Surface processing method of circuit board

A surface treatment and circuit board technology, which is applied in the secondary treatment of printed circuits, the improvement of the metal adhesion of insulating substrates, printed circuits, etc., can solve the problems of easy damage, falling off, and small bonding force of the bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

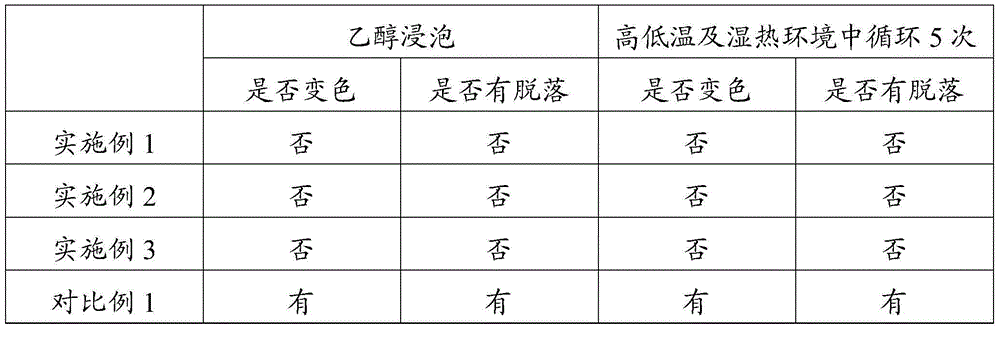

Embodiment 1

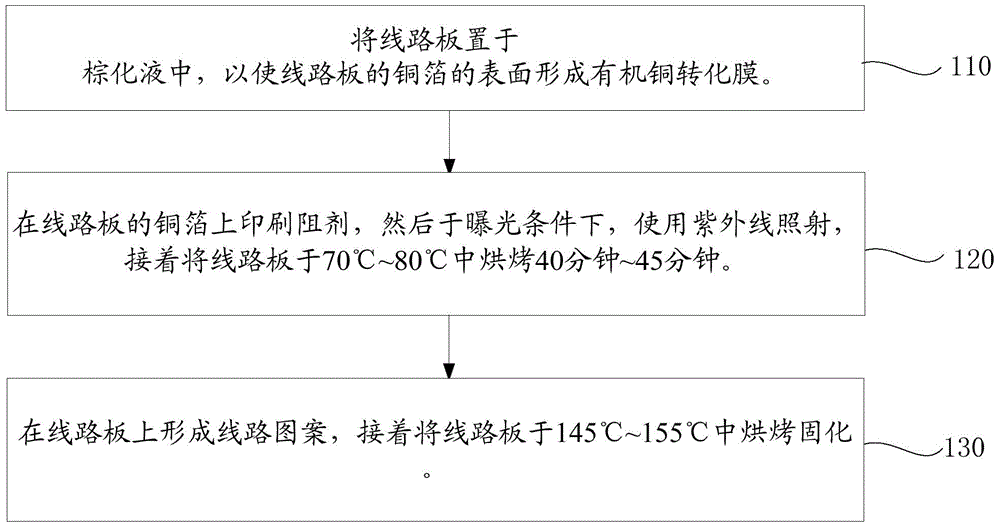

[0066] The surface treatment steps of the circuit board of the present embodiment are as follows:

[0067] (1) Use a nylon needle brush to polish the circuit board to clean and roughen the surface of the circuit board.

[0068] (2) At room temperature, use an acidic solution to horizontally spray the circuit board, wherein the acidic solution is: 20 grams per liter of sodium persulfate, 40 grams per liter of sulfuric acid, 15 grams per liter of copper ions and water; then at room temperature, Rinse the circuit board with tap water horizontally to remove the acidic solution adhering to the circuit board; then at 45°C, use an alkaline solution to horizontally spray the circuit board to remove grease, fingerprints and organic matter on the copper foil, among which alkaline The solution is: sodium hydroxide 10 g / L, sodium phosphate 60 g / L, potassium carbonate 40 g / L and water; finally, use tap water to horizontally spray the circuit board to remove the alkaline solution adhering t...

Embodiment 2

[0076] The surface treatment steps of the circuit board of the present embodiment are as follows:

[0077] (1) Use a nylon needle brush to polish the circuit board to clean and roughen the surface of the circuit board.

[0078] (2) At room temperature, use an acidic solution to horizontally spray the circuit board, wherein the acidic solution is: 20 grams per liter of sodium persulfate, 40 grams per liter of sulfuric acid, 0.1 gram per liter of copper ion and water; then at room temperature, Rinse the circuit board with tap water horizontally to remove the acidic solution adhering to the circuit board; then at 55°C, use an alkaline solution to horizontally spray the circuit board to remove grease, fingerprints and organic matter on the copper foil, among which alkaline The solution is: 20 g / L sodium hydroxide, 40 g / L sodium phosphate, 60 g / L potassium carbonate and water; finally, use tap water to horizontally spray the circuit board to remove the alkaline solution adhering to...

Embodiment 3

[0086] The surface treatment steps of the circuit board of the present embodiment are as follows:

[0087] (1) Use a nylon needle brush to polish the circuit board to clean and roughen the surface of the circuit board.

[0088] (2) At room temperature, use an acidic solution to horizontally spray the circuit board, wherein the acidic solution is: 30 grams per liter of sodium persulfate, 25 grams per liter of sulfuric acid, 8 grams per liter of copper ion and water; then at room temperature, Rinse the circuit board with tap water horizontally to remove the acidic solution adhering to the circuit board; then at 50°C, use an alkaline solution to horizontally spray the circuit board to remove grease, fingerprints and organic matter on the copper foil, among which alkaline The solution is: sodium hydroxide 15 g / L, sodium phosphate 50 g / L, potassium carbonate 50 g / L and water; finally, use tap water to horizontally spray the circuit board to remove the alkaline solution adhering to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com