Pole pit tamping device for electric power engineering

A compaction device and a technology for electric power engineering, applied in the field of electric power engineering, can solve the problems of poor compaction effect, influence, trouble, etc., and achieve the effects of simple and reliable structure, long service life, and easy market promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

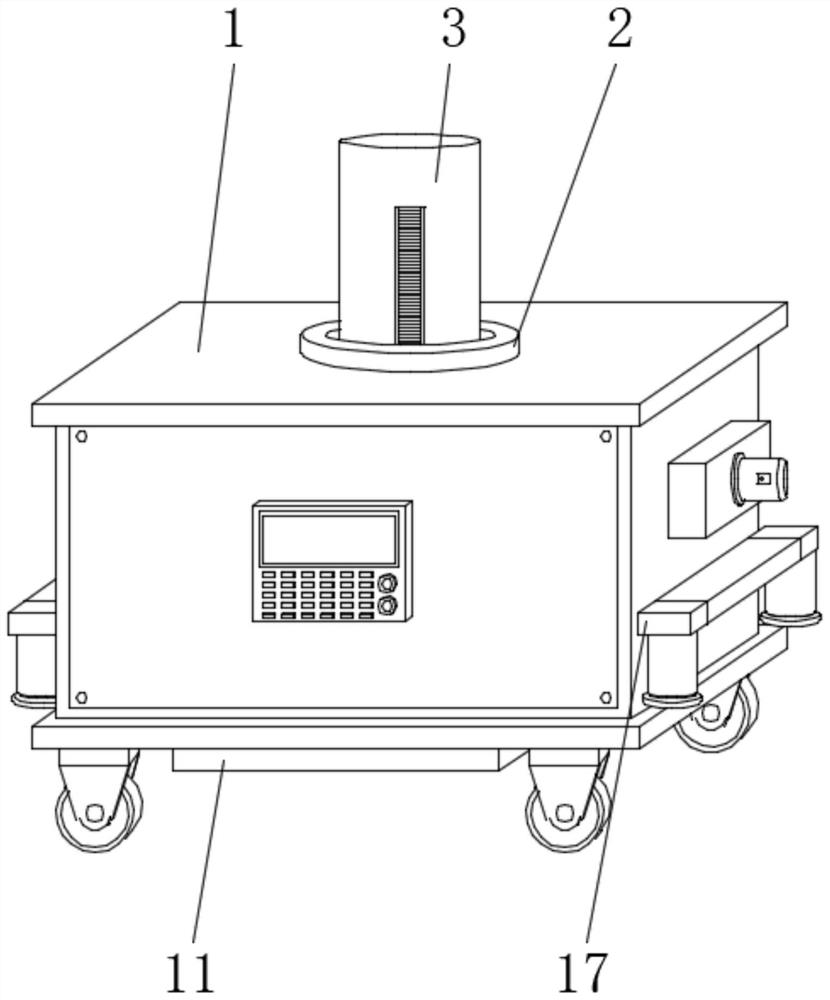

[0041] A pole hole compaction device for electric power engineering, such as Figure 1-3 shown, including:

[0042] Conveyance car body 1, the interior of the transport car body 1 is provided with a guide sleeve 2, the interior of the guide sleeve 2 is provided with a lifting assembly, and the lower end surface of the transport car body 1 is provided with a ground compacting device; and

