A kind of label glue capable of high-speed die cutting and preparation method thereof

A label glue and die-cutting technology, applied in adhesives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve problems such as production speed that cannot meet market demand, poor waste discharge, and fractures. Achieve the effect of satisfying conventional performance and fast processability, strong wettability, and good high-speed die-cutting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

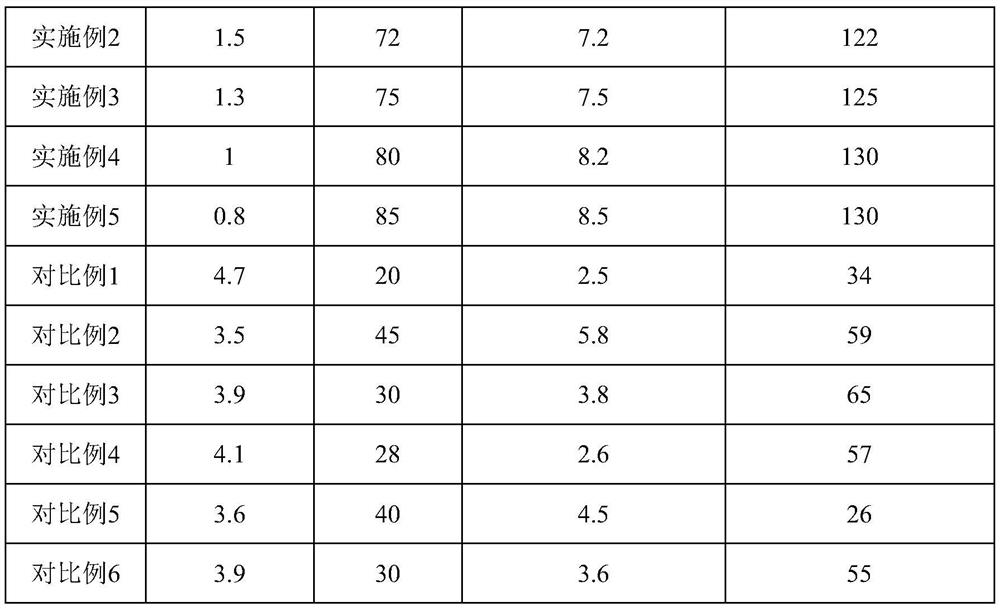

Examples

preparation example Construction

[0052] The second aspect of the present invention provides a kind of preparation method of high-speed die-cut label glue, and the step comprises:

[0053] (1) drop described citric acid ester, antioxidant into stainless steel reactor;

[0054] (2) After the temperature rises to 140°C, add SBR rubber, and control the temperature of the reactor at 150°C;

[0055] (3) After the SBR rubber is completely dissolved, put in hydrogenated C5 / C9 copolymerized petroleum resin, rosin modified phenolic resin, and functional additives, control the temperature of the stainless steel reactor within 200°C and stir for 30-60min, then vacuumize to -0.085MPa , discharge cooling package.

Embodiment 1

[0059] Embodiment 1 provides a kind of high-speed die-cut label glue, by weight, the high-speed die-cut label glue includes the following components: 15 parts of SBR rubber, 10 parts of hydrogenated C5 / C9 copolymerized petroleum resin, rosin 5 parts of modified phenolic resin, 0.5 part of citric acid ester, 0.3 part of functional auxiliary agent, and 1 part of antioxidant.

[0060] The SBR rubber is a product commercially available from Yueyang Baling Huaxing Petrochemical Co., Ltd. with the brand name SBS-1401.

[0061] The hydrogenated C5 / C9 copolymerized petroleum resin is an aromatic hydrocarbon-modified alicyclic hydrocarbon resin, and the aromatic hydrocarbon-modified alicyclic hydrocarbon resin is a product commercially available from ExxonMobil, USA, with the brand name Escorez5600.

[0062] The rosin-modified phenolic resin is a product commercially available from French DRT Chemicals under the brand name DERTOPHENET105.

[0063] The citric acid ester is tributyl cit...

Embodiment 2

[0071] Embodiment 2 provides a kind of high-speed die-cut label glue, by weight, the high-speed die-cut label glue includes the following components: 25 parts of SBR rubber, 20 parts of hydrogenated C5 / C9 copolymerized petroleum resin, rosin 10 parts of modified phenolic resin, 3 parts of citric acid ester, 1 part of functional auxiliary agent, 3 parts of antioxidant.

[0072] The SBR rubber is a product commercially available from Yueyang Baling Huaxing Petrochemical Co., Ltd. with the brand name SBS-1401.

[0073] The hydrogenated C5 / C9 copolymerized petroleum resin is an aromatic hydrocarbon-modified alicyclic hydrocarbon resin, and the aromatic hydrocarbon-modified alicyclic hydrocarbon resin is a product commercially available from ExxonMobil, USA, with the brand name Escorez5600.

[0074] The rosin-modified phenolic resin is a product commercially available from French DRT Chemicals under the brand name DERTOPHENET105.

[0075] The citric acid ester is tributyl citrate,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com