Patents

Literature

65results about How to "Fast compaction compaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Total-biodegradation plastic film and preparation method thereof

InactiveCN101240086AQuality improvementImprove performanceFlat articlesPlastic filmMechanical property

A full-biodegradable plastic membrane, which uses thermoplastic starch with diameter of 1-9 mu m, biodegradable polymer and auxiliary component as raw material, processed by screw extruding apparatus and membrane producing apparatus. The raw material comprises 30-70 parts by weight of thermoplastic starch with diameter of 1-9 mu m, 10-40 parts by weight of biodegradable polymer, 5-10 parts by weight of compatible modified component, 3-5 parts by weight of complex plasticized component, 10-30 parts by weight of lubricant. These materials are mixed and processed by screw extruding apparatus and membrane producing apparatus, wherein the lubricant is at least adding into other materials for mixture before process by screw extruding apparatus and during melt blending, and the adding amount of lubricant before process by screw extruding apparatus is not more than 1 / 3 of the total amount thereof. By highly increasing dosage of lubricant and changing mixing way, thermoplastic degree of starch is increased, rheological property of the system and processing quality of product are dramatically improved, mechanical property of the product is enhanced.

Owner:上海悦仕生物材料有限公司 +1

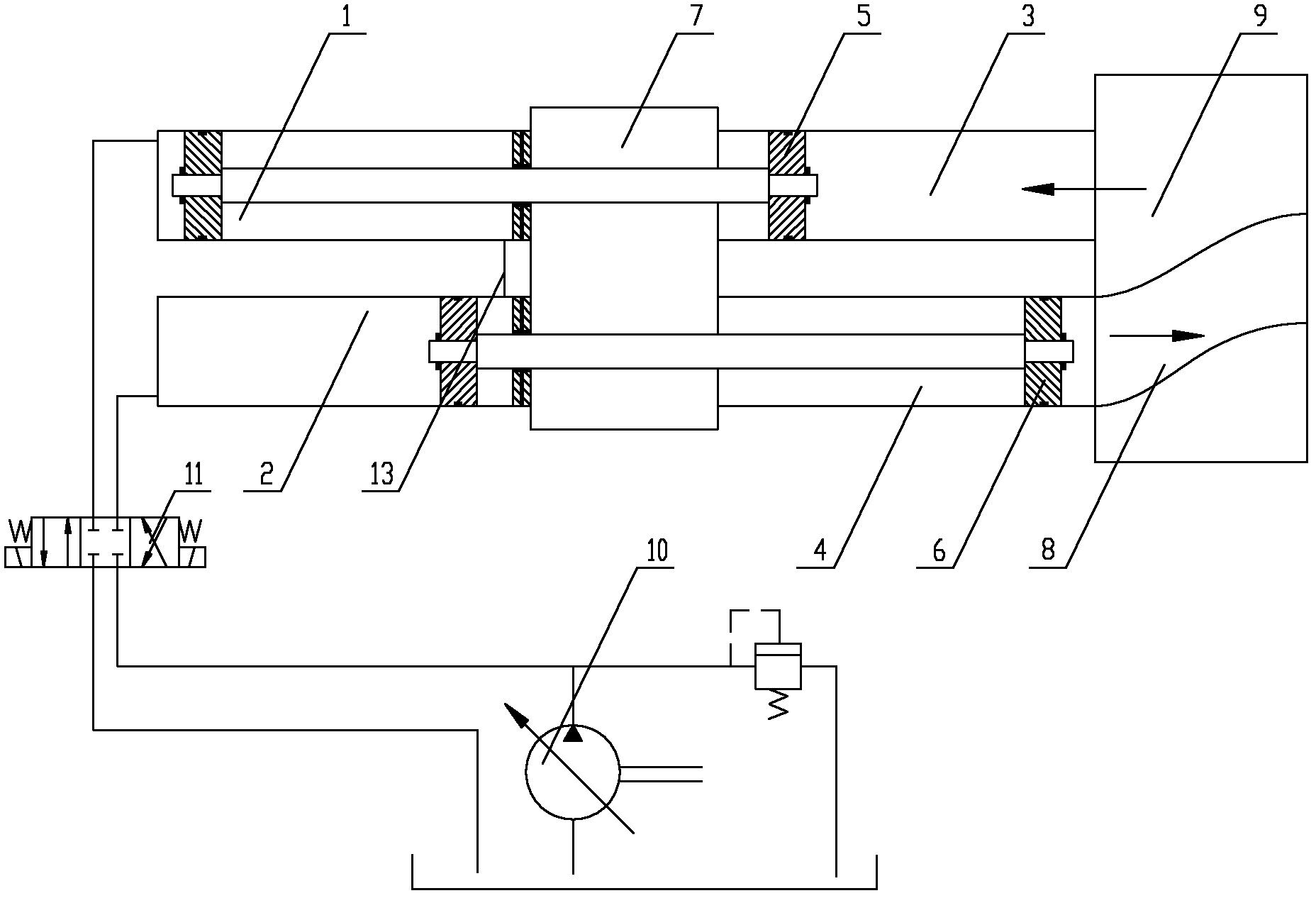

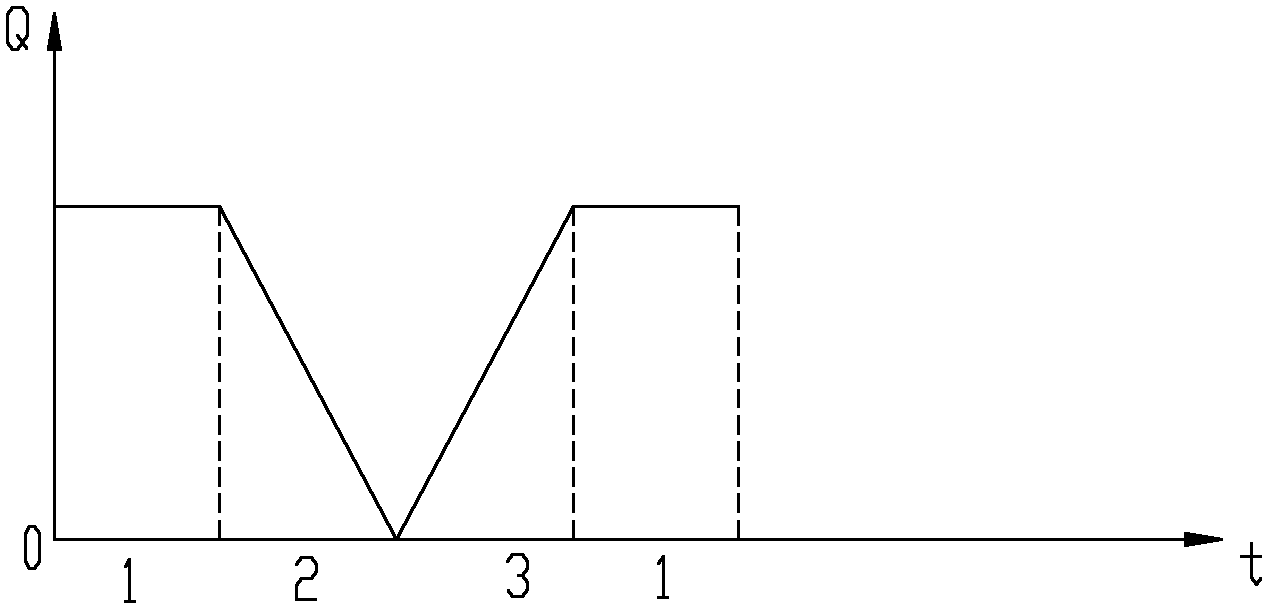

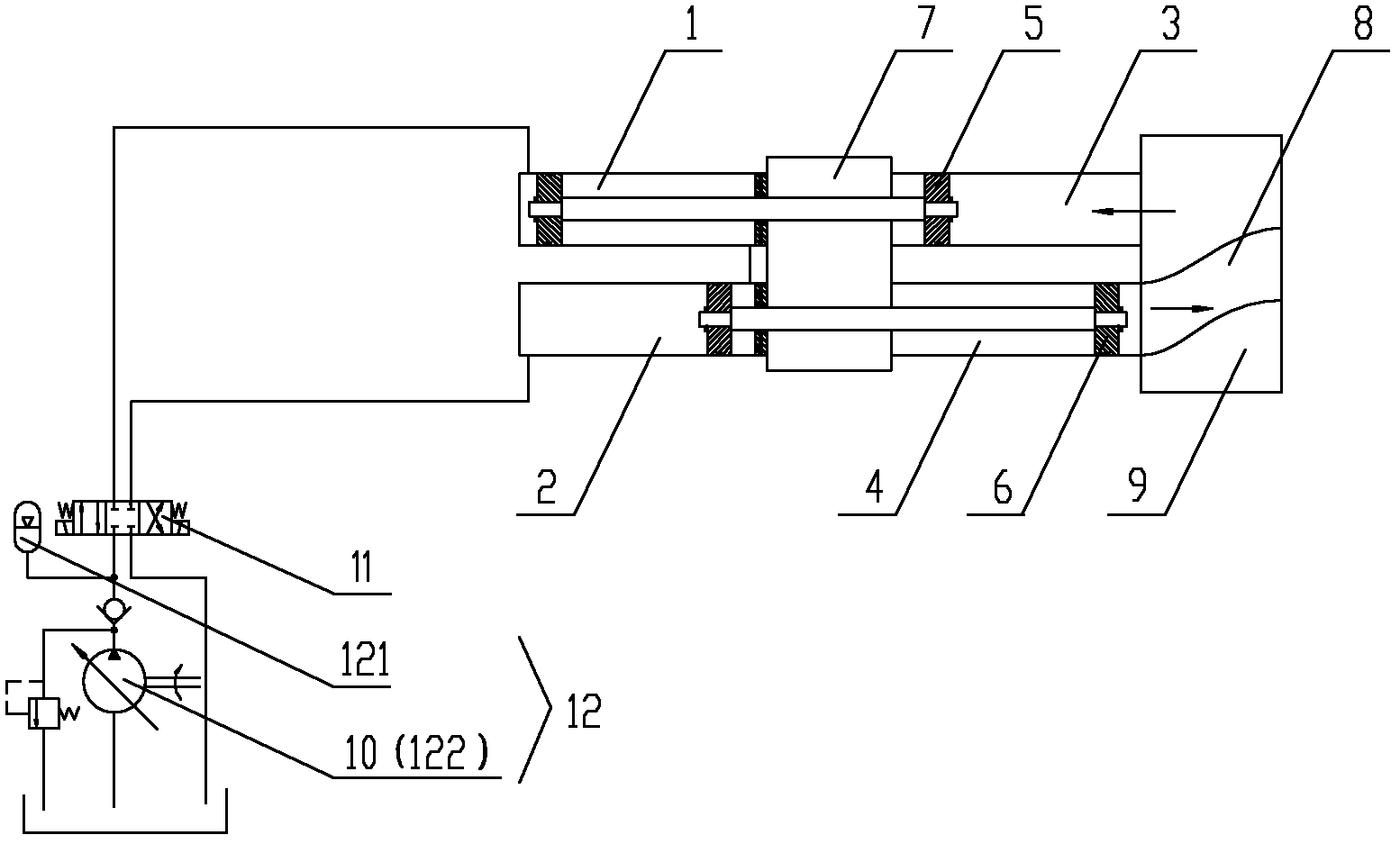

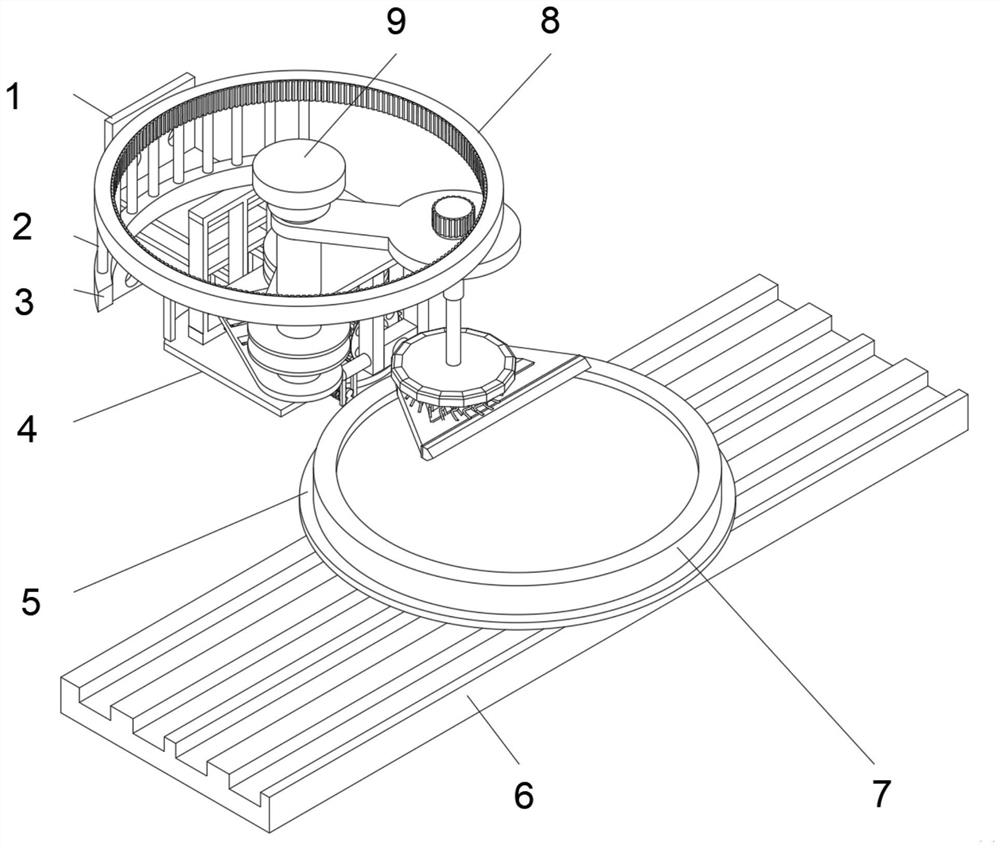

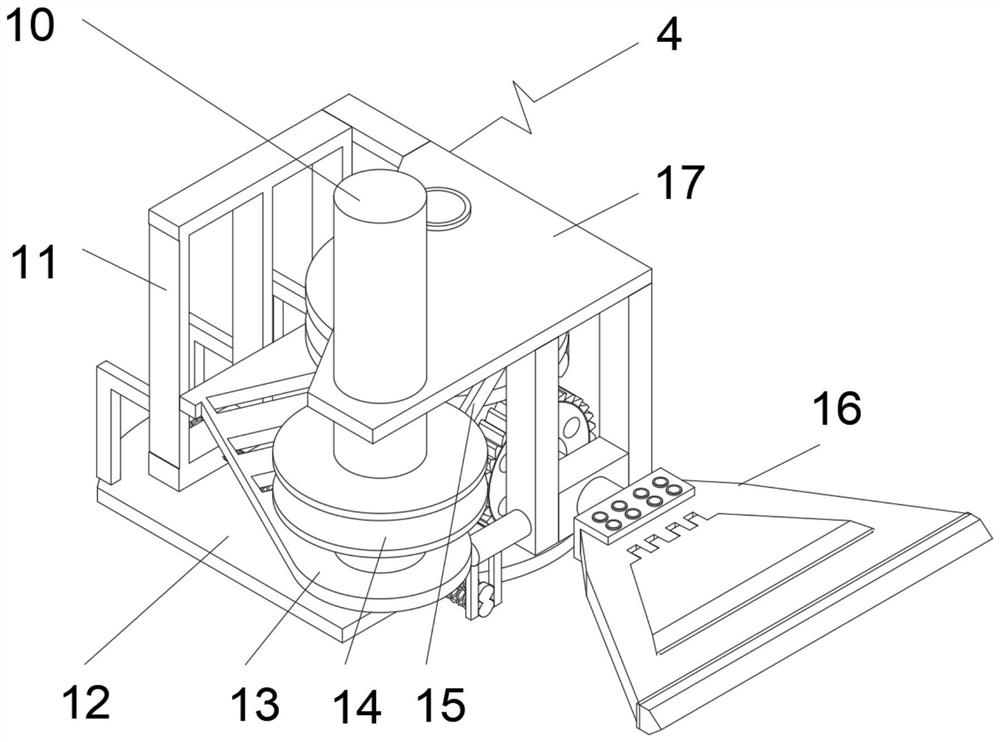

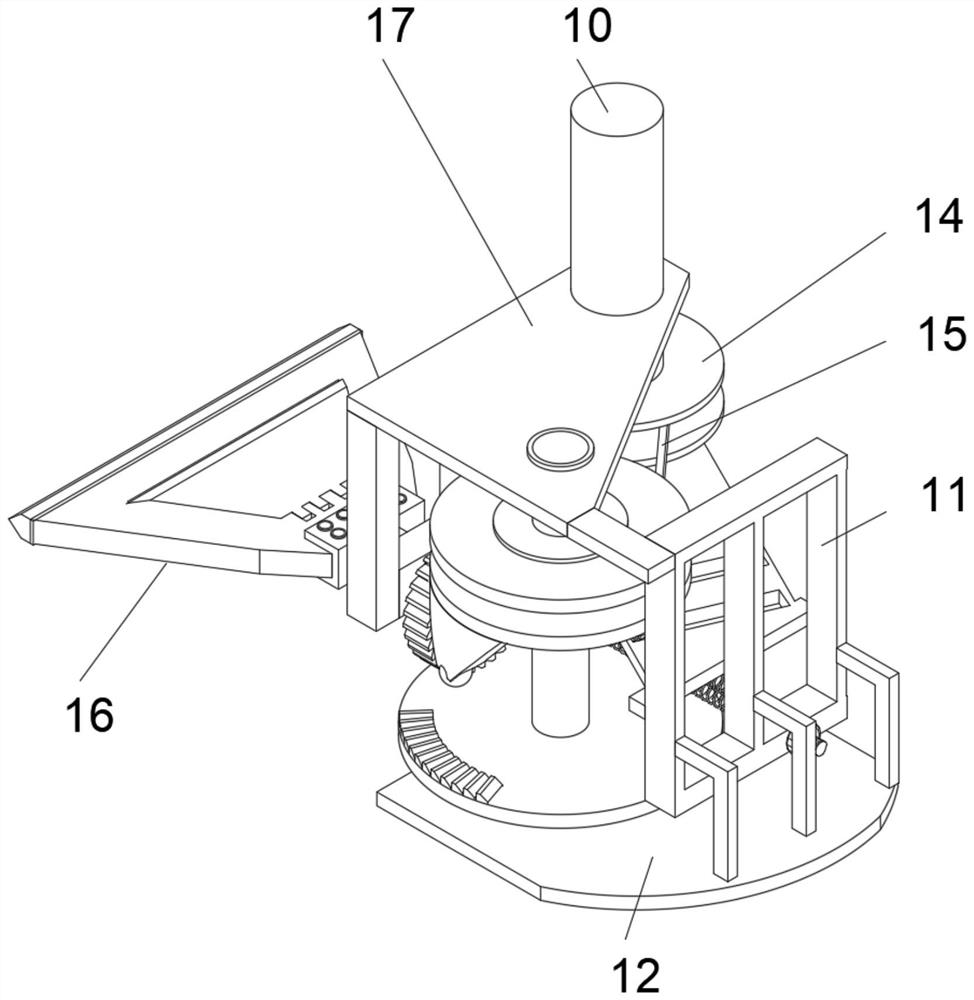

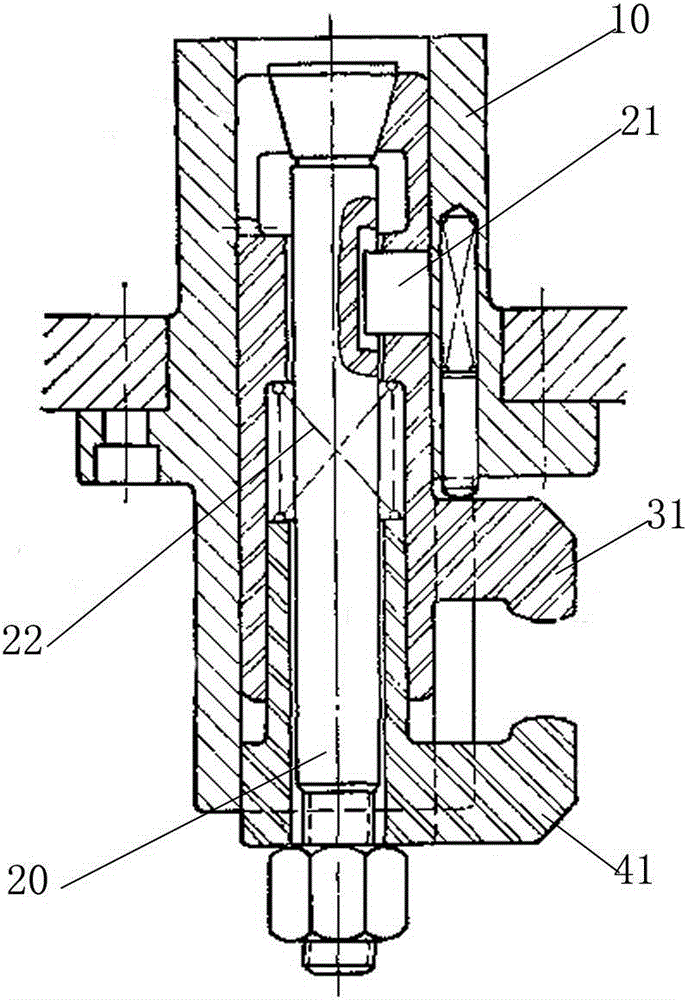

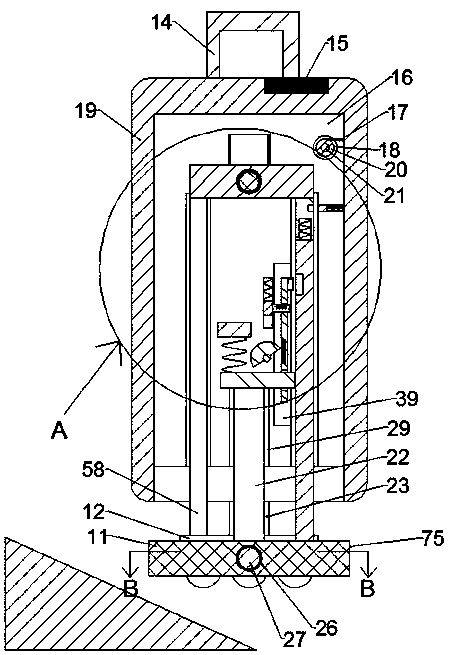

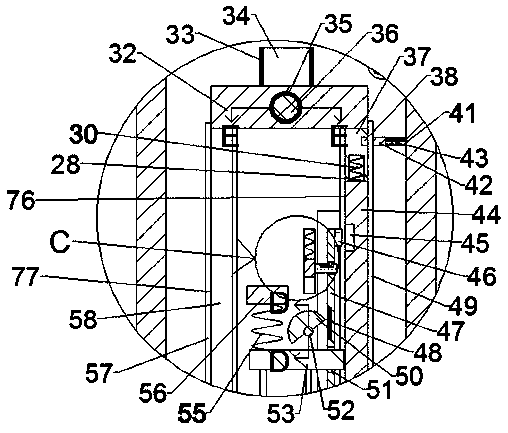

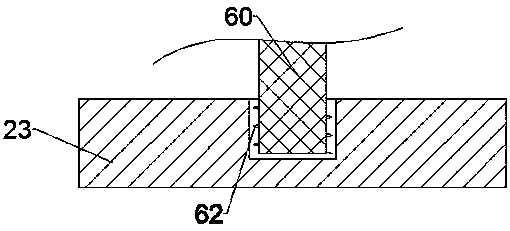

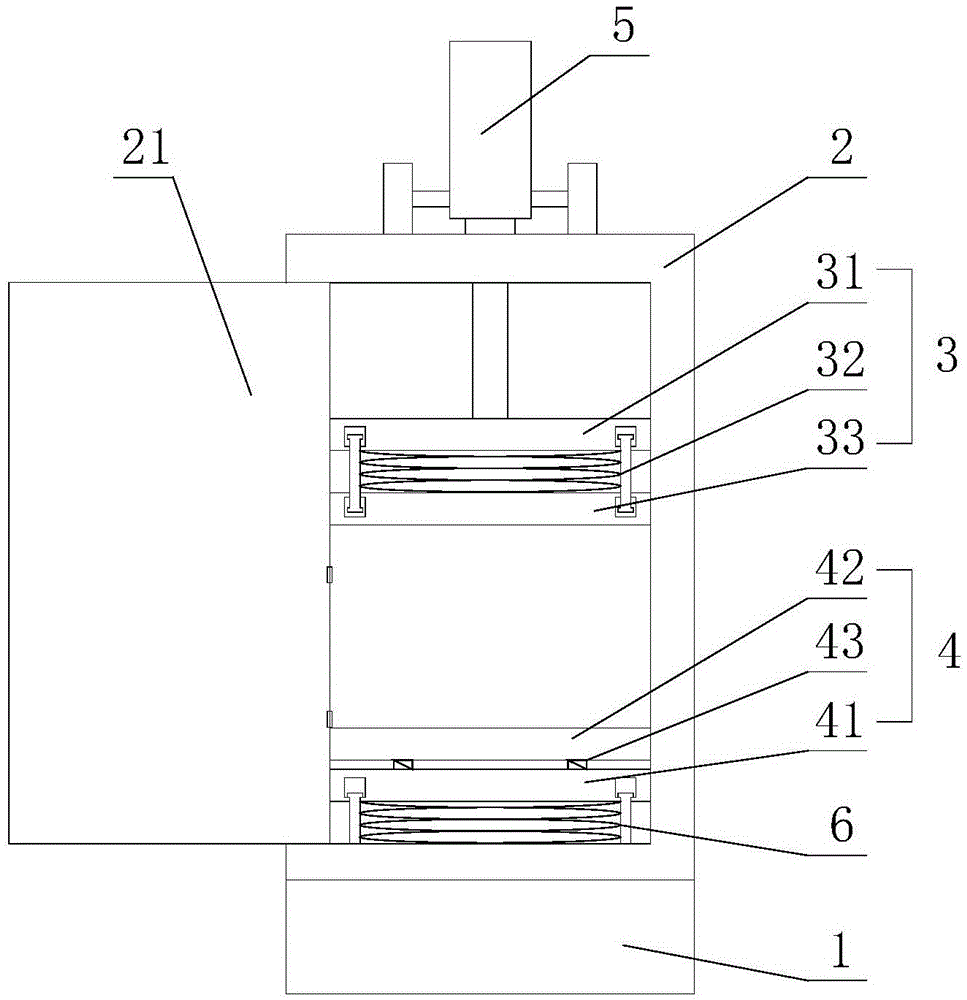

Hydraulic pumping system and concrete-pumping equipment comprising same

ActiveCN102536933AImprove job stabilityFast compaction compactionServomotorsTelemotorsHigh pressureConcrete pump

The invention discloses a hydraulic pumping system for concrete-pumping equipment, which comprises a first main oil cylinder (1), a second main oil cylinder (2), a main oil pump (10) and a pressure-stabilizing device (12), wherein the main oil pump (10) is used for alternately supplying oil for the first main oil cylinder (1) and the second main oil cylinder (2); and the pressure-stabilizing device (12) is used for supplying high-pressure hydraulic oil for the first main oil cylinder (1) or the second main oil cylinder (2) and realizing rapid concrete compaction when the hydraulic pumping system is reversed, and an oil outlet of the pressure-stabilizing device (12) is communicated with an oil-supplying path of the main oil pump (10). Concrete in a conveying cylinder can be rapidly compacted by the hydraulic pumping system, so that the generation of concrete impacts at the stage of concrete compaction is avoided, and the working stability of the pumping system is improved. The invention also discloses the concrete-pumping equipment which comprises the hydraulic pumping system and has the same effect.

