Rapid gap reducing device for ancient building grey tile carving

A technology of gray tiles and brick carvings, applied in the field of gap reduction devices, which can solve the problems of high manpower consumption and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

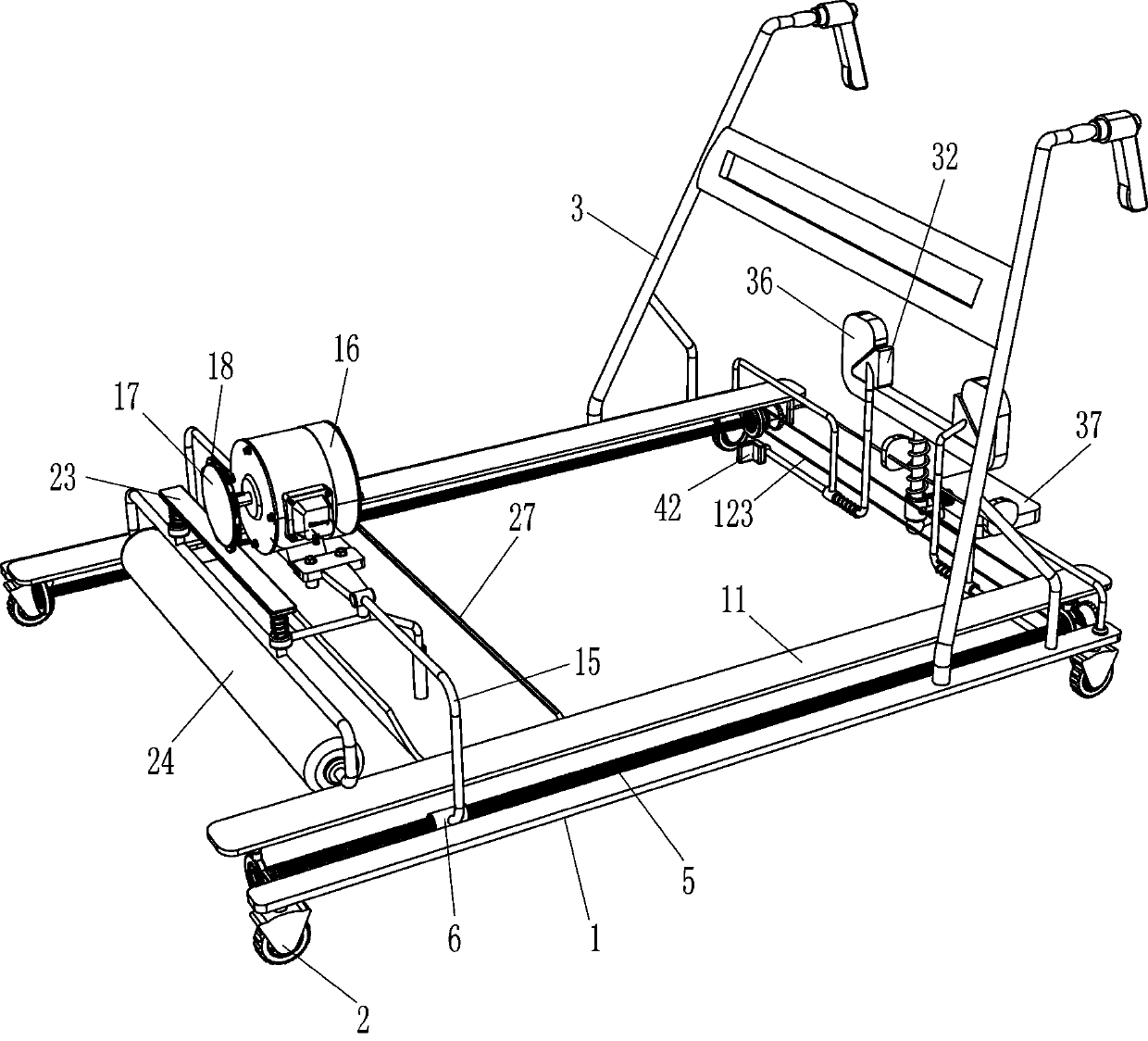

[0021] A device for quickly reducing gaps in ancient blue tile brick carvings, such as figure 1 , 2 , 3 and 4, including mounting plate 1, wheel 2, push rod 3, moving assembly, driving assembly and flattening assembly, the bottom of mounting plate 1 is provided with wheel 2, and the right side of mounting plate 1 is provided with push rod 3, Both sides of the mounting plate 1 are provided with moving components that move through rotation, between the moving components on both sides is a drive component that provides power through rotation, and the drive component is provided with a flattening component that is flattened by pressing down .

