Sticky candy pressing device

A technology of candy and equipment, which is applied in confectionery, confectionery industry, food science and other directions, can solve the problems of low efficiency and high labor intensity, and achieve the effect of improving bearing capacity, improving efficiency, and rapid compaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below by means of specific embodiments:

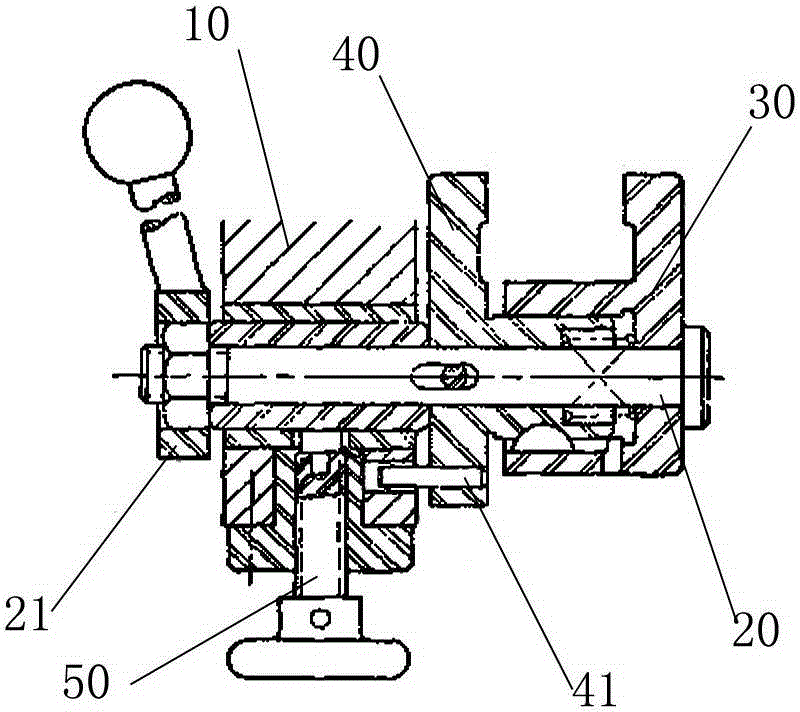

[0014] The reference numerals in the drawings of the description include: frame 10 , bolt 20 , wrench 21 , right compression block 30 , left compression block 40 , anti-rotation pin 41 , and adjustment screw 50 .

[0015] The embodiment is basically as attached figure 1 Shown: the brown sugar pressing equipment, including the frame, also includes wrenches, bolts, sleeves, left pressing blocks and right pressing blocks arranged in the horizontal direction. There are through holes through the horizontal direction on the frame. The barrel is located in the through hole, the bolt is slidingly set in the sleeve, the left end of the screw protrudes from the sleeve and is connected with a nut, the wrench is connected to the nut, the side of the wrench is welded with a handle, the middle part of the bolt has a strip hole, and the left pressing block Socketed in the middle of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com