Owner:SANY HEAVY IND CO LTD (CN)

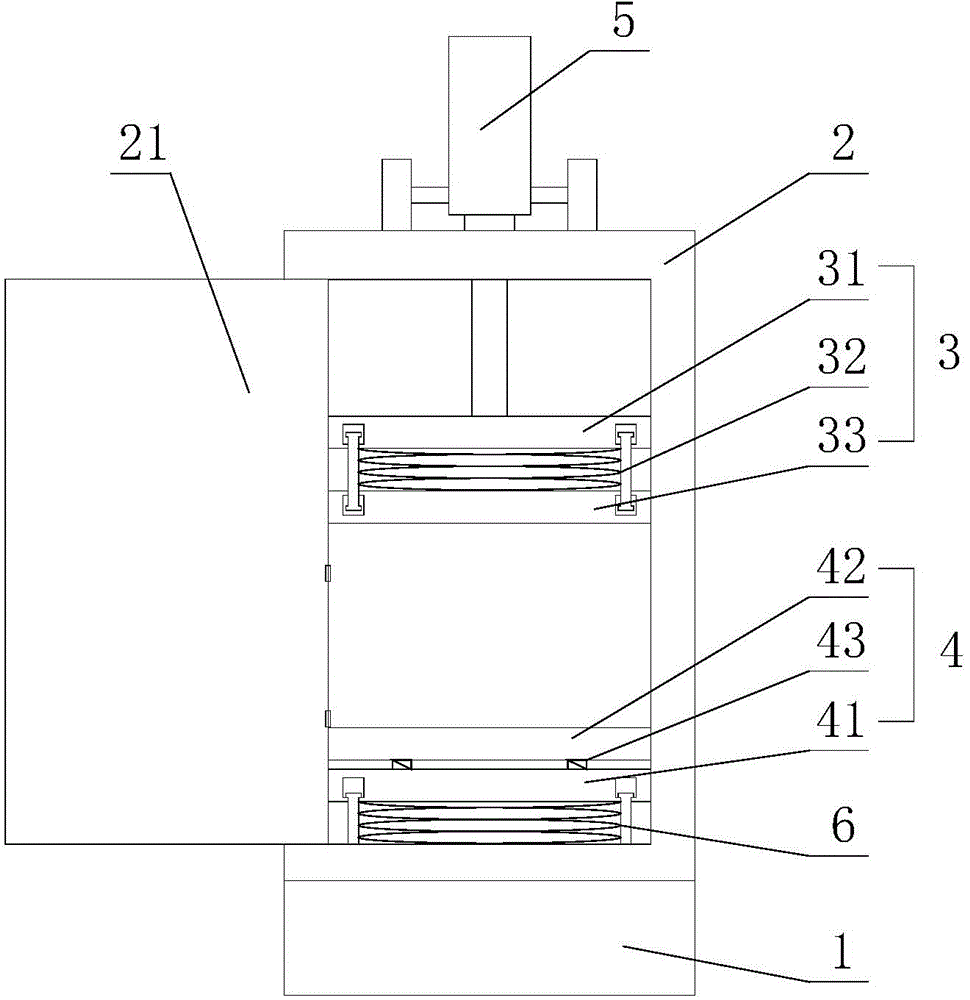

Waste compressing machine

The invention discloses a waste compressing machine which is provided with a box. An upper impacting plate and a lower impacting plate are arranged in the box, the impacting faces of the upper impacting plate and the lower impacting plate are parallel to the bottom face of the box, the upper impacting plate can be vertically moved in the box through a driving mechanism, buffer devices are arranged at the positions of the upper impacting plate and the lower impacting plate respectively, and the lower impacting plate comprises a supporting plate and a pressed plate located on the supporting plate. By means of the waste compressing machine, incompact metal waste can be rapidly and tightly and firmly compressed, waste blocks capable of being stacked and stored are obtained, convenience is brought to unloading, and occupied space is reduced.

Owner:ANHUI NINGGUO DONGBO FASTENER

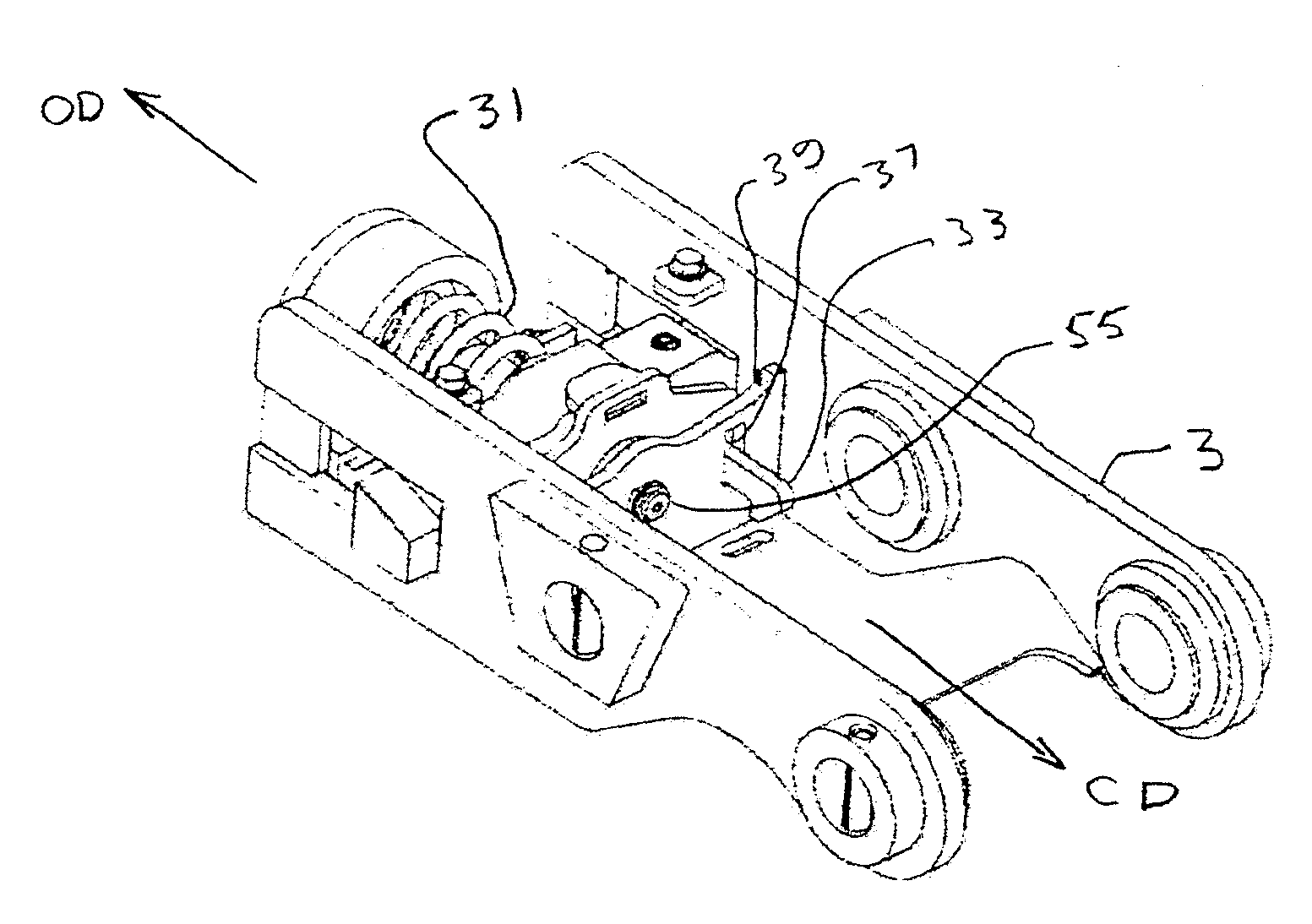

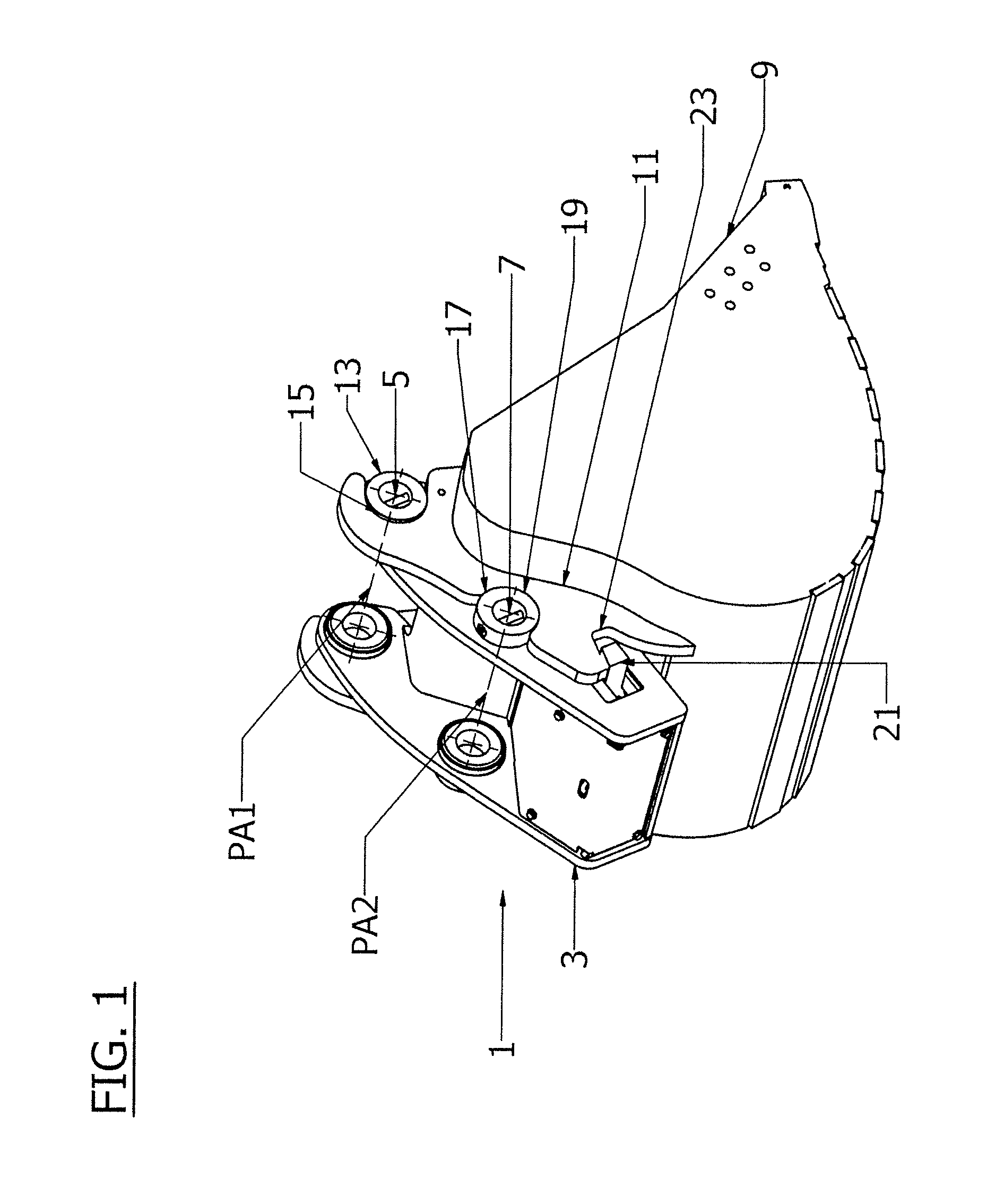

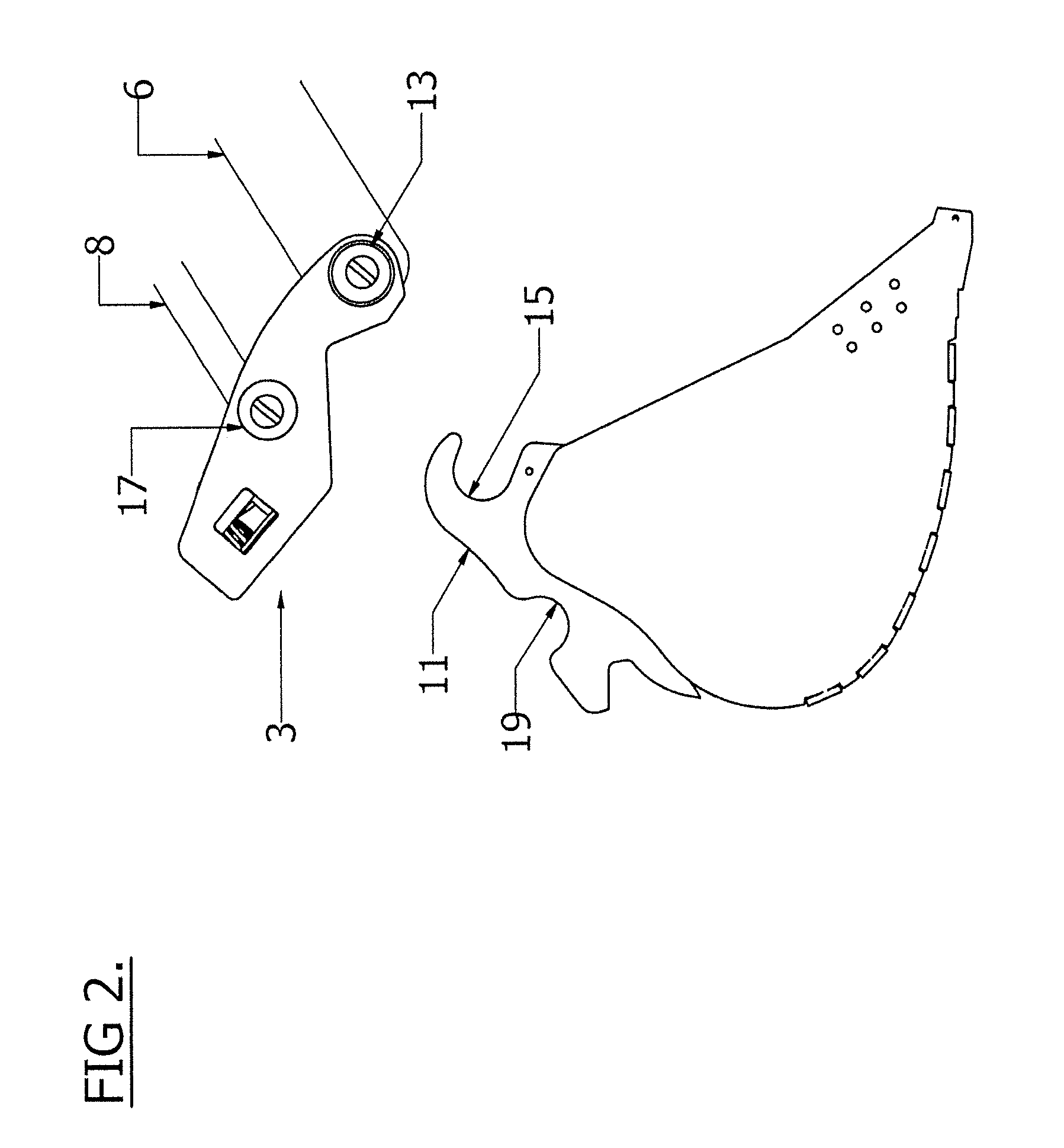

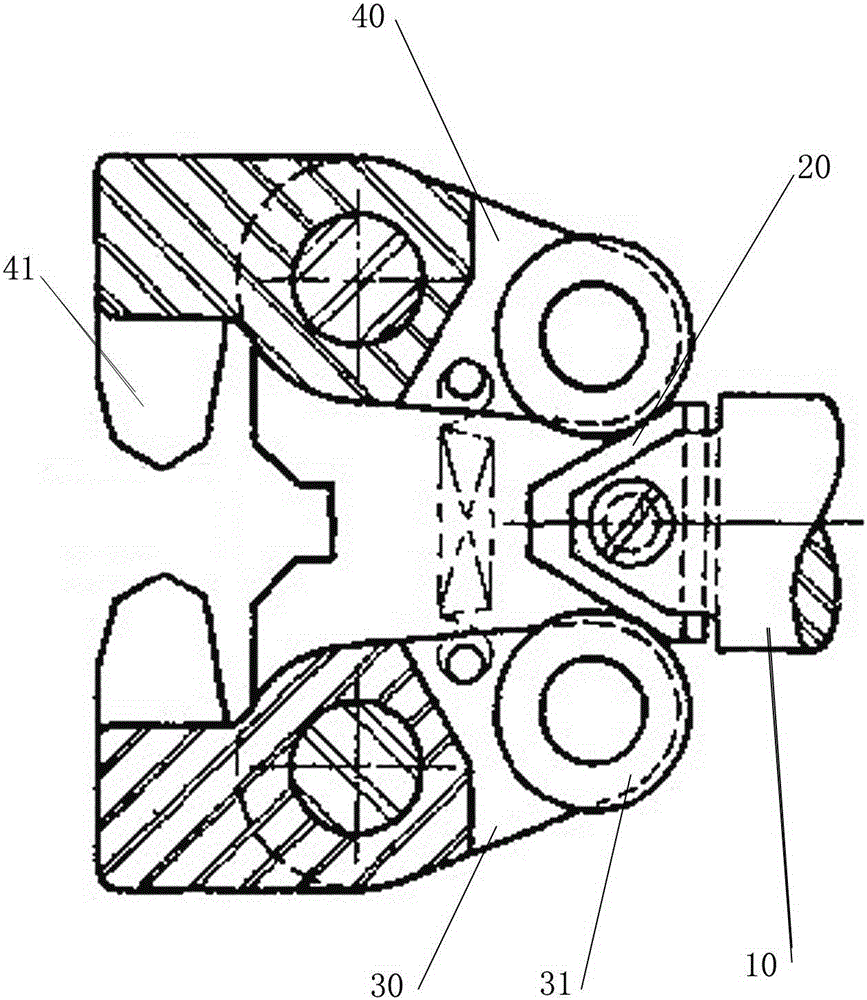

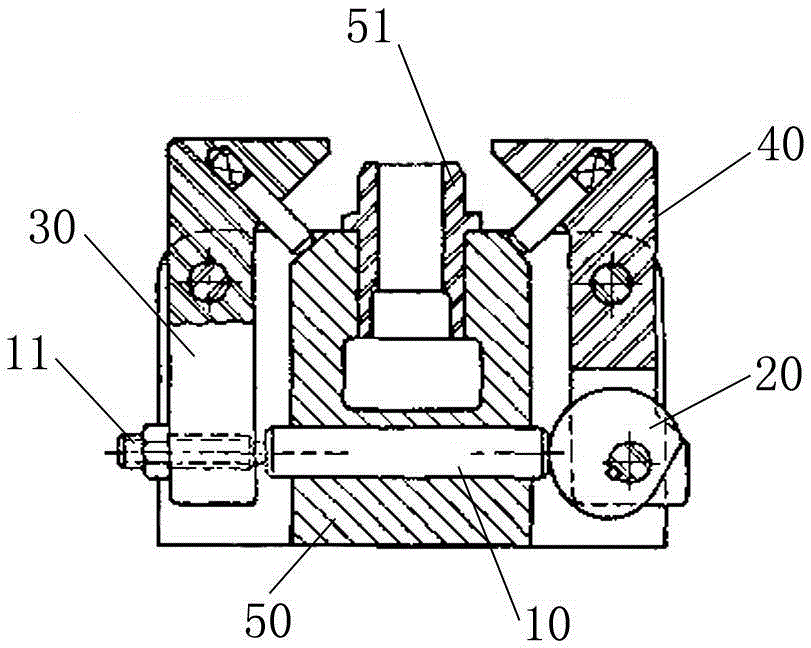

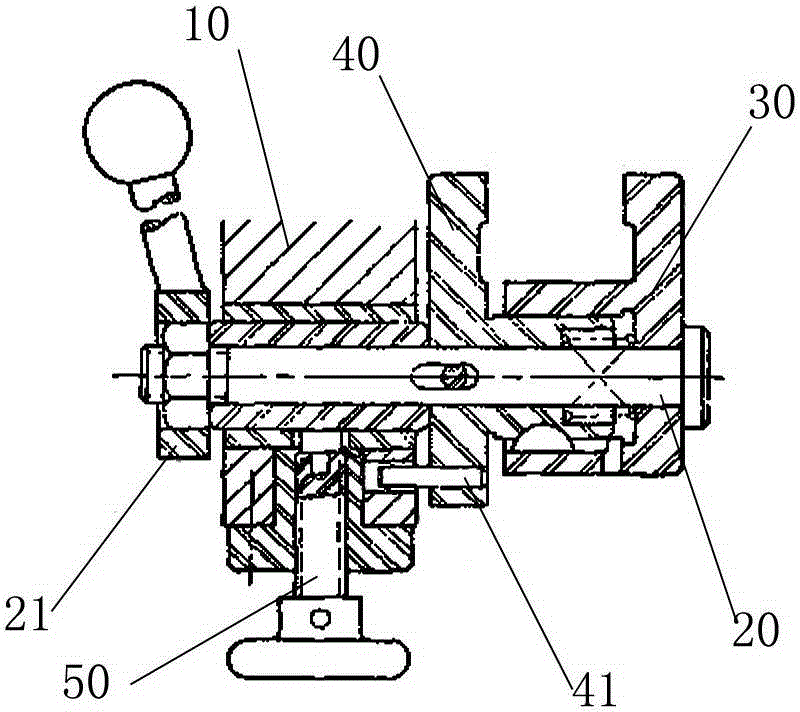

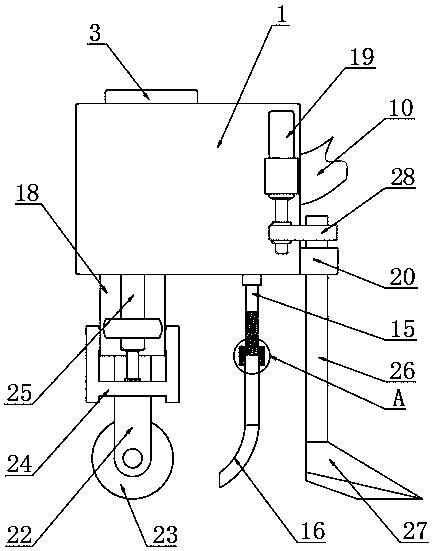

Compact quick coupling mechanism for tool attachment

ActiveUS20120237283A1Fast compaction compactionPrevent movementYielding couplingFluid pressure sealed jointsEngineeringHydraulic cylinder

A compact quick coupling apparatus has a wedge movable between closed and open positions. A wedge spring extends in the opening direction from the wedge and urges the wedge in the closing direction. A latch spring urges a safety latch to a latched position to prevent the wedge from moving. A single acting hydraulic cylinder extends through the wedge and extends in the opening direction from the wedge. As the hydraulic cylinder extends it first moves the safety latch to the unlatched position, and then moves the wedge in the opening direction. When pressurized fluid is released from the hydraulic cylinder, it retracts and the wedge moves in the closing in response to the wedge spring until the wedge reaches the closed position, and then the hydraulic cylinder further retracts in response to the latch spring and the safety latch moves to the latched position.

