Full-automatic intelligent screen printing machine

A screen printing machine, fully automatic technology, applied in the field of workpiece processing, to save time and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

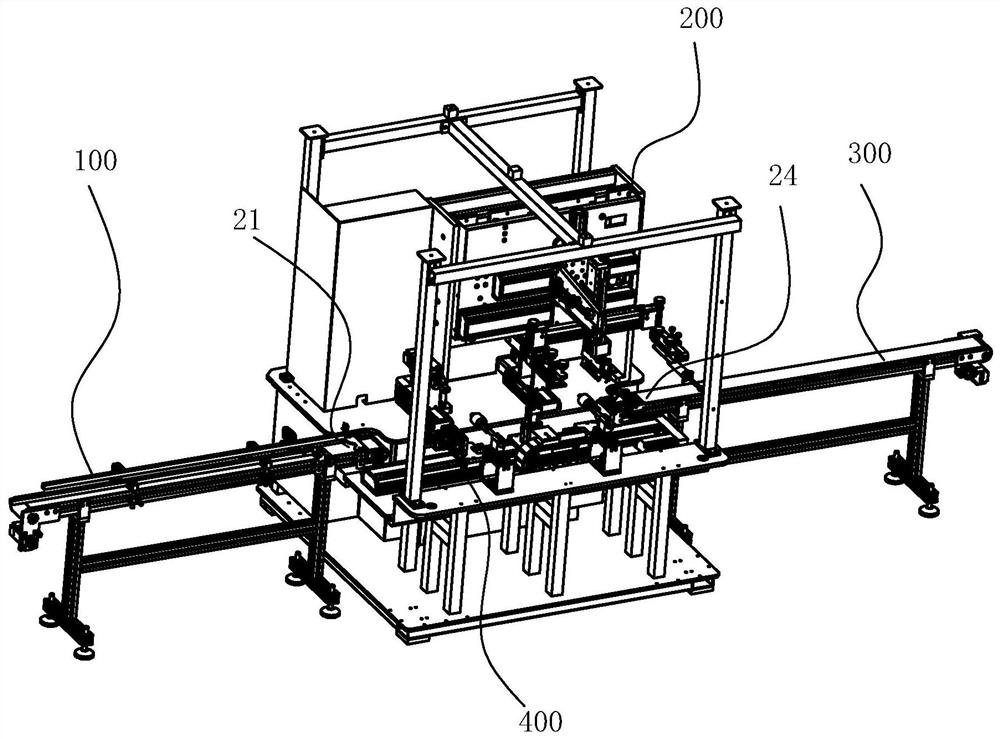

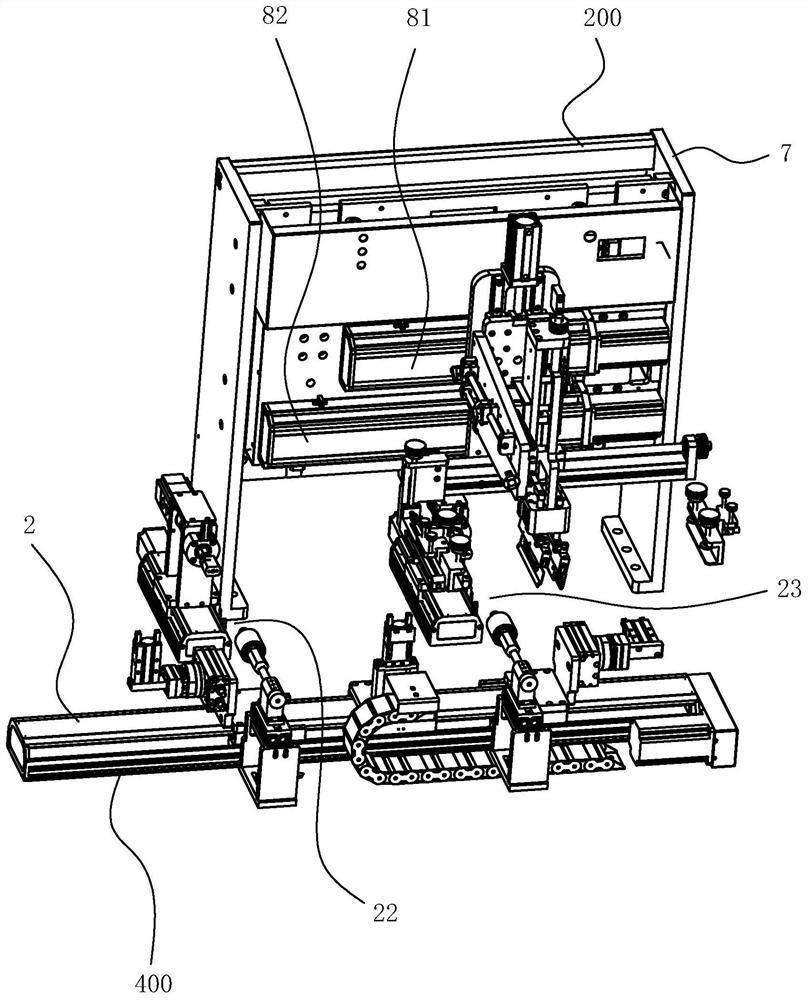

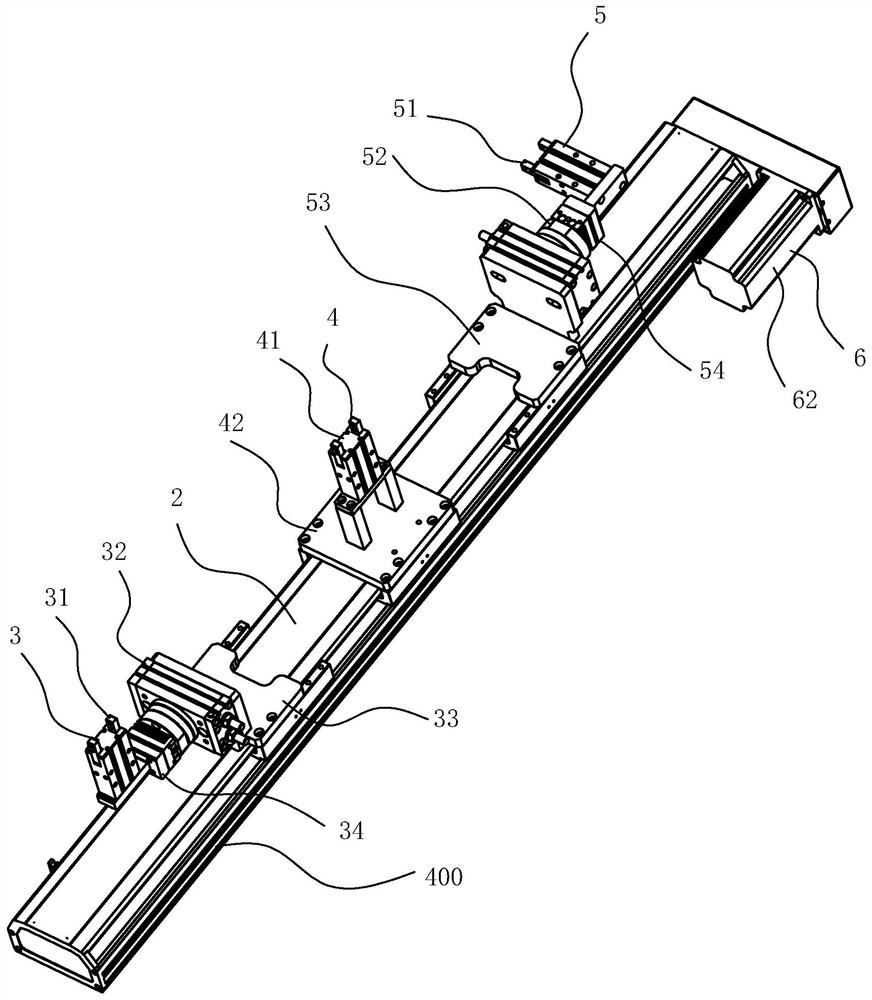

[0024] Such as Figure 1-5 As shown in , a fully automatic intelligent screen printing machine provided by an embodiment of the present invention includes a feeding device 100 , a processing device 200 , an output conveyor belt 300 and a feeding device 400 . The feeding device 100 includes a feeding conveyor belt 1 for transporting workpieces. The feeding conveyor belt 1 is a nylon conveyor belt and is driven by a motor to transport workpieces from the initial end of the feeding conveyor belt 1 to the feeding conveyor belt. 1 end. The end of the feeding conveyor belt 1 is provided with a first station 21, wherein placing the workpiece on the initial end of the feeding conveyor belt 1 can be done by human hands or other machines. The processing device 200 is provided with a second station 22 and a third station 23 both for processing workpieces.

[0025] Such as Figure 1-8 As shown in , the initial end of the output conveyor belt 300 is provided with a fourth station 24. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com