Solvent-free polyurethane paint and manufacture method thereof

A solvent-free polyurethane and manufacturing method technology, applied in polyurea/polyurethane coatings, anti-corrosion coatings, coatings, etc., can solve the problems of short application period of coatings, fast curing speed of coatings, unfavorable small area construction and repair, etc. Impactful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

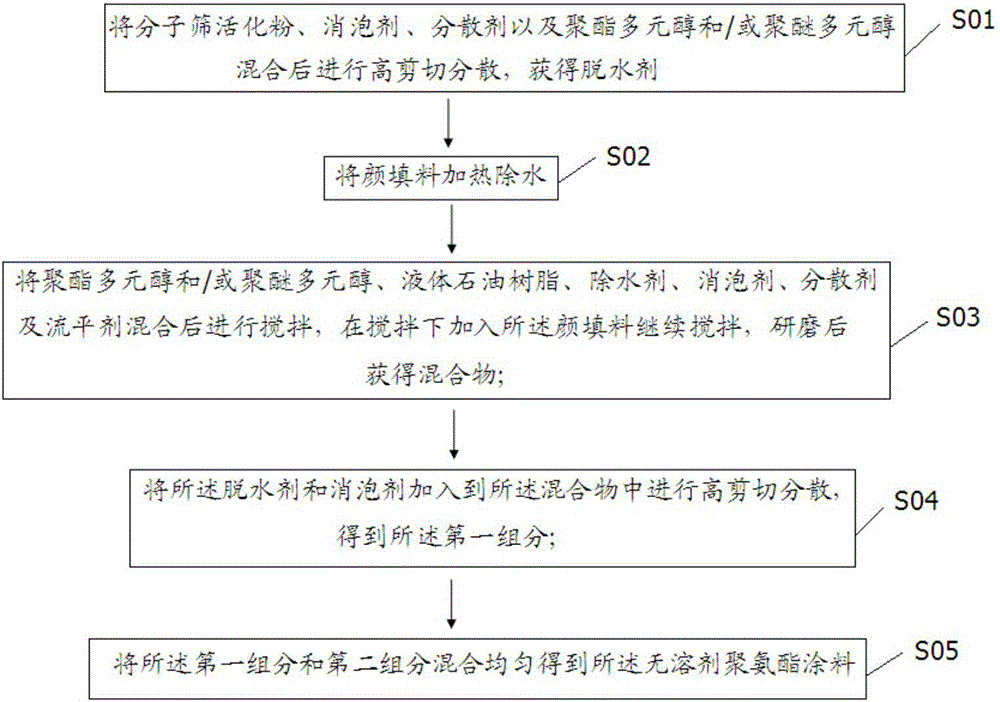

Method used

Image

Examples

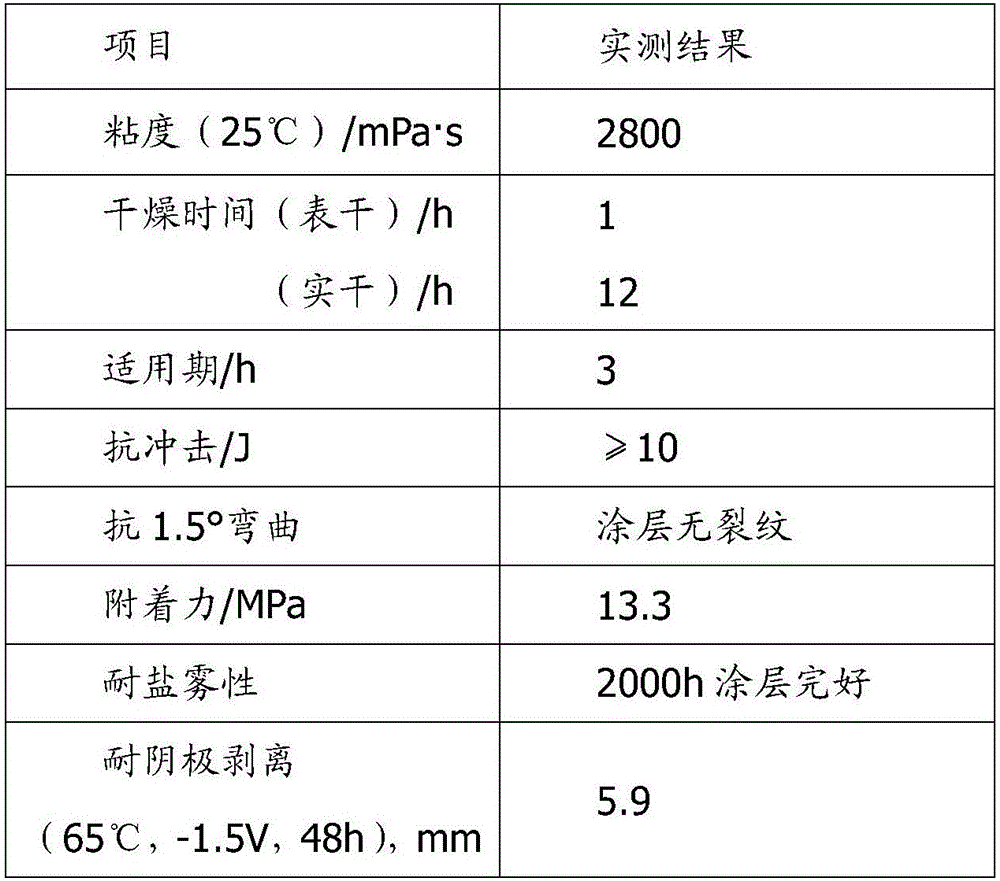

Embodiment 1

[0097] The steps of the manufacturing method of the solvent-free polyurethane coating of Example 1 are as follows, and the proportion of each component is parts by weight:

