Vacuum suction cup pressure-suction auxiliary device replacing vacuum pump outside CNC machining machine

A vacuum suction cup and auxiliary device technology, which is applied to metal processing mechanical parts, positioning devices, metal processing equipment, etc., can solve the problems of high price and large volume, and achieve the effect of simple structure, small volume and production cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

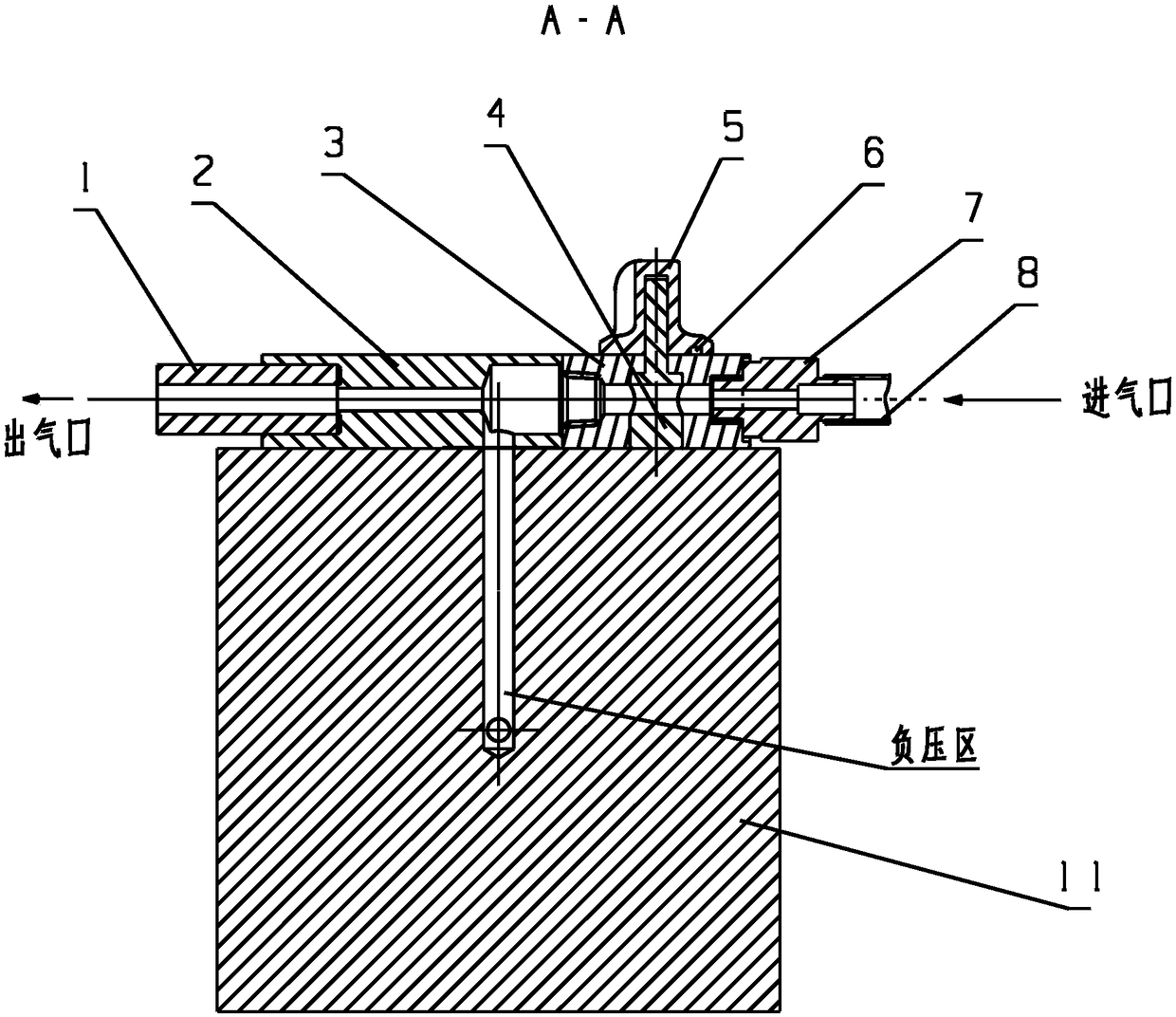

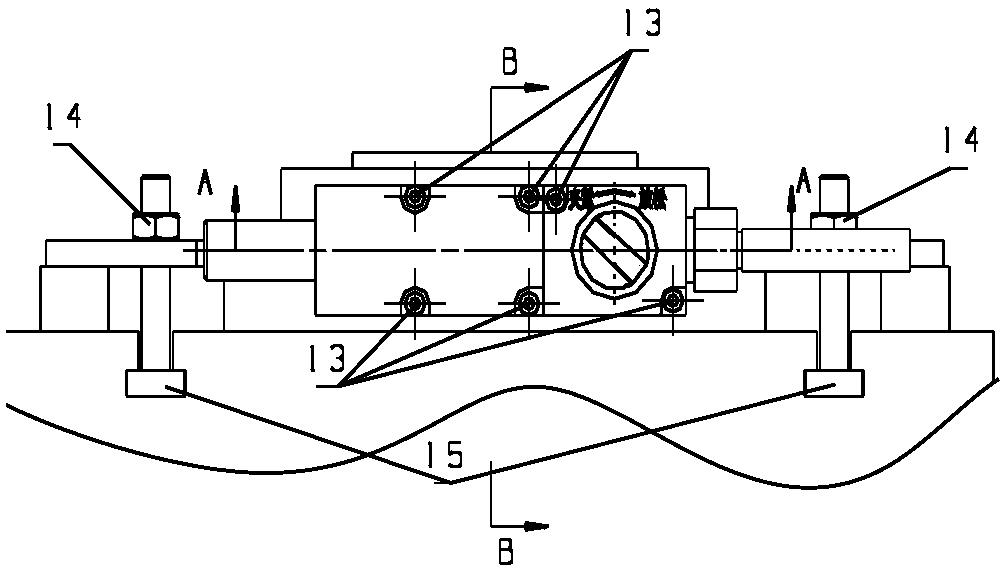

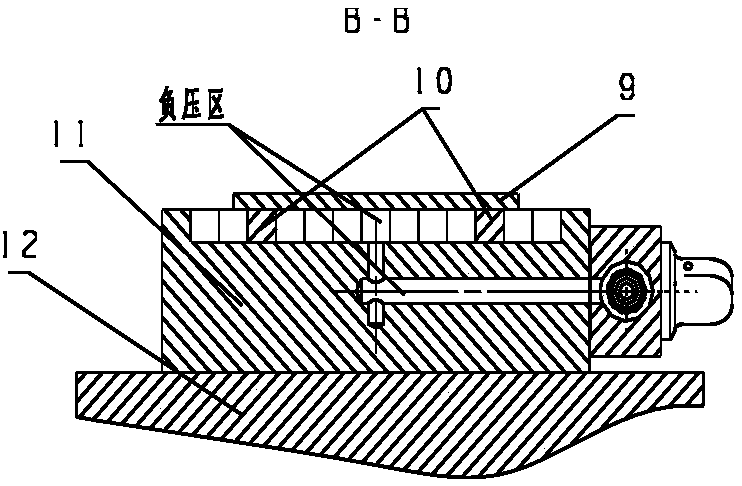

[0019] refer to figure 1 . The lower part of the valve core 4 of the suction device for the vacuum suction cup is fitted with the steering body 3 through the round hole, and is screwed to the vacuum suction cup 11 of the CNC machining center equipment accessory through the hexagon socket bolt 13, and the steering body 3 is equipped with a stop pin 6 Sliding arc-shaped groove, the knob 5 is clearance-fitted with the upper part of the valve core 4 through the rectangular groove, and has an interference fit with the stop pin 6. By rotating the knob 5, the stop pin 6 is driven to slide along the arc-shaped pin groove of the steering body 3 to be in "clamping" Or at the "relaxed" position mark, realize the state that the valve core 4 is connected or blocked with compressed air. One side of the steering body 3 is equipped with a threaded connection nozzle 7, and after the intake pipe 8 is pressed into the nozzle 7, the compressed air enters the air passage of the whole device throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com