Antifoaming gradient porous structure in plasma-facing material

A technology of plasma and gradient porosity, which is applied to the structure of plasma materials and the field of gradient porous structure, which can solve the problems of shortening the life of plasma materials, affecting plasma stability, and surface peeling, so as to improve the service life and avoid breakdown. Foam, good binding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

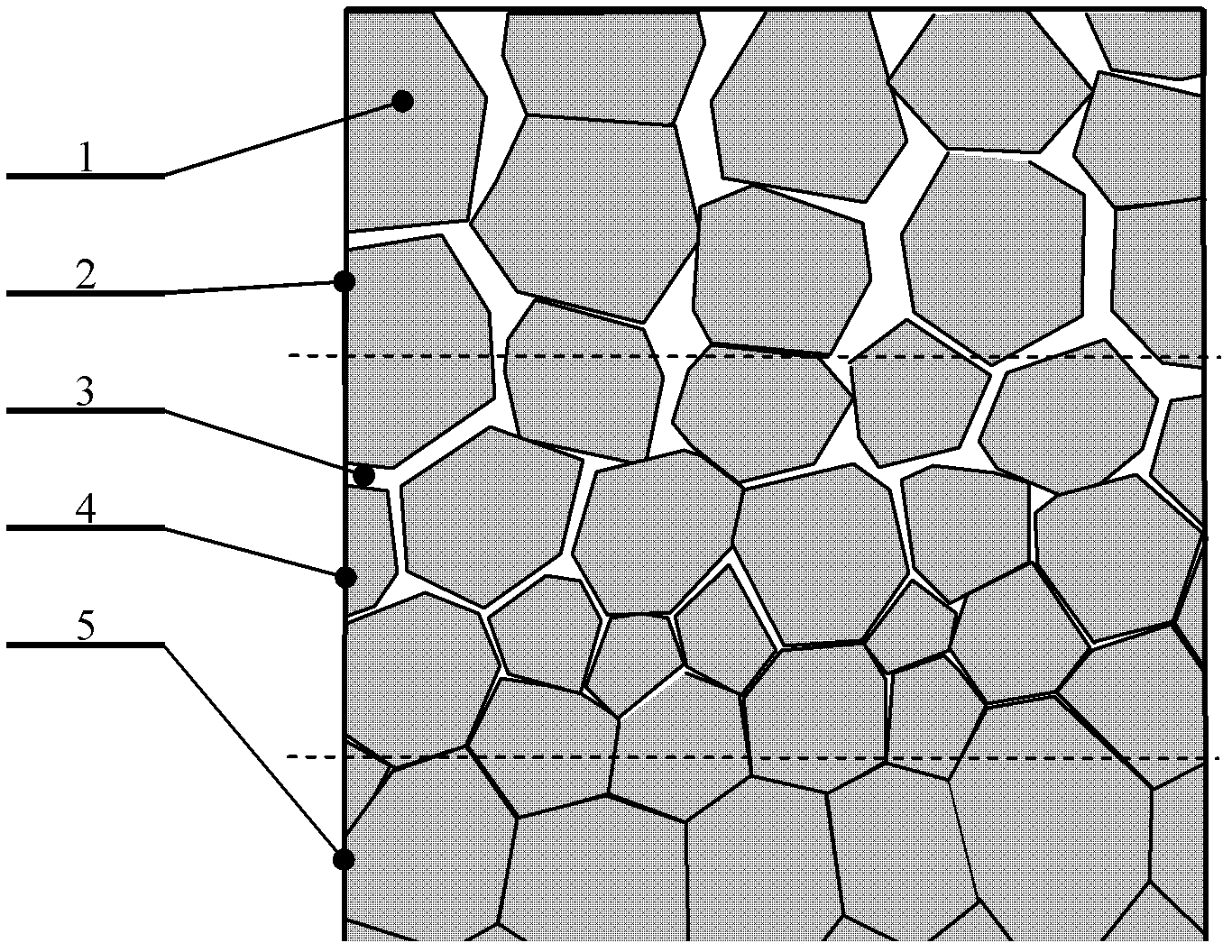

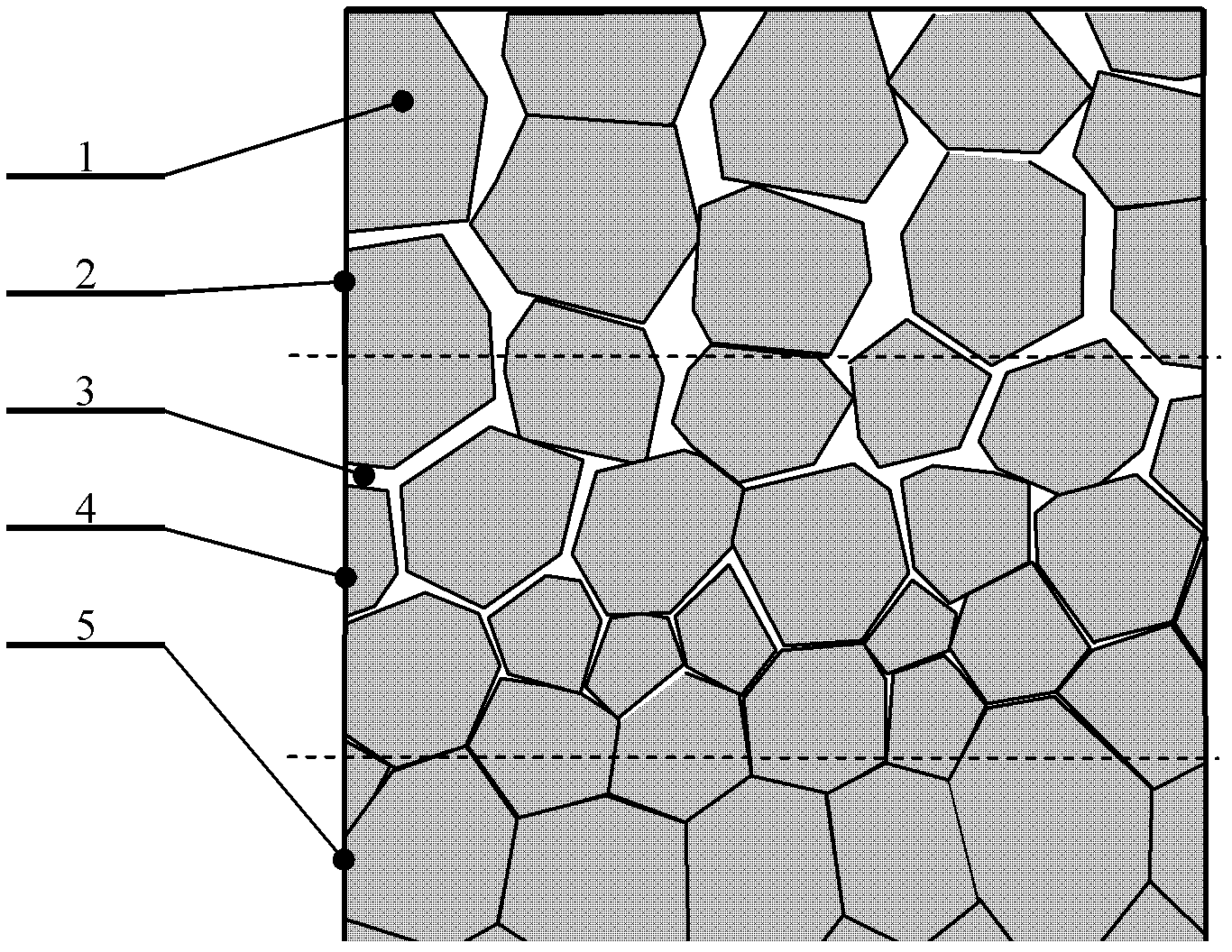

[0019] Such as figure 1 As shown, this is a form of gradient porous structure of tungsten-based plasma material, which can be prepared by conventional powder sintering method. This form of porosity is characterized by irregularities. The gradient porous structure is composed of three layers in the thickness direction according to the change of porosity, such as figure 1 , the most surface part is the surface porous layer 2, the part closely connected with the surface porous layer 2 is the gradient transition layer 4, and the bottom part closely connected with the gradient transition layer 4 is the matrix 5;

[0020] The thickness of the superficial porous layer 2 is 3 microns. Wherein there is a large amount of pores 3, and its porosity is 35%, and all pores 3 are all connected with the surface, and there is horizontal interpenetration, and the lateral particle diameter of the solid tungsten 1 that forms the network frame is 2 microns; The described pores 3 consists of a ne...

