Flat-board type electromagnetic vibration compaction machine

An electromagnetic vibration, flat-plate technology, applied in the direction of road, soil protection, road repair, etc., can solve the problem of non-adjustable parameters such as voltage, current, frequency, etc., achieve fast and light transition, low failure rate, and expand the scope of application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

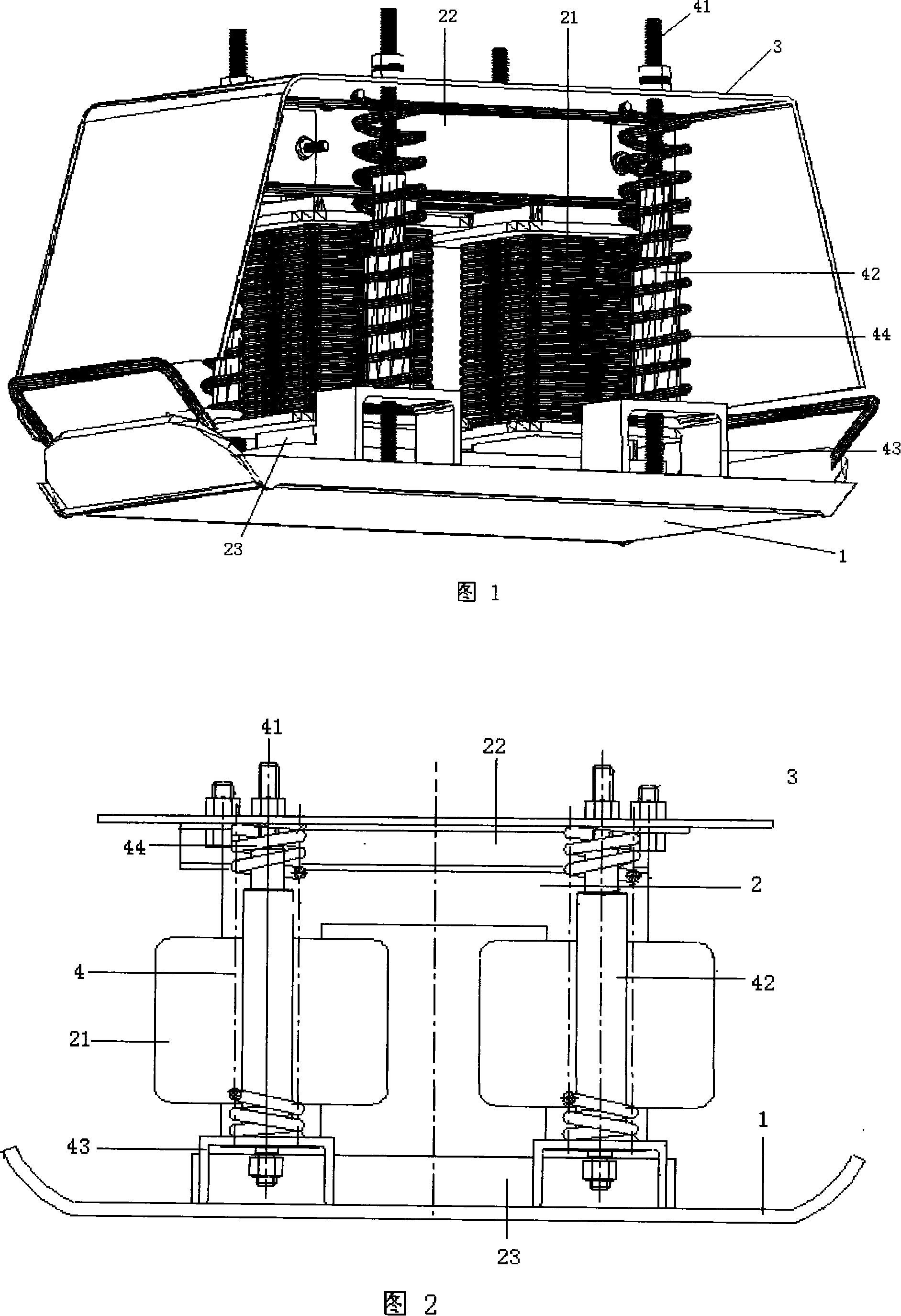

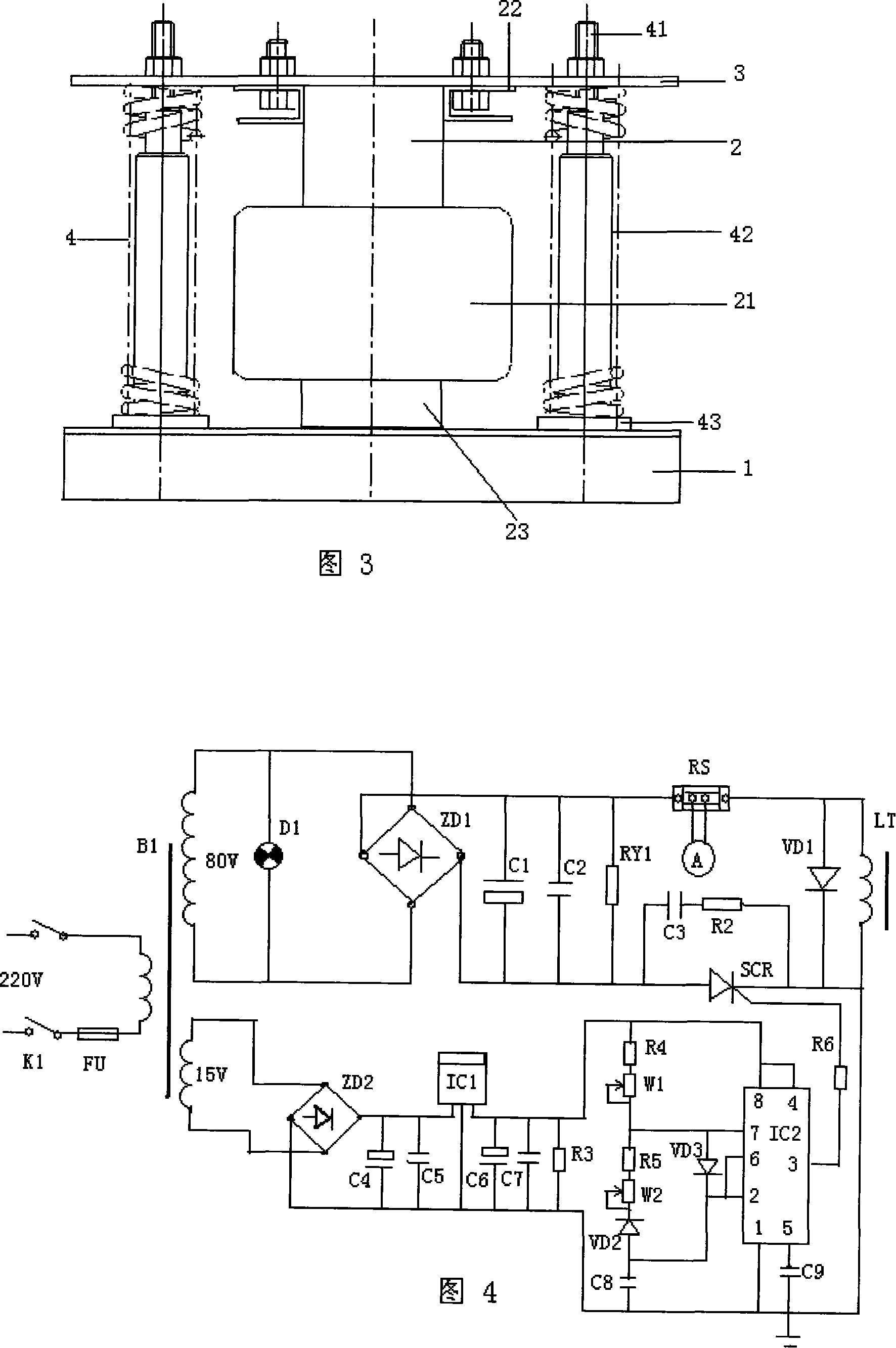

[0015] As shown in Figures 1, 2, and 3, the central part of the plane base plate 1 of the present invention is provided with an electromagnetic device, and the electromagnetic device consists of a "II" shaped magnetic core 2 and parallel coils wound on the two columns of the magnetic core. Composed of 21 turns. An upper cover plate 3 is arranged on the upper part of the electromagnetic device, and a spring column 4 is arranged on the outer four corners. The spring column is centered on the guide rod 41 connecting the upper cover plate 3 and the plane bottom plate 1, and the guide rod sleeve 42 and its sleeve seat 43 are arranged on the outside. The spring 44 is sleeved outside the sleeve 42 and stands upright on the sleeve seat 43. superior. The magnetic core of the electromagnetic device is made of silicon steel sheet material with high magnetic flux, and its upper part is clamped by channel steel 22 on both sides and connected to the upper cover plate. The lower part of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com