Extrusion process for preparing high-strength and high-plasticity rare earth-magnesium alloy

A technology of rare earth magnesium and high plasticity, which is applied in the field of alloy extrusion, and can solve the problems of reduced material strength and plasticity, and less precipitation of the second phase.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

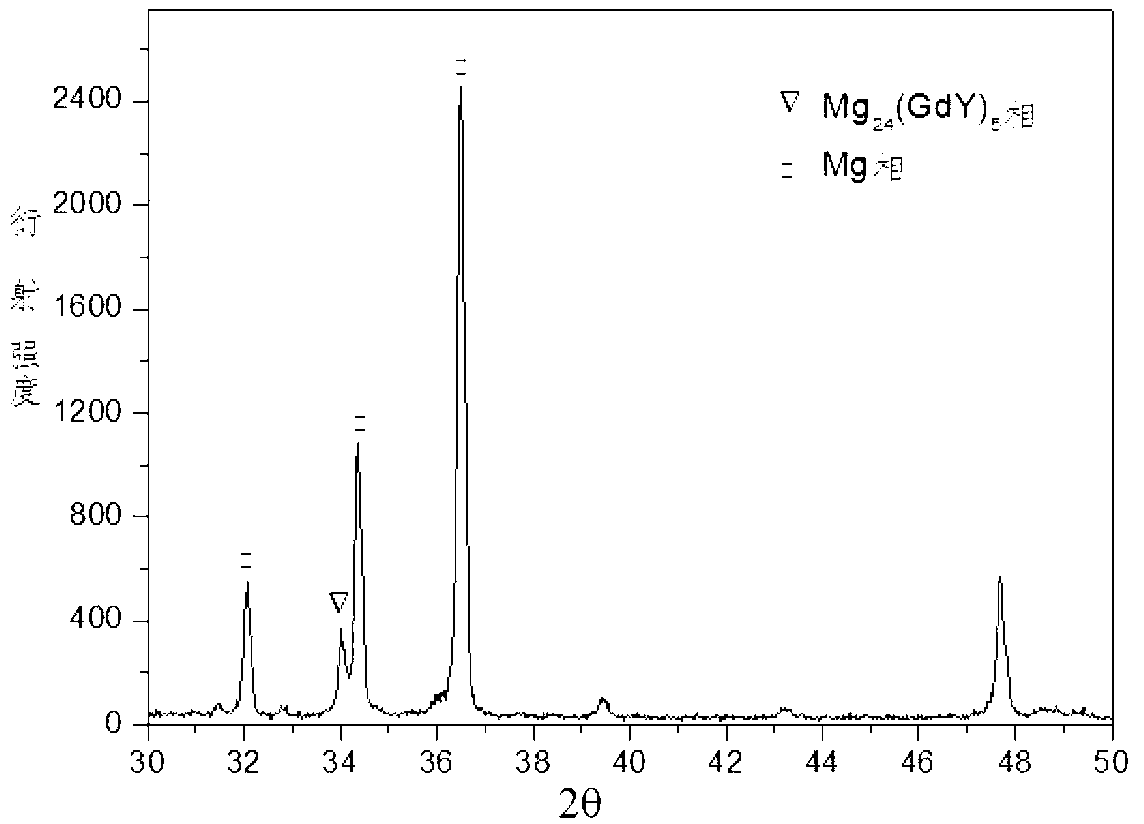

[0022] The raw material is GW103 magnesium alloy. The composition of the alloy is: Gd: 10%; Y: 3%; Zr: 0.4%, and the rest is magnesium, and the ratio is mass percentage.

