Brick paving device for sidewalk pavement construction

A technology for laying bricks and sidewalks, applied in roads, roads, road repair and other directions, can solve the problems of affecting work efficiency, low work efficiency, high labor intensity, etc., to improve accuracy and efficiency, reduce labor, and improve safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

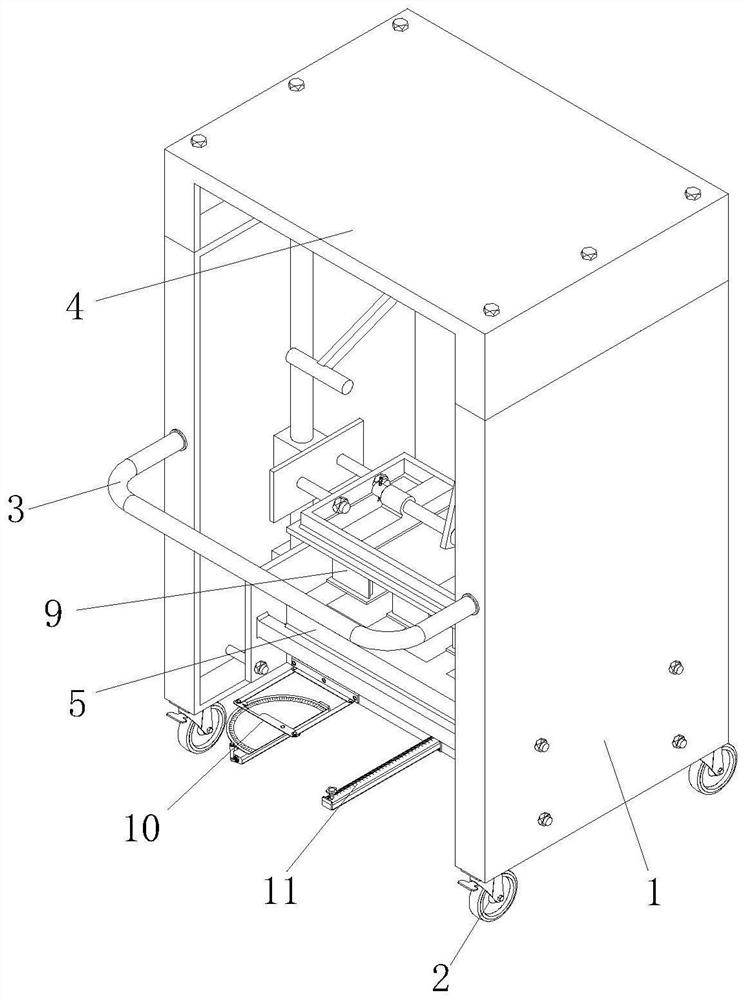

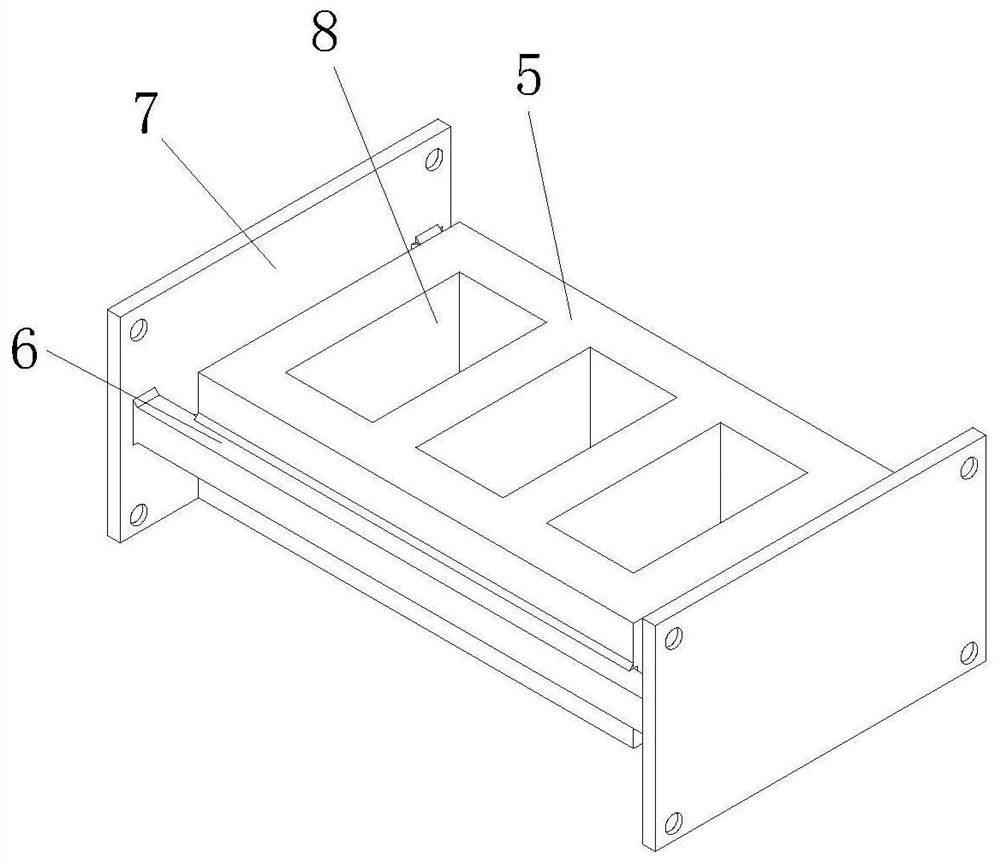

[0032] see Figure 1-2 As shown, the present invention provides a paving device for sidewalk surface construction through improvement, including a body 1, a walking wheel 2, a push rod 3, a top cover 4, a brick laying frame 5, a support horizontal frame 6, and a side fixing plate 7. Brick falling trough 8, manual compaction device 9, angle measuring device 10 and distance measuring device 11, the bottom of the body 1 is provided with a walking wheel 2 for moving, and the middle part of the front end of the body 1 is equipped with a push rod 3, which can be manually Apply force to push, the top cover 4 is installed on the top of the body 1, and the inner bottom of the body 1 is provided with a brick laying frame 5 for laying bricks. The brick laying frame 5, the two ends of the supporting horizontal frame 6 are welded with side fixing plates 7, the two sides of the supporting horizontal frame 6 are fixedly installed with the body 1 through the side fixing plates 7, and the side...

