Post-grafting device used for silane crosslinking cable production line

A silane cross-linking, production line technology, applied in cable/conductor manufacturing, conductor/cable insulation, circuits, etc., can solve the problems of difficulty in dispersing trace additives, difficult to control side reactions, easy to cause pre-crosslinking, etc. Simple, reduced cable stress, lower extrusion temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

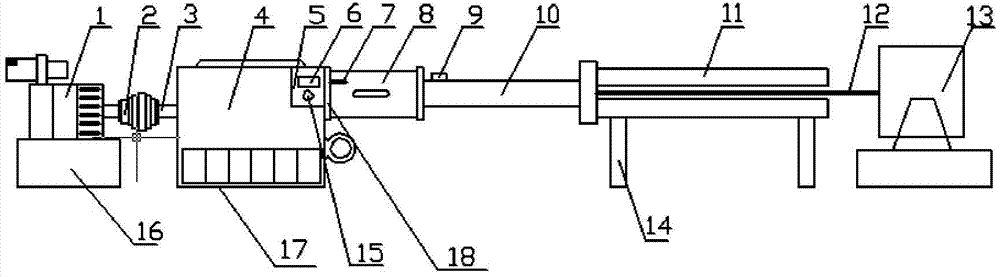

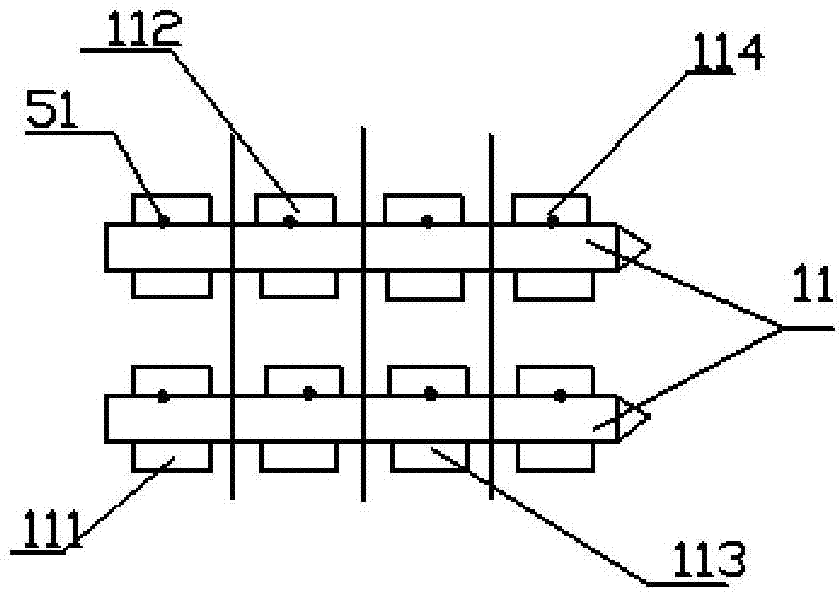

[0026] A post-grafting device for a silane cross-linked cable production line, which consists of an extruder 17, an electric heating post-grafting device 11 and a cable forming machine 13. The extruder is sequentially connected by a speed-regulating motor 1, a coupling shaft from left to right The extruder 2, the reduction box 4, the gearbox 18, the shaft sleeve 8 and the screw barrel 10 are composed of the extruder 17. The electric heating post-grafting device 11 and the cable forming machine 13 are connected to the extruder 17. The outer surface of the reduction box 4 is provided with There is a temperature control operation panel 5, a temperature display screen 6 and a switch 15 are arranged on the operation panel, a temperature detector 7 is arranged on the inner surface of the shaft sleeve 8, a screw is arranged in the screw barrel 10, and the barrel is The body 10 is provided with a heating device 9, and the grafting device 11 after the electric heating is a screw extrude...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com