Highland barley wine brewing process and highland barley wine produced by same

A kind of highland barley wine and craft technology, applied in the field of wine making, can solve the problems such as bad taste of wine body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0061] The content of the present invention will be described below in conjunction with specific embodiments, but the content of the present invention is not limited thereto.

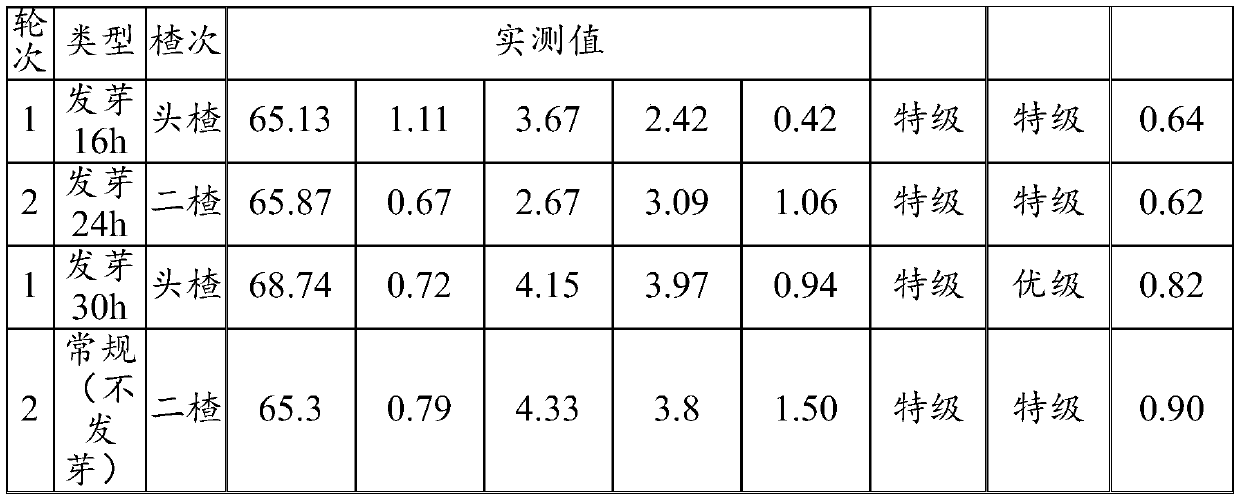

[0062] Take 3,500 kg of highland barley, pick the highland barley with full grains, no moths, mildew and deterioration, remove dust and impurities, soak in water at 20°C for 20 hours, and the amount of water is 5 cm above the surface of the highland barley. After soaking, flatten the highland barley to a thickness of 5 cm, germinate at 20°C for 24 hours, turn over every 8 hours, avoid direct sunlight, until the sprouts are 1-2 mm long, and the germination rate is 86%.

[0063] The germinated highland barley is steamed according to the steamer principle of "see steam cover material", the steam pressure is controlled at 0.1-0.2Mpa, and the steaming time is 60 minutes to obtain grain unstrained spirits (grain unstrained spirits of hawthorn); Sprinkle cold water of about 10% of the mass of the grain unstrai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com