Sticky candy pressing machine

A compacting machine and brown sugar technology, which is applied in confectionary, confectionary industry, food science, etc., can solve the problems of high labor intensity and low efficiency, and achieve the effects of improving efficiency, good wear resistance, and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below through specific implementations:

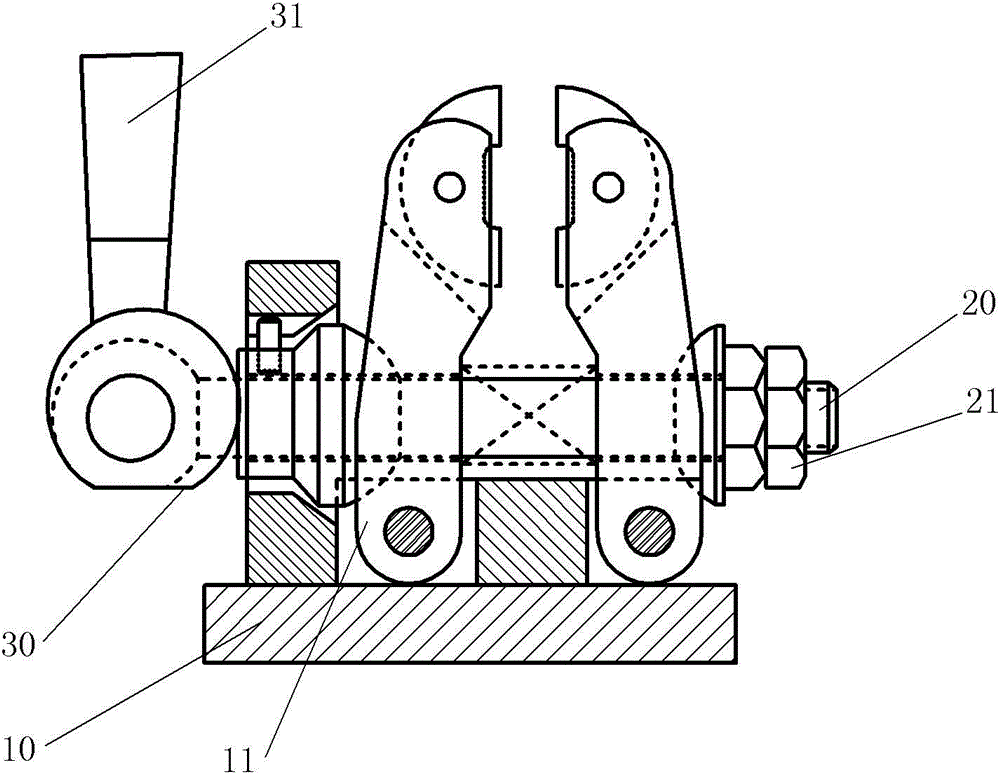

[0013] The reference signs in the drawings of the specification include: frame 10, left clamping jaw 11, eye bolt 20, lock nut 21, cam 30, and handle 31.

[0014] The embodiment is basically as attached figure 1 Shown: the cowhide candy compacting machine, including the frame, the frame is arranged horizontally from left to right with cams, eye bolts, brackets, left top sleeve, guide pins, left jaws, springs, right jaws, and right Top sleeve and lock nut, in which the cam is hinged with the head of the eye bolt, the upper part of the cam is fixed with a handle, the middle of the bracket is opened with a through hole, the left top sleeve is located in the through hole and sleeved on the eye bolt, the guide pin The thread is connected to the left top sleeve, the through hole is correspondingly provided with a guide groove, the guide pin extends into the guide groove, the left s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com