Local strengthening method for road subgrade

A technology of local strengthening and subgrade, applied in the protection of roads, roads, soil, etc., can solve the problems of damage to subgrade, long detection time, low detection efficiency, etc., and achieve the effect of improving efficiency, high construction efficiency and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] like Figure 4-6 As shown, a local strengthening method of a road subgrade includes the following steps: S1, subgrade detection, including the following steps, the first step, the detection host reads the electromagnetic wave echo data of the ground penetrating radar; the second step, the returned Perform data processing and data conversion on the electromagnetic wave echo to eliminate the influence of noise; the third step is to obtain the level map after encoding processing by the host computer, and perform edge detection processing on it; the fourth step is to obtain the subgrade by performing edge transformation processing on the level map Thickness, compaction and voiding of structural layers;

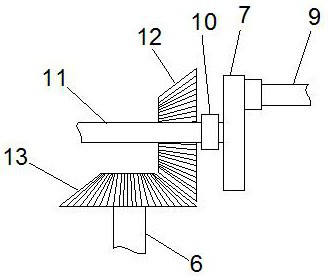

[0041] S2, subgrade compaction. During the compaction process, if it is detected that the subgrade is empty or the degree of compaction and thickness does not meet the requirements, the casing is pushed to drive the first helical gear and the second helical gear through the...

Embodiment 2

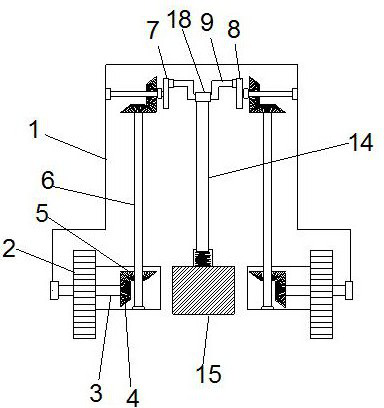

[0048] like Figure 1-3 As shown, a local reinforcement structure of a road subgrade includes a mechanical module and a detection module; the mechanical module includes a housing 1, and the bottom of the housing 1 is symmetrically provided with two runners 2, and the two runners 2 are connected with a rotating shaft 3, and the runner 2 is rotationally connected with the housing 1 through the rotating shaft 3. One end of the rotating shaft 3 is connected with a first helical gear 4, and the first helical gear 4 is meshed with a second helical gear 5. The center position of the second helical gear 5 is provided with a transmission rod 6 through which a drive mechanism is connected above the transmission rod 6 , and the lower end of the transmission rod 6 is rotationally connected with the housing 1 ;

[0049] The detection module includes a detection host, a ground penetrating radar, and the sending end of the ground penetrating radar sends electromagnetic waves to the roadbed, ...

Embodiment 3

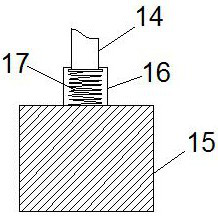

[0055] On the basis of Embodiment 1, a spring 17 is provided between the pressure rod 14 and the pressure head 15 to increase the buffer between the pressure rod 14 and the pressure head 15 to prevent the downward impact force from being too large and the pressure head 15 to rebound, causing If the equipment is damaged, the rebound force F of the spring 17 and its pitch t, length L and pitch D satisfy the following relationship: F=kD·(L / t) 2 ; k is the coefficient of elasticity, the value range is 20%-85%; the unit of F is N / m; the unit of t and L is cm. In order to ensure the compaction effect and prevent damage to the indenter 15 caused by excessive pressure, and the pressure is too small, the degree of subgrade compaction is not up to standard, the pressure F1 of the indenter 15 on the subgrade satisfies: F1=λ·mg+ kD·(L / t) 2 ;λ is the adjustment coefficient, the value range is 0.69-3.622.

[0056] The device obtained through the above technical solution is a local reinfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com