[0098] Step (1), add 0.14 parts of molecular sieve activation powder, 0.0014 parts of defoamer BYK057 and 0.0014 parts of dispersant BYK163 to 0.14 parts of polyol Sovermol 750, and disperse for 1 hour at high shear (2500r / min) to obtain a dehydrating agent;

[0099] Step (2): Put 0.8 parts of quartz powder, 0.3 parts of talc powder, 0.26 parts of titanium dioxide, 0.41 parts of barium sulfate and 0.004 parts of carbon black in a high temperature box at 150°C for 12 hours to remove water to obtain paint pigments and fillers;

[0100] Step (3), add 0.53 parts of polyol Sovermol 750, 0.15 parts of liquid petroleum resin, 0.018 parts of dewatering agent ALT-201, 0.018 parts of defoaming agent BYK057, 0.018 parts of dispersant BYK163 and 0.016 parts of leveling agent EFKA-3777 Add 1 part of polyol Sovermol 805 to 1 p...

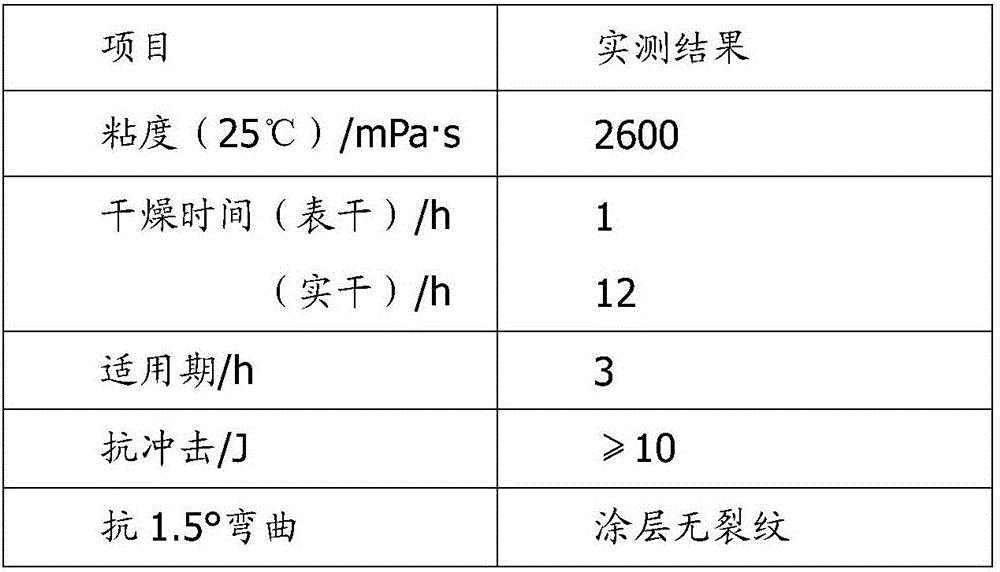

Embodiment 2

[0108] The steps of the manufacturing method of the solvent-free polyurethane coating of this embodiment 2 are as follows, and the ratio of each component is parts by weight:

[0109] Step (1), adding 0.15 parts of molecular sieve activation powder, 0.0015 parts of defoamer BYK057 and 0.0015 parts of dispersant BYK163 to 0.13 parts of polyol Sovermol 750, and high shear (2500r / min) dispersion for 1 hour to obtain a dehydrating agent;

[0110] In step (2), 0.75 parts of quartz powder, 0.35 parts of talc powder, 0.3 parts of titanium dioxide, 0.35 parts of barium sulfate and 0.005 parts of carbon black are placed in a 150°C high temperature box for heating and dewatering for 12 hours to obtain paint pigments and fillers;

[0111] Step (3), add 0.55 parts of polyol Sovermol 750, 0.2 parts of liquid petroleum resin, 0.02 parts of dewatering agent ALT-201, 0.014 parts of defoamer BYK057, 0.014 parts of dispersant BYK163 and 0.02 parts of leveling agent EFKA-3777 Add 1 part of polyol Sover...

Embodiment 3

[0120] The steps of the manufacturing method of the solvent-free polyurethane coating of this embodiment 3 are as follows, and the proportion of each component is parts by weight:

[0121] Step (1), adding 0.12 parts of molecular sieve activation powder, 0.001 parts of defoamer BYK057 and 0.002 parts of dispersant BYK163 to 0.1 part of polyol Sovermol 750, and high shear (2500r / min) dispersion for 1 hour to obtain a dehydrating agent;

[0122] Step (2): Put 0.7 parts of quartz powder, 0.25 parts of talc powder, 0.25 parts of titanium dioxide, 0.35 parts of barium sulfate and 0.003 parts of carbon black in a high temperature box at 120°C for 15 hours to obtain paint pigments and fillers;

[0123] Step (3), add 0.5 parts of polyol Sovermol 750, 0.1 parts of liquid petroleum resin, 0.015 parts of water remover ALT-201, 0.0145 parts of defoamer BYK057, 0.013 parts of dispersant BYK163 and 0.015 parts of leveling agent EFKA-3777 Add 1 part of polyol Sovermol 805 to 1 part of polyol Soverm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com