Rigid polyvinyl chloride pipe material and preparation method thereof

A technology of rigid polyvinyl chloride and silicone powder, applied in the field of polymer materials, can solve problems such as difficulty in threading, and achieve the effects of reducing resistance, reducing construction strength and uniform dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034]Based on the same inventive concept, the application also discloses a preparation method of a rigid polyvinyl chloride pipe material, comprising the following steps:

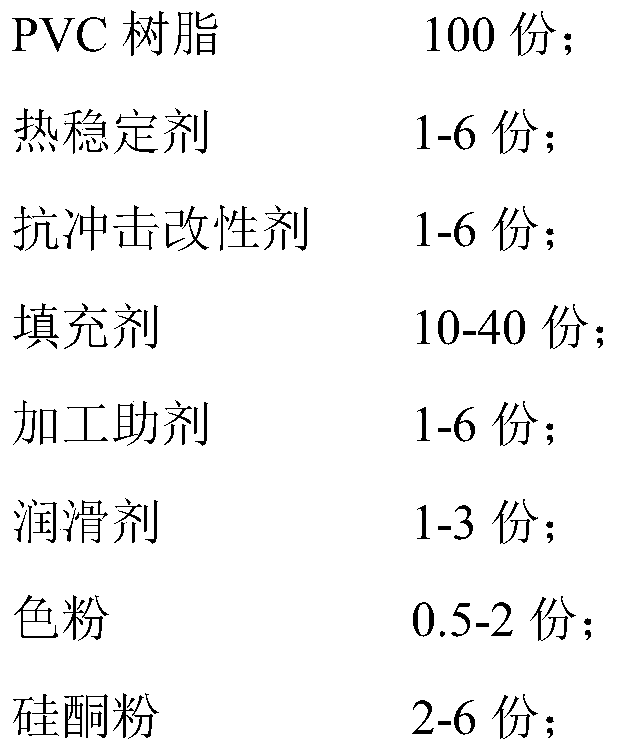

[0035] Taking the material, weighing 100 parts by weight of PVC resin, 1-6 parts by weight of heat stabilizer, 1-6 parts by weight of impact modifier, 10-40 parts by weight of filler, 1-6 parts by weight of processing aids, lubricants of 1-3 parts by weight, toner of 0.5-2 parts by weight and silicone powder of 2-6 parts by weight;

[0036] Mixing, put PVC resin, heat stabilizer, impact modifier, filler, processing aid, lubricant, toner and silicone powder into the mixer and mix;

[0037] Extrude, add the obtained mixture into a twin-screw extruder for mixing, the extruded strands are cooled by a water tank, pelletized by a pelletizer, dried by a dryer, and packaged.

