Film-coated cement package bag

A packaging bag and cement technology, which is applied in the field of cement bags, can solve the problems of reduced firmness of packaging bags, poor exhaust problems, and unresolved moisture-proof problems, and achieves the effects of easy connection, small aperture, and increased strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

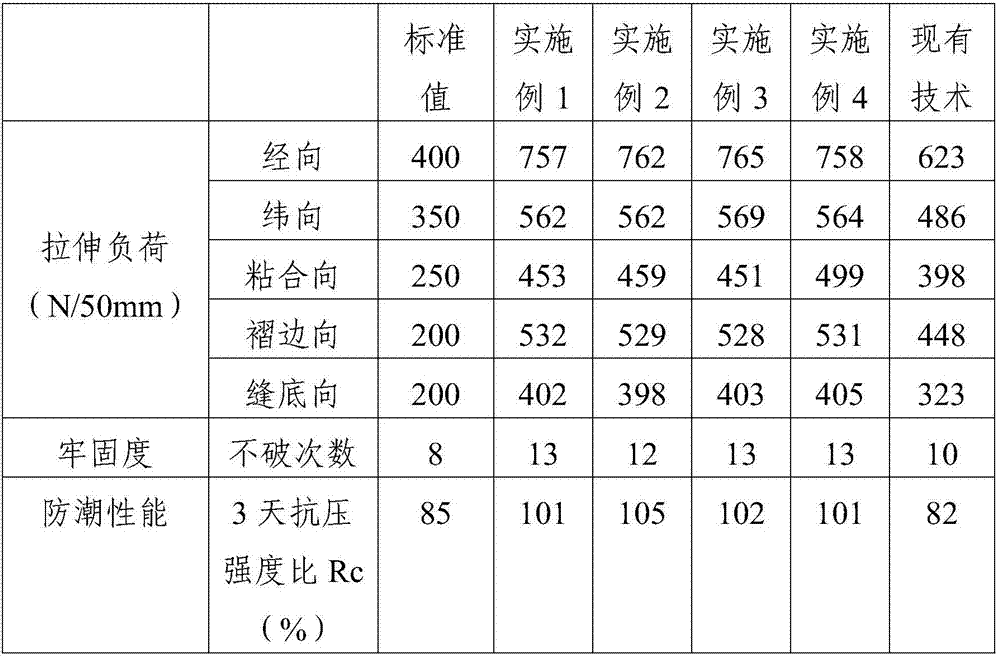

Examples

Embodiment 1

[0022] A compounded cement packaging bag, comprising a plastic woven bag and a film, the plastic woven bag is composed of the following raw materials in parts by weight: 55 parts of modified polypropylene, 35 parts of polyethylene, 15 parts of polyester fiber, and 18 parts of ABS resin , 5 parts of asbestos powder, 12 parts of urea-formaldehyde melamine resin, 12 parts of aluminum oxide, 17 parts of dicumyl peroxide, 7 parts of recycled materials, 3 parts of color masterbatch, 3 parts of whitening agent;

[0023] The preparation method of the modified polypropylene is as follows: dissolve the polypropylene in xylene, heat it in a water bath to 130°C, keep it warm, add sodium peroxide, raise the temperature to 140°C, turn on the magnetic stirring, stir for 35min, and let it go quickly. Put it into cold water to cool, and after all the polypropylene is precipitated, put it into an internal mixer for internal mixing, and pass through a 1000-mesh sieve to obtain a modified polyprop...

Embodiment 2

[0030] A compounded cement packaging bag, comprising a plastic woven bag and a film, the plastic woven bag is composed of the following raw materials in parts by weight: 50 parts of modified polypropylene, 30 parts of polyethylene, 20 parts of polyester fiber, and 15 parts of ABS resin , 6 parts of asbestos powder, 15 parts of urea-formaldehyde melamine resin, 14 parts of aluminum oxide, 15 parts of dicumyl peroxide, 6 parts of recycled materials, 4 parts of color masterbatch, 4 parts of whitening agent;

[0031] The preparation method of the modified polypropylene is as follows: dissolve the polypropylene in xylene, heat it in a water bath to 130°C, keep it warm, add sodium peroxide, raise the temperature to 140°C, turn on the magnetic stirring, stir for 35min, and let it go quickly. Put it into cold water to cool, and after all the polypropylene is precipitated, put it into an internal mixer for internal mixing, and pass through a 1000-mesh sieve to obtain a modified polyprop...

Embodiment 3

[0038] A composite cement packaging bag, comprising a plastic woven bag and a film, the plastic woven bag is composed of the following raw materials in parts by weight: 60 parts of modified polypropylene, 40 parts of polyethylene, 25 parts of polyester fiber, and 13 parts of ABS resin , 8 parts of asbestos powder, 10 parts of urea-formaldehyde melamine resin, 16 parts of aluminum oxide, 17 parts of dicumyl peroxide, 10 parts of recycled materials, 3 parts of color masterbatch, 5 parts of whitening agent;

[0039] The preparation method of the modified polypropylene is as follows: dissolve the polypropylene in xylene, heat it in a water bath to 130°C, keep it warm, add sodium peroxide, raise the temperature to 140°C, turn on the magnetic stirring, stir for 40min, and let it go quickly. Put it into cold water to cool, and after all the polypropylene is precipitated, put it into an internal mixer for internal mixing, and pass through a 1000-mesh sieve to obtain a modified polyprop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com