A waste packing machine

A technology for packing machines and waste materials, which is applied in the direction of presses and manufacturing tools, and can solve the problems of injury to the handling equipment staff, inability to collect, and increased recycling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

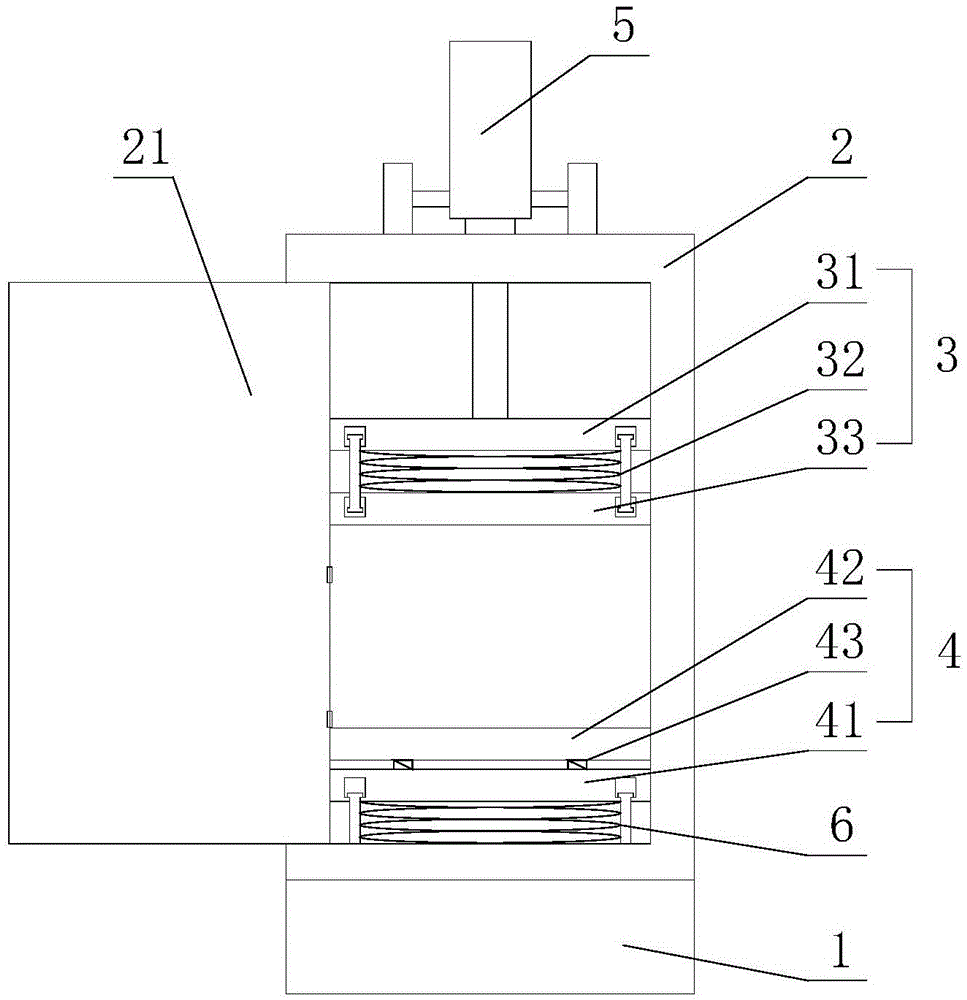

[0017] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of a waste packing machine proposed by the present invention.

[0018] refer to figure 1 , a waste packing machine proposed by the present invention, comprising: a base 1, a box body 2, an upper action plate 3, a lower action plate 4, and a drive mechanism 5;

[0019] The box body 2 is located above the base 1, an opening is provided in front of the box body 2, a first buffer mechanism 6 is provided on the bottom surface of the box body 2, an openable partition 21 is provided at the opening of the box body 2, and the metal is pressed In the process of scrapping, it is convenient for the metal scrap to be compacted into blocks, so as to prevent it from being pressed out of the box 2;

[0020] The upper action plate 3 is suspended in the box body 2 through the drive mechanism 5, and its action surface is parallel to the bottom surface of the box body 2. The upper action plate 3 can move vertically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com