Rapid consolidation and compaction method for soil improvement of various layers of soils and intermediate geomaterials in a soil deposit

a soil deposit and intermediate geomaterial technology, applied in the direction of bulkheads/piles, construction, foundation engineering, etc., can solve the problem of not being able to pull out the pipe section out of the ground, and achieve the effect of reducing the cost, increasing the density of sandy soil, and reducing the cost of using the rapid consolidation and compaction method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

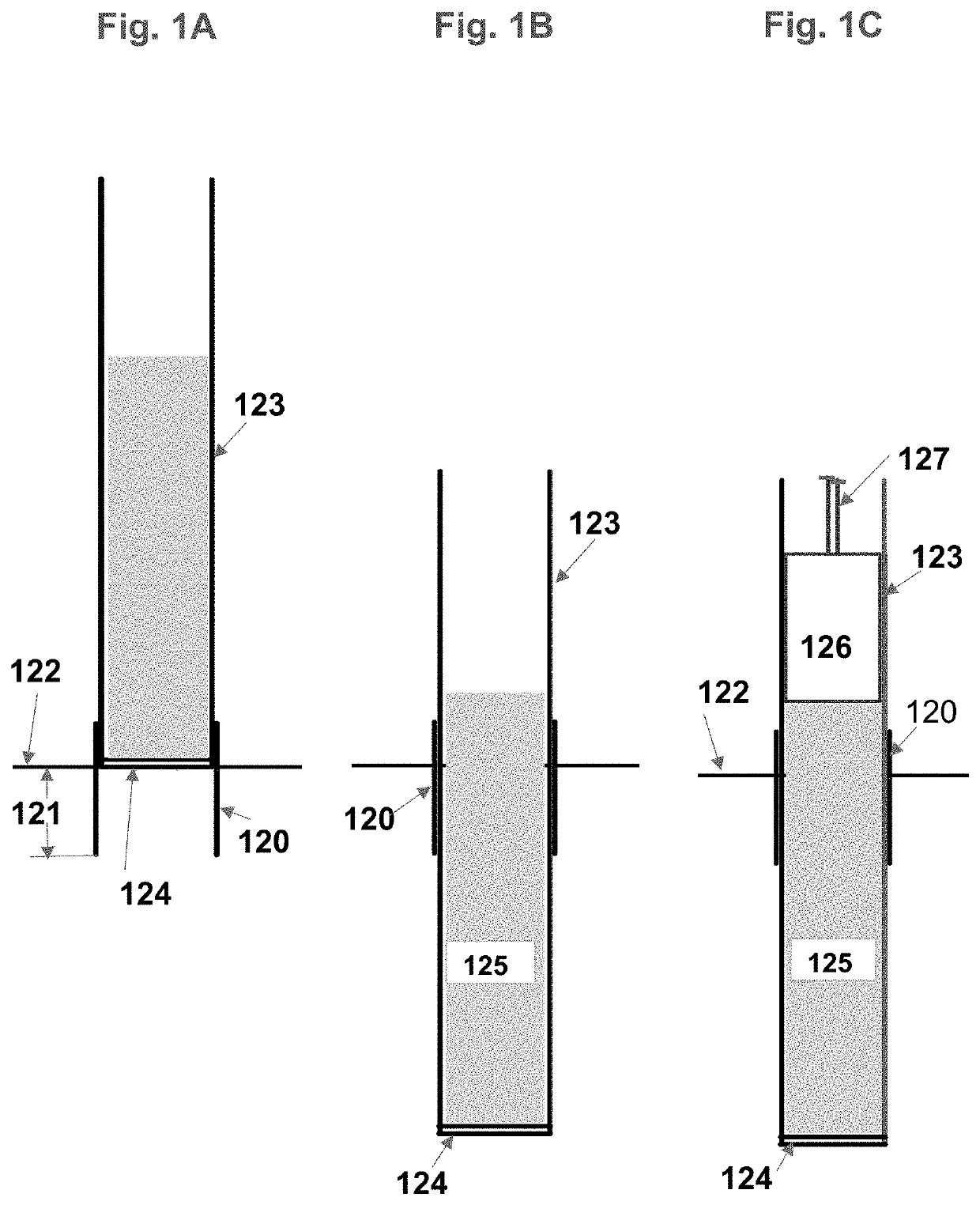

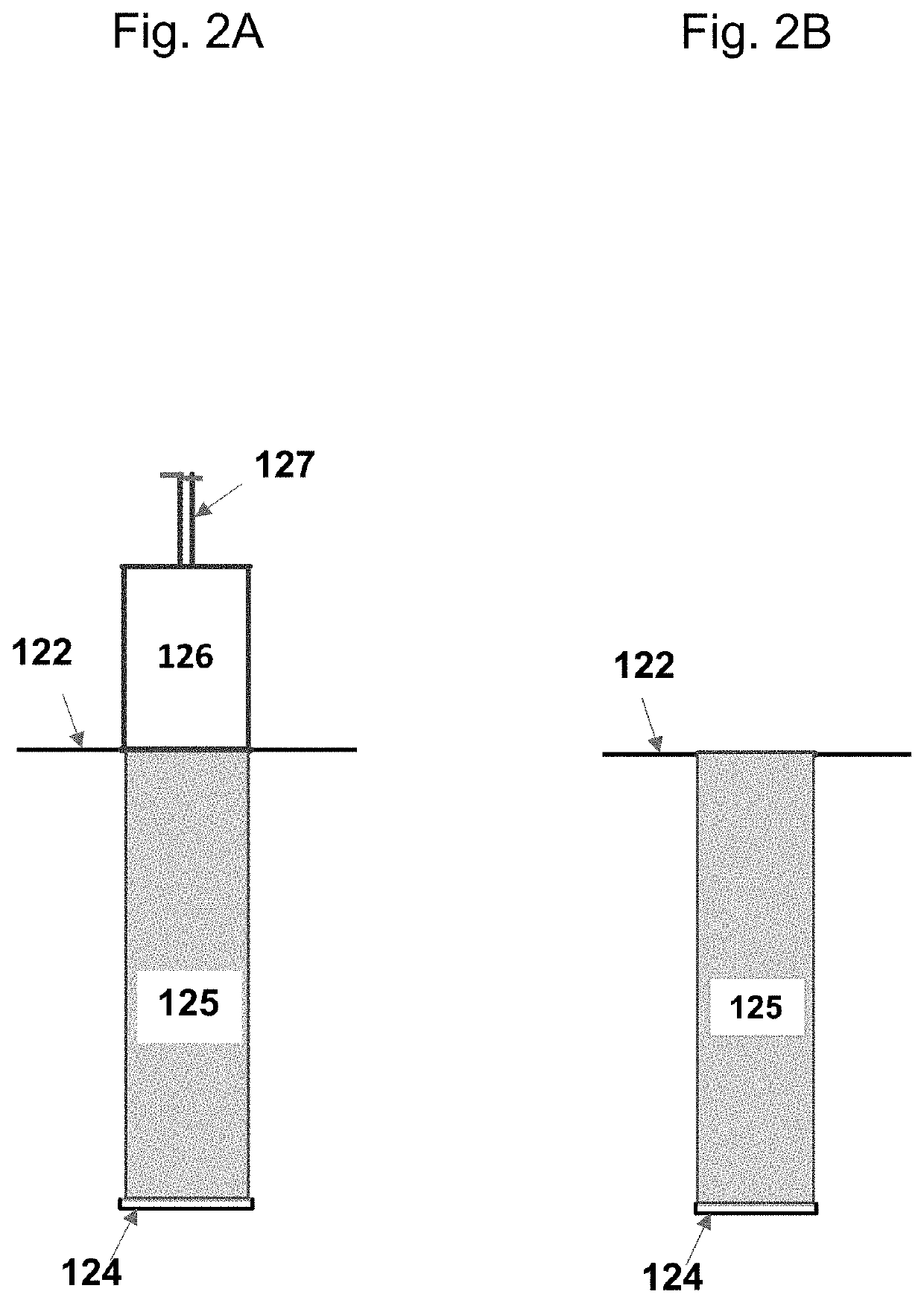

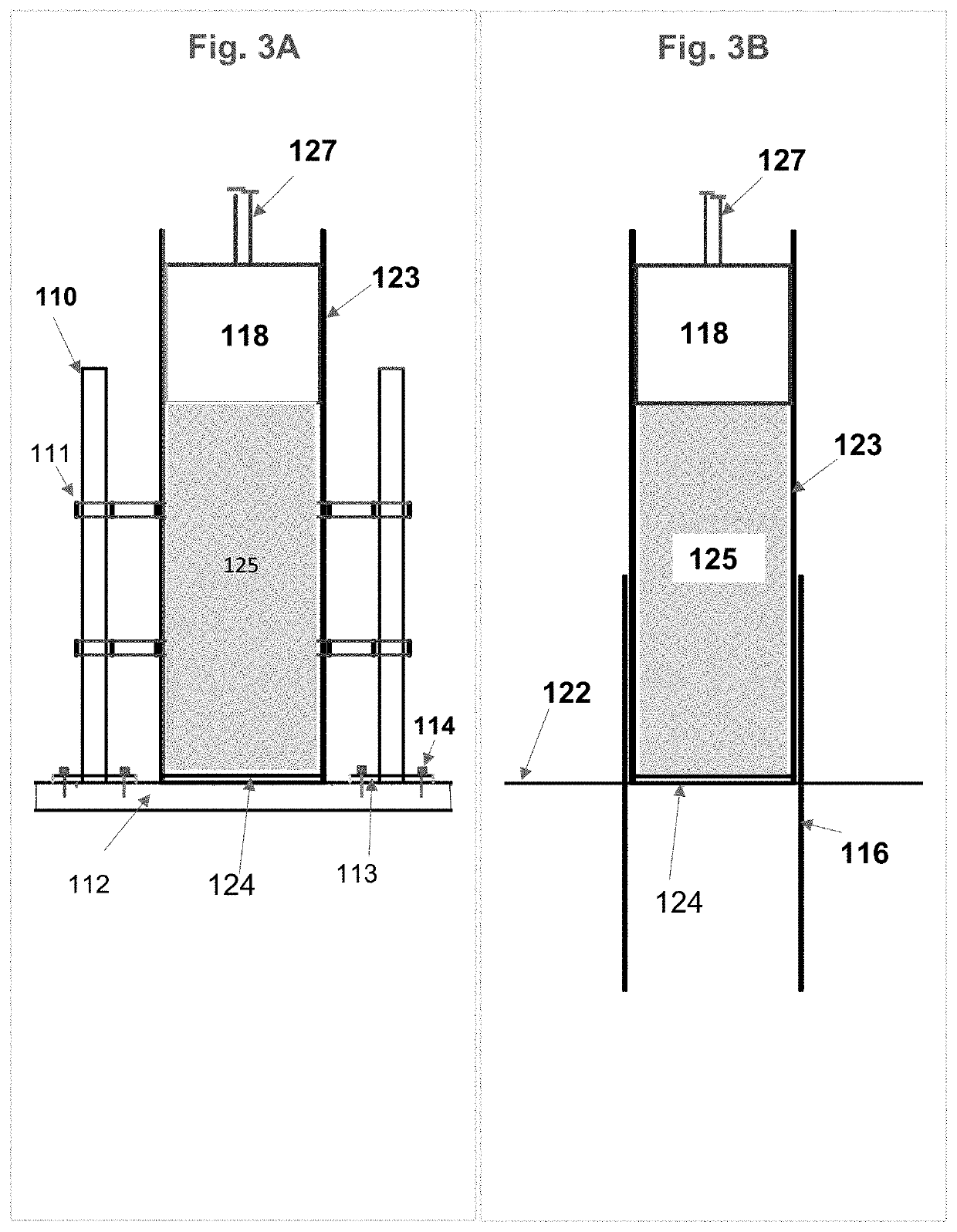

[0032]The main motivation for the invention of the rapid consolidation and compaction method (RCCM) is to develop a method for soil improvement which can densify a layer of the soil or the intermediate geomaterial (IGM) in a soil deposit. Cohesionless soils are defined as having N60 less than 50 blows / 0.3 m, whereas cohesionless Category 3 IGMs are defined as having N60 greater than 50 blows / 0.3 m (AASHTO, 2012). Cohesive soils are defined as having undrained shear strength less than 0.25 MN / m2, whereas cohesive IGMs Category 1 are defined as having undrained shear strength greater than 0.25 MN / m2 (AASHTO, 2012). The invention in this application comprises of a rapid consolidation and compaction method (RCCM) to produce rapid consolidation of the layer of clayey soil resulting in increase of its density and consistency. The RCCM comprises (i) first driving a hollow pipe section to some depth to minimize heave at the ground surface or above the layer of soil requiring improvement, (i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com