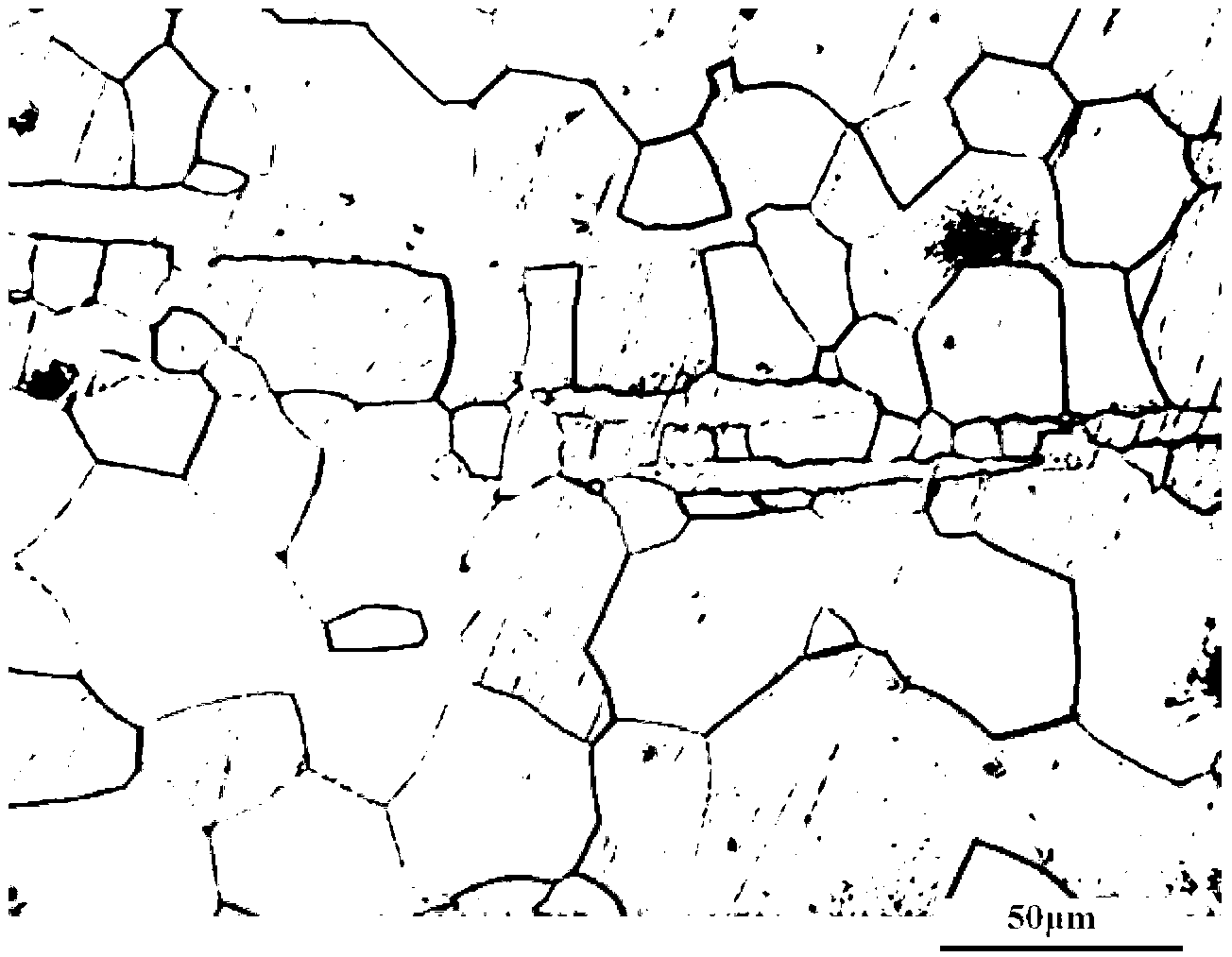

[0023] The extrusion die used is an equal-channel extrusion die. For details, please refer to the patent: Patent No.: 2012100833603, a back-pressure equal-channel extrusion die. The angle between the horizontal channel and the vertical channel is 90°C. The size of the extruded sample is: 12mmx12mmx90mm. After the sample is cut, the surface is polished. The heating ring surrounding the mold is used for heating, and the temperature of the mold is controlled by a temperature controller. At the beginning, the mold heating temperature is preset at 400°C. The sample is heated in a holding furnace next to the hydraulic press, and the temperature of the holding furnace is set at 400 °C. After the temperature of the holding furnace reaches the preset temperature, the surface of the sample is coated with a layer of g...

Embodiment 2

[0026] A rare-earth magnesium alloy with the brand name GW103 is used, and the mass percentage of the alloy composition is: Gd: 10%; Y: 3%; Zr: 0.4%, and the rest is magnesium.