Owner:BRANDT IND

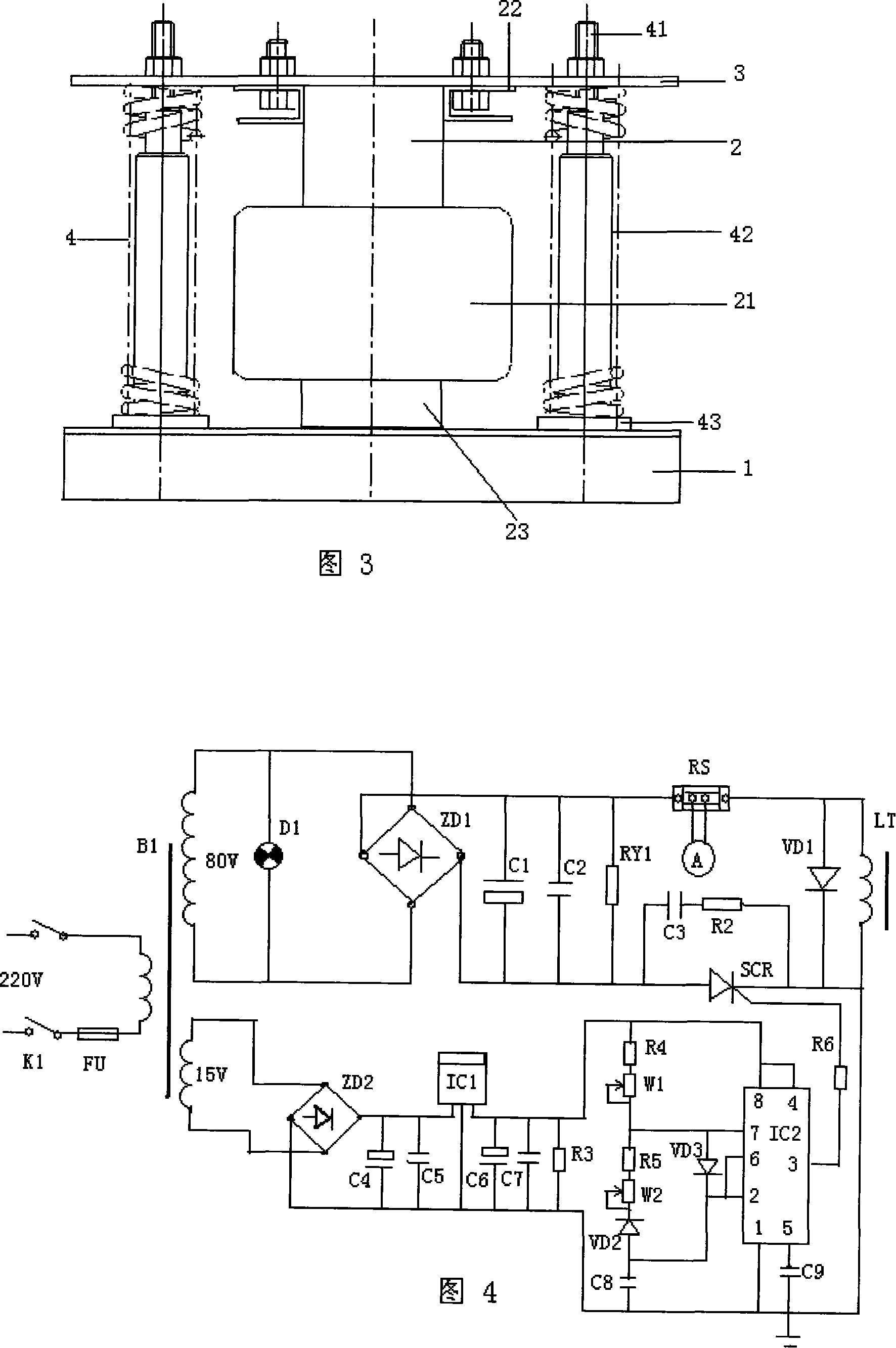

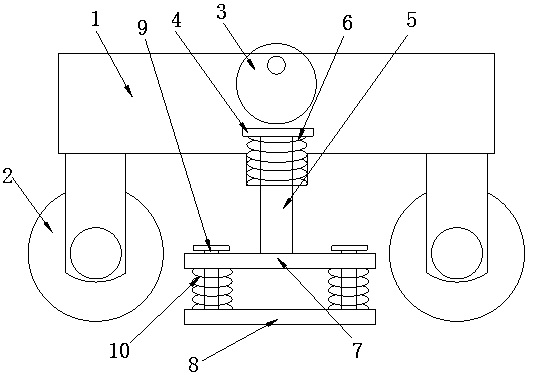

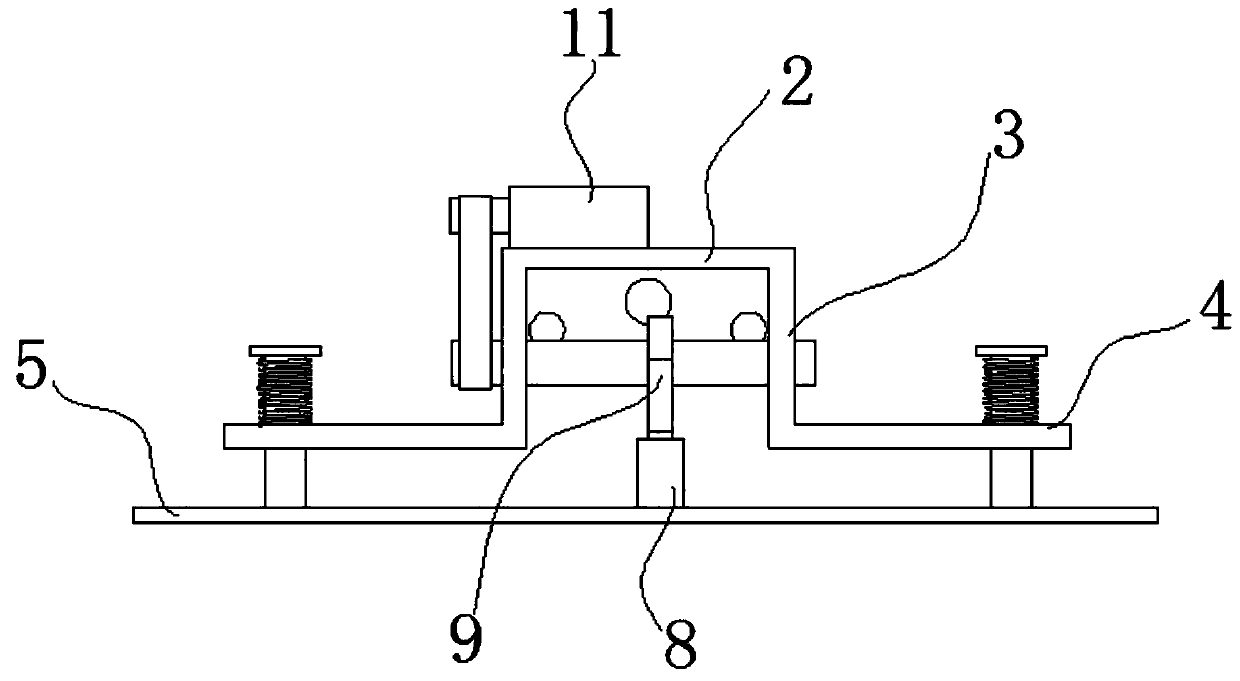

Flat-board type electromagnetic vibration compaction machine

InactiveCN101070700ASimple structureLow failure rateRoads maintainenceSoil preservationMicrocontrollerSilicon-controlled rectifier

This invention discloses a plate-type electromagnetism vibration beater. This beater overcame existing diesel engine, electric motor as power causes the tamp machine have screw loose, the working life is short, the weight is big. To improve the power unit of electronic maganet equipment including'U' shape magnet core, as well as circles the core's two column parallel winding circles. This electromagnetism installment was controlled mainly by the monolithic integrated circuit control silicon-controlled rectifier frequency conversion electricity return route. The electromagnetism installment leads the magnet core to be controlled under the electricity return route's function, produces with the plane ledger wall has the frequency mutual attraction with to escape serves the ramming purpose. This invention may adjust the ramming vibration the frequency, the oscillation amplitude, the impulse, therefore adapts the different operating mode construction, is suitable specially for the road, the bridge roadbed concretes compaction and the road surface maintenance. Has the main engine energy use factor high, not to have the pollution, the structure to be simple, the failure rate is low, the noise is small, the complete machine weight is small, redeployment quickly facile and so on.

Owner:赵守德

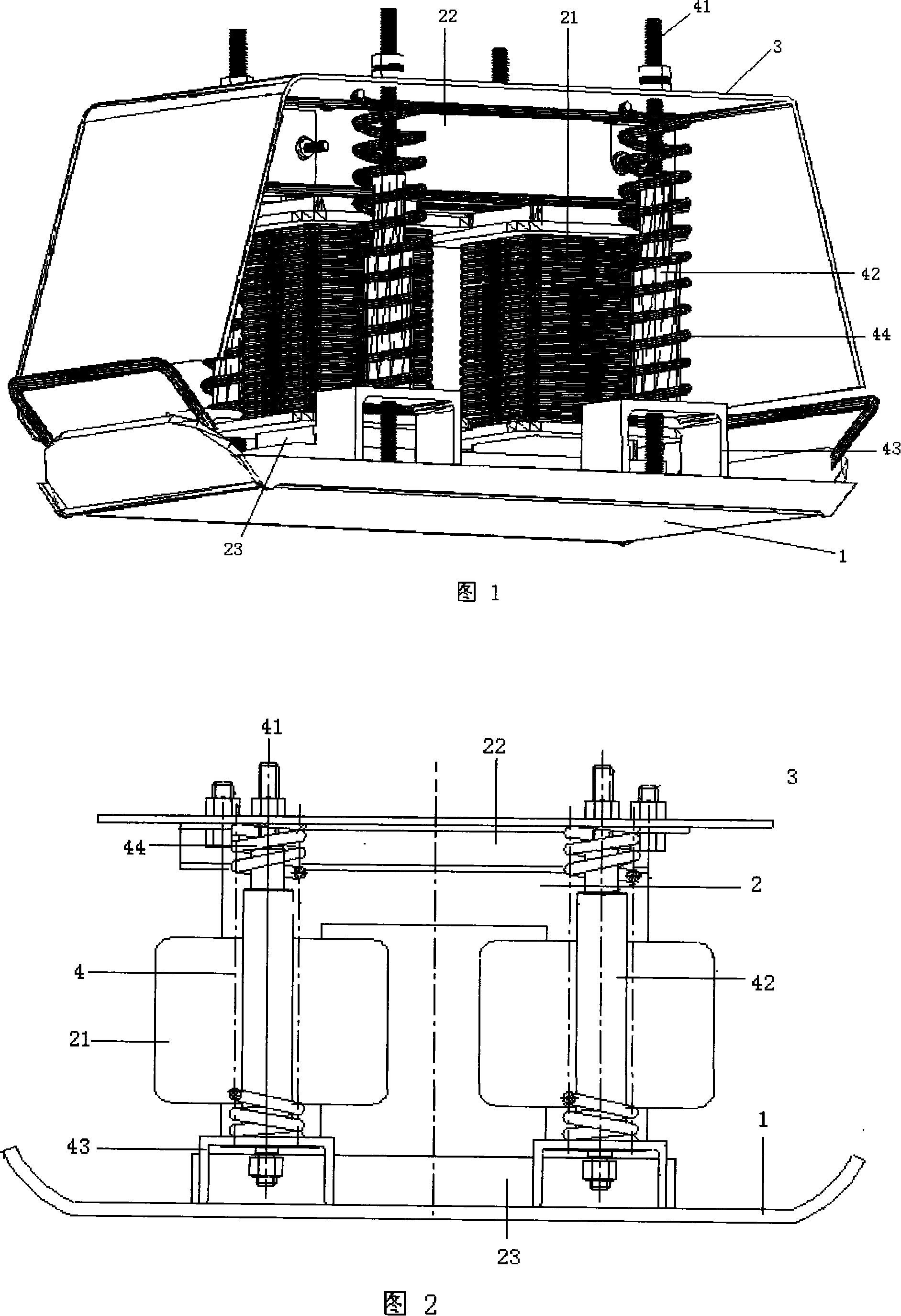

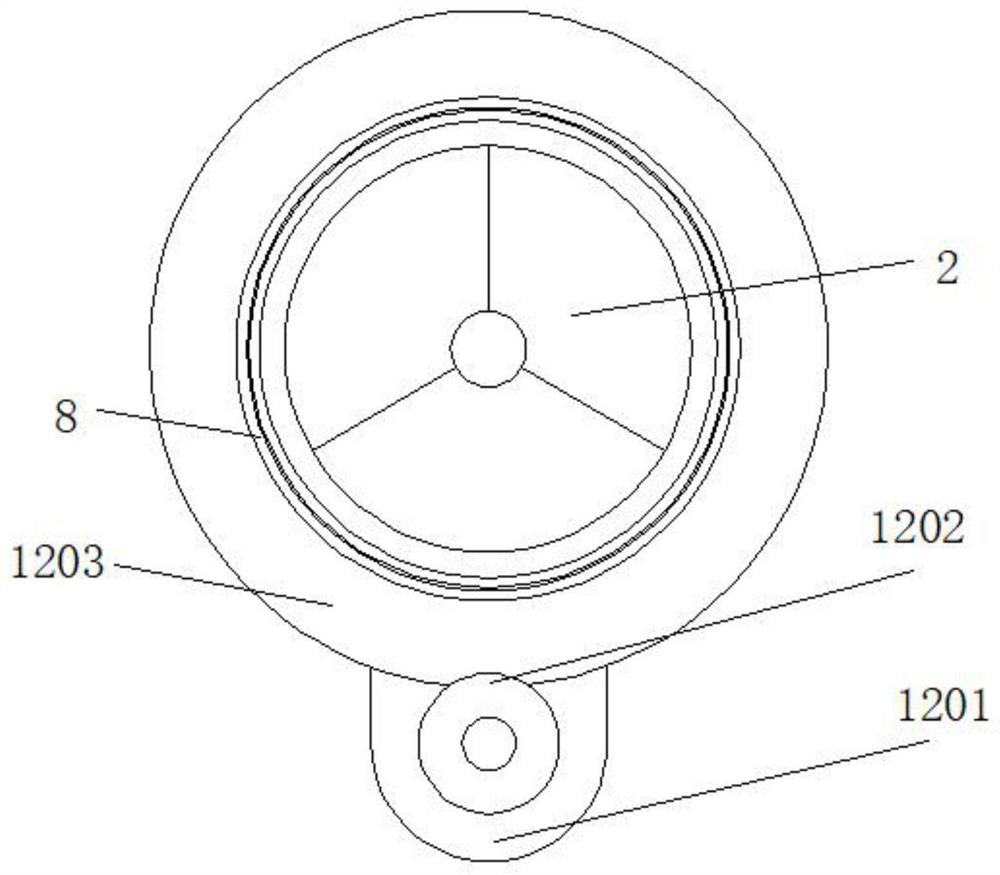

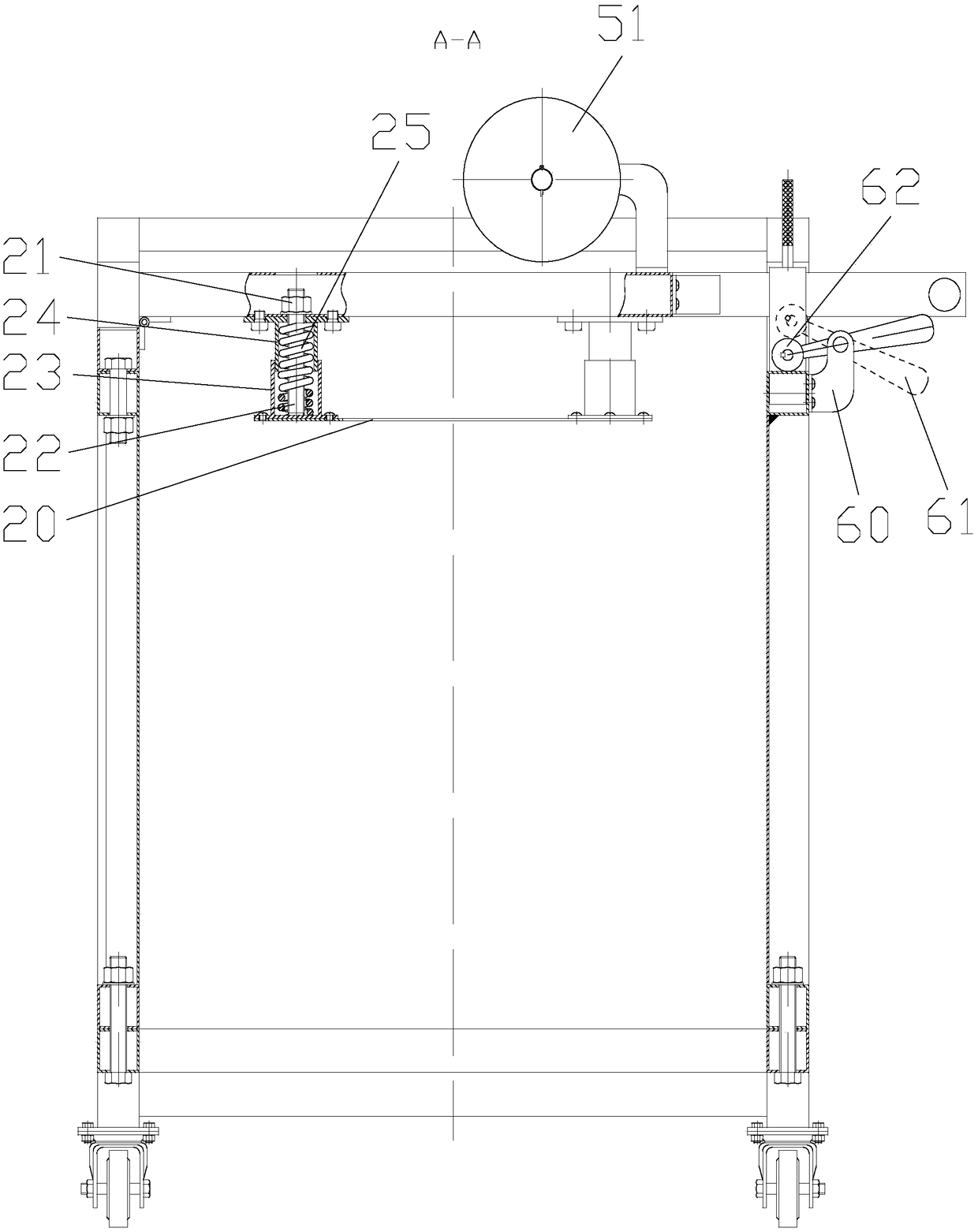

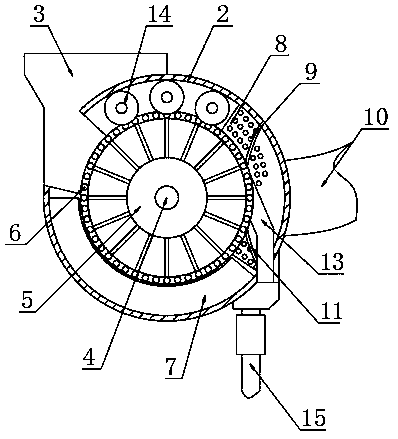

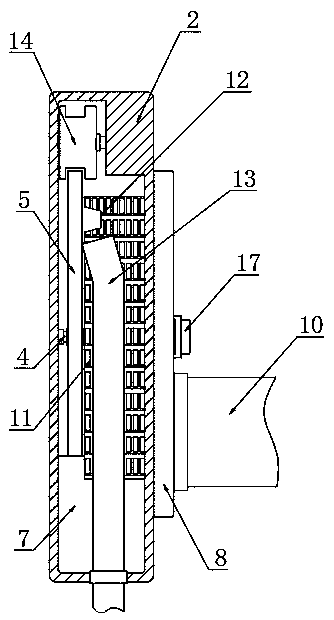

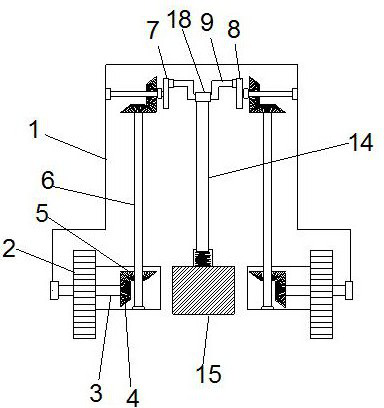

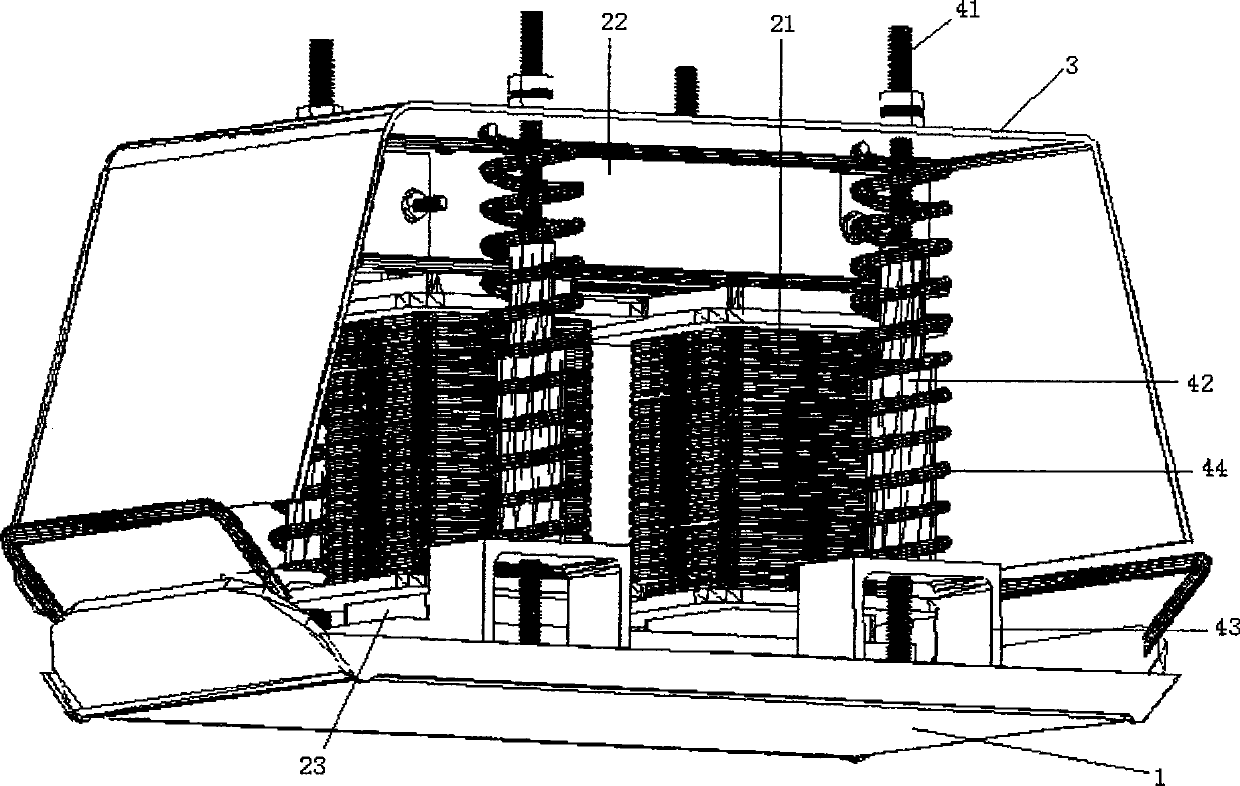

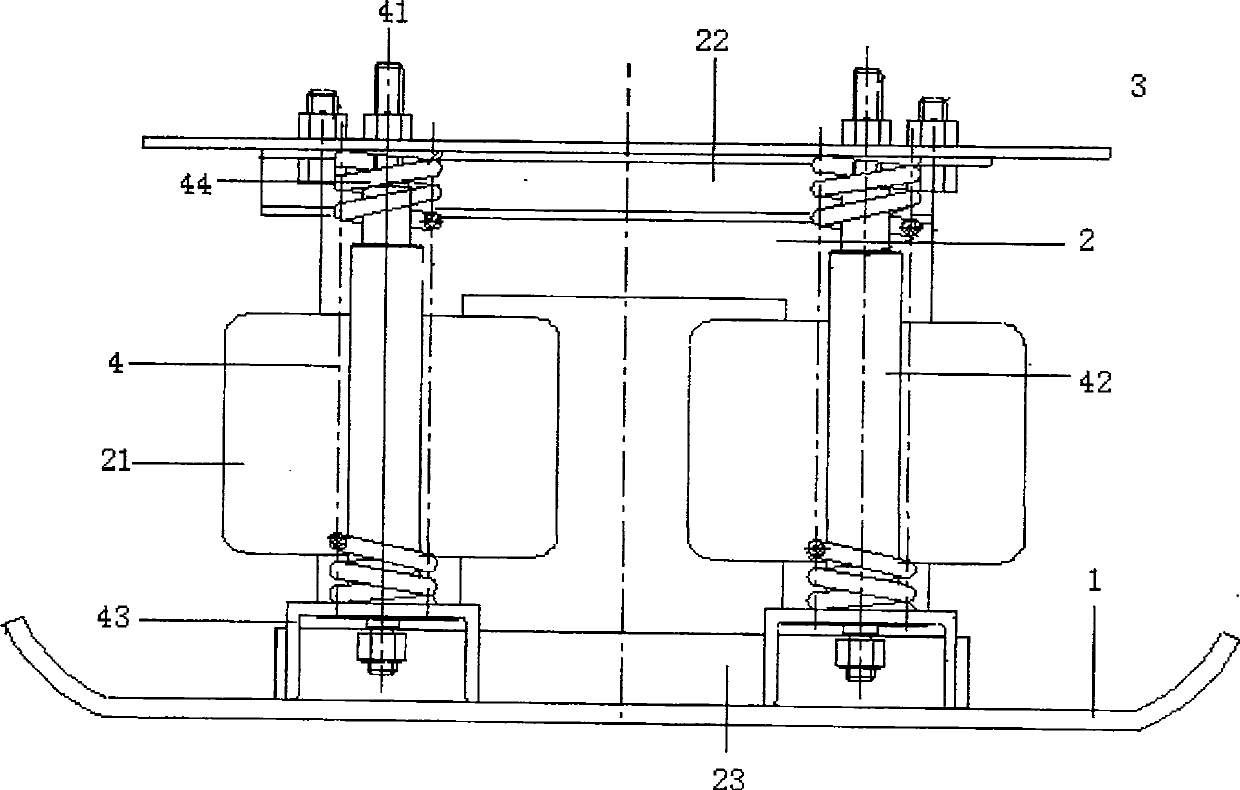

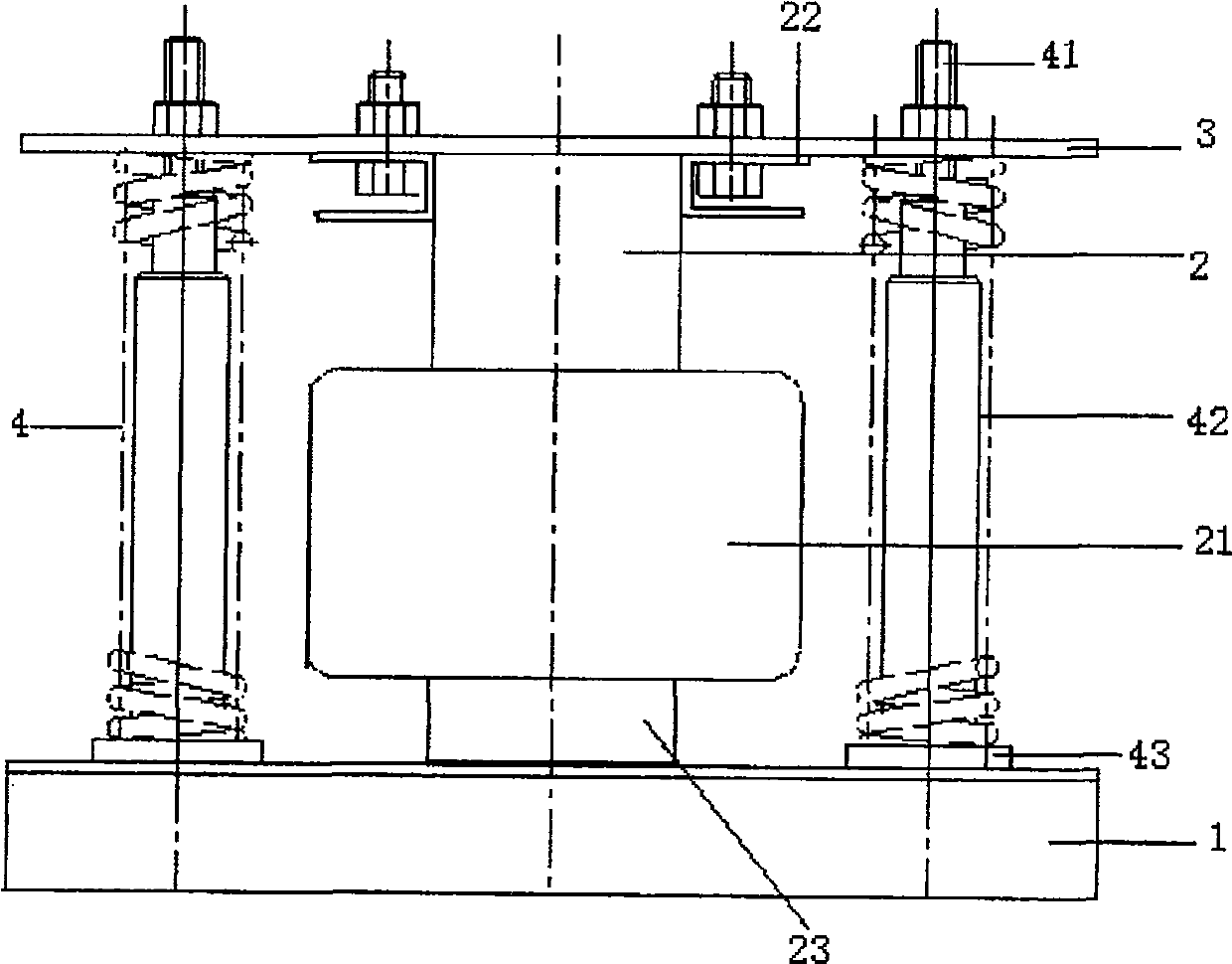

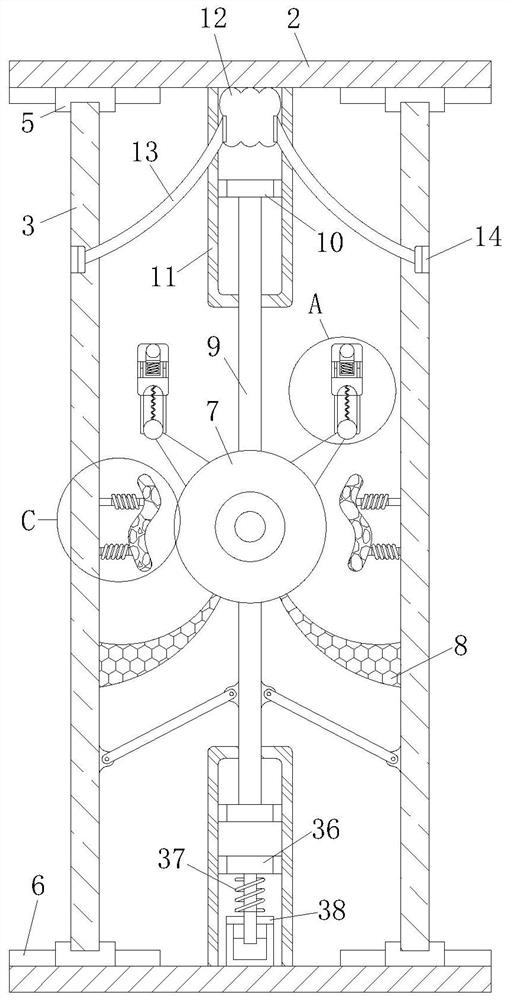

Damping type rammer compacter

The invention discloses a damping type rammer compacter, and relates to the technical field of construction machinery; the both sides of the bottom of a rack are each provided with a compaction roller, and the upper middle part of the rack is provided with an eccentric wheel mechanism; the lower side of an eccentric wheel of the eccentric wheel mechanism is provided with a contact plate body of which the lower end is provided with a lower compression bar body, and the lower end of the lower compression bar body is provided with an upper connecting plate; the lower compression bar body is connected to the interior of a guide hole of the rack in a penetrating manner, and the upper side of the lower compression bar body is dowel joint with a reset spring; the lower side of the upper connecting plate is provided with a compaction plate of which the two upper ends are each provided with a guide bar, and the guide bars are connected to the interiors of guide holes in the upper connecting plate in the penetrating manner; and the lower sides of the guide bars are in dowel joint with damping springs. According to the damping type rammer compacter, quick compaction can be achieved in use, and the damping can be achieved during compaction; the service life is prolonged, and the operation is simple and convenient; the time can be saved during operation; and the damping type rammer compacter is easy to use, and the time can be saved.