Embodiment 2

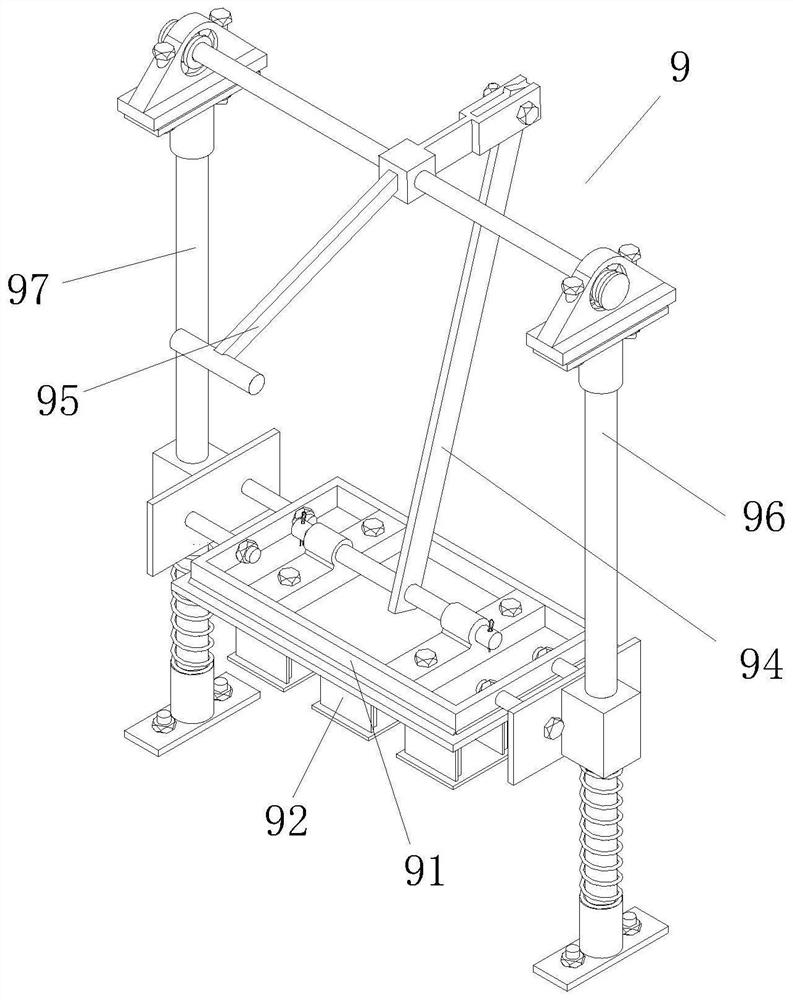

[0039] The present invention provides a brick laying device for sidewalk surface construction through improvement. Three groups of pressing plates 93 are respectively arranged at the bottom of the pressing seat plate 91, and the three groups of pressing plates 93 correspond to three brick falling grooves 8 respectively, and each group of vertical plates 92 and The pressure seat plates 91 are connected by three vertical plates 92 to increase the stability when pressing down and ensure the stable compaction of the bricks. The first rotating shaft 941 runs through the front sides of the movable frame 944 in a transverse direction and is fixed with it, so that the movable The rotation of frame 944 can drive the first rotating shaft 941 to rotate, and the two sides of connecting rod 945 bottom are transversely penetrated with second rotating shaft 946 and fixed therewith, so that connecting rod 945 can drive the second rotating shaft 946 at the bottom to rotate, the first positioning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com