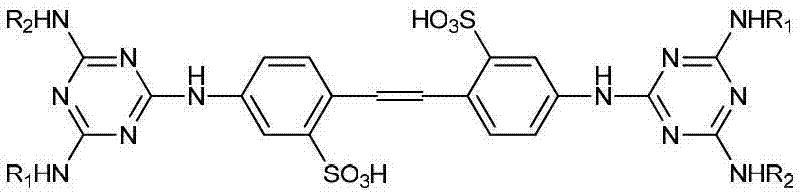

Method for synthesizing DSD (4, 4'-diaminostilbene-2, 2'-disulfonic) acid-triazine fluorescent brightening agents

A technology of fluorescent whitening agent and acid triazine, applied in the field of fluorescent whitening agent, can solve problems such as increasing production cost, and achieve the effects of reducing production cost, eliminating cost increase and pollution problems, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Prepare 0.015mol of DSD acid with 0.03mol of ethanolamine to make a solution of about 30g for later use.

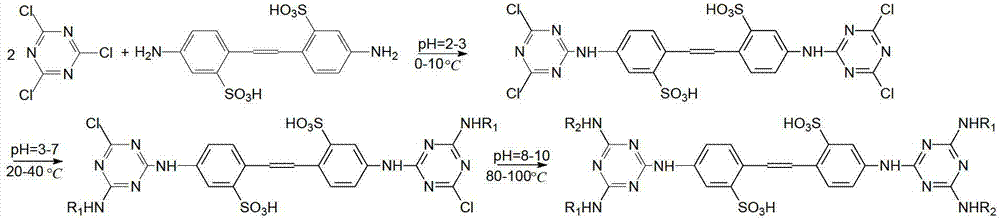

[0047] Suspend 0.0305mol of cyanuric chloride in a 250ml four-necked bottle in 110g of ice water, and add 3 drops of concentrated hydrochloric acid. Under stirring, slowly add DSD acid ethanolamine solution dropwise, keeping pH value = 2-3, temperature 0-5°C. Use 15% sodium hydroxide solution to adjust the pH value to about 2.5, and use an amino reagent to detect the disappearance of the amino group, and the shrinkage reaction is completed.

[0048] The temperature of the reaction material is raised to 20°C, about 0.295mol of aniline is added, and 15% sodium hydroxide solution is added dropwise to keep the pH value at about 5, and the reaction temperature is 20-25°C. In the later stage of the reaction, gradually increase the pH value to 6-6.5 until the two-shrinkage reaction is completed.

[0049] Keeping the reaction temperature, slowly add 0.3 mol of sodium hyd...

Embodiment 2

[0052] Prepare 0.015 mol of DSD acid with 0.03 mol of diethanolamine to make a solution of about 30 g for later use.

[0053] Suspend 0.0305mol cyanuric chloride in 250ml four-necked bottle in 110g ice water, slowly add DSD acid diethanolamine solution dropwise under stirring, keep pH=2-3, temperature 0-5℃. Use 15% sodium hydroxide solution to adjust the pH value to about 2.5, and keep warm at 6-8°C for reaction. The disappearance of the amino group is detected by the amino reagent, and the shrinkage reaction is completed.

[0054] The temperature of the reaction material was raised to 20°C, about 0.295 mol of aniline was added, and 15% sodium hydroxide solution was added dropwise to keep the pH value at 5-6.5 until the bicondensation reaction was completed.

[0055] Keeping the reaction temperature, 0.3 mol of sodium hydroxide solution was added dropwise to the reaction liquid for about 0.5 hr, and then 0.003 mol of diethanolamine was added to the reaction liquid, and the te...

Embodiment 3-16

[0058] The experimental operation is the same as before. The experimental data are as follows:

[0059]

[0060]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com