Mixed pin barrel cold feeding extruder

A technology of cold feeding and extruder, which is applied in the field of mixed pin barrel cold feeding extruder, which can solve the problems of small radial pin contact length, reduced production capacity and economy, and limited cooling surface area. Achieve the effects of increasing cooling area and cooling effect, wide processing range, and increasing plasticizing and mixing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

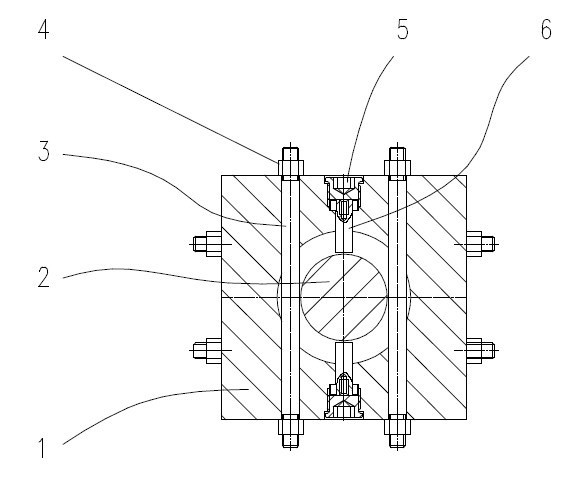

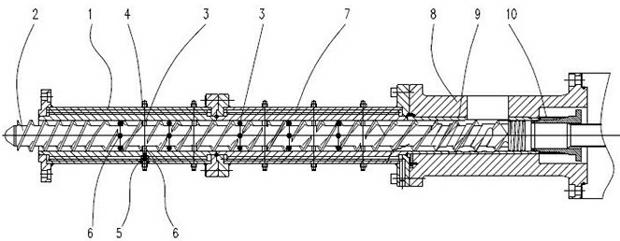

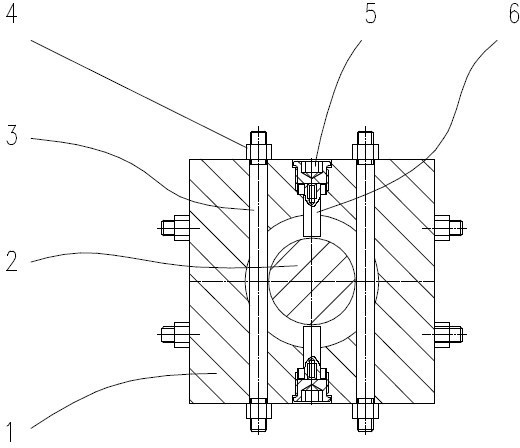

[0016] see figure 1 with figure 2 , the present invention provides a hybrid pin-barrel cold-feed extruder structure, comprising an organic barrel 1, several rows of tangential pins 3 and radial pins 6 are arranged along the length direction of the barrel, and each row is two tangential pins 3 and two radial pins 6. The tangential pin 3 passes through the pin hole in the barrel 1 and is placed in the screw groove along the tangential direction of the screw 2 without interfering with the screw 2 . The two ends of the tangential pin are fixed on the barrel 1 with nuts 4 through external threads. Inside the tangential pin 3, a cooling fluid channel (not shown in the figure) is provided to cool the tangential pin 3 and take away the frictional heat during the extrusion process. All the rows of tangential pins 3 are divided into several groups for cooling, and the tangential pins 3 on each row in each cooling group and the tangential pins 3 of each row are connected in series th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com