Owner:苏州苏高建筑机械租赁有限公司

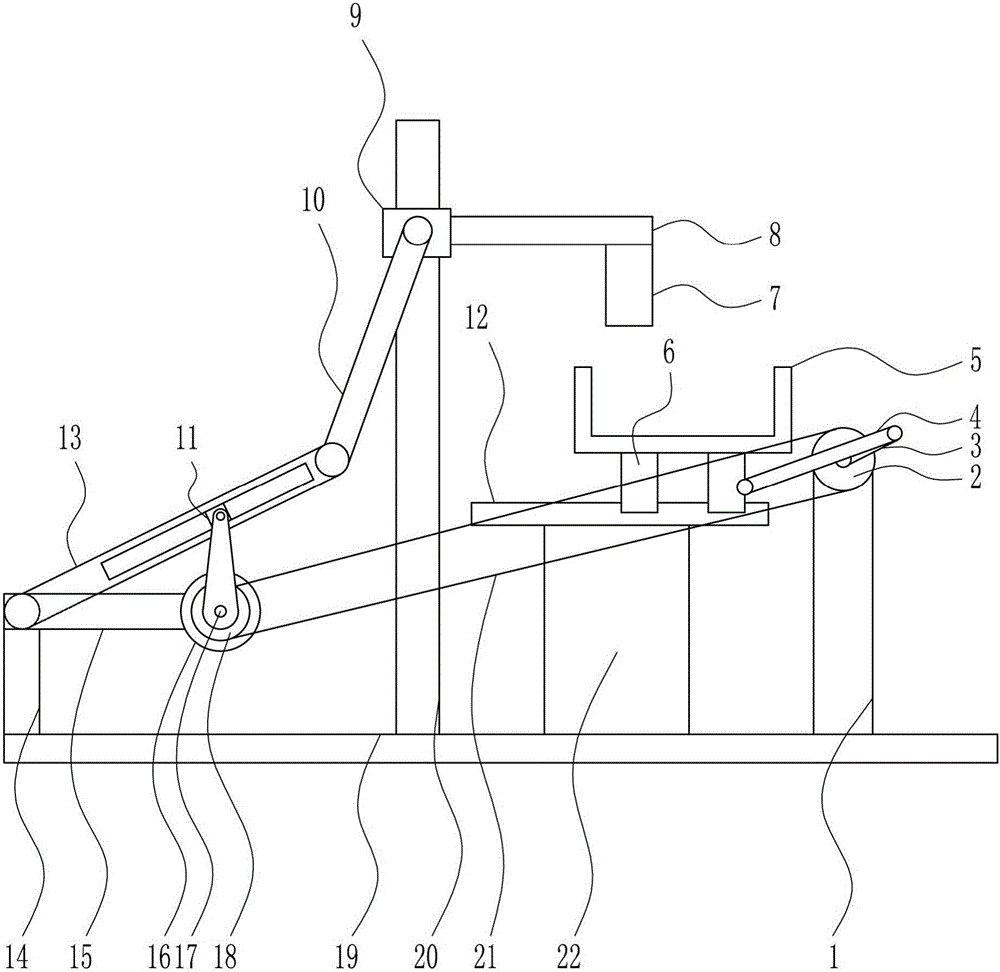

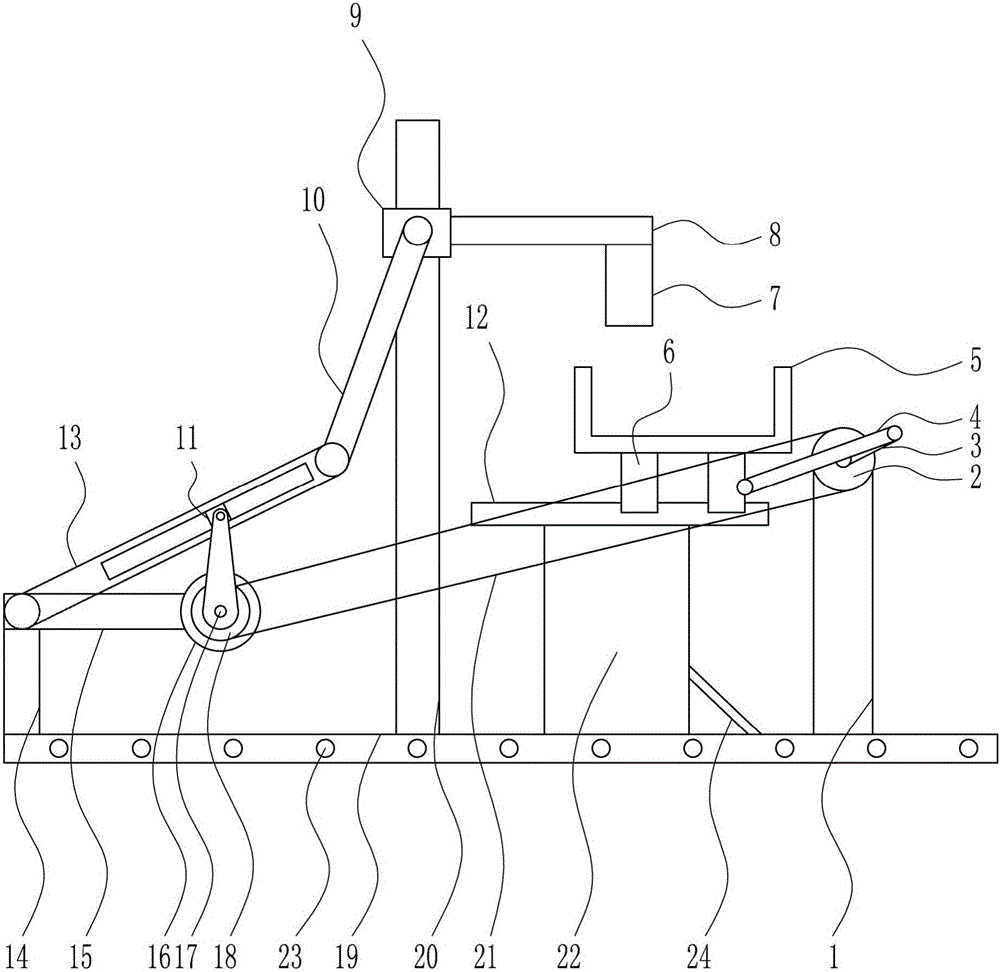

High-efficiency compaction device for discarded cotton cushions in medical gynecology department

The invention relates to discarded cotton cushion compaction devices used in the medical gynecology department, in particular to a high-efficiency compaction device for discarded cotton cushions in the medical gynecology department. The high-efficiency compaction device for discarded cotton cushions in the medical gynecology department is convenient to operate, high in compaction speed, and capable of saving time and labor. In order to solve the technical problems, the high-efficiency compaction device for discarded cotton cushions in the medical gynecology department comprises a supporting rod, a first belt pulley, a first oscillating rod, a second oscillating rod, a compaction frame, first sliding blocks, a pressing block, a fixing plate, a guide sleeve, a connecting rod, a second sliding block and the like. A fulcrum bar, a guide rod, a placing table and the supporting rod are sequentially arranged at the top of a base plate from left to right. A connecting rod is arranged at the top end of the fulcrum bar. According to the high-efficiency compaction device, the effects of being convenient to operate, high in compaction speed, and capable of saving time and labor are achieved; and moreover, the manufacturing cost is low, the structure is reasonable, maintenance and repair are easy, using is convenient, manpower and material resource input is reduced, and working efficiency is improved.

Owner:山东东明石化集团有限公司

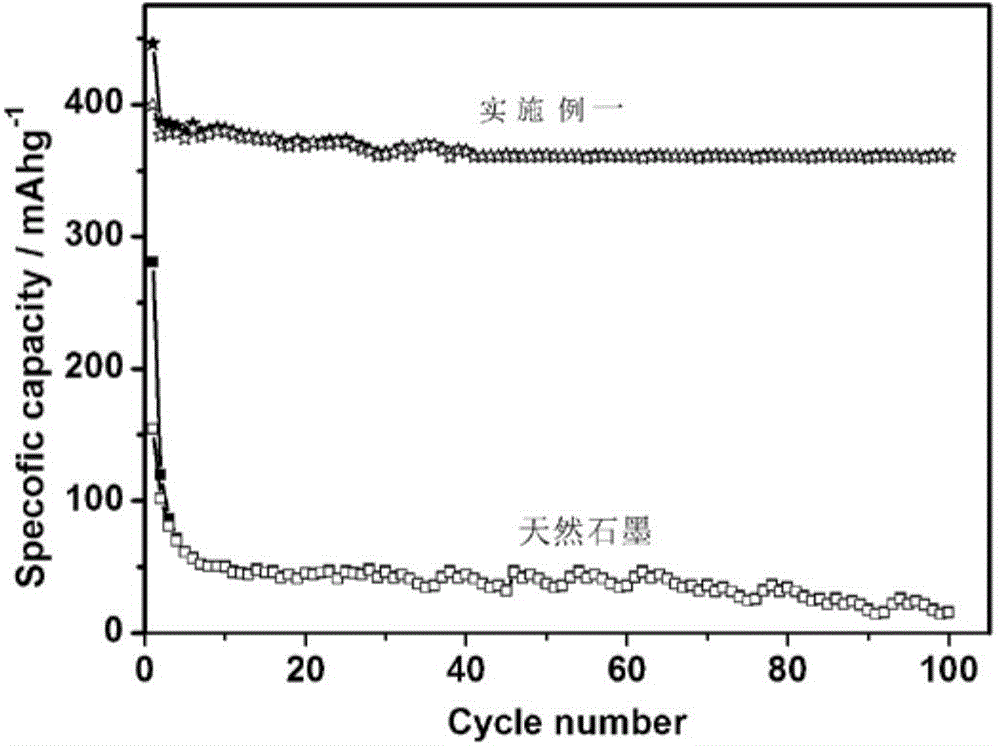

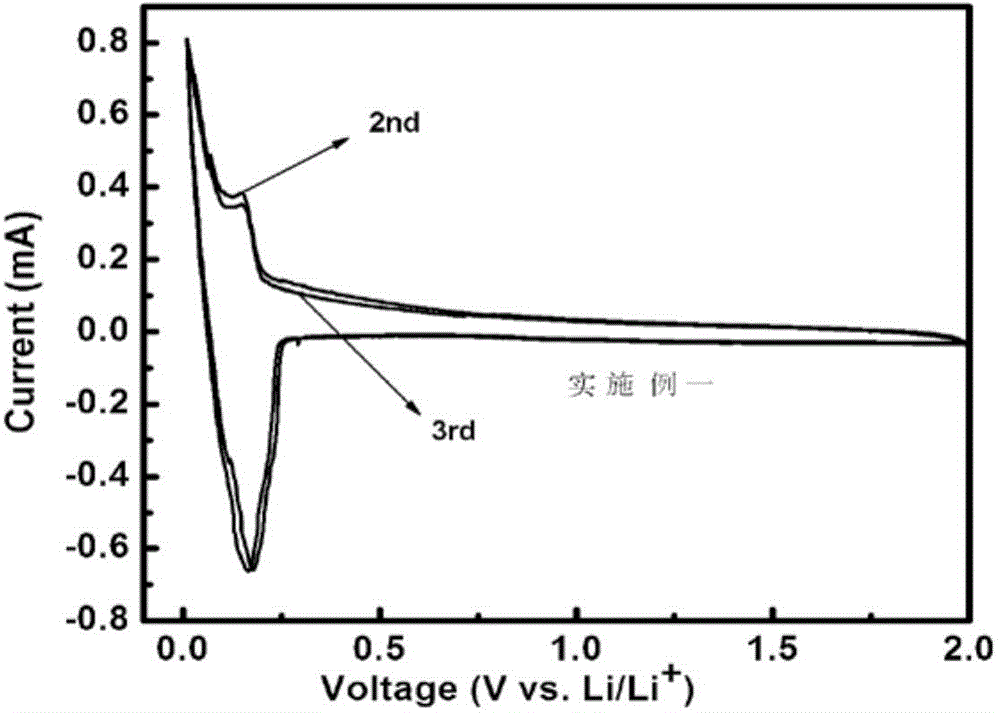

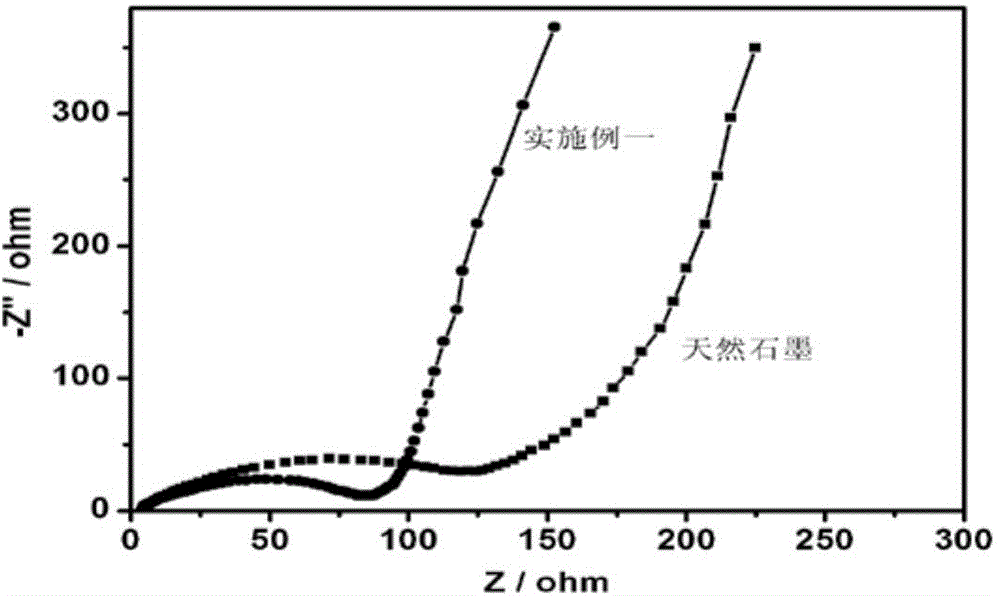

Preparation method of natural graphite composite N-doped carbon nanofibers webs cathode material

ActiveCN103606680AImprove cycle stabilityFacilitate de-intercalationCell electrodesSecondary cellsArgon atmosphereCarbon nanofiber

Belonging to the technical field of lithium ion battery electrode material preparation, the invention particularly discloses a preparation method of a natural graphite composite N-doped carbon nanofibers webs cathode material. The method includes: firstly subjecting natural flake graphite to spheroidizing treatment, and activating natural graphite under a small argon flow, then mixing the activated natural graphite with a mixed solution of emulsified asphalt / water-soluble polymer uniformly in certain proportion, conducting spray drying, then performing high temperature heat treatment in an argon atmosphere, mixing the obtained product with N-doped carbon nanofibers webs, an inorganic lithium salt and a composite conductive agent according to certain mass ratio, and then carrying out spheroidizing fusion treatment, sieving, and vacuum heat treatment, thus obtaining the natural graphite composite N-doped carbon nanofibers webs cathode material. The method provided by the invention can effectively improve the conductivity and structural stability of the material, greatly increases the compaction density of natural graphite, enhances the specific capacity, the reversible capacity and the coulombic efficiency, and effectively improves the cycle stability of the lithium ion battery cathode material.

