Low gel content vinylidene fluoride thermoplastic resin, preparation method and applications thereof

A technology of thermoplastic resin and vinylidene fluoride, which is applied in the field of vinylidene fluoride thermoplastic resin with low gel content and its preparation, and can solve the problems of poor thermal stability and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] This embodiment provides a vinylidene fluoride thermoplastic resin with low gel content, and also provides its preparation method.

[0064] Preparation of Vinylidene Fluoride-Based Fluoropolymer A:

[0065] In a 50L stainless steel vertical reaction kettle, add 33.3L of deionized water, blow nitrogen and oxygen three times, evacuate until the oxygen content is less than or equal to 25ppm, add 80g of fluorine-containing compound emulsifier, 400ml of liquid paraffin (liquid at room temperature), and start stirring , the speed is 200rpm, the temperature is raised to 60°C, and vinylidene fluoride monomer is added to 3.5MPa. After the system is stable, 40g of isopropanol is added to the reactor through a metering pump, and 40ml of IPP (dicarbonate peroxide) is added to the reactor after a few minutes. Diisopropyl ester) into the reactor to start the polymerization reaction. At the same time, continuously add mixed monomers to keep the pressure of the reactor at 3.5 MPa unti...

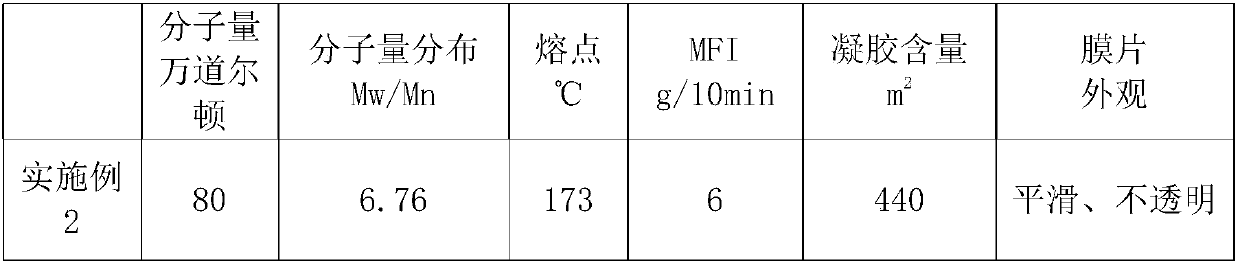

Embodiment 2

[0070] This embodiment provides a low gel content vinylidene fluoride thermoplastic resin, which is prepared from 30Kg of fluoropolymer A and 1.5Kg of fluoropolymer B;

[0071] Wherein, the fluorine-containing polymer A is a homopolymer of vinylidene fluoride; the fluorine-containing polymer B is a PVDF-CTFE polymer emulsion, which contains 95 mol% of vinylidene fluoride and 5 mol% of chlorotrifluoroethylene.

[0072] Fluoropolymer A and Fluoropolymer B are preferably prepared by using Example 1.

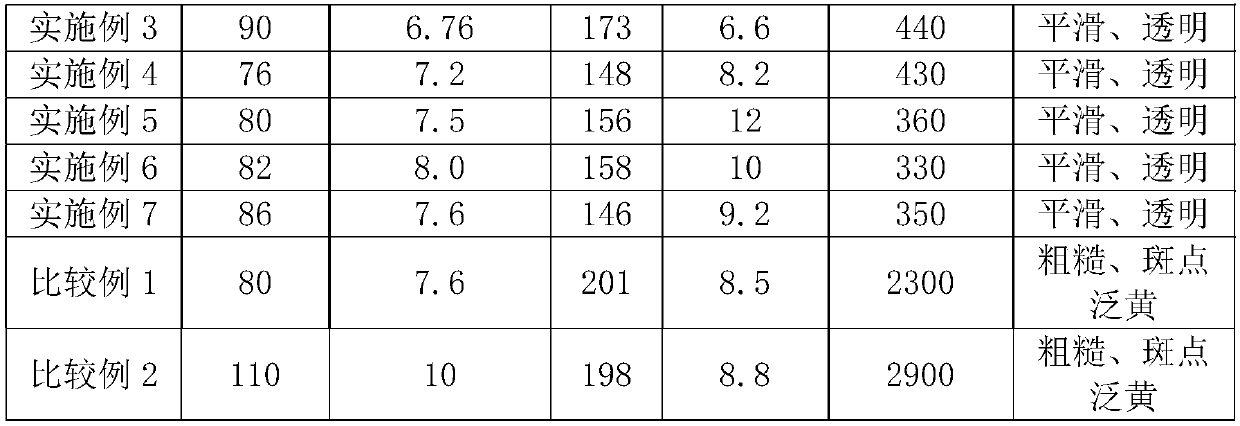

Embodiment 3

[0074] This embodiment provides a low gel content vinylidene fluoride thermoplastic resin, which is prepared from 32Kg of fluoropolymer A and 1.1Kg of fluoropolymer B;

[0075] Wherein, the fluoropolymer A is: PVDF-TFE polymer emulsion, which contains 80mol% vinylidene fluoride and 20mol% tetrafluoroethylene;

[0076] Fluorine-containing polymer B is: PVDF-TFE-HFP polymer emulsion, which contains 70 mol% of vinylidene fluoride, 10 mol% of tetrafluoroethylene and 20 mol% of hexafluoropropylene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com