Sticky candy compactor

A technology of brown sugar and compactor, which is applied in confectionary, confectionery industry, food science, etc., can solve the problems of high labor intensity and low efficiency, and achieve the effects of improving efficiency, rapid processing, and rapid compaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention is described in further detail below by specific embodiments:

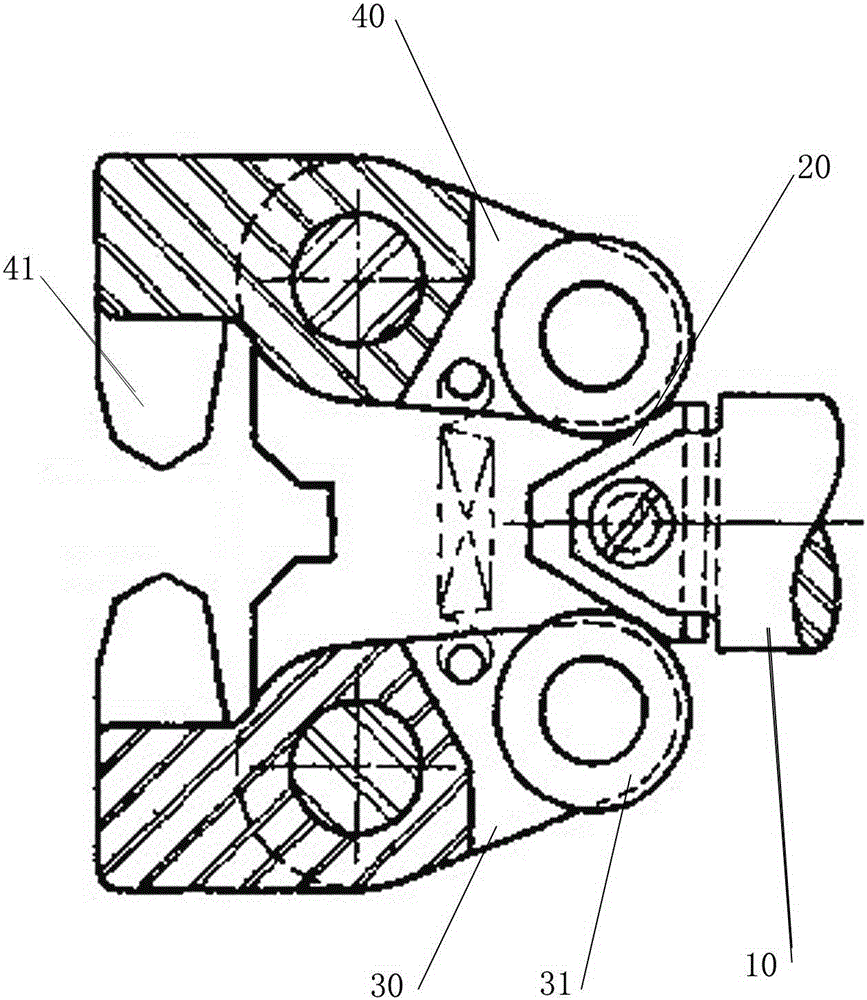

[0013] The reference numerals in the drawings in the description include: the frame 10 , the conical top block 20 , the lower pressing plate 30 , the lower roller 31 , the upper pressing plate 40 , and the upper roller 41 .

[0014] The example is basically as attached figure 1 Shown: Kraft candy compactor, including a frame, the upper platen, the lower platen, the spring, the upper roller, the lower roller, the conical top block and the drive for driving the conical top block are arranged in the horizontal direction from left to right on the rack. Push rod, wherein the left end of the upper pressure plate is welded with an upper pressure block, the middle part of the upper pressure plate is hinged on the frame, the right end of the upper pressure plate is pivoted with an upper roller, the left end of the lower pressure plate is welded with a lower pressure block, the middle part of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com