Owner:百吉瑞(天津)新能源有限公司 +1

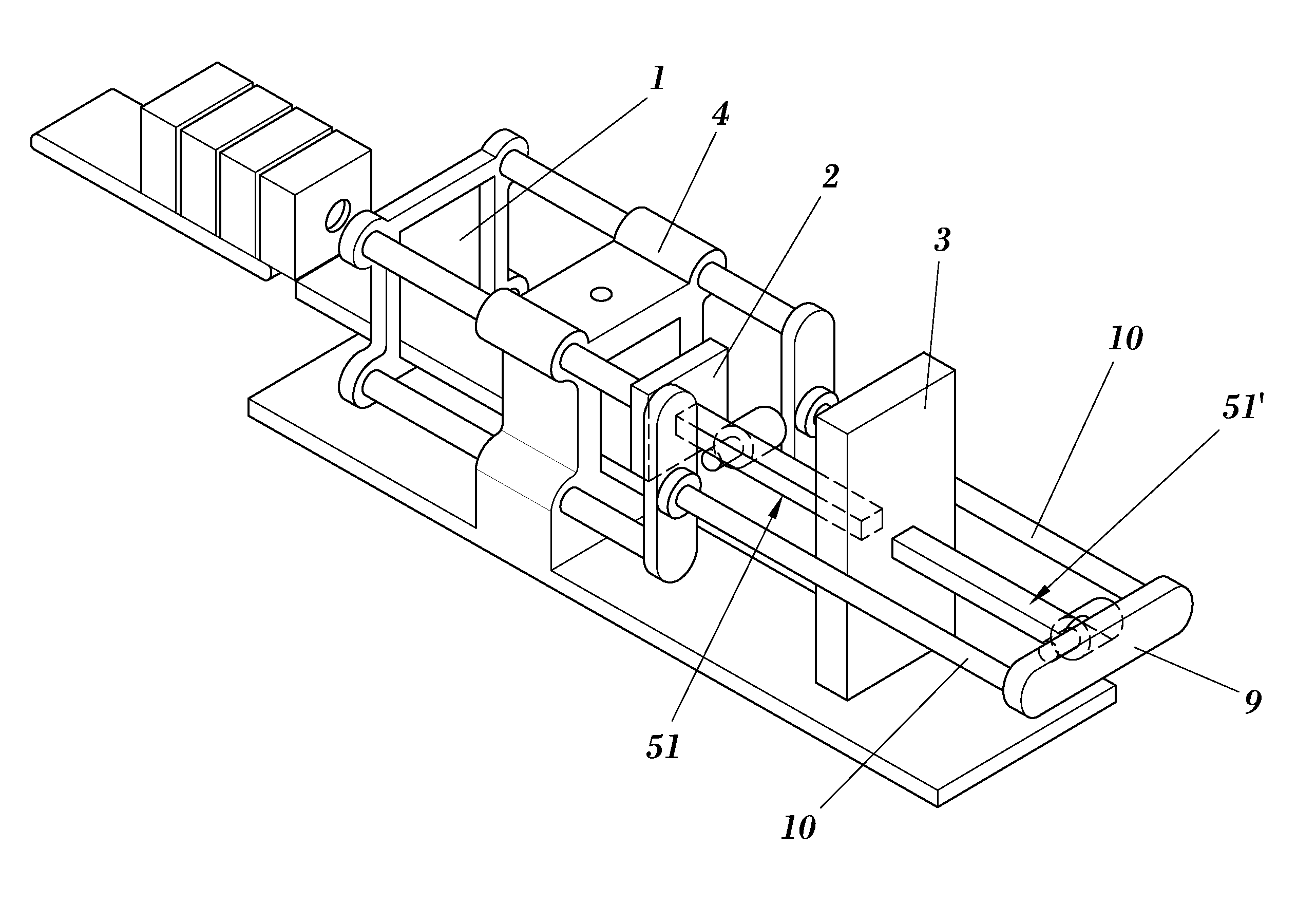

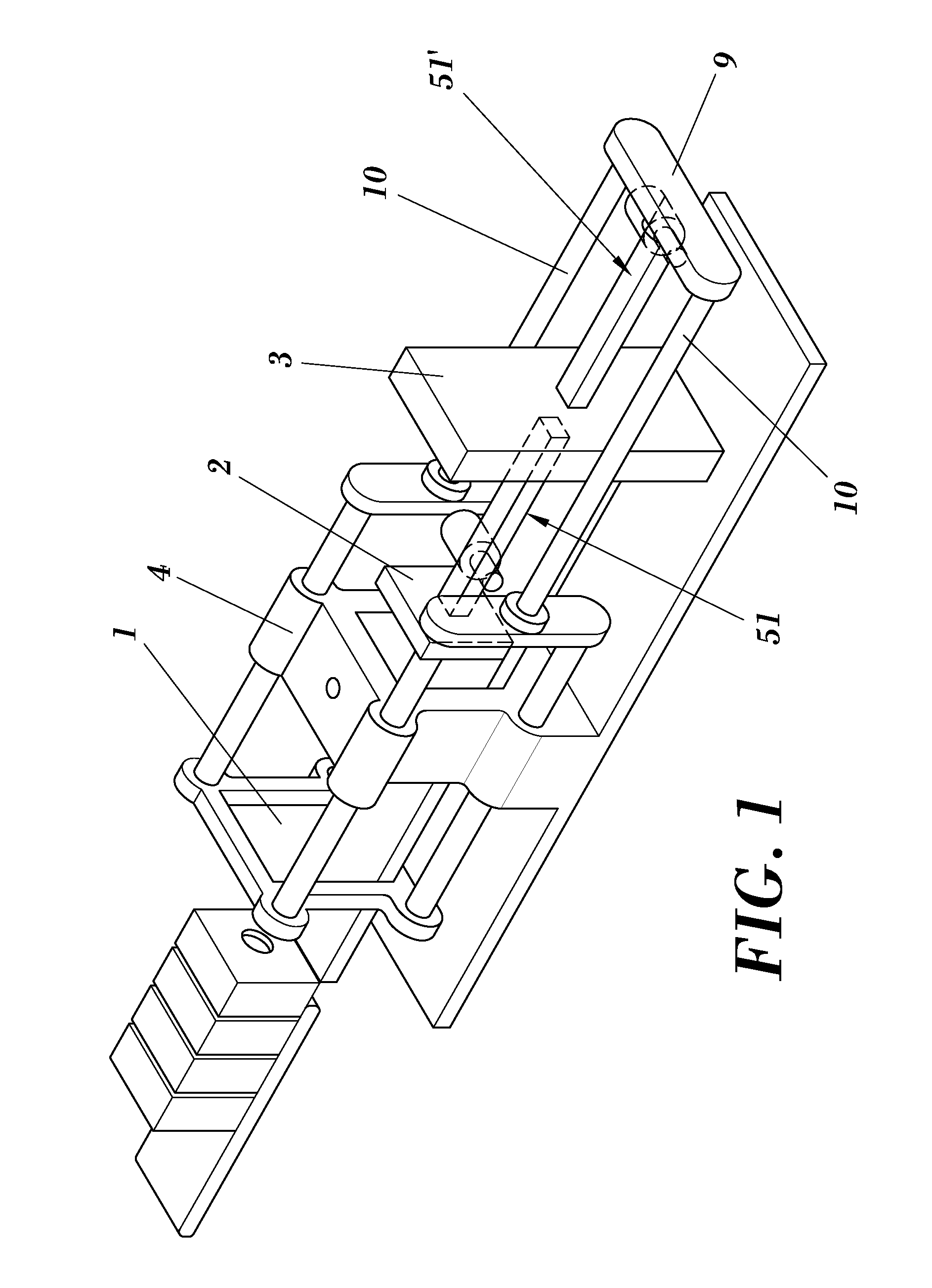

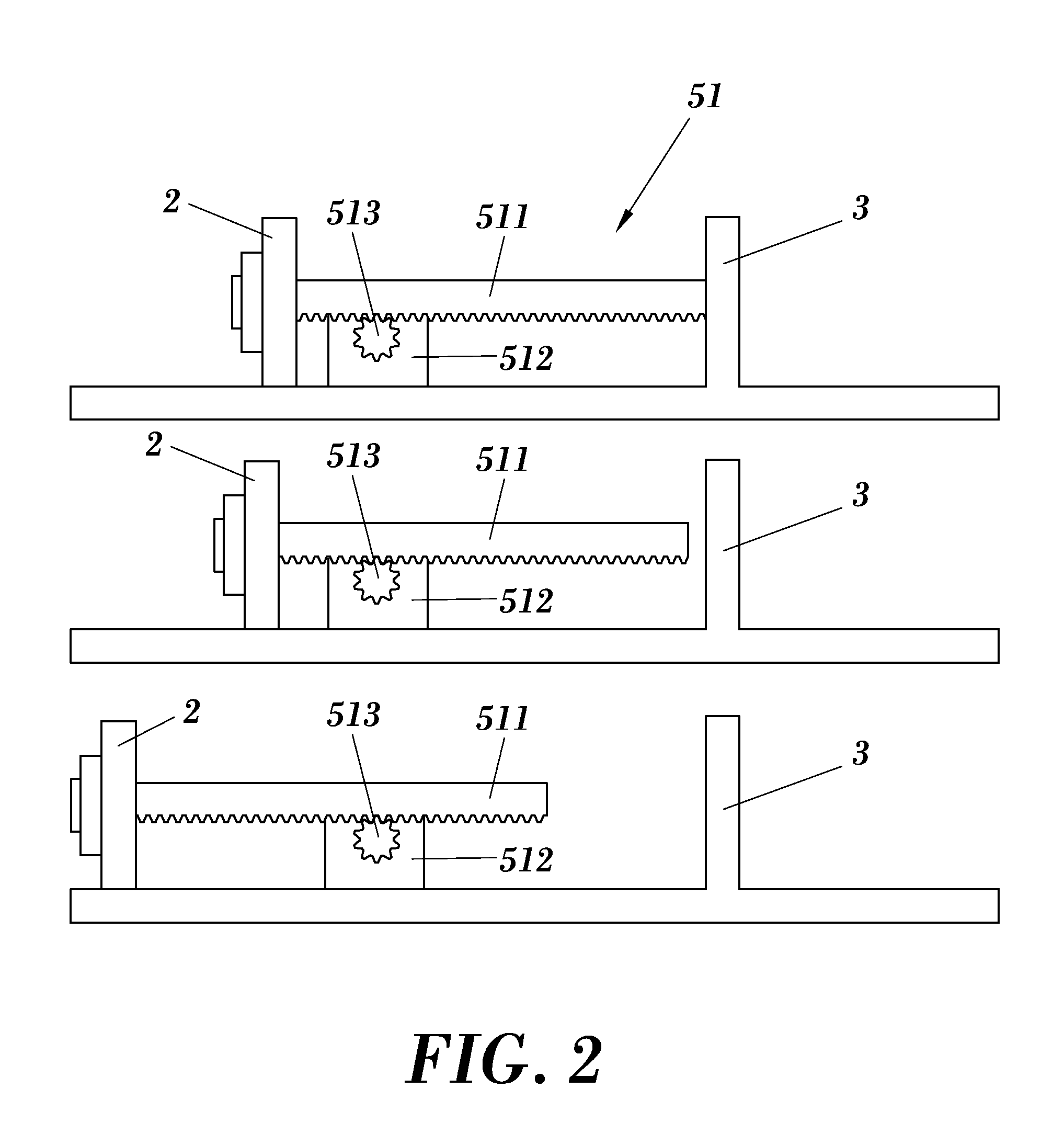

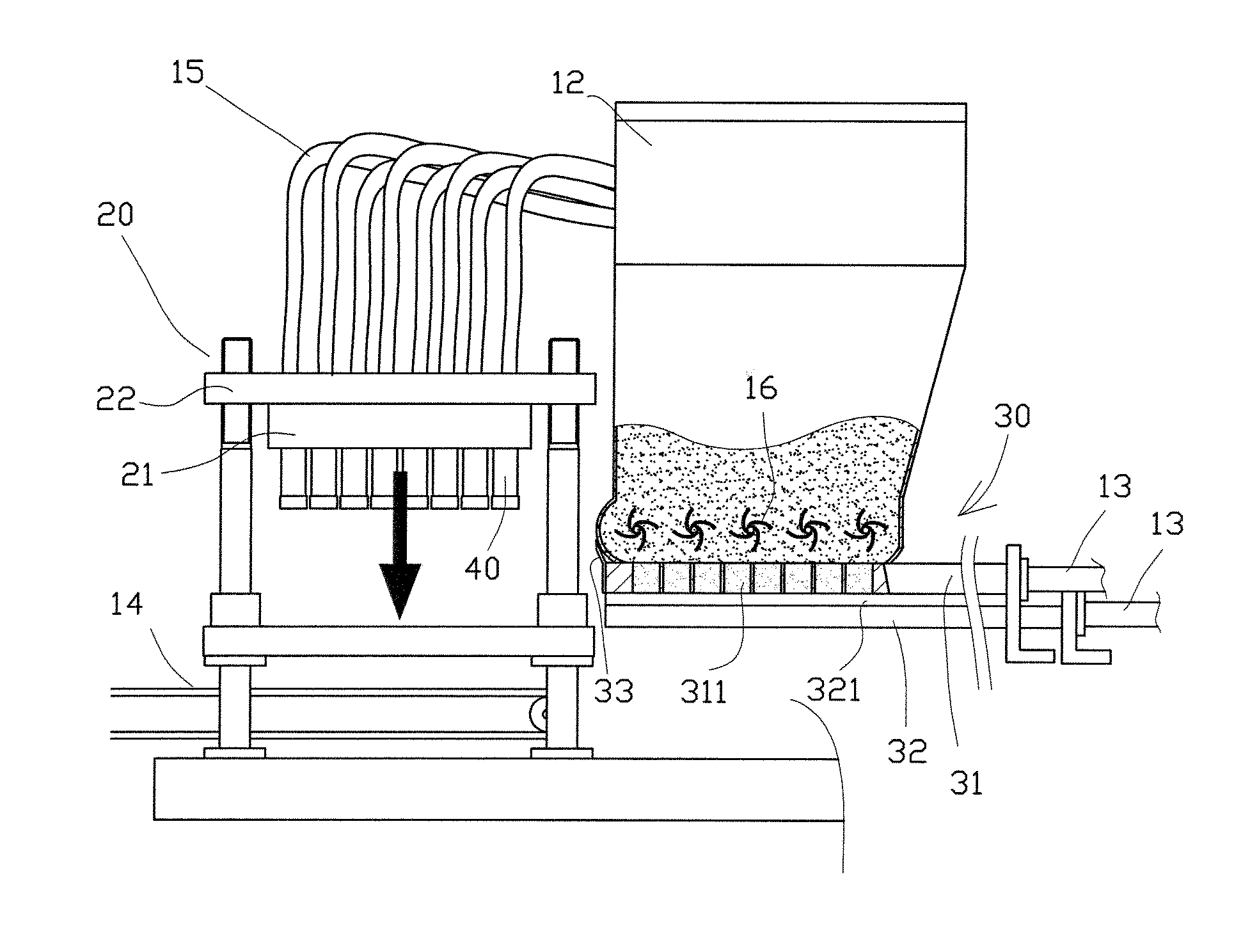

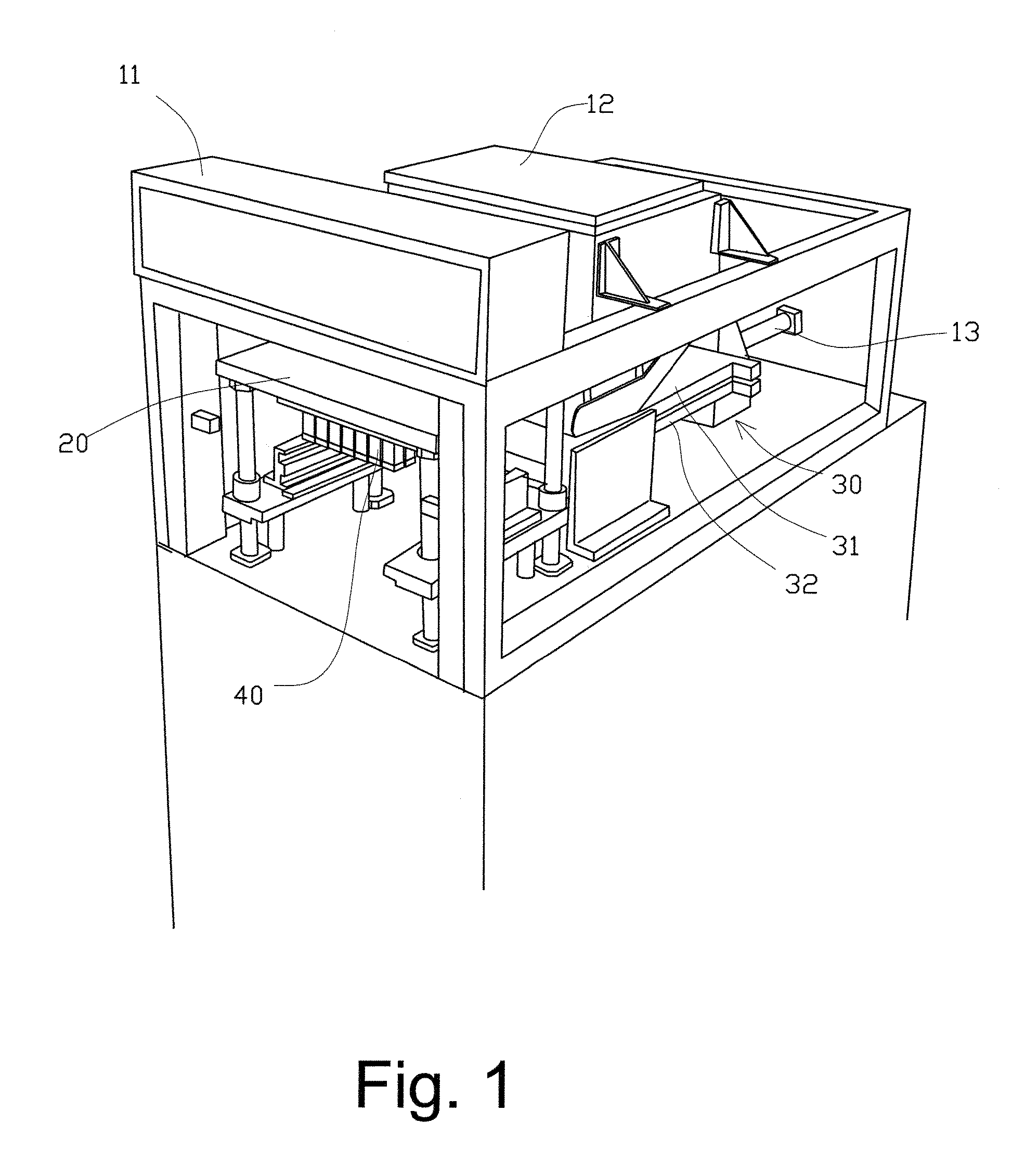

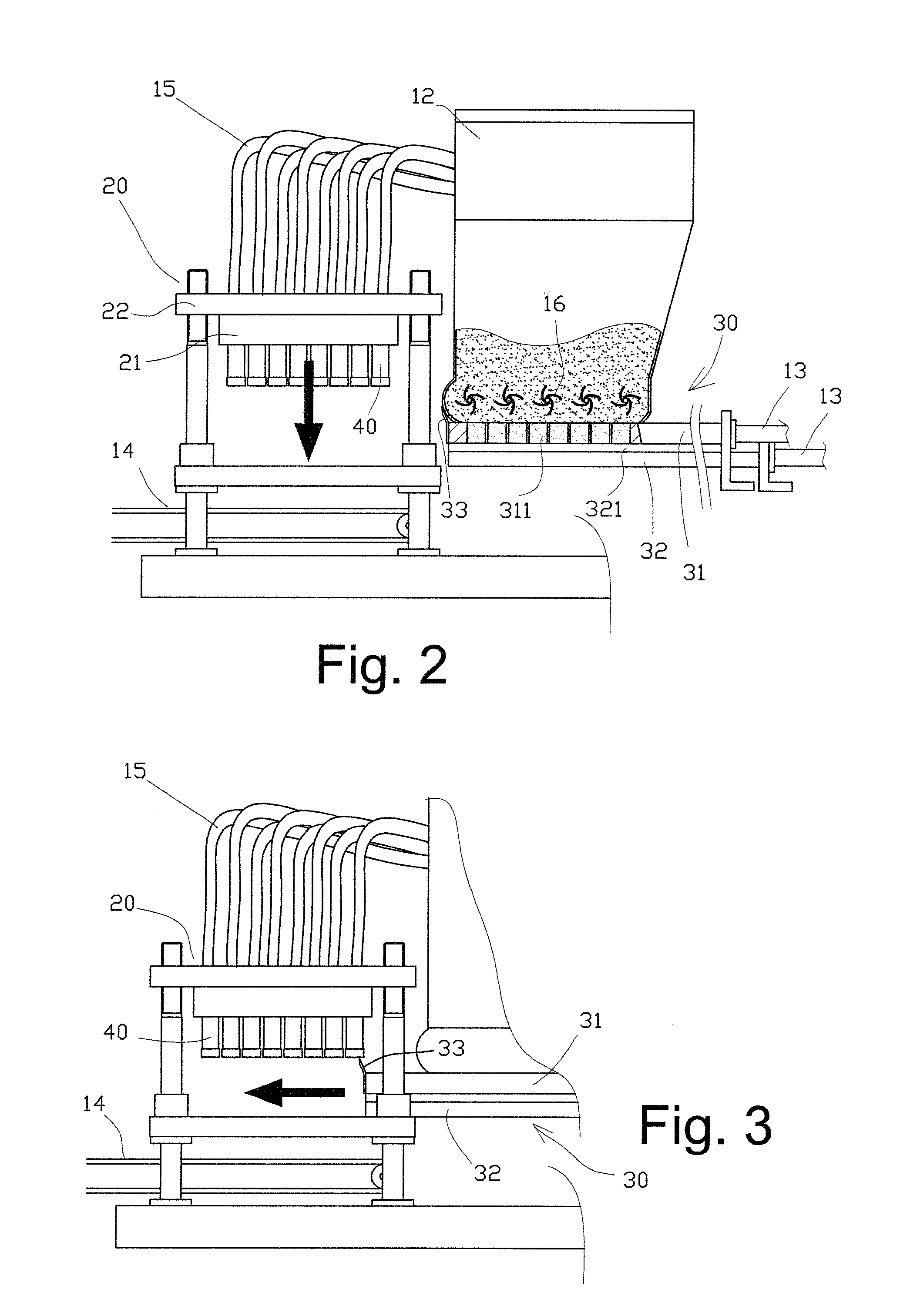

Drive device for driving a closing plate in a vertical mould casting machine and machine comprising said device

InactiveUS20110142980A1Fast compaction compactionQuicker swiveling of the front plateDischarging arrangementMouldsElectricityElectric drive

The invention relates to a drive device for driving a closing plate in a vertical mould casting machine, the mentioned machine comprising displacement means for displacing the closing plate for compacting the casting and for extracting it from the machine. The displacement means comprise electric drive means and transmission means which are arranged between the mentioned electric drive means and the closing plate. The transmission means and the electric drive means are configured to transmit to the closing plate a first displacement with a first speed and a second displacement with a second speed greater than the first.

Owner:LORAMENDI

Vibration temper mill for industrial manufacturing

The invention discloses a vibration temper mill for industrial manufacturing. The vibration temper mill comprises a load bearing plate, a connecting plate, a frame, a drive motor, a connecting rod, a rotating shaft, springs, flail blocks and a handrail. The upper end face of the load bearing plate is connected with the lower end of the frame through the connecting plate. The lower end of the connecting rod is connected with the drive motor. The upper end of the connecting rod is rotationally connected with the upper end of the frame through the rotating shaft. The two springs are located on the two sides of the drive motor correspondingly and located between the drive motor and the frame. Rotary shafts are arranged at the two ends of the drive motor. The two flail blocks are connected with the rotary shafts at the two ends of the drive motor correspondingly. The handrail is fixedly connected with the frame. Compared with the prior art, the vibration temper mill vibrates at high frequency by rotating the flail blocks through the drive motor and can stably vibrate under the action of the springs, and materials can be compacted fast; time and labor are saved; use is convenient; the application range is wide; and the popularization and application value is achieved.