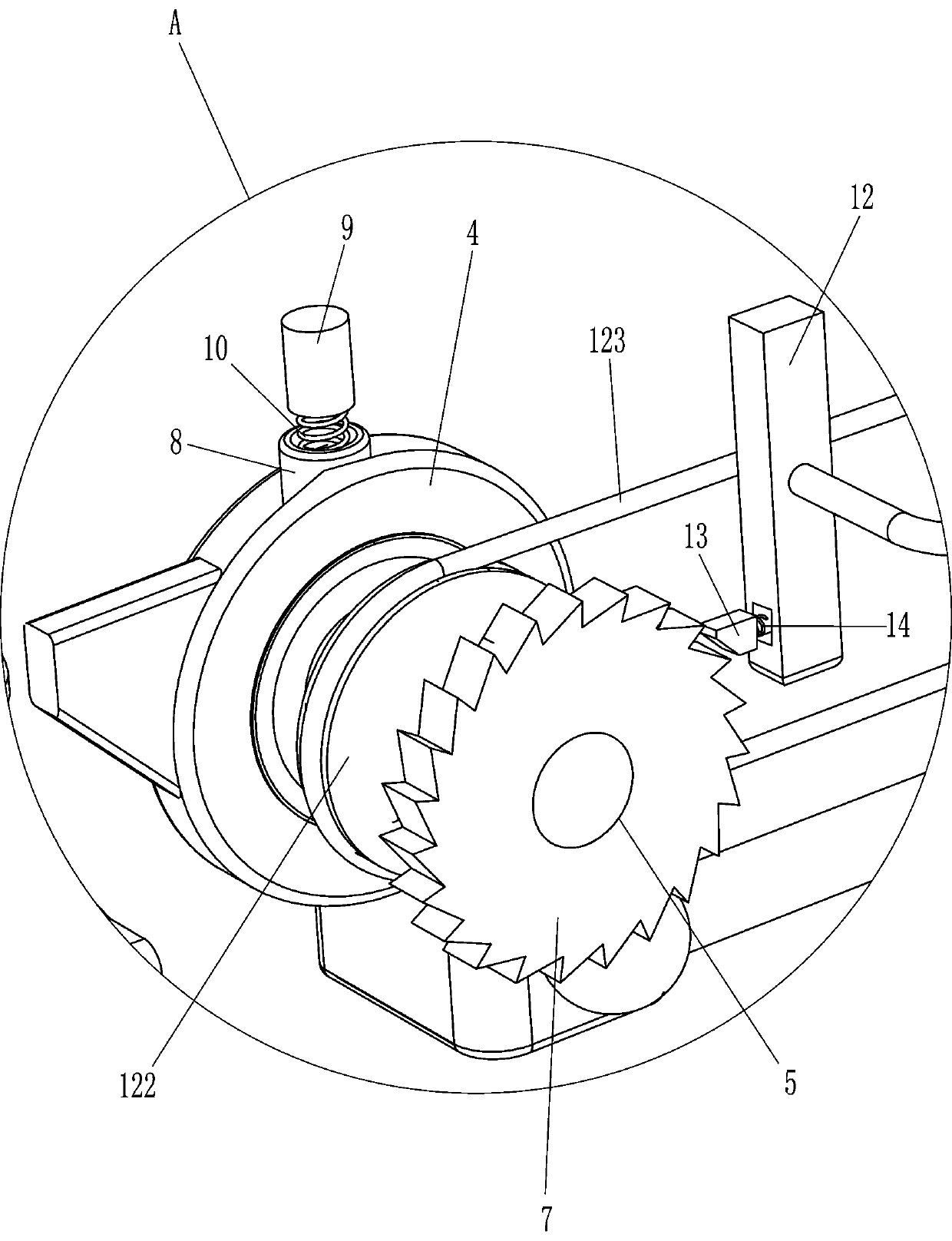

[0022] Such as Figure 1-3 As shown, the moving assembly includes a shaft sleeve 4, a screw rod 5, a nut 6, a ratchet 7, a first guide sleeve 8, a slider 9, a first spring 10, a horizontal plate 11, a mounting block 12, a baffle 121, and a pulley 122 , flat belt 123, the first wedge-shaped block 13 and the second spring 14, the left and ...