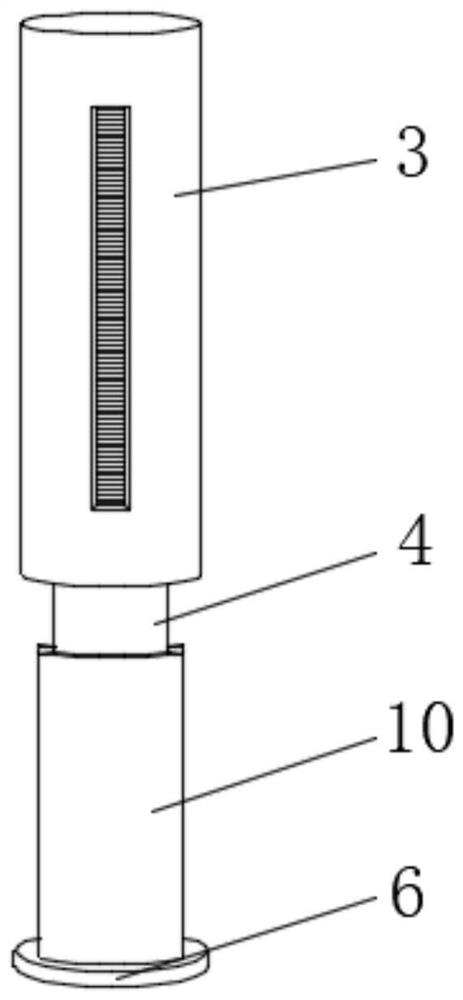

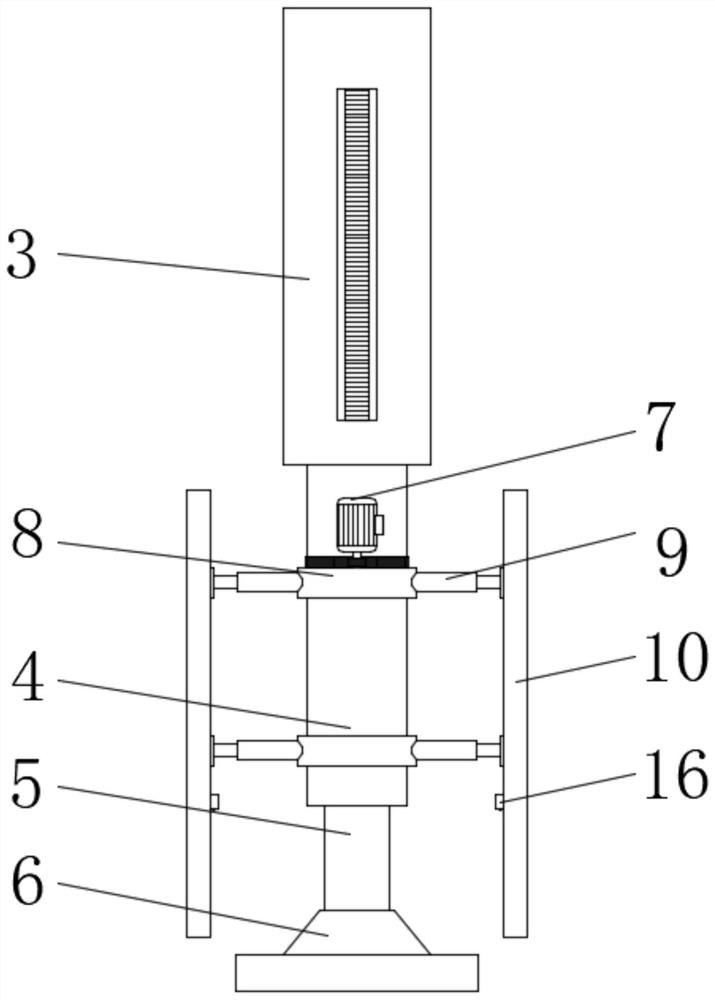

[0043]The tamping column 3 is movably installed in the guide sleeve 2, the tamping column 3 is connected with the lifting assembly, the lower end surface of the tamping column 3 is provided with an installation sleeve 4, and the outer surface of the installation sleeve 4 is provided with an adjustment assembly, adjusting A rod pit inner wall tamping assembly is installed on the assembly, and the inside of the installation sleeve 4 is provided with a lifting column 5, and the bottom end of the lifting column 5 is provided with a pressure plate 6 for compacting the bottom plate of the rod pit; ...

Embodiment 2

[0047] A rod pit compaction device for electric power engineering, such as Figure 1-3 As shown, compared with Embodiment 1, Embodiment 2 also has the following structure:

[0048] The rotating assembly includes a servo motor 7 and two sets of rotating disks 8. The two sets of rotating disks 8 are movably mounted on the outer surface of the installation sleeve 4 through bearings. The servo motor 7 is fixedly installed on the outer surface of the installation sleeve 4. The assembly is connected to one set of rotating discs 8 .

[0049] The servo motor 7 drives the rotating disc 8 to rotate, thereby driving the rotating disc 8 to rotate around the installation sleeve 4, thereby changing the angle of the lateral adjustment assembly, thereby changing the position of the arc-shaped plate 10, so that the arc-shaped plate 10 is completely in line with the rod The inner surface of the rod pit is contacted, and the inner surface of the rod pit is compacted.

[0050] The transmission ...

Embodiment 3

[0058] A rod pit compaction device for electric power engineering, such as Figure 1-7 As shown, compared with the second embodiment, the third embodiment also has the following structure:

[0059] The ground compacting device comprises a lifting frame and a compacting plate 11. The upper end of the compacting plate 11 is fixedly connected with the inner bottom surface of the transport vehicle body 1 through the lifting frame. Through the opening, the lower end of the tamping column 3 passes through the opening.

[0060] The lifting frame can also be replaced by an existing lifting structure, such as a hydraulic lifting column.

[0061] The lifting assembly includes two groups of lifting parts, and the two groups of lifting parts are installed inside the guide sleeve 2. The front end of the outer surface of the tamping column 3 and the rear end of the outer surface thereof are provided with guide grooves, and the lifting parts are located in the inside of the guide groove.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com