Owner:艾和美

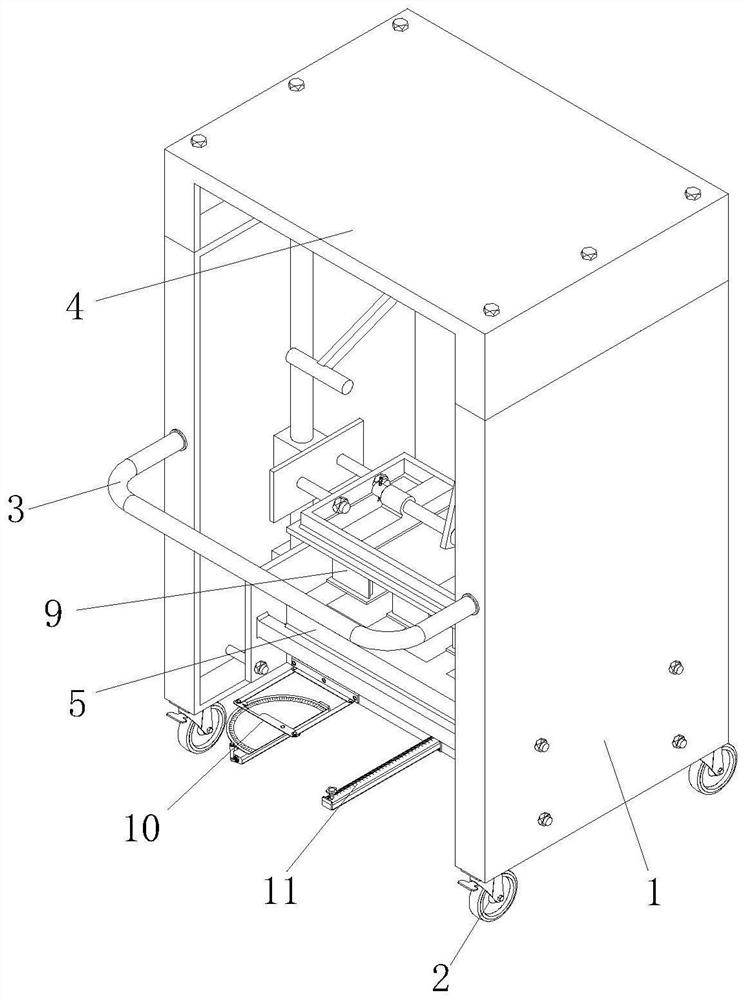

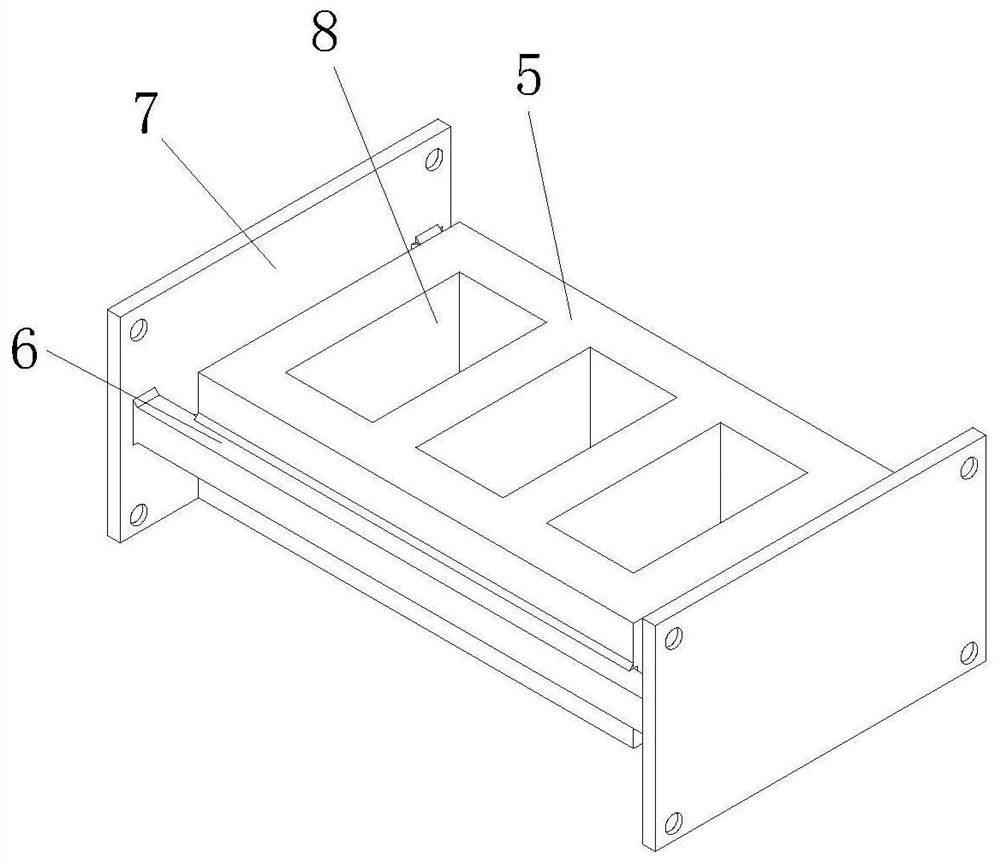

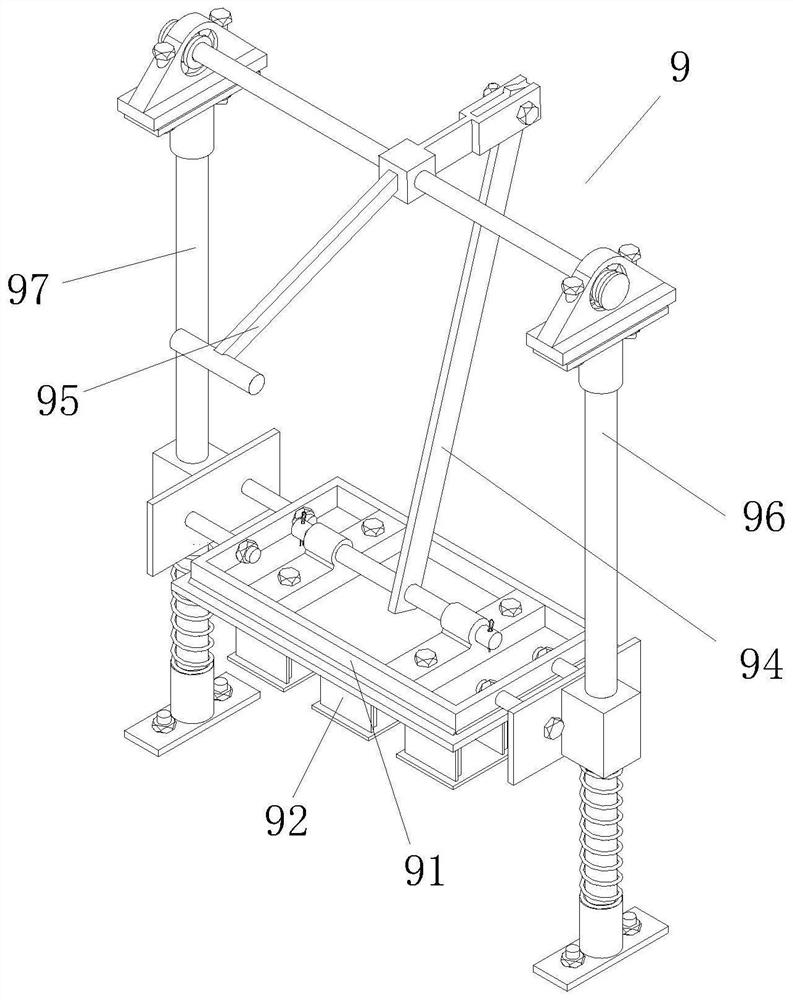

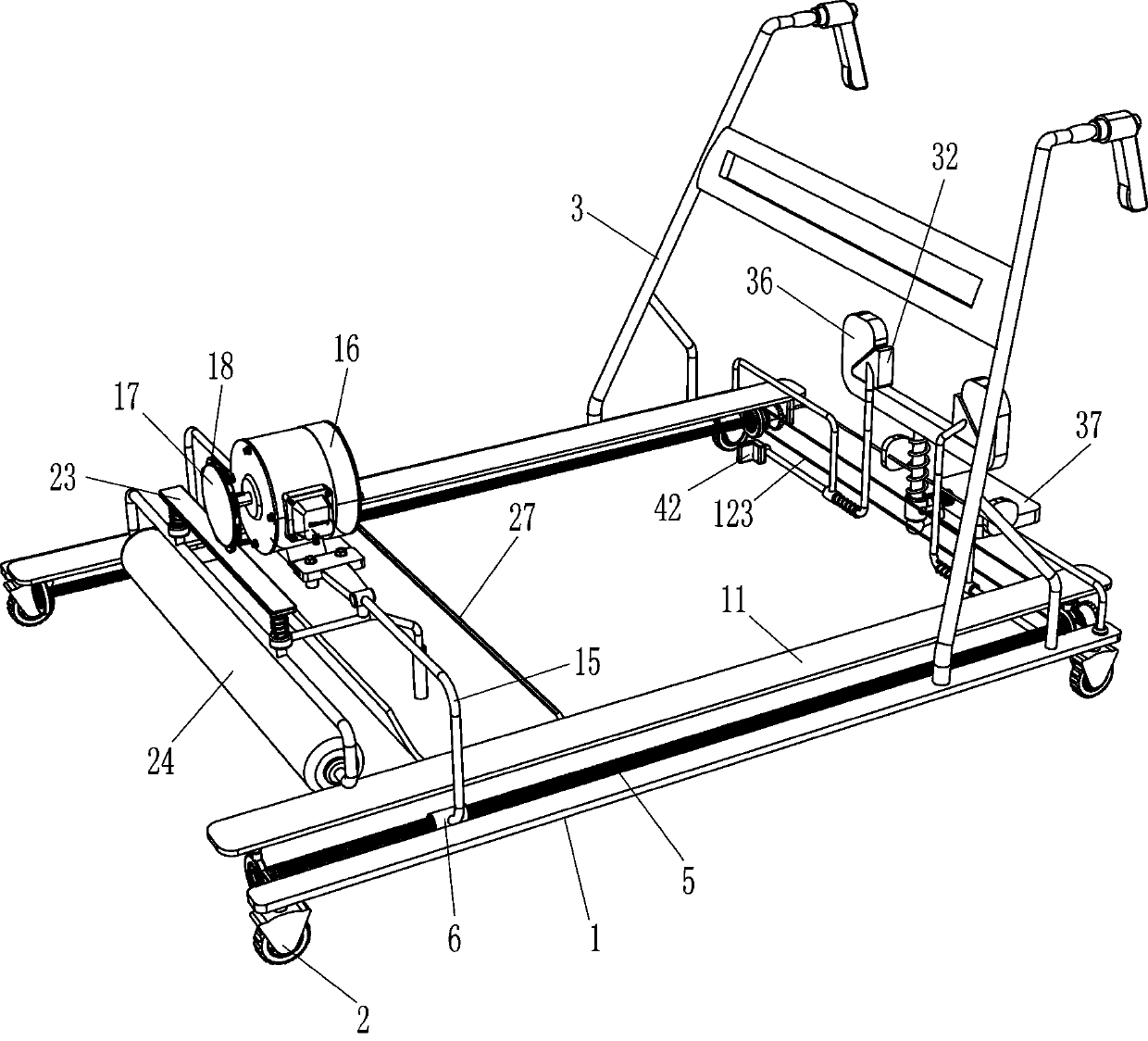

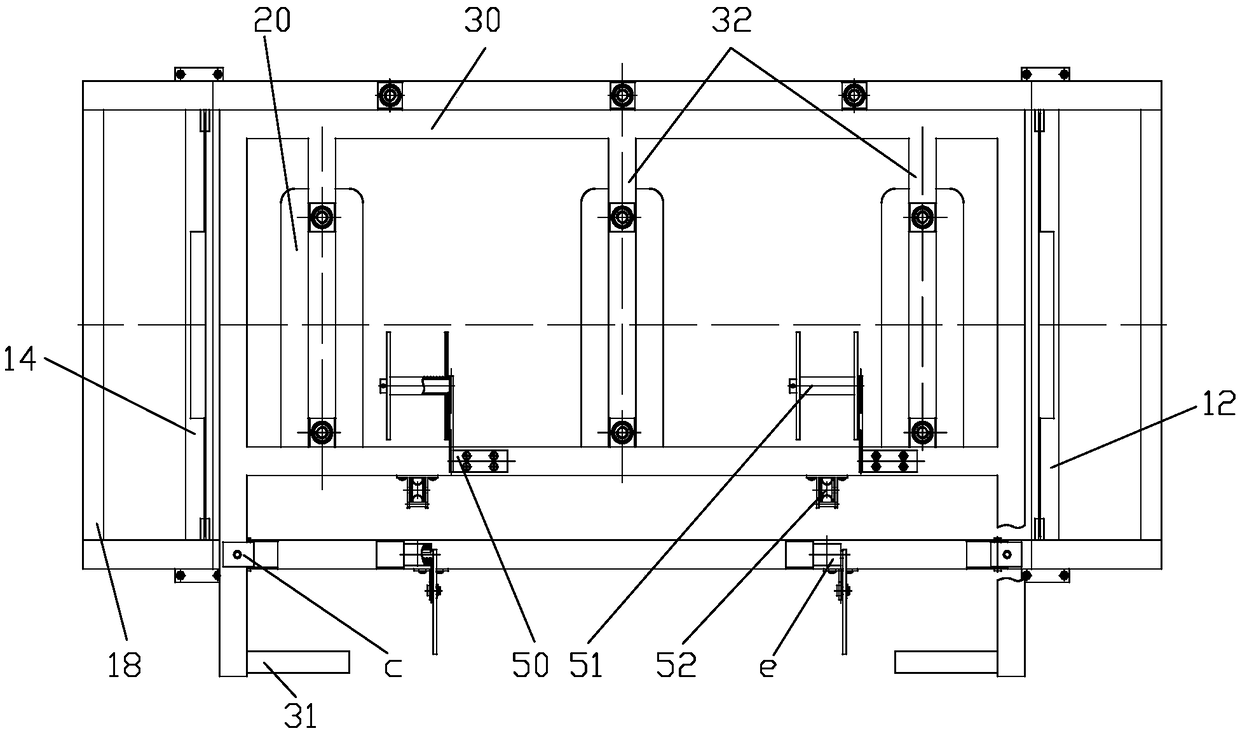

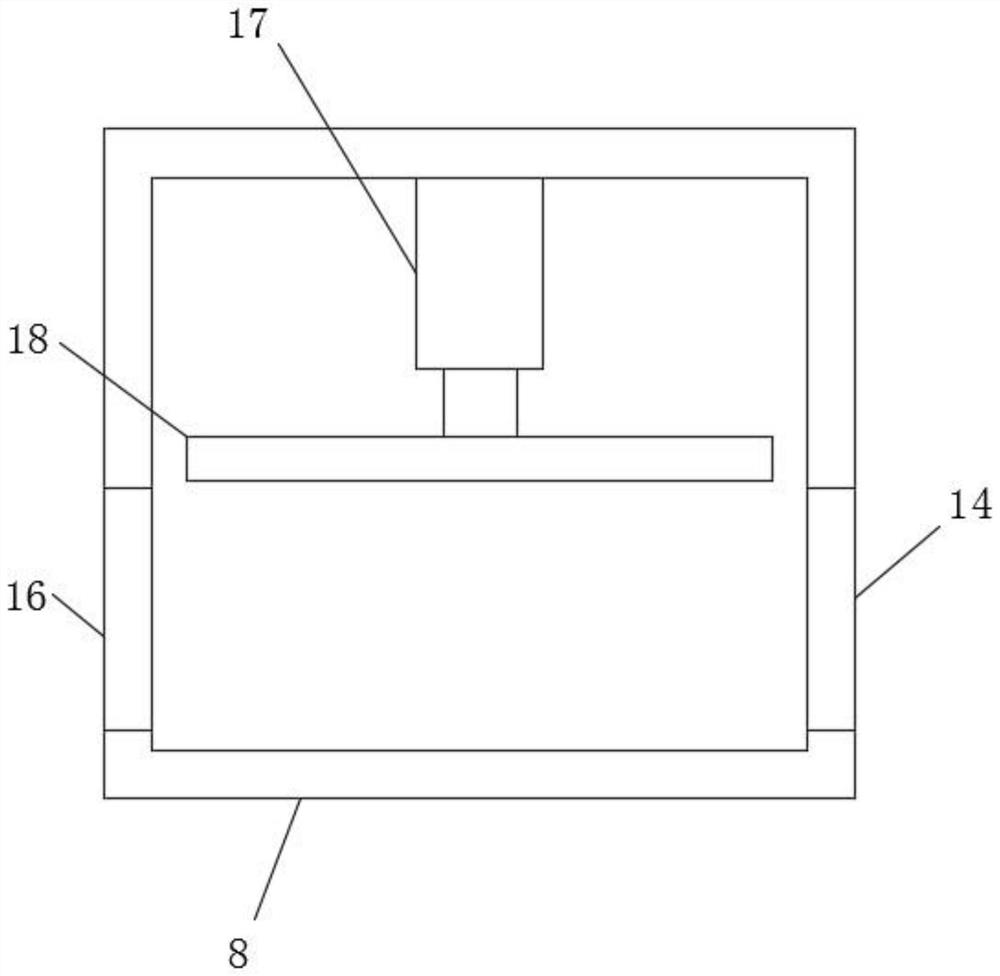

Brick paving device for sidewalk pavement construction

InactiveCN112482154AFast compaction compactionPrevent looseningRoads maintainenceBrickArchitectural engineering

The invention discloses a brick paving device for sidewalk pavement construction. The brick paving device comprises a machine body, walking wheels, a pushing rod, a top cover, a brick paving frame, asupporting transverse frame, a side fixing plate, a brick falling groove, a manual compaction device, an angle measuring device and a distance measuring device. The manual compaction device is arranged, when a push handle is pushed, a pressing seat plate can be driven by a pressing mechanism to press downwards, bricks laid on the bottom face are rapidly compacted through a pressing plate, the laidbricks are prevented from loosening, the compaction efficiency is high, compaction work is manually conducted, the hand can be prevented from being pressed when the bricks are placed, and the safetyis greatly improved; and the angle measuring device is arranged, when a brick paving frame deviates, the angle measuring device can be driven to synchronously deviate, after an adjusting frame is manually adjusted, the angle of a measuring swing frame on the angle scale is changed, and therefore the deviation angle can be rapidly known, a brick paving frame can be adjusted to be in the forward direction, and the paving precision is improved.

Owner:谢艺云

Asphalt road paving process

ActiveCN113756167AEvenly distributed and compactImprove efficiencyRoads maintainenceEnvironmental geologyRoad construction

The invention discloses an asphalt road paving process and relates to the technical field of road construction. The asphalt road paving process specifically comprises an equipment support, wherein a rotating table mechanism is fixedly installed at the bottom of the equipment support, a conveying mechanism is fixedly installed at the top of the equipment support, a storage tank is installed at the top of the conveying mechanism, a heating assembly is installed on the outer side of the storage tank, and a transition pipe is rotatably installed at one end of the outer side of the conveying mechanism; a paving shell of a trumpet-shaped structure is fixedly installed at the bottom of the transition pipe, and a paving assembly is installed between the transition pipe and the paving shell. The asphalt road paving process is advantaged in that the transition pipe is driven by the rotary driving mechanism to rotate and reset, so a vibration flattening assembly is close to an asphalt laying section, the asphalt material is compacted by vibration, and the pavement tamping assembly works in the vibration process, so the asphalt material is distributed more uniformly and compactly, the asphalt material is rapidly tamped, paving and tamping of the asphalt material are combined, and asphalt pavement repairing efficiency is improved.

Owner:龙游吉祥园林建设有限公司

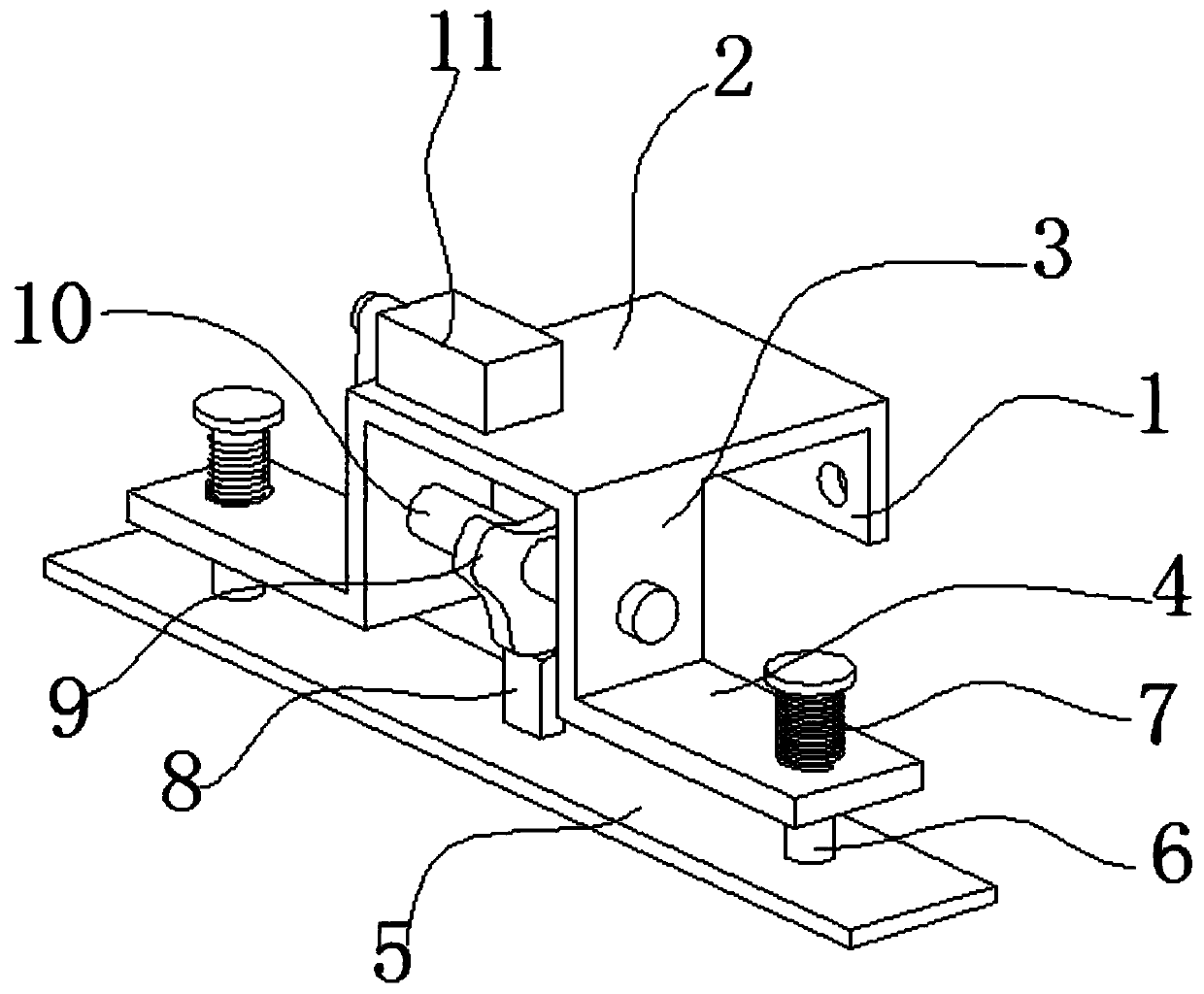

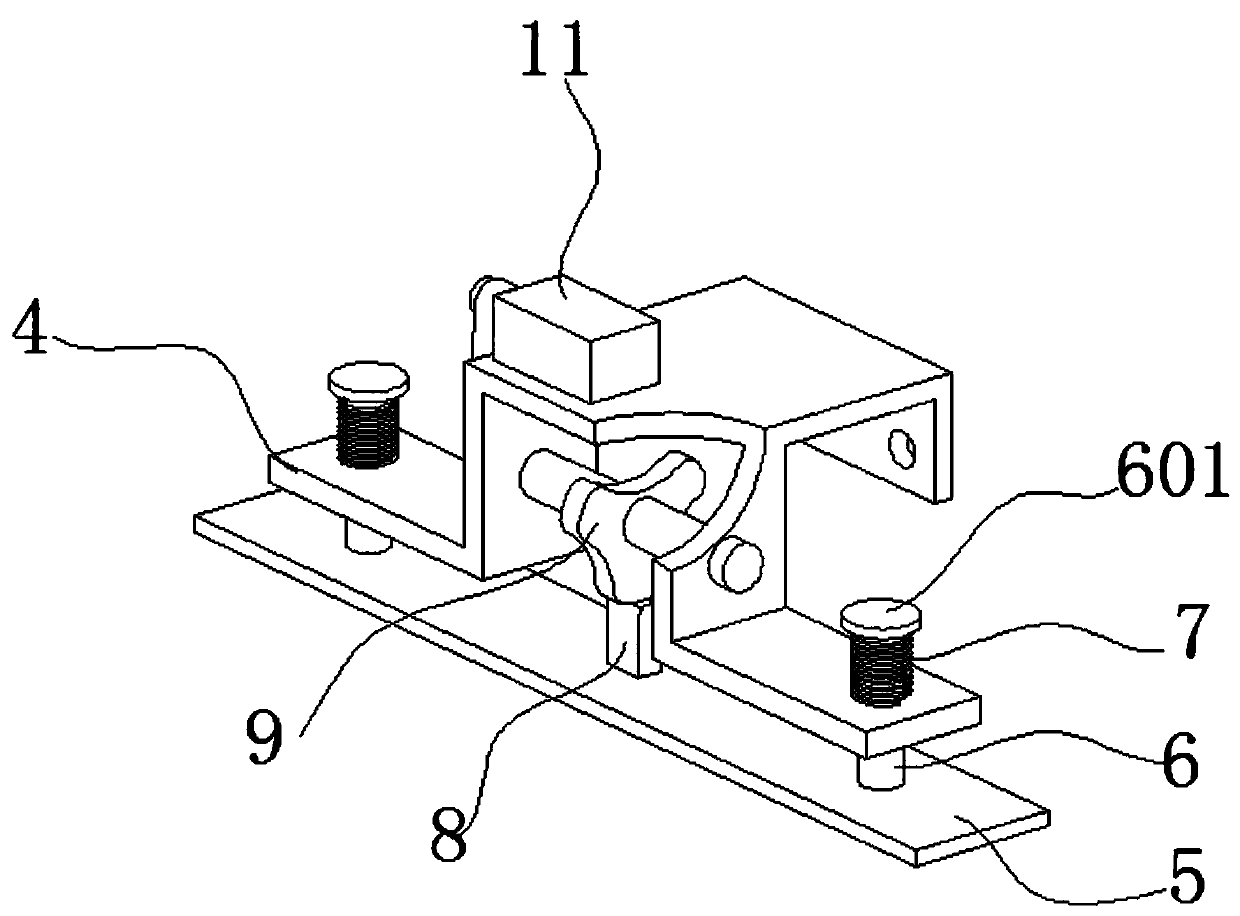

Rapid gap reducing device for ancient building grey tile carving

ActiveCN111376377AFast compaction compactionQuick fixCeramic shaping apparatusConstruction engineeringStructural engineering

The invention relates to a gap reducing device, in particular to a rapid gap reducing device for an ancient building grey tile carving. The rapid gap reducing device for the ancient building grey tilecarving can evenly lay grey tile clay, reduce the manpower consumption and improve the working efficiency. The rapid gap reducing device for the ancient building grey tile carving comprises a mounting plate, wheels, a push rod, moving assemblies, a driving assembly, a flattening assembly and the like, wherein the mounting plate is provided with the wheels, the mounting plate is provided with thepush rod, the two sides of the mounting plate are provided with the moving assemblies moving in a rotating mode respectively, and the driving assembly for providing power in a rotating mode is arranged between the moving assemblies on the two sides. According to the device, through cooperation of screw rods and nuts, the device can be driven to intermittently move during flattening, the grey tileclay can be quickly compacted through cooperation of a rotating disc and a convex block, manual work is not needed, and the working efficiency is improved.

Owner:刘玮

Sticky candy compactor

InactiveCN105230911ARapid processabilityFast compaction compactionConfectionerySweetmeatsHydraulic cylinderEngineering

The present invention discloses a sticky candy compactor which includes a rack. An upper pressing plate, a lower pressing plate, a spring, an upper roller, a lower roller, a conical ejector block and a push rod driving the conical ejector block are horizontally arranged in sequence from left to right on the rack. An upper pressing block is welded at the left end of the upper pressing plate; the middle of upper pressing plate is hinged on the rack; an upper roller is pivoted at the right end of the upper pressing plate; a lower pressing block is welded at the left end of the lower pressing plate; the middle of the lower pressing plate is hinged on the rack; and a lower roller is pivoted at the right end of the lower pressing plate. One end of the spring is winded to the fixed pin on the right end of the upper pressing plate, and the other end of the spring is winded to the fixed pin on the right end of the lower pressing plate. The upper roller and the lower roller both abut against the conical ejector block. The center of the conical ejector block is fixed to the push rod via a bolt, and the push rod is driven by an air cylinder or a hydraulic cylinder. The heads of the upper pressing block and the lower pressing block both show obtuse angles. Grooves which are used to contain the bodies of sticky candies and sesame are arranged on the rack correspondingly.

