Method for preparing fresh wet rice noodles from extruding cooked rice

A technology of rice and rice noodles, applied in the direction of food science, application, food ingredients, etc., can solve the problems of damaged starch, excessive, broken strips, etc., and achieve the effects of eating convenience, reducing energy consumption, and avoiding microbial contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

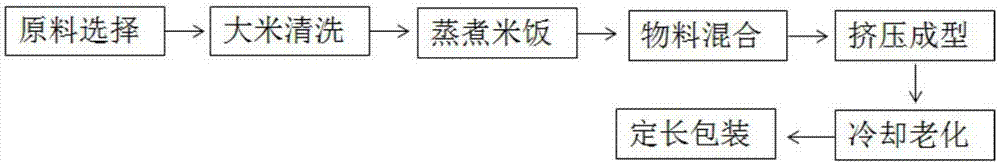

[0027] A method for preparing fresh wet rice noodles by extruding rice, said method comprising the following steps:

[0028] (1) Raw material selection: select 80% early indica rice, 10% late indica rice and 10% japonica rice to mix;

[0029] (2) Cooking rice: wash the mixed rice in step (1), drain the water, then add tap water twice the total mass of the mixed rice, steam in a steamer for 50 minutes at normal pressure, and the degree of gelatinization of the rice after cooking 90%, cooled to make rice;

[0030] (3) material mixing: add the wheat flour that accounts for 10% of rice quality in the rice that step (2) makes, after mixing, add high-speed mixer, stir 1min under the rotating speed of 3000rpm, make mixed material, stir while stirring Add water while making the mixed material have a moisture content of 30% relative to the dry basis;

[0031] (4) Extrusion molding: the mixed material that step (3) makes is added in the self-cooking type rice noodle machine and is pro...

Embodiment 2

[0036] A method for preparing fresh wet rice noodles by extruding rice, said method comprising the following steps:

[0037] (1) Raw material selection: select 45% early indica rice, 30% late indica rice and 25% japonica rice to mix;

[0038] (2) Cooking rice: wash the mixed rice in step (1), drain the water, then add tap water 1.5 times the total mass of the mixed rice, steam in a steamer for 35 minutes, and the degree of gelatinization of the rice after cooking 70%, cooled to make rice;

[0039] (3) material mixing: in the rice that step (2) makes, add the wheat flour that accounts for 10% of rice quality, the potato whole powder that accounts for 15% of rice quality, add high-speed stirrer after mixing, stir 2min under the rotating speed of 2000rpm, Prepare the mixed material, add water while stirring during the stirring process, so that the relative dry basis water content of the mixed material is 35%;

[0040] (4) Extrusion molding: the mixed material that step (3) make...

Embodiment 3

[0043] A method for preparing fresh wet rice noodles by extruding rice, said method comprising the following steps:

[0044] (1) Raw material selection: select 30% early indica rice, 50% late indica rice and 20% japonica rice to mix;

[0045] (2) Cooking rice: wash the mixed rice in step (1), drain the water, then add 1.2 times the tap water of the total mass of the mixed rice, cook in a pressure cooker with high-pressure steam for 25 minutes, and the degree of gelatinization of the cooked rice is 60 %, cooled to make rice;

[0046] (3) material mixing: in the rice that step (2) makes, add the wheat flour that accounts for 40% of rice quality, the potato whole powder that accounts for 10% of rice quality, the mung bean starch that accounts for 5% of rice quality, add high-speed mixer after mixing , stirring at a rotating speed of 1500rpm for 3min to obtain a mixed material, adding water while stirring during the stirring process, so that the relative dry basis moisture conten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com