Embodiment 2

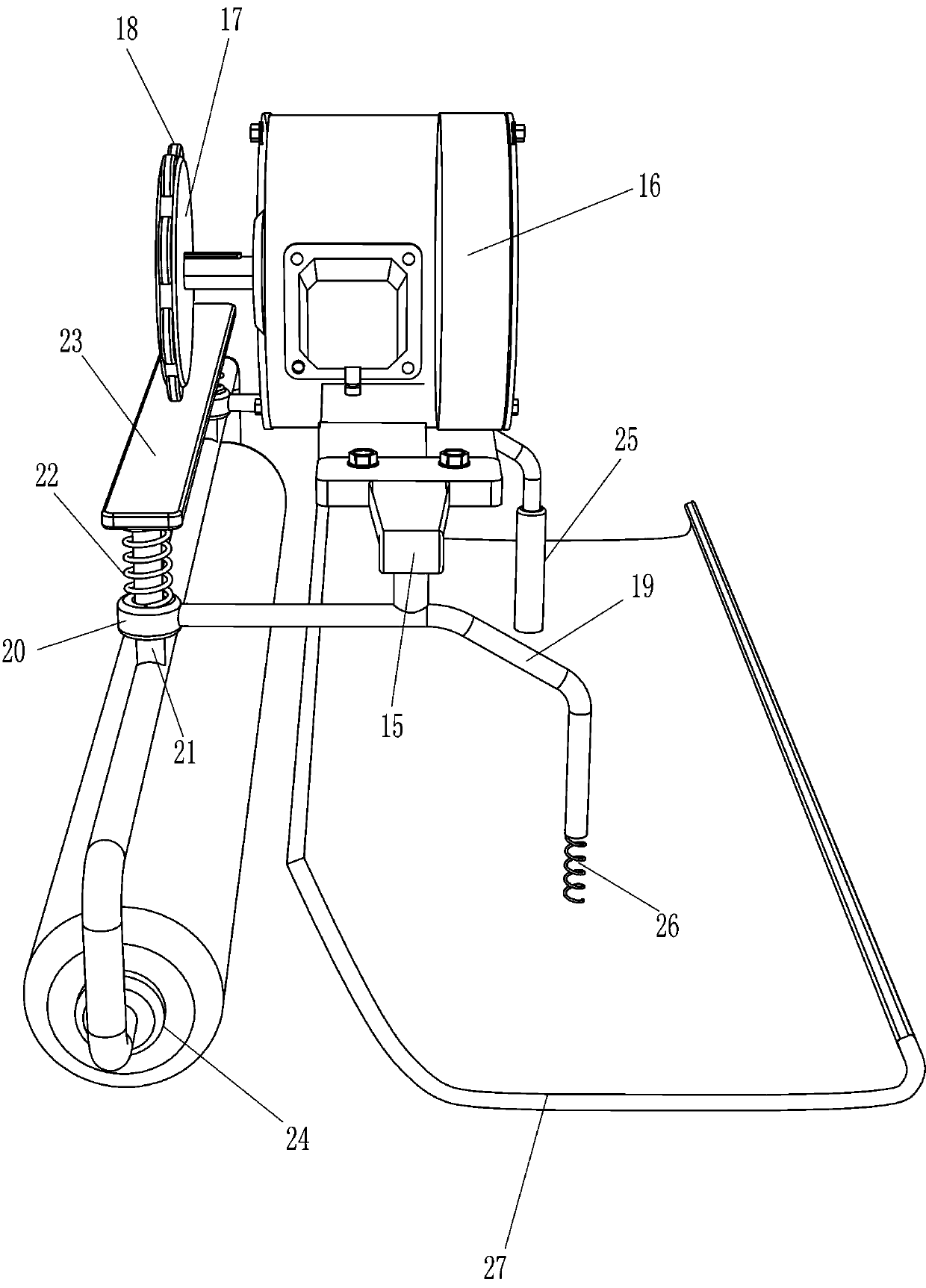

[0030] On the basis of Example 1, such as Figure 4 As shown, in order to better pave the brick clay, it also includes a third guide sleeve 25, a fourth spring 26 and a pressing plate 27, and the right end of the second L-shaped installation rod 19 is provided with a third guide sleeve in a sliding manner. 25. A pressure plate 27 is fixedly connected between the bottoms of the third guide sleeve 25 through bolts, and a fourth spring 26 is connected between the second L-shaped installation rod 19 and the pressure plate 27 .

[0031] Such as figure 1 , 2 As shown in and 5, in order to make the equipment work more stably, it also includes a U-shaped mounting rod 28, a fourth guide sleeve 29, an L-shaped slide bar 30, a fifth spring 31, a second wedge block 32, and a fifth guide sleeve 33 , the second slide bar 34, the sixth spring 35, the concave block 36, the pedal 37, the sixth guide sleeve 38, the insertion rod 39, the seventh spring 40 and the L-shaped splint 42, the right ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com