Embodiment 2

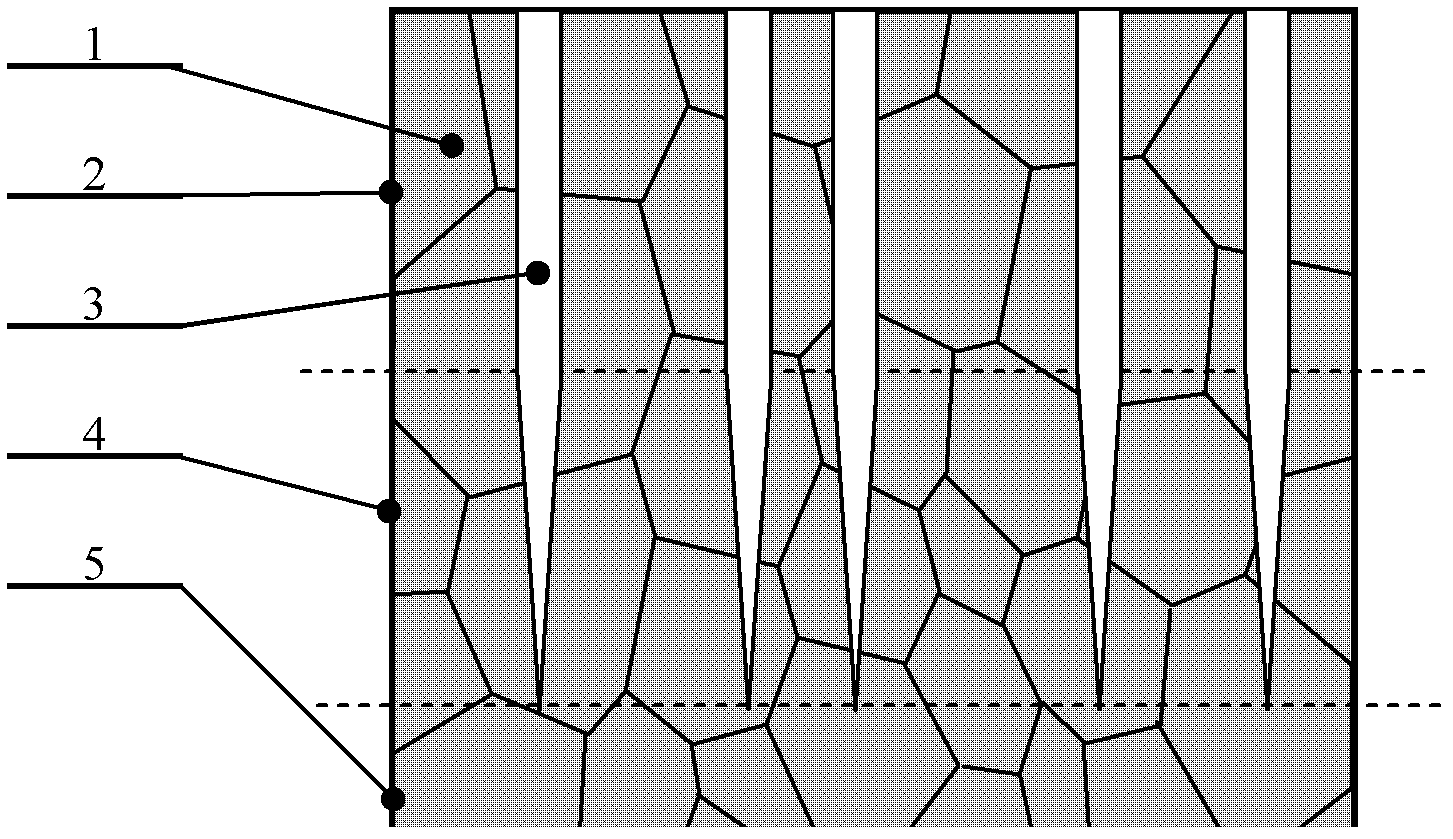

[0024] This is another form of gradient porous structure with tungsten substrates facing plasmonic materials, such as figure 2 , can be prepared by conventional template electrochemical etching method. The characteristic of this form of pores is that the pores are basically perpendicular to the surface, which is relatively regular and smooth. It is also composed of three layers in the thickness direction according to the change of porosity: the most surface part is the surface porous layer 2, the part closely connected with the surface porous layer 2 is the gradient transition layer 4, and the bottom part is the gradient transition layer 4. The closely connected part of the transition layer 4 is the matrix 5;

[0025] The thickness of the superficial porous layer 2 is 8 microns. There are a large number of pores 3, the porosity of which is 20%, and all pores 3 are connected to the surface, and the transverse grain size of the network frame composed of solid tungsten 1 is 1....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com