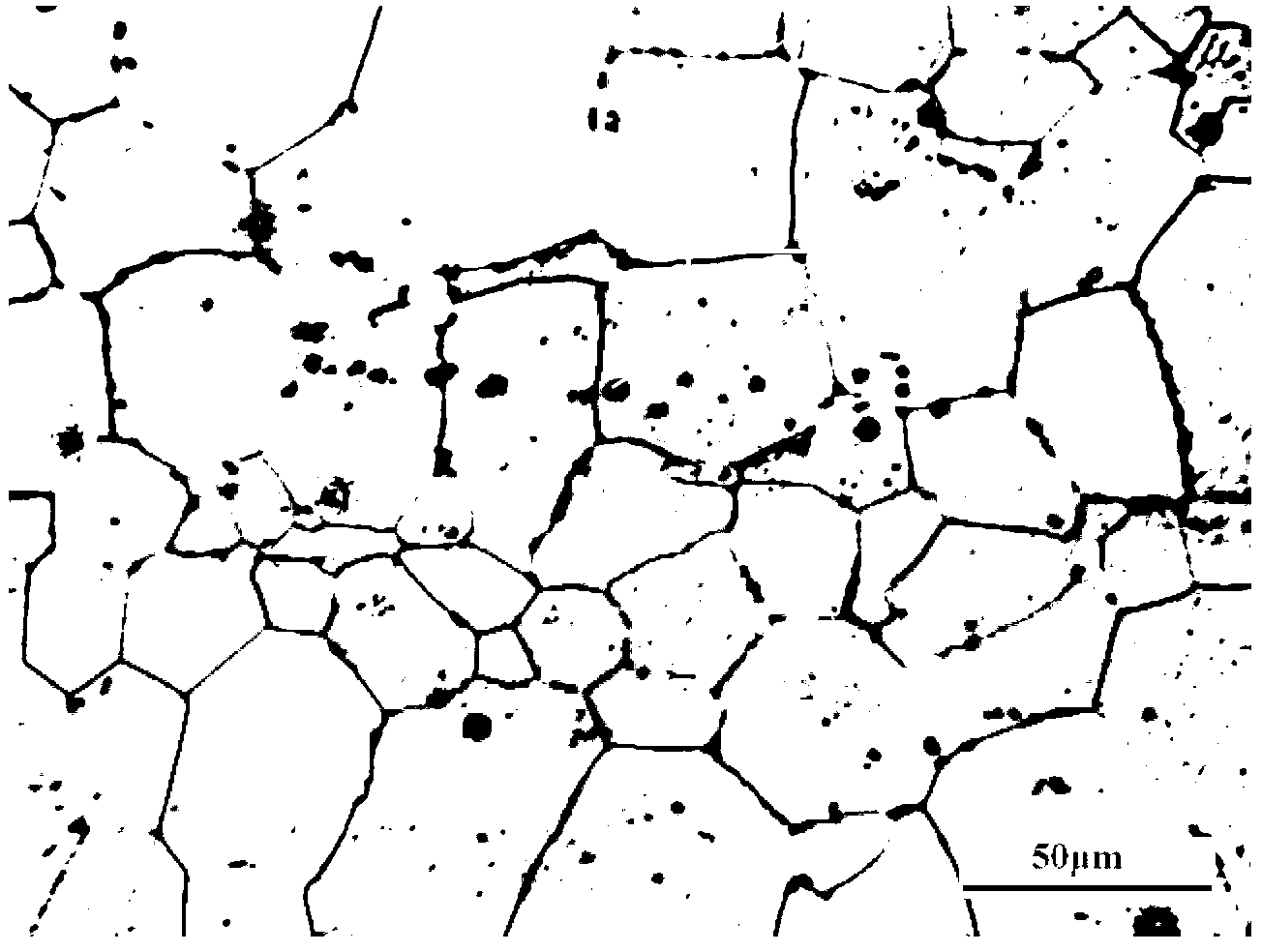

[0027]The extrusion die used is an equal-channel extrusion die, the angle between the horizontal channel and the vertical channel is 90°C, and the size of the extrusion sample is: 12mmx12mmx90mm. After the sample is cut, the surface is polished. The mold is heated by a heating ring surrounding the mold, and the temperature of the mold is controlled by a temperature controller. At the beginning, the mold heating temperature is preset to 400°C. The sample is heated in a holding furnace next to the hydraulic press, and the temperature of the holding furnace is set at 350°C. After the temperature of the holding furnace reaches the preset temperature, the surface of the sample is coated with a layer of graphite lubricant to reduce the friction between the sample and the mold, and the sample is put into the...

Embodiment 3

[0030] The raw material is GW103 magnesium alloy composition mass percentage: Gd: 10%; Y: 3%; Zr: 0.4%, and the rest is magnesium.

[0031] The extrusion die used is an equal-channel extrusion die, the angle between the horizontal channel and the vertical channel is 90°C, and the size of the extrusion sample is: 12mmx12mmx90mm. After the sample is cut, the surface is polished. The mold is heated by a heating ring surrounding the mold, and the temperature of the mold is controlled by a temperature controller. At the beginning, the mold heating temperature is preset to 400°C. The sample is heated in a holding furnace next to the hydraulic press, and the temperature of the holding furnace is set at 330°C. After the temperature of the holding furnace reaches the preset temperature, the surface of the sample is coated with a layer of graphite lubricant to reduce the friction between the sample and the mold, and the sample is put into the holding furnace for heating. According to m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com