Owner:CHONGQING YU NIU FOOD CO LTD

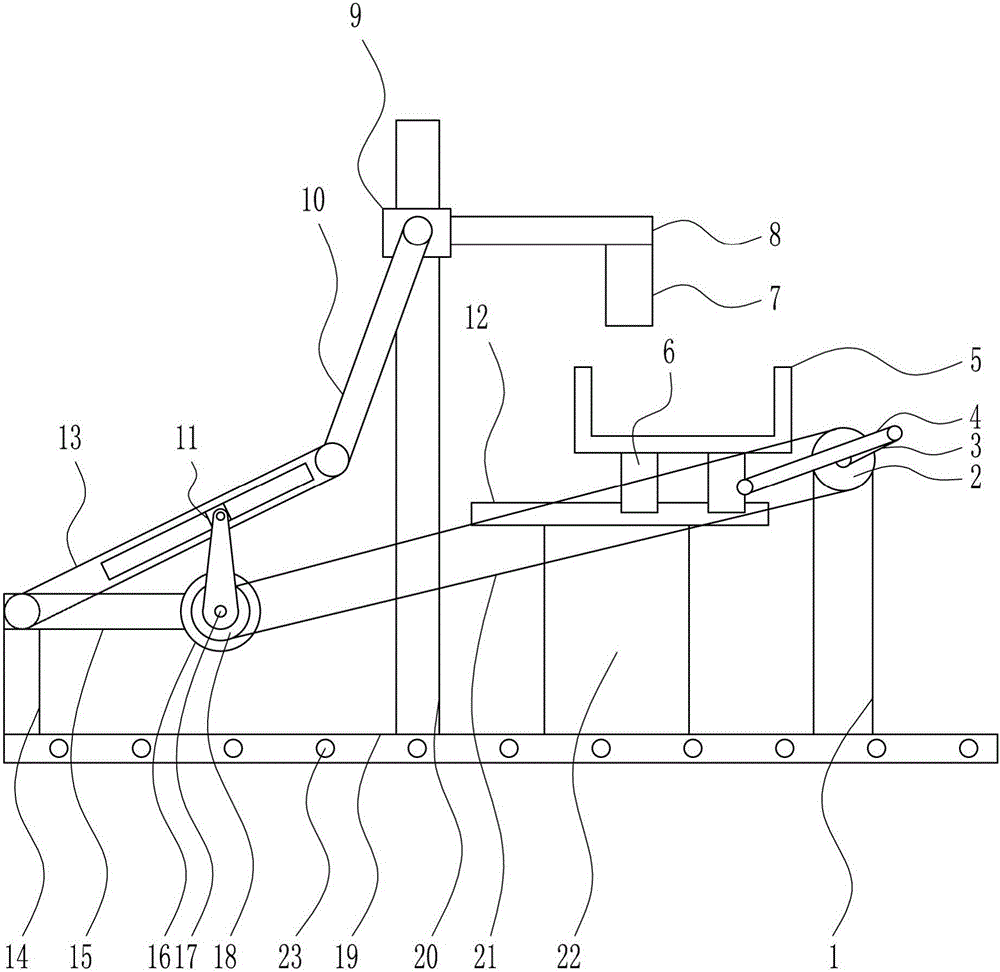

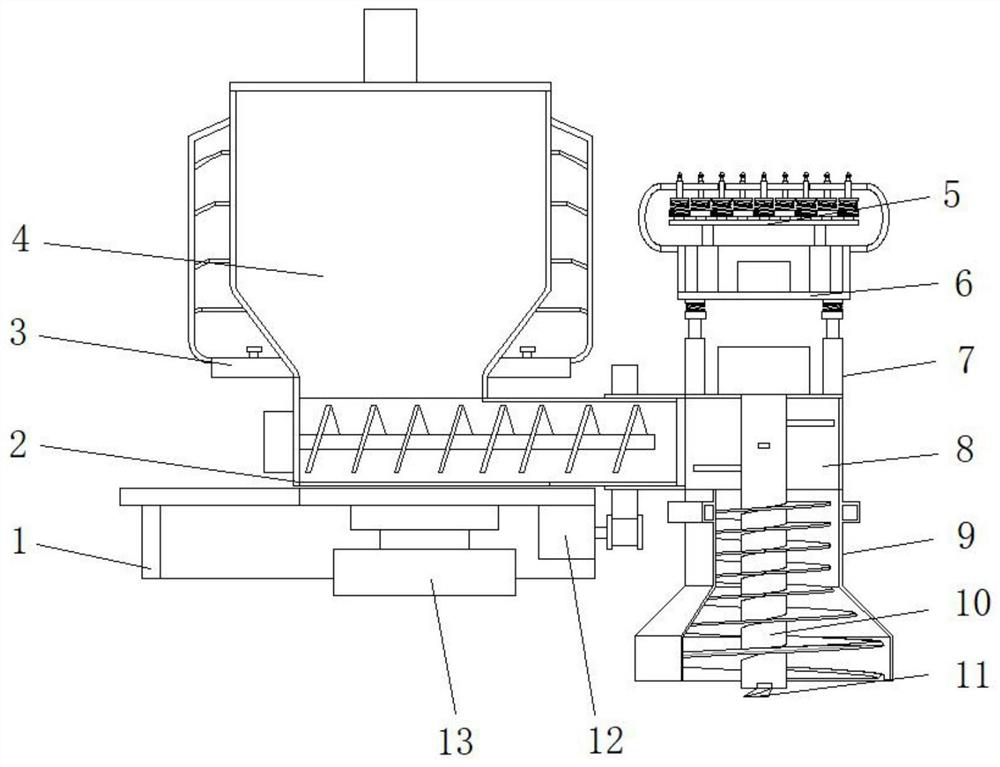

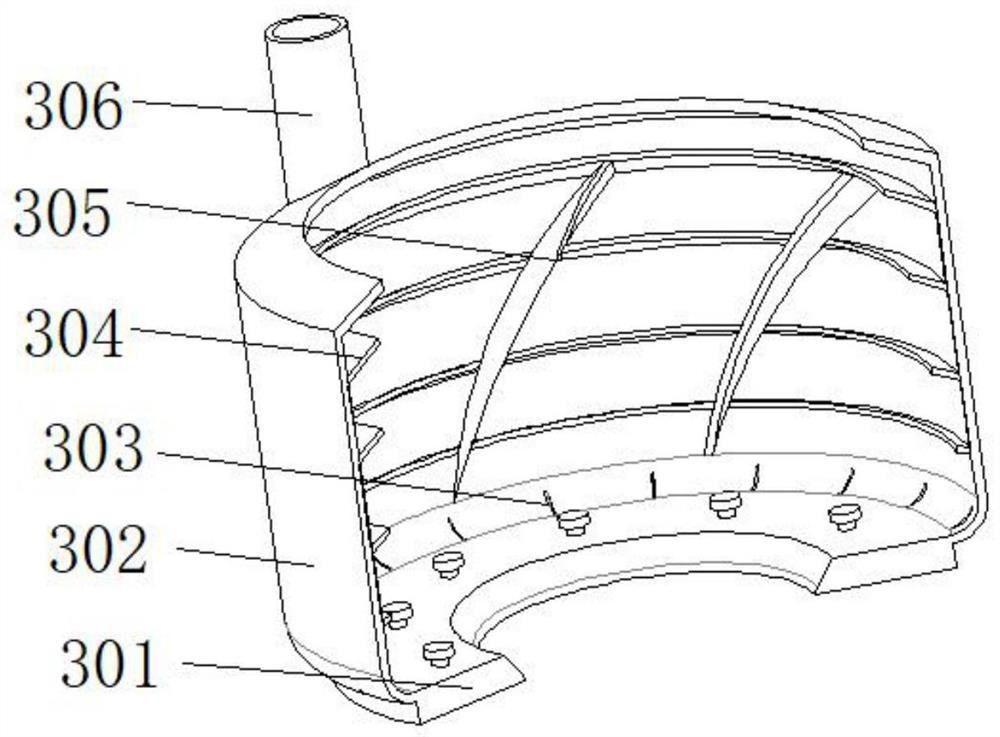

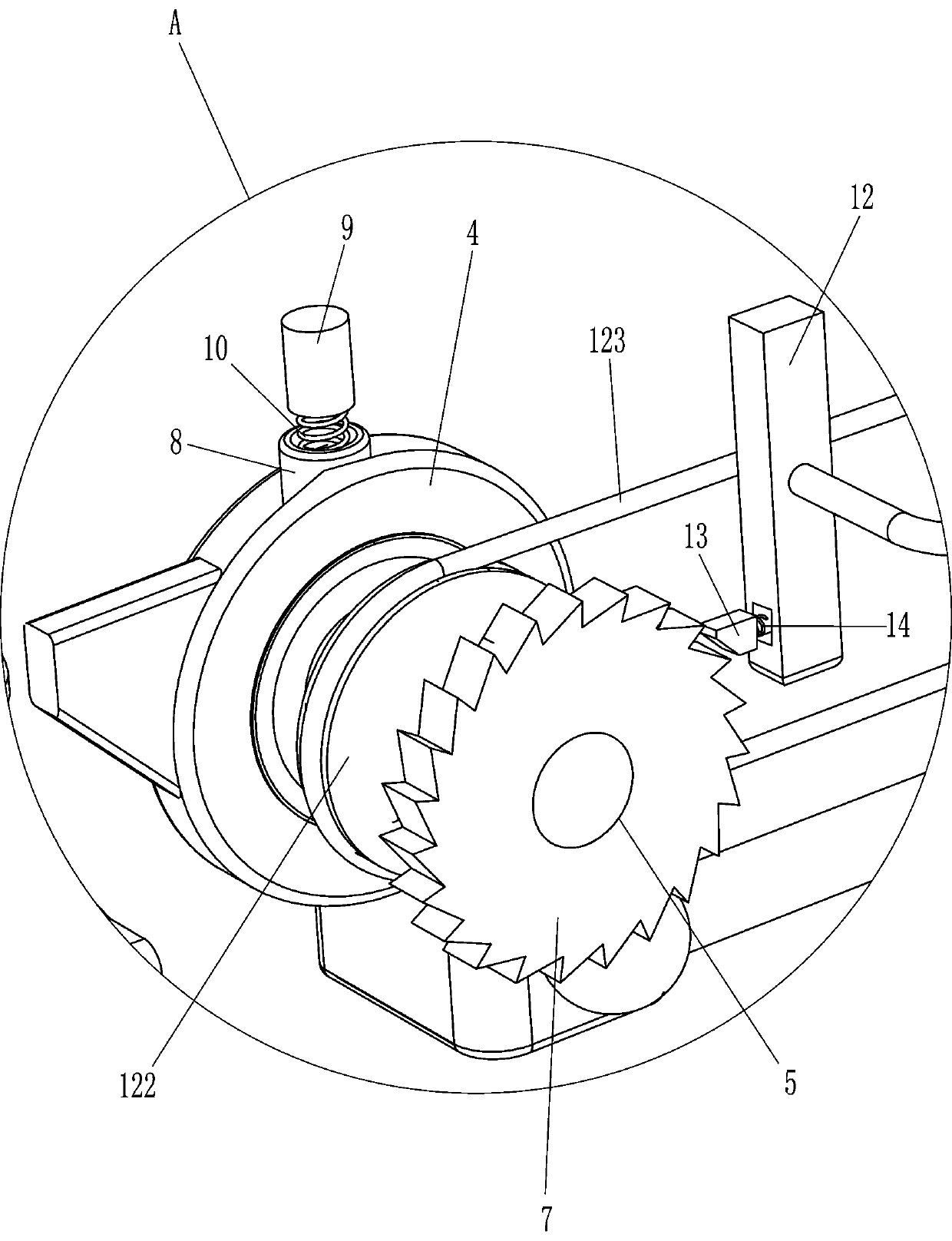

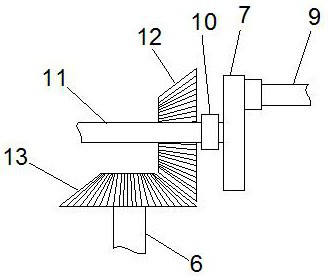

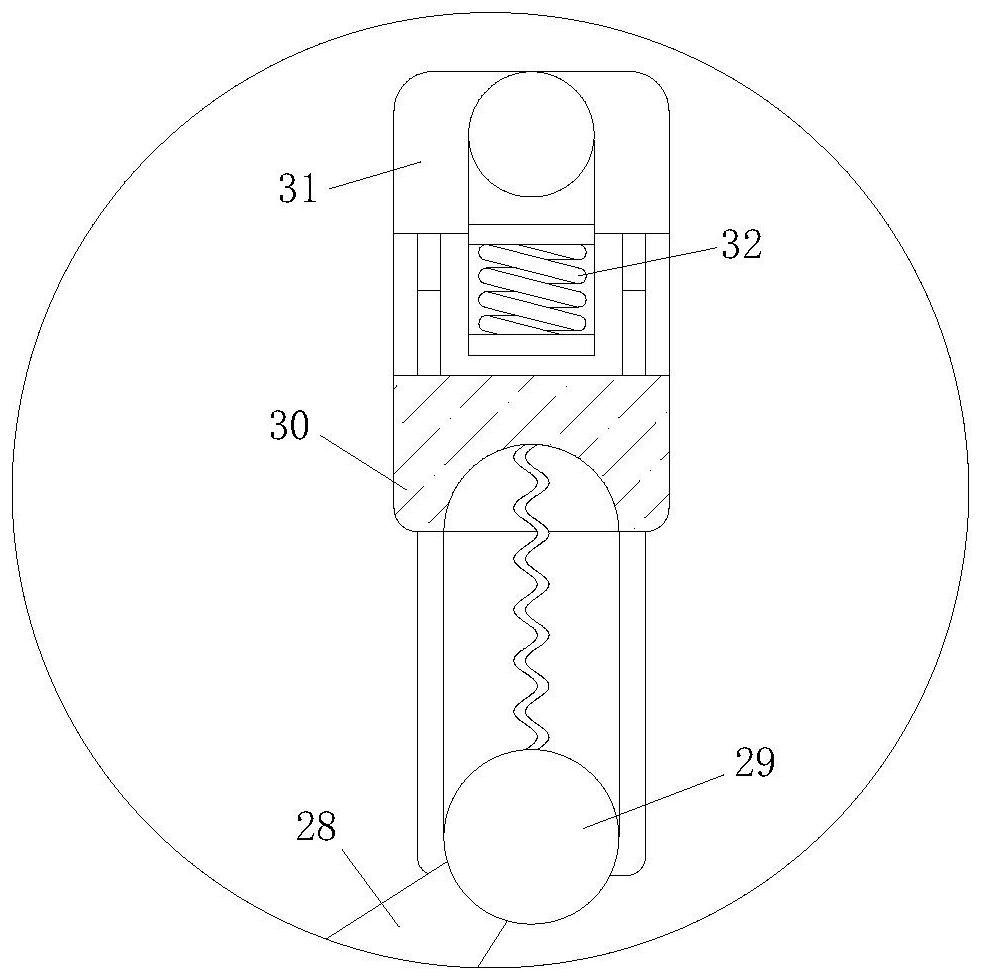

Quick vibration and tamping mechanism of asphalt for road and bridge construction, using method and asphalt paver of same

ActiveCN110258265AQuick vibrationFast compaction compactionRoads maintainenceRoad surfaceUltimate tensile strength

The invention discloses a quick vibration and tamping mechanism of asphalt for road and bridge construction, and a using method and an asphalt paver of the same, and relates to the technical field of road construction. The quick vibration and tamping mechanism comprises a support seat, a vibration and tamping plate, a lug and a driving wheel. The vibration and tamping plate is arranged on the lower part of the support seat and moves vertically, and the driving wheel is rotatably connected with the support seat. The lug is arranged on the lower part of the driving wheel, and the bottom of the lug is connected with the upper part of the vibration and tamping plate. The driving wheel drives the vibration and tamping plate to perform vibration of different strengths through the lug. The vibration and tamping plate tend to move upward in the absence of external force. The quick vibration and tamping mechanism of the asphalt for the road and bridge construction is capable of performing vibration of different strengths on a same asphalt layer, further performs vibrating and tamping on the asphalt layer, facilitates exhausting of air from the asphalt layer and further facilitates quick tamping of the asphalt layer, thereby avoiding over-vibration and damages to edges of surface pellet materials. The quality of an asphalt pavement is guaranteed and the life cycle of the asphalt pavement is prolonged. The quick vibration and tamping mechanism of the asphalt for the road and bridge construction has the advantages of being simple in structure, reasonable in design and easy to manufacture.

Owner:陈洁

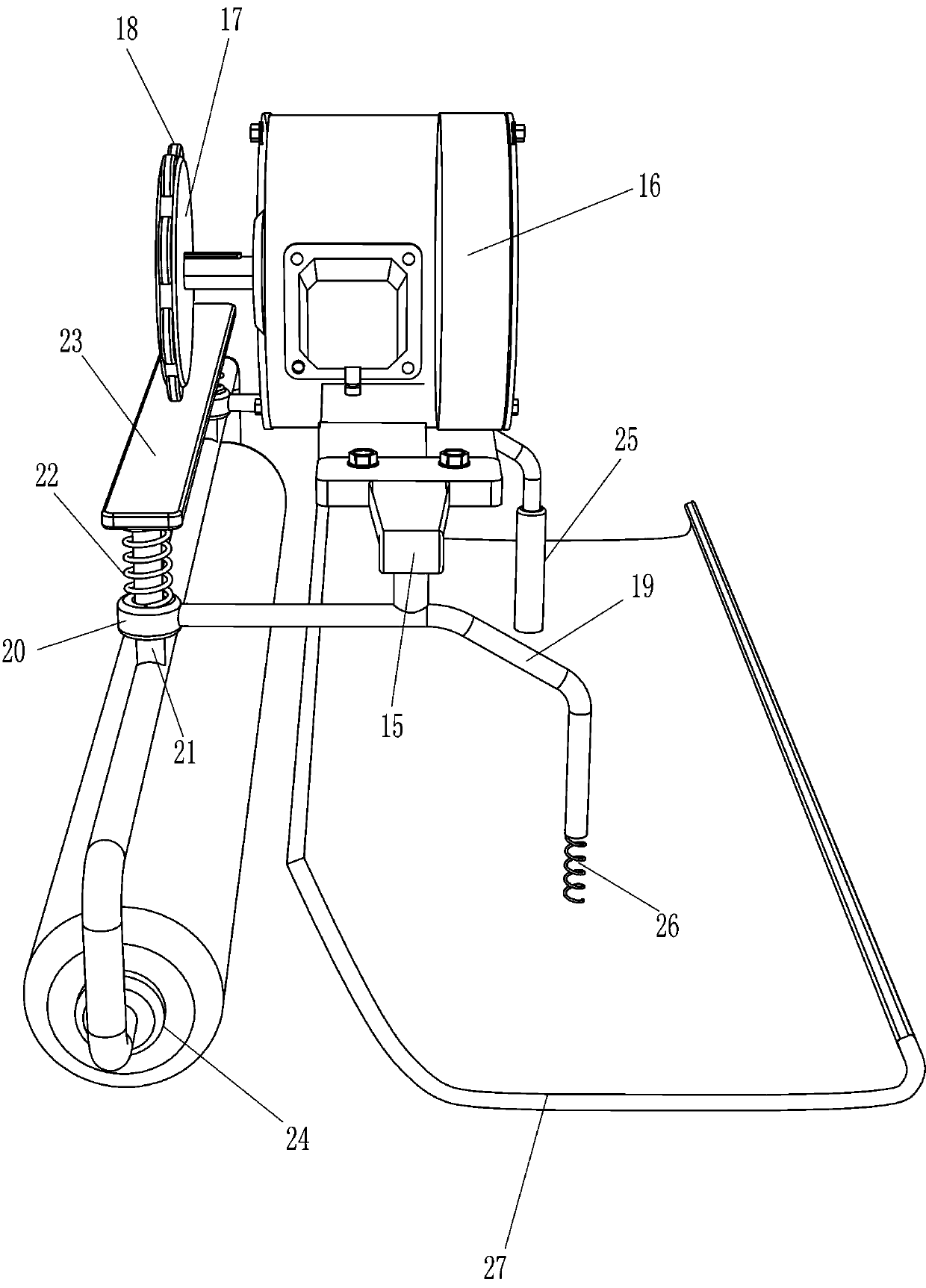

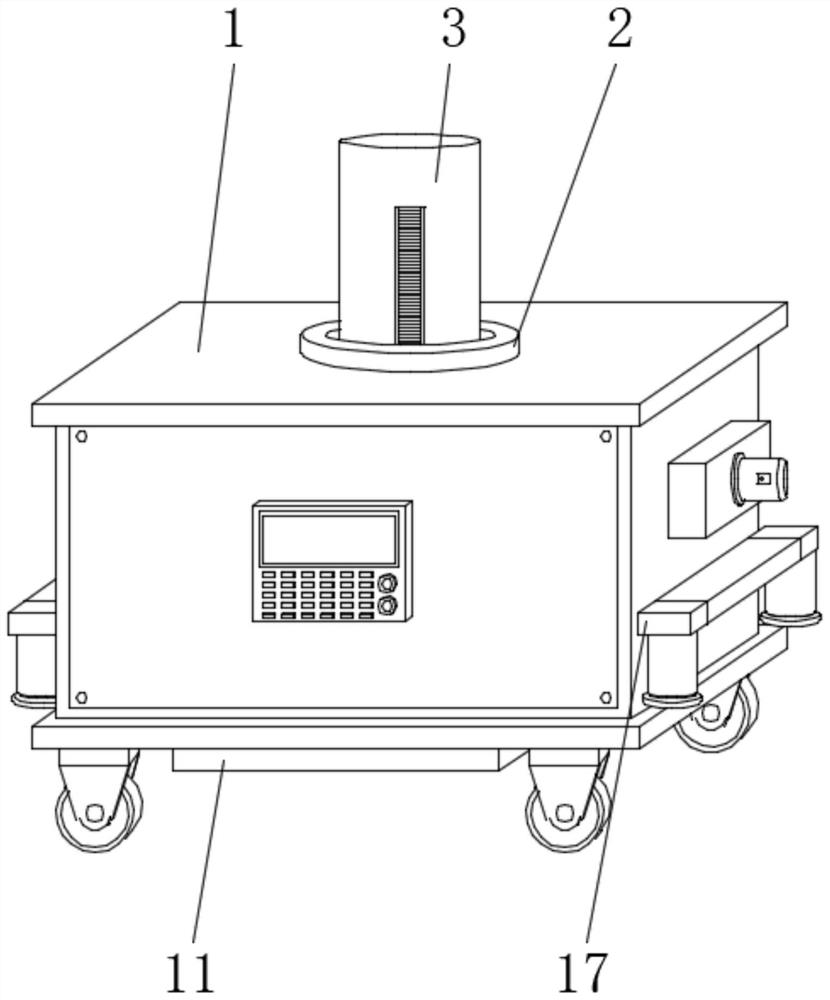

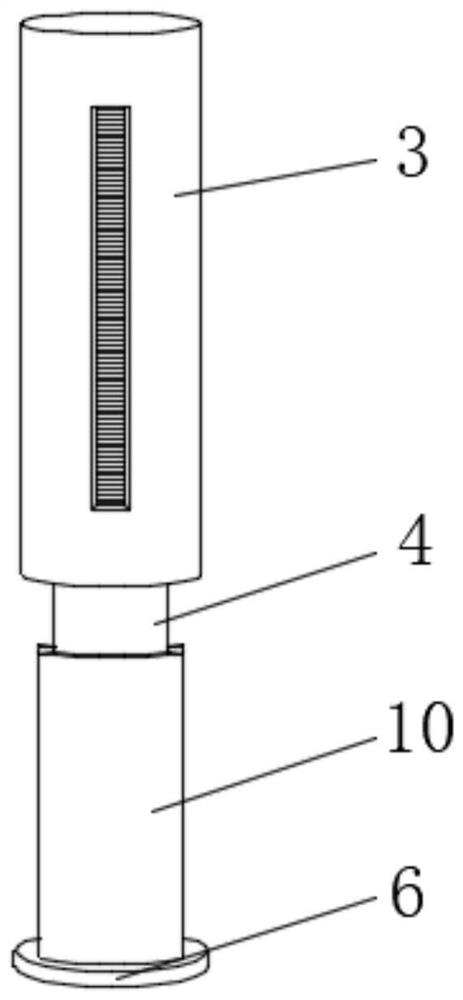

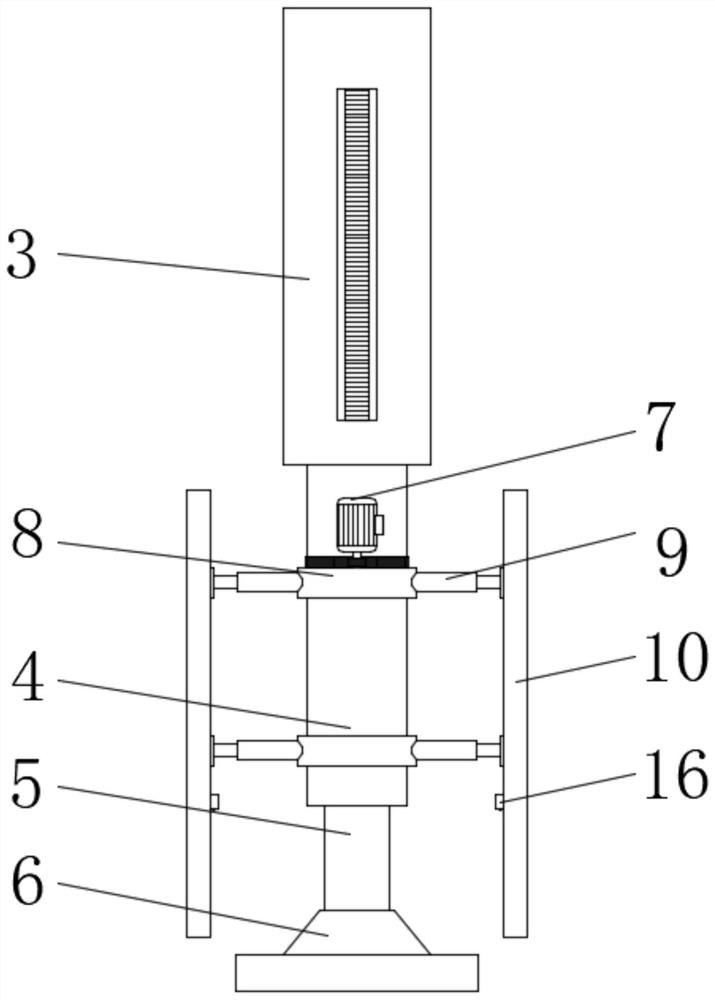

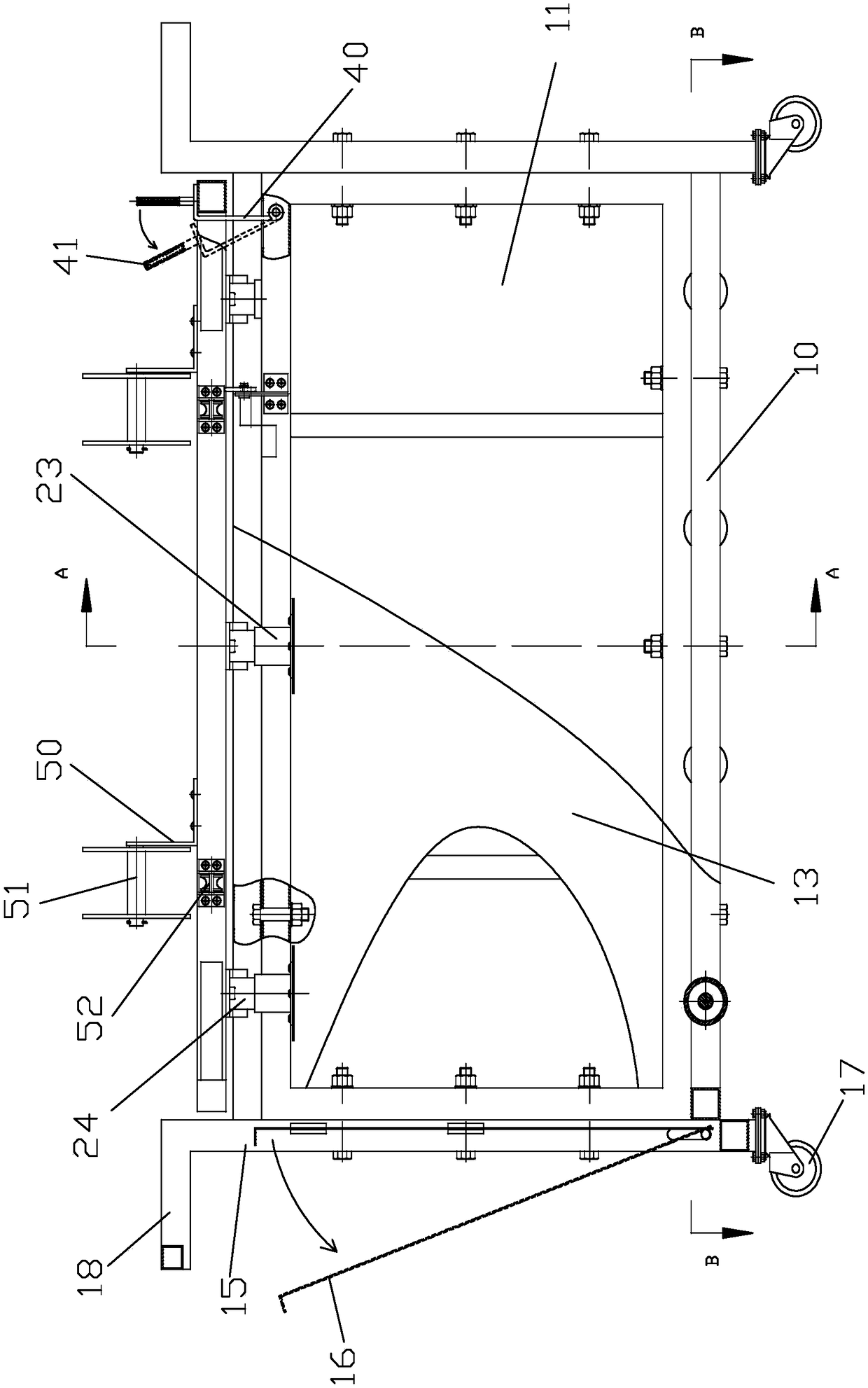

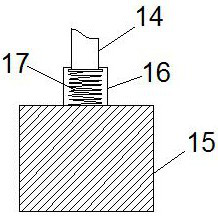

Pole pit tamping device for electric power engineering

ActiveCN113882352AFast compaction compactionImprove compaction efficiencySoil preservationStructural engineeringPower engineering

The invention discloses a pole pit tamping device for electric power engineering, and belongs to the field of electric power engineering. The pole pit tamping device comprises a conveying vehicle body and a tamping column, a guide sleeve is arranged in the conveying vehicle body, a lifting assembly is arranged in the guide sleeve, and a ground tamping device is arranged on the lower end face of the conveying vehicle body; and the tamping column is movably installed in the guide sleeve, the tamping column is connected with the lifting assembly, an installation sleeve is arranged on the lower end face of the tamping column, and an adjusting assembly is arranged on the outer surface of the installation sleeve. According to the pole pit tamping device for the electric power engineering, pit tamping can be carried out on the surface of a pole pit, the bottom surface of the pole pit and the ground around the pole pit at a time, multiple times of pit tamping is not needed, the pole pit tamping speed is high, the pole pit tamping efficiency is relatively high, the pole pit tamping device can tamp pole pits of different sizes, the applicability is high, the use effect is good, people can conveniently calibrate the position of the pole pit tamping device for the electric power engineering, and a better use prospect is brought.

Owner:STATE GRID HEBEI ELECTRIC POWER CO LTD +2

Metal powder processing, paving and forming device

The invention discloses a spreading forming device for metal powder processing. The spreading forming device comprises a fixed mounting plate, a supporting connecting column, a supporting fixing ring, a flattening and compacting mechanism, an electric rotating table, a movable sliding rail, a placing mold, an automatic cleaning device and a motor. In the using process, through cooperative work of an auxiliary flattening plate and a main flattening plate in the paving and compacting main body, metal powder placed in the mold is flattened and compacted sufficiently and rapidly, and the automatic cleaning device can be used for automatically and clearly cleaning the metal powder adhering to the auxiliary flattening plate and the main flattening plate; a large amount of metal powder is prevented from being adhered to the auxiliary flattening plate and the main flattening plate in the process of flattening and compacting the metal powder by using the auxiliary flattening plate and the main flattening plate; and the phenomenon that the metal powder adhering to the auxiliary flattening plate and the main flattening plate adheres to and attracts the powder in the placing mold in the automatic flattening process of the placing mold is also prevented from happening in the mode that the metal powder adhering to the auxiliary flattening plate and the main flattening plate adheres to and attracts the powder in the placing mold.

Owner:李文平

Sticky candy compacting equipment

InactiveCN105211459ARapid processabilityFast compaction compactionConfectionerySweetmeatsEngineeringLocknut

Owner:CHONGQING YU NIU FOOD CO LTD

Compacting equipment for processing sticky candies

The invention discloses compacting equipment for processing and producing sticky candies. A mounting hole is formed in the horizontal direction of a machine frame, wherein a fixing sleeve is fixed in the mounting hole in the machine frame through a screw, and an anti-rotation clamping groove is formed in the side wall of the sleeve; the head part of a bolt is arranged in the fixing sleeve in a sliding manner, and an anti-rotation pin is in threaded connection to the side wall of the head part of the bolt and extends into the anti-rotation clamping groove; the tail part of the bolt penetrates through a right clamping jaw and a left clamping jaw and is in threaded connection with a locking nut; a second through hole through which the bolt penetrates is formed in the middle part of the right clamping jaw, the lower part of the right clamping jaw is hinged to the machine frame, and the upper part of the right clamping jaw is used for fixing a right pressing block; a first through hole through which the bolt penetrates is formed in the middle part of the left clamping jaw, the lower part of the left clamping jaw is hinged to the machine frame, and the upper part of the left clamping jaw is used for fixing a left pressing block; a spring is also mounted between the left clamping jaw and the right clamping jaw, the spring is connected to the bolt in a sleeving manner, the right side of the right clamping jaw is propped against the fixing sleeve, and the left side of the left clamping jaw is propped against the locking nut.

Owner:CHONGQING YU NIU FOOD CO LTD

Forming machine that quickly compacts hollow materials and automatically recycles the materials

A forming machine that quickly compacts hollow materials and automatically recycles the materials includes molds, each of which is provided with a feeder having a hollow hole. An opening of the feeder is exactly located at a hollow position of a food product to be formed, and an upper end of the hollow feeder is connected with recycling tubes coming from a feed tank. When a cope and a nowel compact and form the materials into the hollow food products, the feeders will automatically push upward remainders at hollow places of the food products that are stacked constantly, enabling the remainders to enter into the feed tank along the recycling tubes, so as to achieve effects of quickly compacting and processing the materials and automatically recycling the remainders.

Owner:CHIANG WEN DI

Sticky candy pressing device

InactiveCN105230910AFast compaction compactionImprove efficiencyConfectionerySweetmeatsEngineeringScrew thread

The present invention discloses a sticky candy pressing device which includes a body rack. A perforative through-hole is arranged horizontally on the body rack, a sleeve is located in the through-hole, a bolt is slidably arranged within the sleeve, a left end of a screw protrudes from the sleeve and connected with a nut, a wrench is in a bell socket on the nut, a hand shank is welded on a side face of the wrench, a bar-type hole is opened in the central part of the bolt, a left clamping block is in a bell socket of the middle part of the bolt, the left side of the left clamping block counterbalances with the left side of the left clamping block, the right side of the left clamping block projects to formed a boss, the side face of the left clamping block is socketed with a pin, the pin passes through a bar groove, the screw thread of an anti-rotating pin is connected to the lower end of the left clamping block, one end of the anti-rotating pin is socketed to a guide hole below the body rack, the left end of the right clamping block projects to form a bulge loop, the bulge loop is in a bell socket with the boss, a spring is also arranged between the boss and the bulge loop, the right end of the right clamping block is socketed with a bolt, a semicircle is used to bind the bulge loop and the boss, a regulation hole to the through-hole is opened at the lower end of the body rack, a regulation screw is in a screw thread connection within the regulation hole, and the inside end of the regulation screw counterbalance the sleeve.

