Continuous cladding method and device of obtuse angle flowing channel

A technology of flow channels and obtuse angles, which is applied in the field of continuous coating and coating equipment of obtuse angle flow channels, and can solve the problems of high temperature and large extrusion force of blocking blocks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

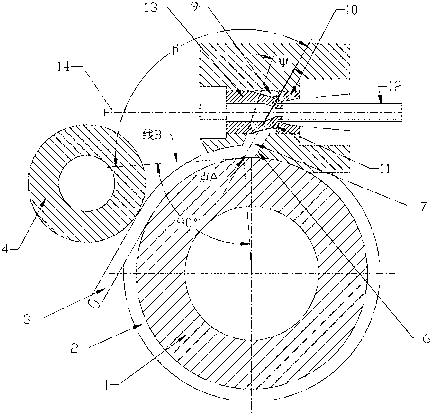

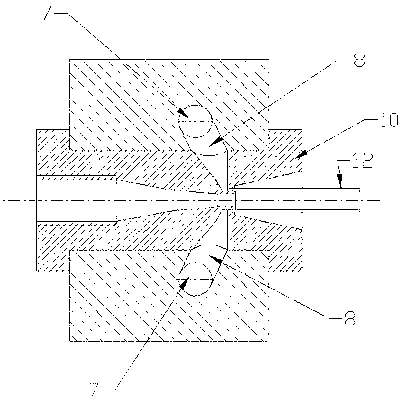

[0024] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the continuous coating method of the obtuse angle flow channel, the rotating extrusion wheel 1 has grooves 2 in the circumferential direction, the billet 3 is pressed down by the compacting wheel 4, and the friction between the billet 3 and the groove 2 of the extrusion wheel Driven by force, when the blank 3 advances to the block 6, it enters the feed hole 7 of the extrusion cavity. At the end of the feed hole 7, there is a metal flow channel 8 at an obtuse angle greater than 95° with the center line of the mold. When the metal flows The end of the channel 8 is an overmolded metal cavity 9, a metal flow rate shunt 11 is installed in front of the die 10, the product 12 is extruded through the annular gap formed by the die 10 and the punch 13, and the core wire 14 passes through the punch 13. Penetrate and extrude the cladding metal to form a cladding layer outside the core wire; figure 1 Among them, poi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com