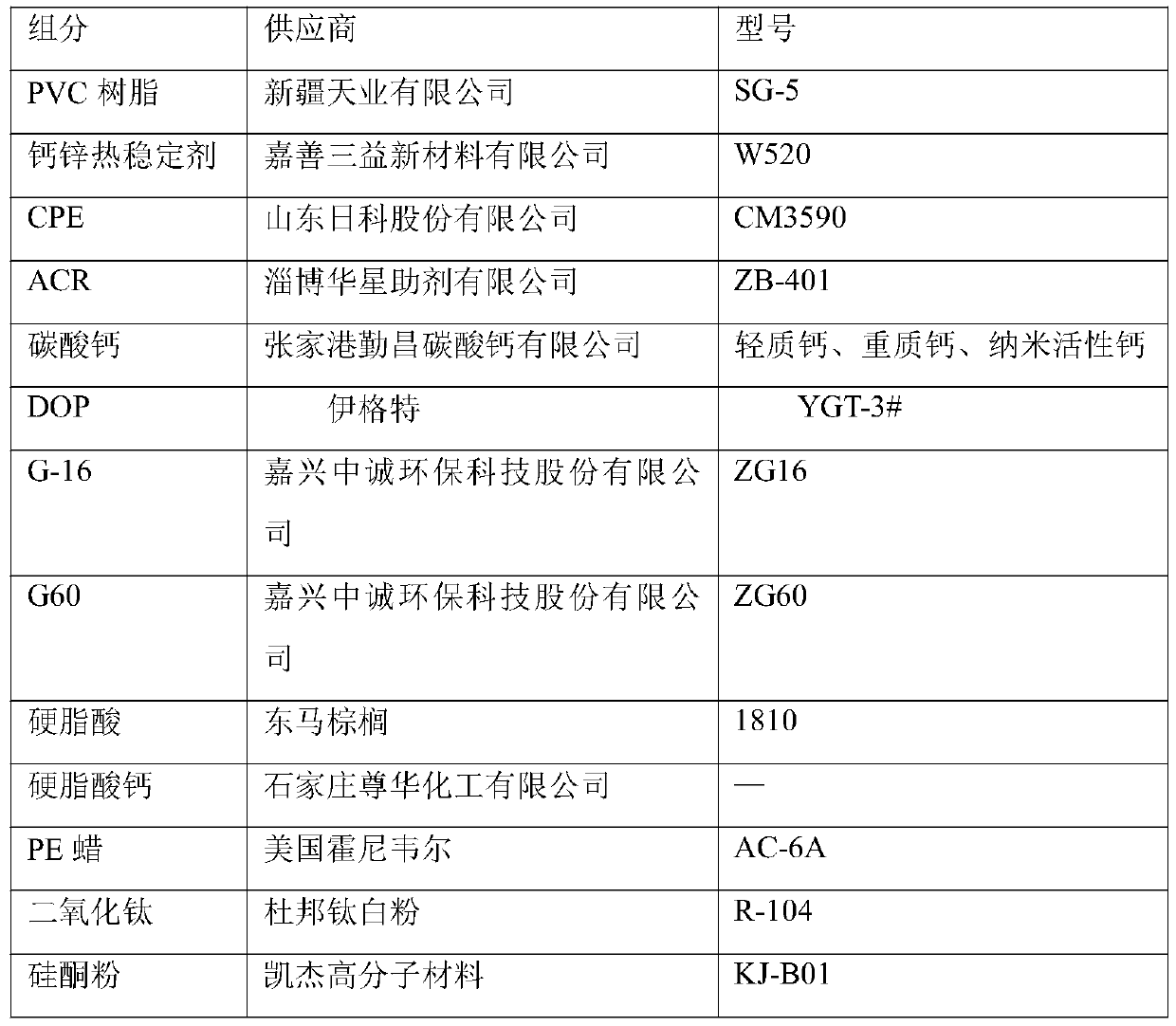

Embodiment 1

[0043] Weigh 100 parts by weight of PVC resin, 5 parts by weight of calcium zinc heat stabilizer, 2.5 parts by weight of CPE, 20 parts by weight of calcium carbonate, 4 parts by weight of ACR, 0.5 parts by weight of G-16 and 1 weight part The mixture of the stearic acid of part, the titanium dioxide of 1 weight part and the silicone powder of 2 weight parts;

[0044] Mixing, put PVC resin, heat stabilizer, impact modifier, filler, processing aid, lubricant, toner and silicone powder into the mixer and mix;

[0045] Extrude, add the obtained mixture into a twin-screw extruder and knead, the extruded material strands are cooled by a water tank, pelletized by a pelletizer, dried by a dryer, and packaged to obtain a product.

Embodiment 2

[0047] Weigh 100 parts by weight of PVC resin, 6 parts by weight of calcium zinc heat stabilizer, 4 parts by weight of CPE, 10 parts by weight of calcium carbonate, 2 parts by weight of ACR, 2 parts by weight of G60 and 1 part by weight of The mixture of calcium stearate, the titanium dioxide of 1 weight part and the silicone powder of 3 weight parts;

[0048] Mixing, put PVC resin, heat stabilizer, impact modifier, filler, processing aid, lubricant, toner and silicone powder into the mixer and mix;

[0049] Extrude, add the obtained mixture into a twin-screw extruder and knead, the extruded material strands are cooled by a water tank, pelletized by a pelletizer, dried by a dryer, and packaged to obtain a product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com