High-flame-retardant low-gloss dynamically vulcanized thermoplastic elastomer material and continuous preparation method thereof

A thermoplastic elastomer, dynamic vulcanization technology, applied in the field of polymer material synthesis and processing, can solve the problems of complicated preparation process, and achieve the effect of simplifying preparation process, convenient processing, and improving impact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4 and comparative example 1-2

[0109] According to the above-mentioned preparation method of high flame-retardant and low-gloss dynamically vulcanized thermoplastic elastomer material, the materials of Examples 1-4 and Comparative Examples 1-2 were prepared. The specific component ratios and material performance results are shown in Table 2.

[0110] Table 2 embodiment 1-4 and comparative example 1-2 component formula and performance

[0111]

[0112]

[0113]

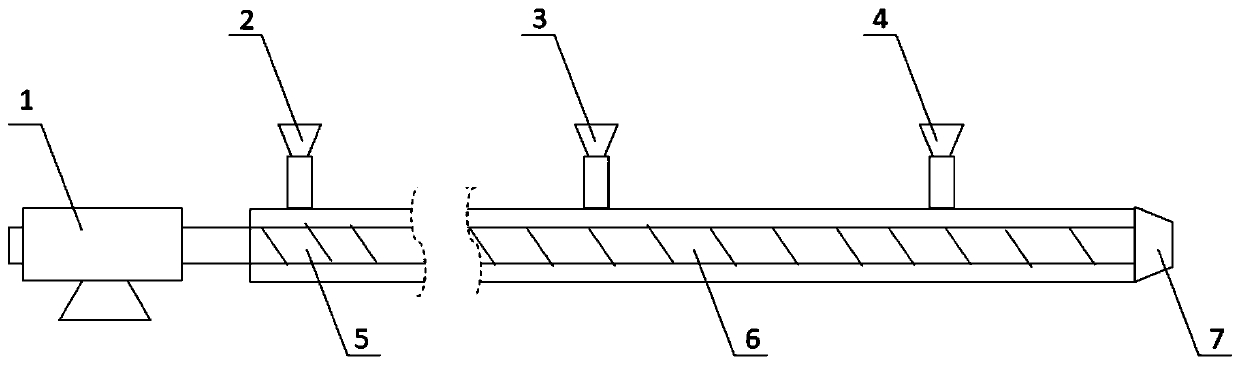

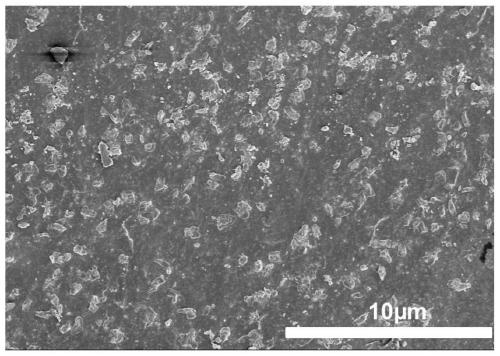

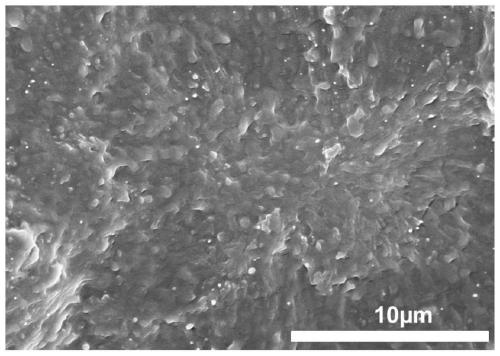

[0114] As shown in Table 2, the ethylene-butylene elastomer with low glass transition temperature used in Examples 1-4 can be successfully used in the preparation of dynamic vulcanized special plastic elastomer as the rubber phase. Figure 2-5 It is the SEM picture of the material of Example 1-4. It can be seen that the rubber phase is evenly distributed in the matrix, the size of the rubber phase is 1-5 μm, and the notched Izod impact performance of the material at room temperature is 35 kJ / m 2 Above, the flexural modulus is above 700MPa, ...

Embodiment 5-10

[0125] According to the preparation method of the above-mentioned high flame-retardant low-gloss dynamic vulcanization thermoplastic elastomer material, the preparation of the materials of Examples 5-10 was completed, and the specific component ratio and material performance results are shown in Table 4.

[0126] Table 4 embodiment 5-10 component formula and performance

[0127]

[0128]

[0129]

[0130] As shown in Examples 5-10, all relevant compositions and formulations can be produced by dynamic vulcanization with high flame retardancy and low gloss performance, excellent flame retardancy and impact resistance, low gloss, simple process and high production efficiency.

[0131] The present invention unexpectedly finds that the selection of ethylene-butene elastomer to replace traditional rubber can effectively simplify the preparation process of dynamically vulcanized thermoplastic elastomer, and the processing and production efficiency is greatly improved. Under ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural modulus | aaaaa | aaaaa |

| Flexural modulus | aaaaa | aaaaa |

| Impact performance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com