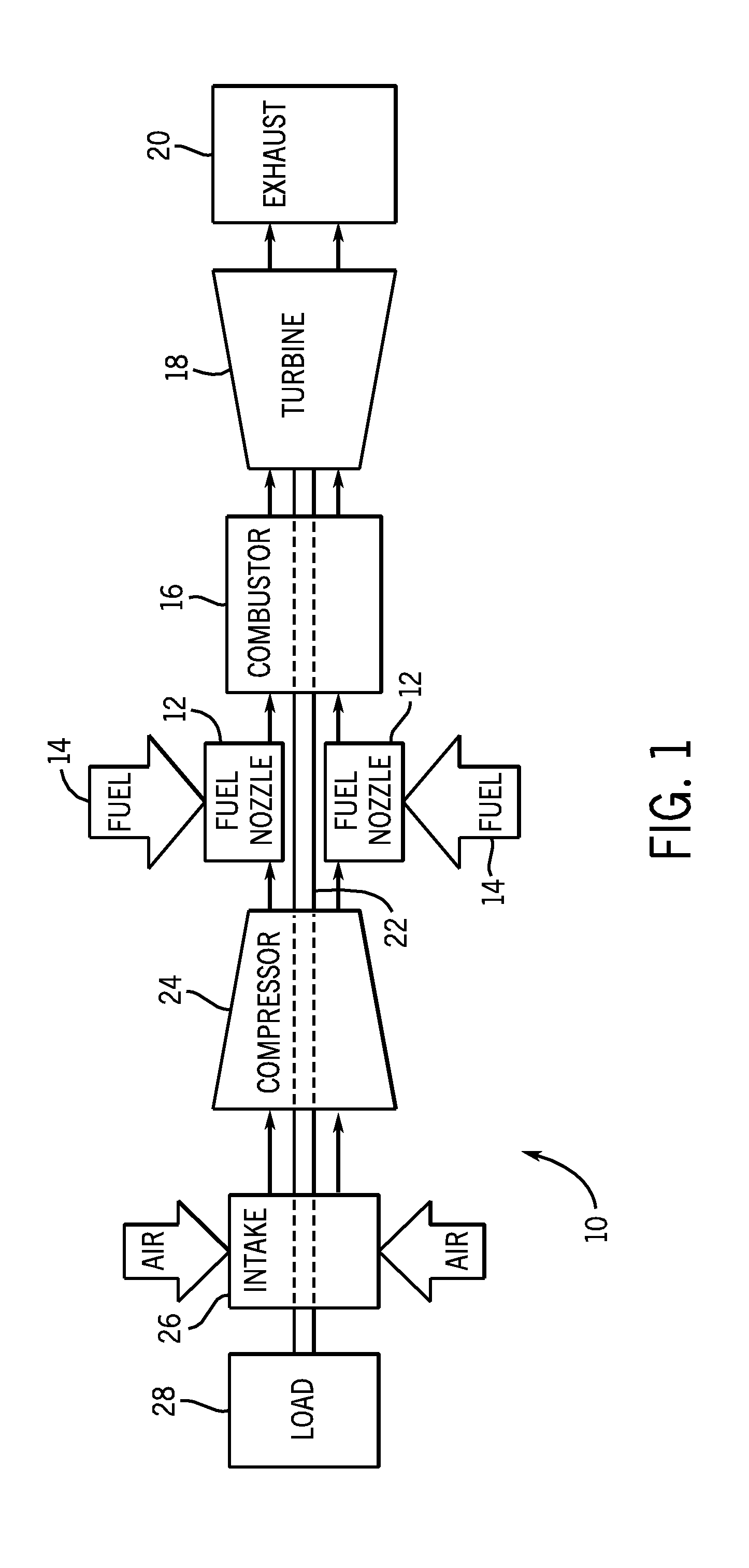

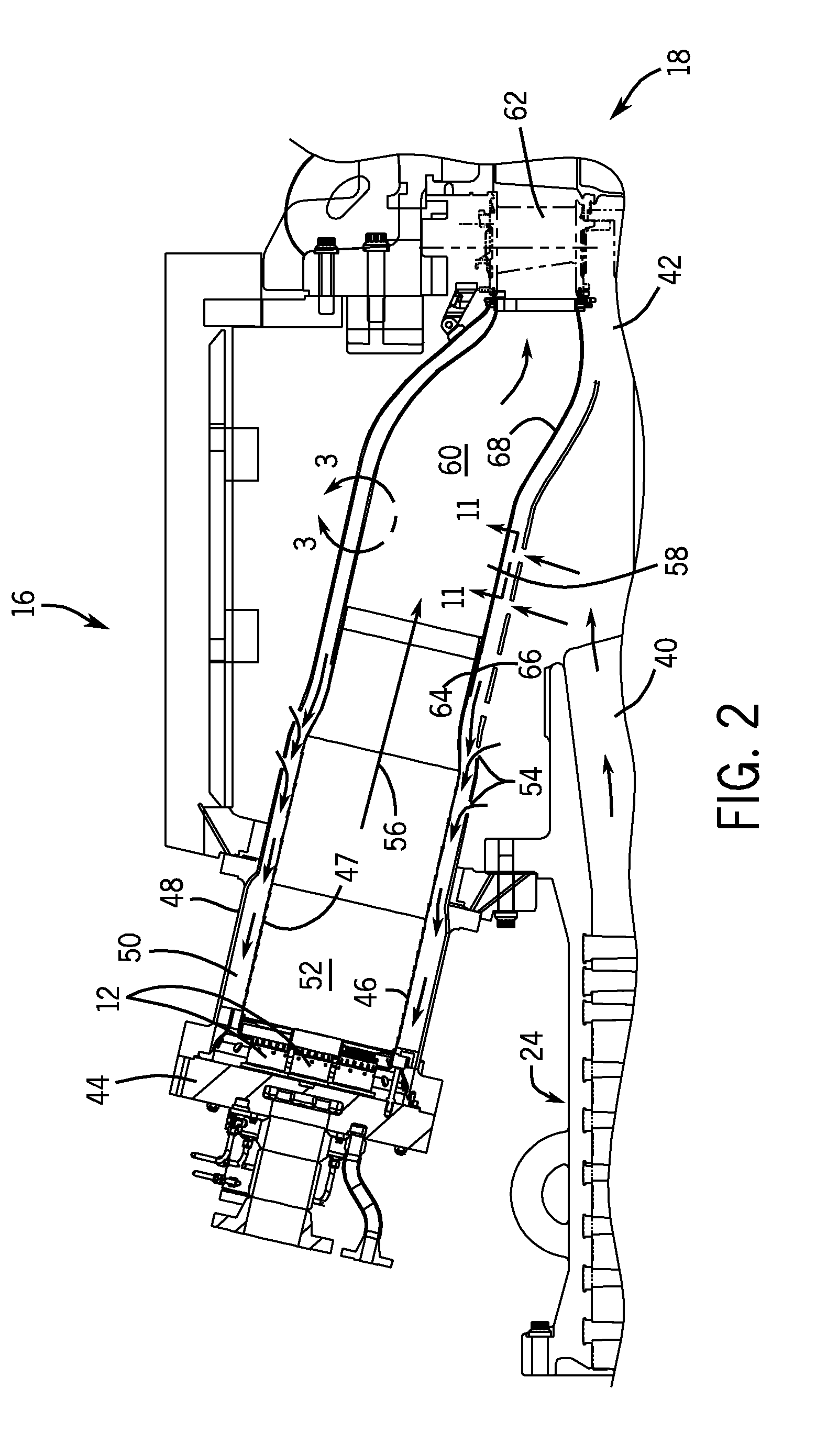

[0020]The disclosed embodiments are generally directed towards a system for protecting an inner wall of a combustor. More specifically, the disclosed embodiments are directed towards an oxidation initiated effusion cooling system, a thermal barrier coating spallation initiated effusion cooling system, or a combination thereof. These systems enable a cooling airflow or protective film to cover the inner wall of the combustor, thereby blocking the hot combustion gases from oxidizing (e.g., depleting, consuming, etc.) the combustor wall. For example, the oxidation ini...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com