Owner:CHONGQING YU NIU FOOD CO LTD

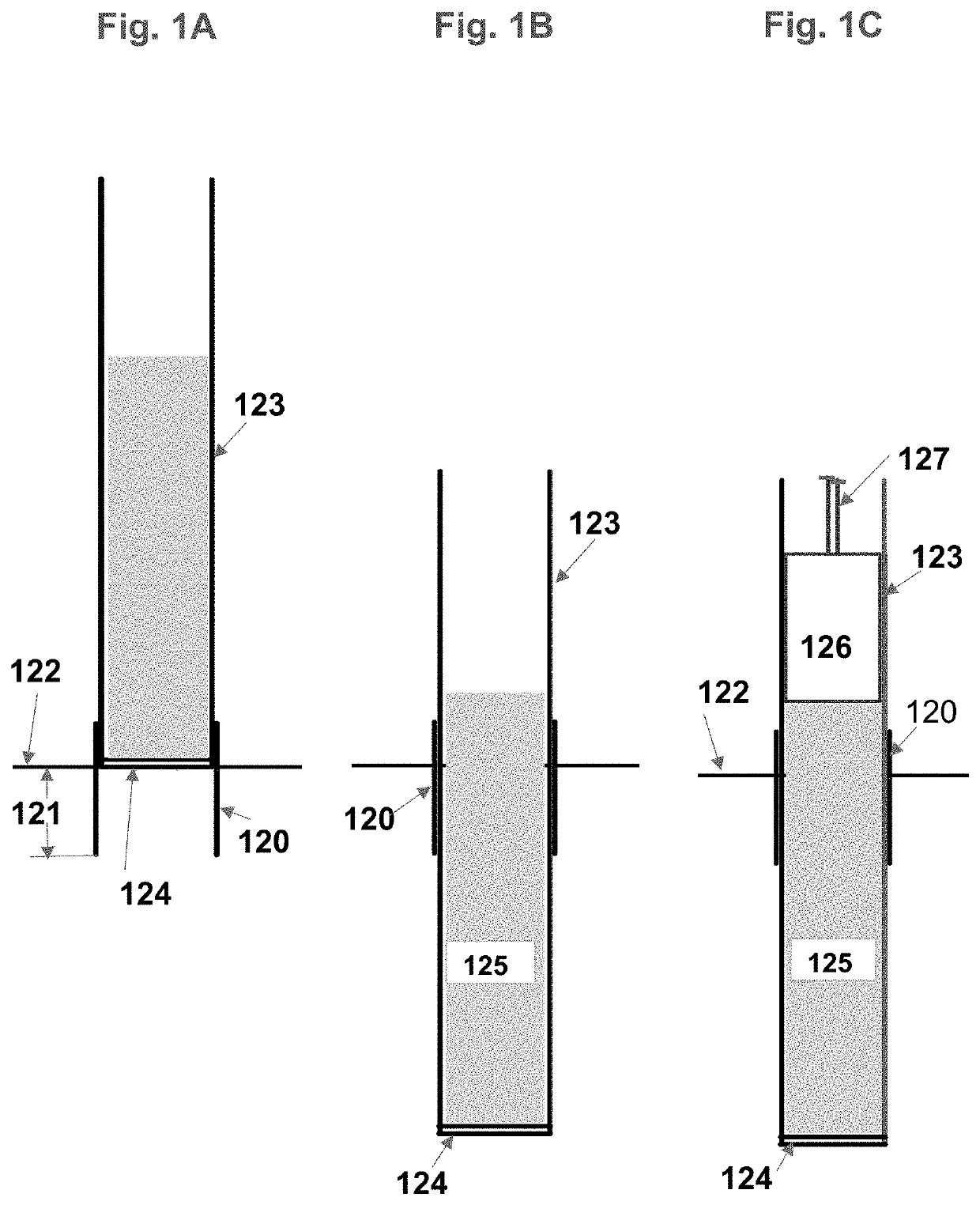

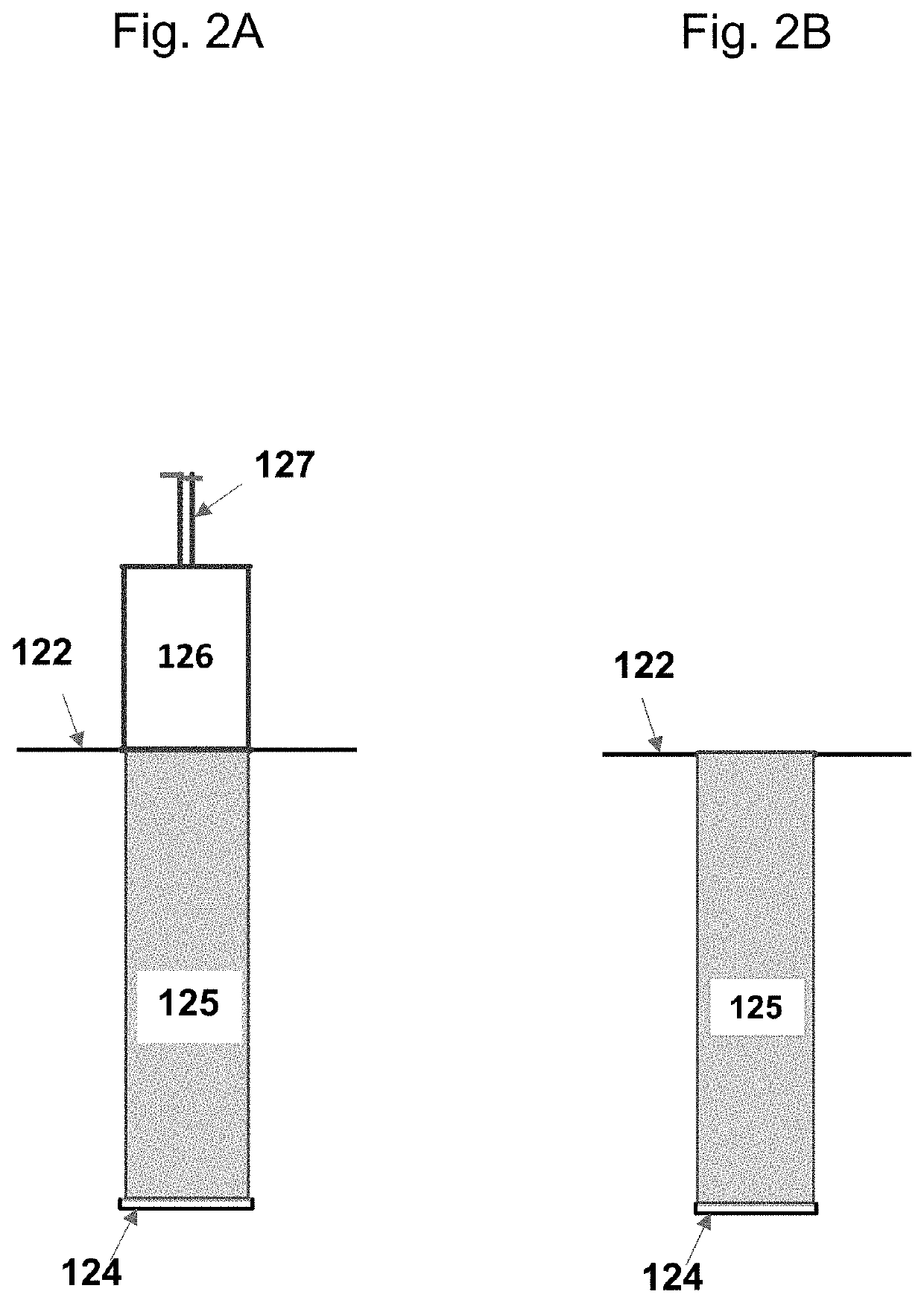

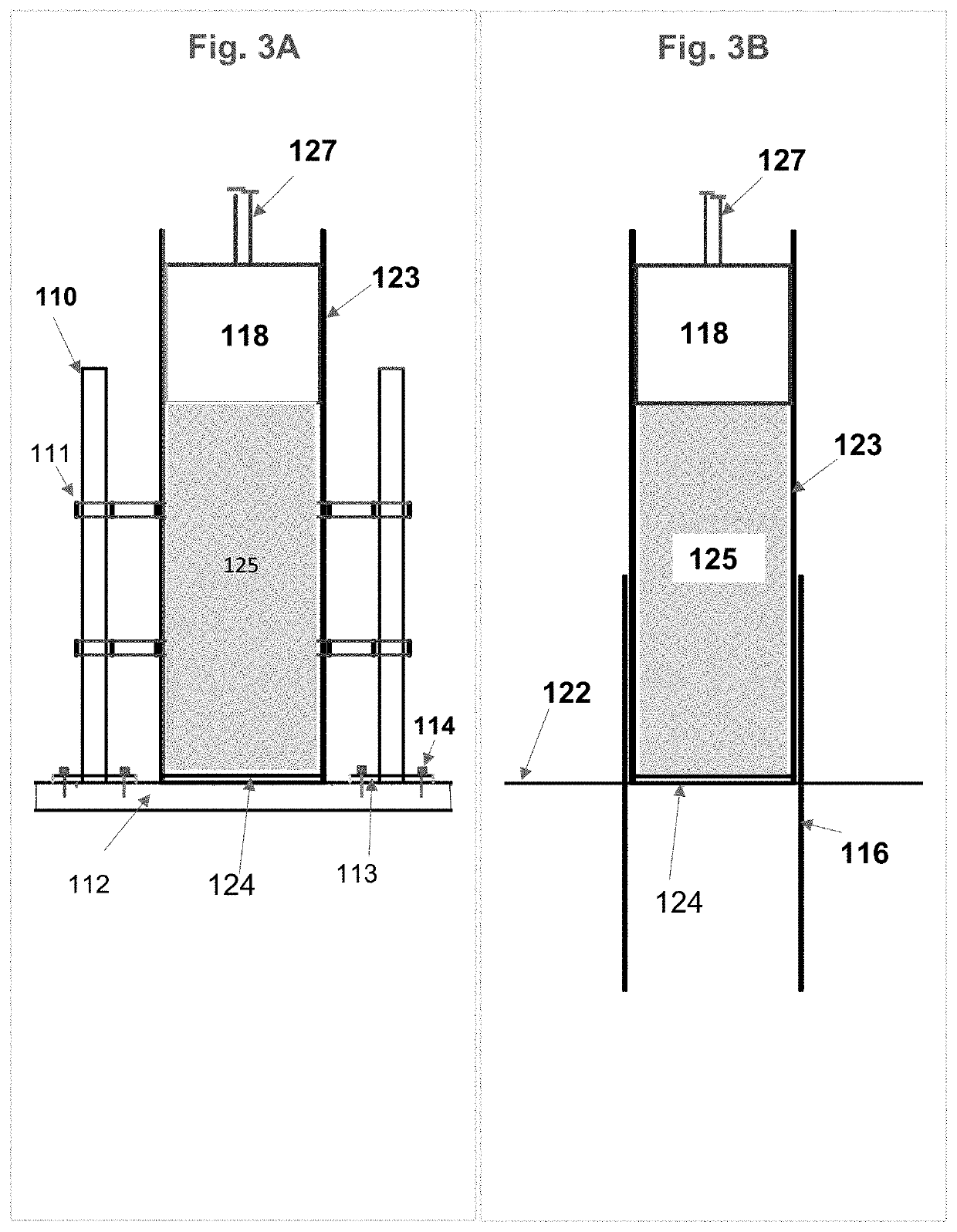

Rapid consolidation and compaction method for soil improvement of various layers of soils and intermediate geomaterials in a soil deposit

The rapid consolidation and compaction method comprises (i) first driving a hollow pipe, (ii) driving a pipe with a removable end plate after filling and compacting the sandy material in it, through the hollow pipe, to required depth, creating high excess pore-water pressures in the range of 50 to 300 KPa in clayey soils, (iv) pulling out the pipe section leaving behind the removable end plate and thereby installing porous displacement piles which allows dissipation of the excess pore-water pressures horizontally to the porous displacement pile, in which the excess water flows out vertically to the ground surface, and (v) the length of the drainage path is reduced to half the spacing between adjoining porous displacement piles, allowing rapid consolidation resulting in increase in density. Installing the porous displacement piles in the layer of loose to medium dense sand layer results in the instantaneous increase in its density.

Owner:GUPTA RAMESH CHANDRA

Rapid packing machine

InactiveCN109051023AFast strappingEasy to shipBinding material applicationBundling machine detailsWaste treatment

The invention relates to the technical field of waste resource recycling and processing equipment, in particular to a rapid packing machine. The machine comprises a waste containing box with a top endopening and a waste abutting-pressing cover whose rear end part is connected with the rear side of the top end opening of the waste containing box in a turnover mode, the front side of the top end opening of the waste containing box is provided with a tensioning lock used for locking the waste abutting-pressing cover on the waste containing box, a rope guiding mechanism used for winding binding ropes is further arranged on the front side of the waste abutting-pressing cover, and a rope pressing mechanism used for fixing ends of the binding ropes is arranged at a position on the front side ofthe top end opening of the waste containing box and in the same straight line with each rope guiding mechanism. According to the machine, packaging waste with different specifications and different shapes can be quickly compacted, bound and packaged based on specified size so as to provide convenience for waste conveying or stacking, and meanwhile, the waste treatment efficiency is greatly improved; and the structure of the machine is simple and compact, operation is convenient and rapid and strong practical value and market popularization value are achieved.

Owner:青海天纵网络技术有限公司

Cultivating rake device of automatic corn planter

ActiveCN111587636AEasy to operateEasy to usePlantingFurrow making/coveringAgricultural engineeringMechanical engineering

The invention discloses a cultivating rake device of an automatic corn planter. The cultivating rake device includes a cultivating rake body, the inner cavity of the cultivating rake body is fixedly connected with a discharge box, and the top of the discharge box communicates with a feeding hopper. The inner cavity of the discharge box is rotatably connected with a drive shaft, the surface of thedrive shaft is rotatably connected with a feeding plate, and material clamping holes are formed in the surface of the feeding plate. The invention relates to the technical field of corn planting. According to the cultivating rake device of the automatic corn planter, corn seeds are added along the feeding hopper, the drive shaft rotates to drive the feeding plate to rotate, at the time, the piledcorn seeds are stuck in the material clamping holes and move with the rotation of the feeding plate, the corn is remained to be stuck in the material clamping holes through blowing of a blowing hole,then when the feeding plate rotates to a scraping groove at a scraper, the corn seeds are scraped by the scraping groove and fall into a discharging pipeline, the seeds can be planted one by one, theplanting interval can be adjusted by adjusting the rotation speed of the feeding plate, the operation is simple, and use is convenient.

Owner:山西农业大学山西有机旱作农业研究院

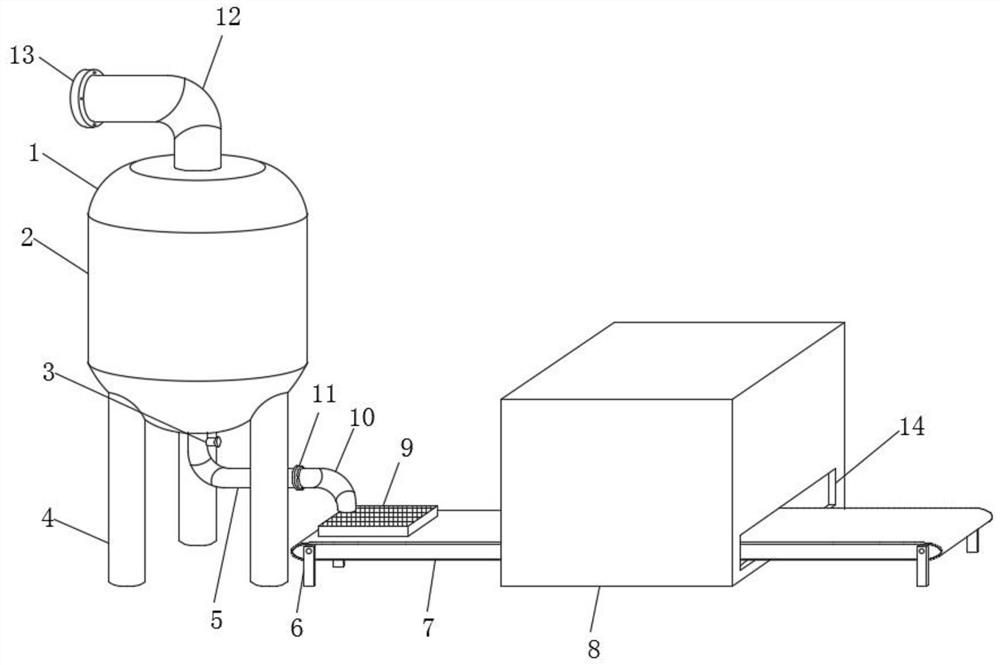

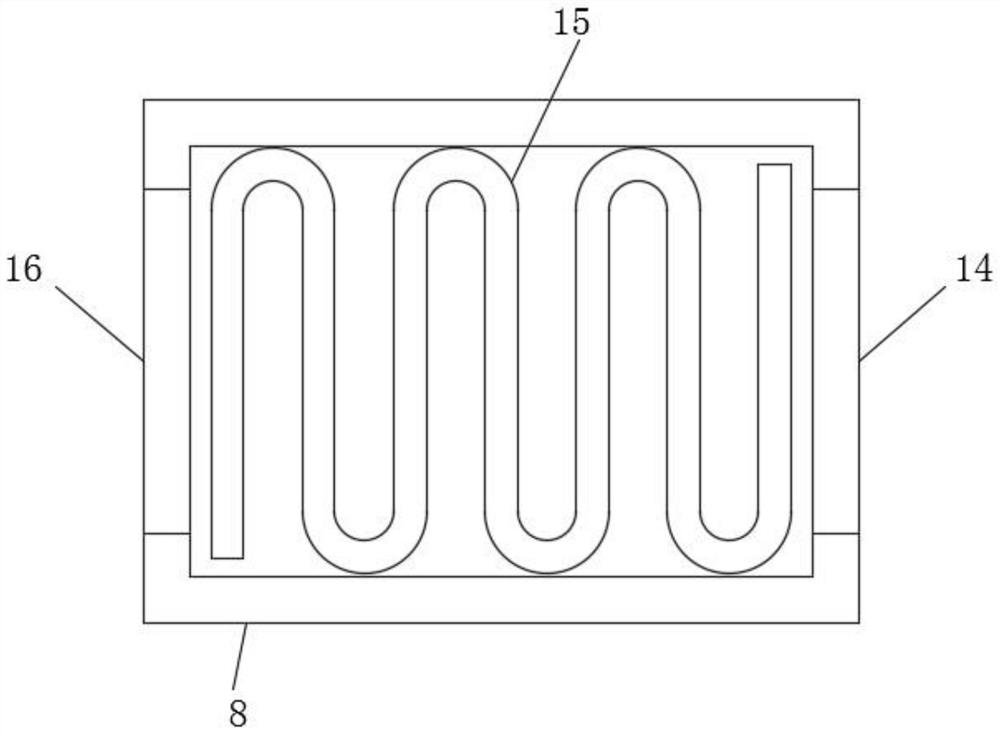

Lead-acid storage battery grid production equipment with good compaction effect and process thereof

InactiveCN111916759AImprove corrosion resistance and hardnessImprove overcharge resistanceElectrode carriers/collectorsGrid alloyEngineering

The invention discloses lead-acid storage battery grid production equipment with a good compaction effect and a process thereof. The equipment comprises a preparation furnace, a material conveying pipe, a conveyor, a cooling box, a forming mold, a cooling pipe electric telescopic rod and a compaction plate. According to the invention, metal additives such as selenium, sulfur and arsenic are addedinto a lead-acid storage battery grid alloy; therefore, the corrosion resistance and hardness of the grid of a lead-acid storage battery are effectively improved, the overcharge resistance is improved, the loss of the lead-acid storage battery is greatly reduced, and the problems of thermal cracking, shrinkage cavity and the like of a lead-acid storage battery grid caused by different surface tensions of various metal additives are avoided; the lead-acid storage battery grid is subjected to aging curing in an excellent environment, the interior of an external curing box is dehumidified throughsteam, the dehumidified lead-acid storage battery grid is dried for 2-22 hours, the grid curing effect is good, and the curing quality of the lead-acid storage battery grid is guaranteed; and throughcooperative use of an electric telescopic rod and a compaction plate, rapid compaction of the forming die span is facilitated, and the compaction effect is good.

Owner:JIESHOU HUAYU POWER SUPPLY

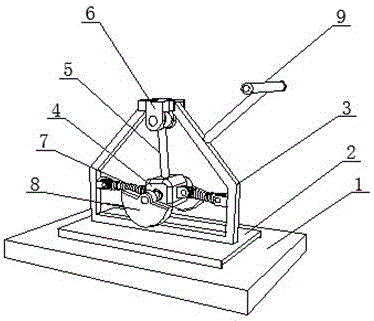

Local strengthening method for road subgrade

PendingCN113622239AFlexible operationImprove construction efficiencyRoadwaysDetection using electromagnetic wavesGear wheelReciprocating motion

The invention discloses a local strengthening method for road subgrade, which comprises the steps of S1, subgrade detection and S2, subgrade compaction. In the compaction process, when it is detected that the subgrade is void or the compaction degree and the thickness do not meet the requirements, a shell is pushed, a first bevel gear and a second bevel gear are driven to rotate by rotation, meanwhile, a third bevel gear and a fourth bevel gear are driven to rotate by a transmission rod, when the third bevel gear rotates, a first cam and a second cam are driven to rotate by a coupler, a crankshaft further rotates along with the first cam and the second cam, the crankshaft drives a pressing rod and a pressing block to perform circulating reciprocating motion, and a subgrade is compacted by means of the gravity of a pressing head and the pressure of the pressing rod; meanwhile, in combination with a ground penetrating radar technology, a level map of electromagnetic wave echoes is acquired, and in combination with an edge detection technology, then edge conversion is performed according to the level map to accurately obtain the thickness, the compaction condition and the void condition of a subgrade structure layer, so that the detection efficiency is improved, the pavement is not damaged, the pavement is comprehensively detected, and problems can be timely found and treated.

Owner:吴海涛

A kind of special compacting equipment for slope surface

ActiveCN110409412BReduce operational burdenFast compaction compactionSoil preservationElectric machineryStructural engineering

The invention discloses a special punning device for an inclined slope surface. A machine body is included, and internally provided with a work cavity; an adjusting mechanism is arranged in the work cavity, and comprises a first vertical groove; the first vertical groove is formed in the rear end wall of the work cavity; the right side of the adjusting mechanism is provided with a lifting mechanism; the lifting mechanism comprises a second vertical groove formed in the rear end wall of the work cavity; a punning mechanism is arranged on the lower side of the adjusting mechanism; and the rear end wall of the work cavity is provided with a fourth vertical groove in which a push rod is arranged in an up-down moving manner. The device is easy to operate, a worker pushes the device to a slope needing to be punned, and the device can be used for automatically adjusting the punning angle according to the gradient of an inclined surface; and after a motor is started, the device can be used forfast performing punning on the slope surface, when the device works, a worker is not needed to lift a punning machine all the time, and the operation load of the worker can be greatly relived.

Owner:恒喜工程有限公司

A waste packing machine

The invention discloses a waste compressing machine which is provided with a box. An upper impacting plate and a lower impacting plate are arranged in the box, the impacting faces of the upper impacting plate and the lower impacting plate are parallel to the bottom face of the box, the upper impacting plate can be vertically moved in the box through a driving mechanism, buffer devices are arranged at the positions of the upper impacting plate and the lower impacting plate respectively, and the lower impacting plate comprises a supporting plate and a pressed plate located on the supporting plate. By means of the waste compressing machine, incompact metal waste can be rapidly and tightly and firmly compressed, waste blocks capable of being stacked and stored are obtained, convenience is brought to unloading, and occupied space is reduced.

Owner:ANHUI NINGGUO DONGBO FASTENER

Flat-board type electromagnetic vibration compaction machine

InactiveCN100507156CSimple structureLow failure rateRoads maintainenceSoil preservationMicrocontrollerFailure rate

The invention discloses a plate type electromagnetic vibration compacting machine. The tamping machine overcomes the shortcomings of the existing diesel engine and electric motor as the power device that the tamping machine is prone to failure, short working life, and heavy weight. The electromagnetic device is composed of parallel coil turns on the two columns of the permeable core, and the electromagnetic device is controlled by an electric circuit mainly controlled by a single-chip microcomputer to control the frequency conversion of the thyristor. Under the action of the controlled electric circuit, the magnetic core of the electromagnetic device will attract and detach with the flat bottom plate at a frequency to achieve the purpose of compaction. The invention can adjust the frequency, amplitude and impact force of the compaction vibration, so it is suitable for construction under different working conditions, and is especially suitable for the compaction of road and bridge subgrade concrete and the maintenance of road surfaces. It has the advantages of high host energy utilization rate, no pollution, simple structure, low failure rate, low noise, small weight of the whole machine, quick and light transition, etc.

Owner:赵守德

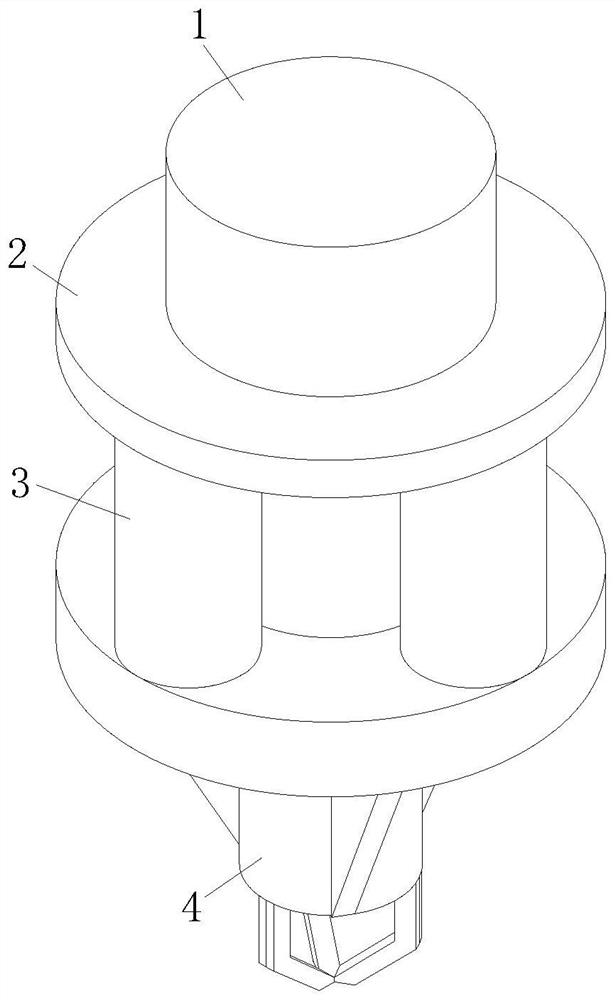

Hole wall reinforcing structure of large-diameter deep and long pile construction hole

The invention discloses a hole wall reinforcing structure of a large-diameter deep and long pile construction hole, and belongs to the technical field of building construction equipment. The structure comprises a rotating shaft and a drill bit, the drill bit is connected with the rotating shaft through a mounting frame, a plurality of hole wall reinforcing mechanisms are movably arranged on the mounting frame, and the hole wall reinforcing mechanisms can move in the radial direction of the drill bit. In the drilling process, all the hole wall reinforcing mechanisms can continuously hit and compact the hole walls under the centrifugal force and the collision effect; meanwhile, the hole wall reinforcing mechanism is in sliding connection with the mounting frame, so that the process of striking and tamping the hole wall by the hole wall reinforcing mechanism is more flexible and is basically not limited by conditions such as the shape of the hole wall.

Owner:中国水利水电建设工程咨询贵阳有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com