Low-density foamed thermoplastic polyurethane elastic body and preparation process thereof

A plastic polyurethane and preparation technology, which is applied in the field of low-density foamed thermoplastic polyurethane elastomer and its preparation, can solve problems such as blanks, and achieve the effect of increasing the mixing effect, high tensile force, and high tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

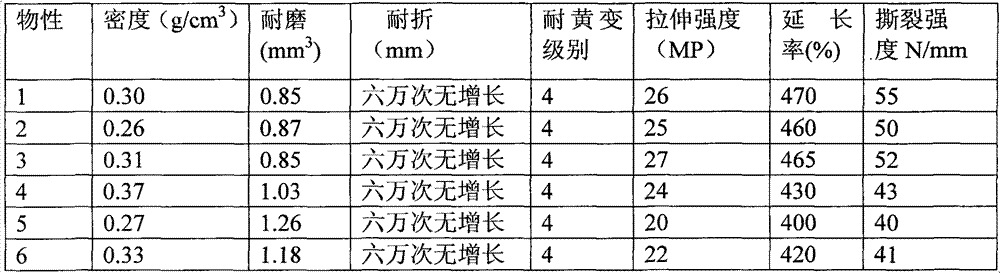

Embodiment 1

[0026] The low-density expanded thermoplastic polyurethane elastomer of the present embodiment comprises the raw material of following weight ratio:

[0027] Macromolecular polyol: chain extender: isocyanate: azo foaming agent = 50:10:40:5;

[0028] The isocyanate is diphenylmethane diisocyanate, the azo foaming agent is azodicarbonamide, the macromolecular polyol is polyester polyol, synthesized from adipic acid and diethylene glycol, and the hydroxyl value is 56±3mgKOH / g , the acid value is 0.1-0.3mgKOH / g, the chain extender is ethylene glycol, and the density of low-density foamed thermoplastic polyurethane elastomer is 0.3g / cm 3 , the corresponding hardness is 55 degrees Shore A, the tensile strength of the low-density foamed thermoplastic polyurethane elastomer is 26MP, and the tear strength is 55N / mm.

Embodiment 2

[0030] The difference between this embodiment and embodiment 1 is: comprise the raw material of following weight ratio:

[0031] Isocyanate: macromolecular polyol: chain extender: azo foaming agent = 60:8:32:6;

[0032] The isocyanate is a mixture of hexamethylene diisocyanate and toluene diisocyanate. The azo foaming agent is 2,2-azobisisobutyronitrile. The macromolecular polyol is ethylene oxide polyether polyol. The value is 110±3mgKOH / g, the acid value is 0-0.10mgKOH / g, the chain extender is propylene glycol, and the density of low-density foamed thermoplastic polyurethane elastomer is 0.26g / cm 3 , the corresponding hardness is Shore A type 75 degrees; the tensile strength of low-density foamed thermoplastic polyurethane elastomer is 25MP, and the tear strength is 50N / mm;

Embodiment 3

[0034] The difference between this embodiment and embodiment 1 is: comprise the raw material of following weight ratio:

[0035] Isocyanate: macromolecular polyol: chain extender: azo foaming agent = 55:9:37:5;

[0036] The isocyanate is a mixture of diphenylmethane diisocyanate, hexamethylene diisocyanate and toluene diisocyanate. The azo foaming agent is diisopropyl azodicarboxylate. The macromolecular polyol is polyester polyol. Synthesized from adipic acid and diethylene glycol, the hydroxyl value is 56±3mgKOH / g, the acid value is 0.1-0.3mgKOH / g, the chain extender is butylene glycol, and the density of the low-density foamed thermoplastic polyurethane elastomer is 0.31g / cm 3 , the corresponding hardness is Shore A type 65 degrees, the tensile strength of the low-density foamed thermoplastic polyurethane elastomer is 27MP, and the tear strength is 52N / mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com