Compacting equipment for sticky candy production

A technology of brown sugar and equipment, applied in confectionary, application, confectionery industry, etc., can solve the problems of high labor intensity and low efficiency, and achieve the effect of improving efficiency, increasing carrying capacity and rapid processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below by means of specific embodiments:

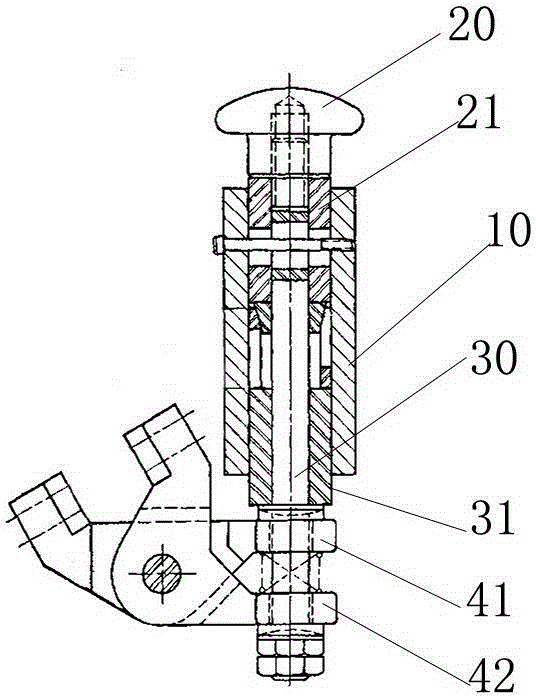

[0014] The reference signs in the drawings of the description include: the sleeve 10 , the lock nut 20 , the first top sleeve 21 , the bolt 30 , the second top sleeve 31 , the upper jaw 41 , and the lower jaw 42 .

[0015] The embodiment is basically as attached figure 1 Shown: Compaction equipment for brown sugar production, including the frame, and also includes lock nuts, bolts, sleeves, first top sleeves, anti-rotation pins, second top sleeves, upper jaws and The lower jaw, the sleeve is fixed on the frame, the bolt passes through the sleeve and its two ends protrude from the sleeve, the first top sleeve and the second top sleeve are both connected with bolts inside and sleeves outside, and the lock nut It is threadedly connected with the upper end of the bolt, and the lock nut is also against the upper end of the first top sleeve. There is a through hole in the midd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com